Abstract

The elliptic pipe jet screech is explored at a pressure ratio from 2 to 6. The pipe length to diameter ratio is 5. The fundamental screech frequency and magnitude are obtained from the sound pressure level spectrum. The screech frequency decreases as the pressure ratio increases. The minor plane has more tones than the major plane at an emission angle of 75 degrees from the jet axis. The amplitude of the screech differs among the planes. The amplitude is higher at lower emission angles from 45 to 75 degrees and lower at a sideline angle of 90 degrees.

1. Introduction

Circular and non-circular shapes, such as rectangles and ellipses, are used in aircraft nozzles. A pipe jet can be used as a fuel injector inside the combustion chamber of a jet engine. Non-circular forms of cross-sections, such as clovers [1], rectangles [2,3], and ellipses [4,5,6,7], are used to provide better mixing. The exit of an aircraft nozzle has a small pipe with a small length-to-diameter (L/D) ratio.

Elliptic jets [8,9] have differential spread along the major and minor axes, whereas the spread is the same for circular jets. This differential spread promotes axis switching in elliptical jets. Off-center peaks can be found in pressure profiles, with asymmetric exits at high nozzle pressure ratios (NPR) for elliptic jets. Thus, elliptic jets promote better mixing than circular jets. K.K. Ahuja et al. [10] studied various nozzle exit modifications, such as rectangular and elliptic shapes, notches, tabs at the exit, and co-flow rectangles used to reduce jet noise [11]. The notches with square and triangle shapes are cut at the elliptic slot exit. Square notches exhibit better noise reduction regarding shock-associated noise. In their experimental work on circular, rectangular, and elliptic jets, J. Panda et al. [4] presented a discussion of different modes of screech and used the standing wavelength (Lsw) to predict the screech frequency, in addition to the conventional technique of using the shock cell spacing (L). S.B. Verma and E. Rathakrishnan [5] investigated the effects of elliptic slot jets with three different moderate aspect ratios on the acoustics of underexpanded jets. The aspect ratio seemed to affect the screech feedback loop, thus reducing the magnitude of the screech tone. Kevin W. Kinzie and D.K. McLaughlin [6] investigated the correctly expanded elliptic M = 1.5 jet under heated and unheated jet flow conditions. The velocity of a large-scale turbulent structure was increased by a helium mixed-air jet, thereby leading to noise due to the Mach wave radiation phenomenon. A clover-shaped pipe jet [1], a circular slot jet for transonic tones [12], an annular jet [13], and a hexagonal pipe jet [14] have been investigated for their acoustic characteristics.

The high-pressure-ratio jet flow from a non-circular cross-section will have mixing- and shock-associated noise. The screech tone appears at one particular frequency with a high amplitude. Screech noise is said to appear with harmonics. The first harmonic is the fundamental screech tone (fs or f1). The fundamental tone moves in the upstream direction (180° from the jet axis) towards the nozzle exit. The screech frequency of the fundamental tone [15] is fs = Uc/(L × (1 + Mc)), where L is the shock cell spacing, and Uc and Mc are the convective speed and Mach number of a turbulent structure. Aoki [16] found that an increase in lip thickness reactivates the screech loop. A detailed review was given by G. Raman [15] on the various features of the screech for a nozzle jet flow. Screech is produced as a result of a feedback mechanism that exists due to the interaction between the large-scale (LS) turbulence and shock cells, thus producing acoustic feedback waves, which in turn trigger instability when they hit the nozzle lip. Sometimes, there may be two feedback mechanisms [17], creating two screech tones at a given Mach number (M).

Noise reduction in circular pipe jets can be achieved by modifying the internal surface roughness [18], exit castellation [19], or co-flow swirler [20], as described in published research works. Jet noise reduction using a non-circular pipe, such as an ellipse, has not yet been investigated by researchers. Pipe jets are operated in underexpanded conditions. An underexpanded jet is one where the nozzle exit pressure (Pe) is greater than the ambient pressure (Pa). Underexpanded operation occurs above the pipe choking pressure ratio (settling chamber pressure/ambient pressure) R = 1.89 [21]. Hence, the operating pressure is chosen from R = 2 to 6, covering low to high underexpansion levels. An underexpanded jet will have a shock cell structure. Shock-associated noise is produced as a result of the interaction between the turbulence structure and shock cells. Screech is a type of shock-associated noise. The aim of this work is to analyze the screech behavior of an elliptic pipe jet in underexpanded conditions.

2. Experimental Methodology

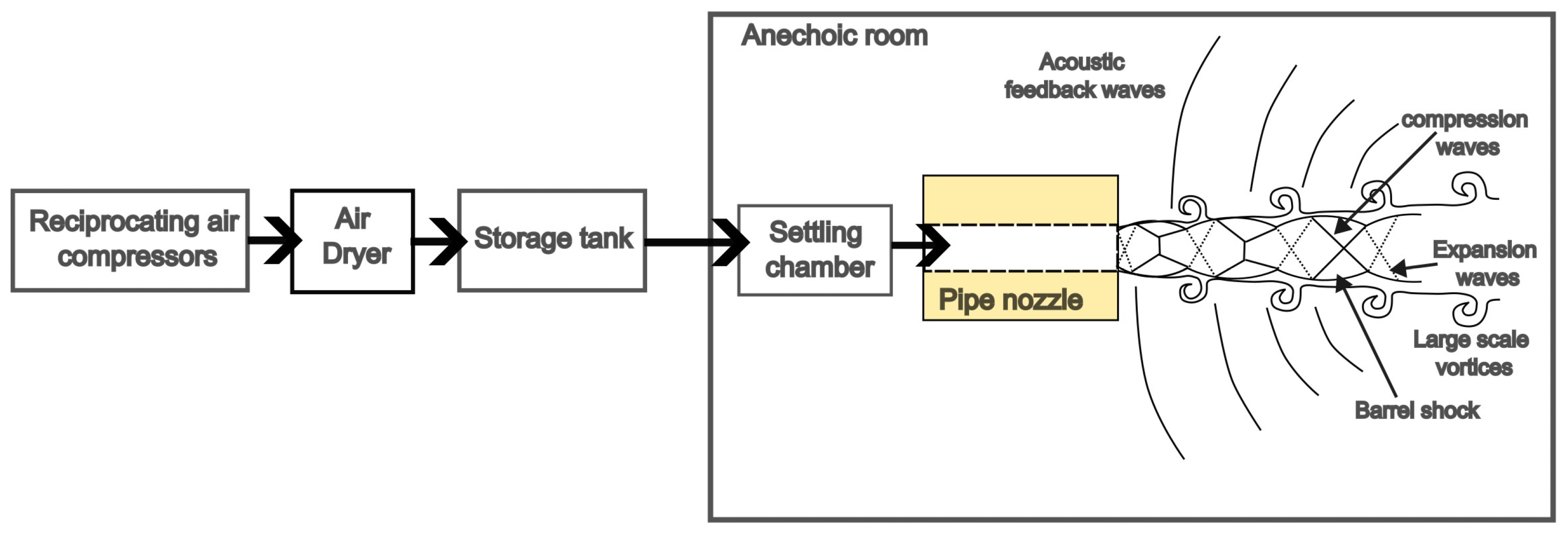

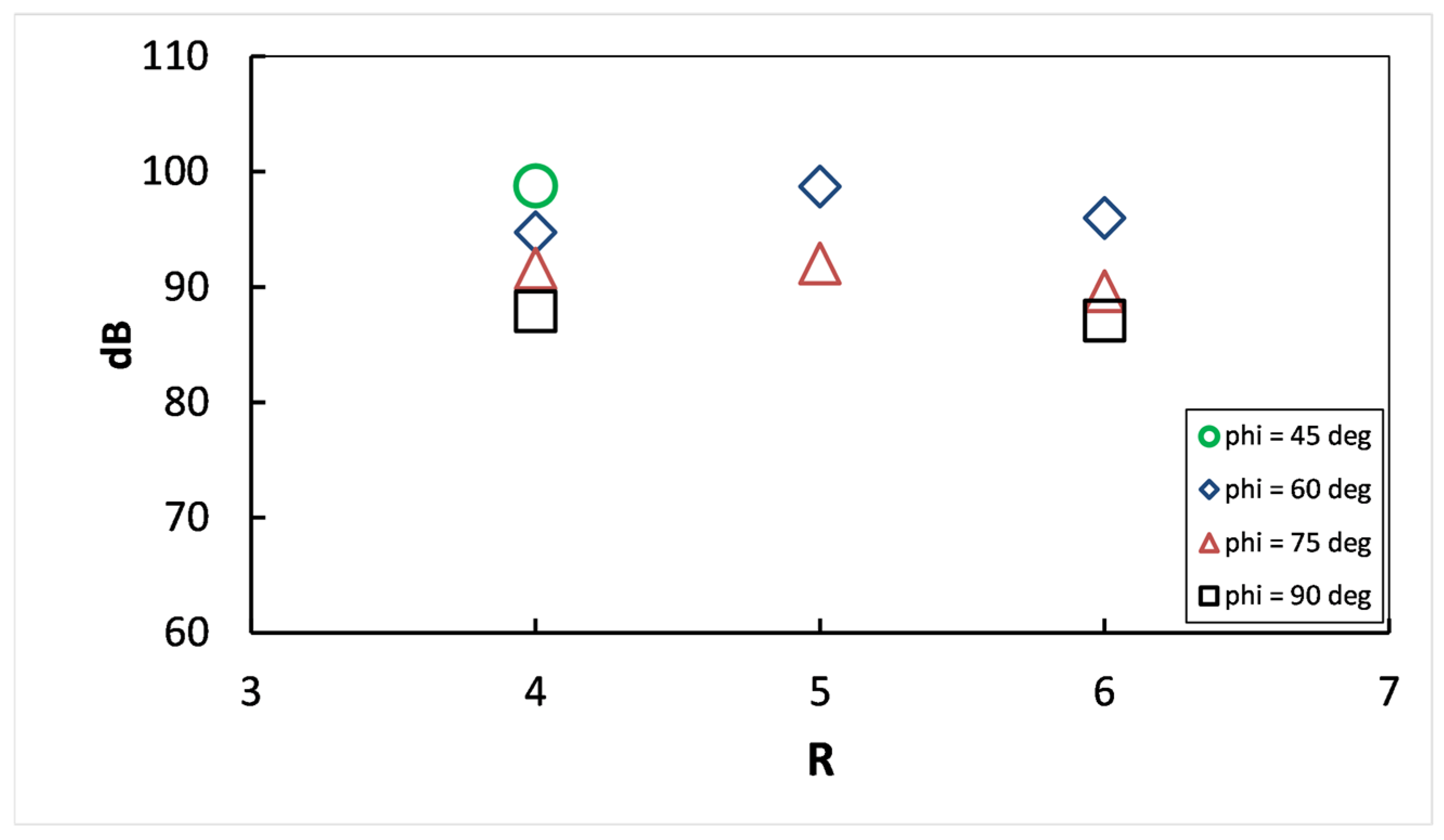

The anechoic chamber and high-speed jet facility at the Department of Aeronautical Engineering, Rajalakshmi Engineering College, Chennai was used for the experiments, and its details can be found in [2,3]. The facility consists of two reciprocating compressors (15 hp), an air dryer, a storage tank (5 m3), and a settling chamber. The elliptic pipe is connected to the settling chamber via proper fitting to produce a compressible jet flow inside the anechoic chamber. The anechoic chamber’s dimensions are 2.8 m 2.5 m 2.15 m; it provides a free field environment for acoustic measurements. The inner walls of the chamber are lined with polyurethane (PU) foam. The jet flow structure arises from a pipe in the underexpanded condition (Pe > Pa), with features such as shock cells, vortices, and acoustic waves (fundamental screech tone), as shown in Figure 1.

Figure 1.

Flowchart showing the components of the anechoic high-speed jet facility and the jet flow and acoustic features.

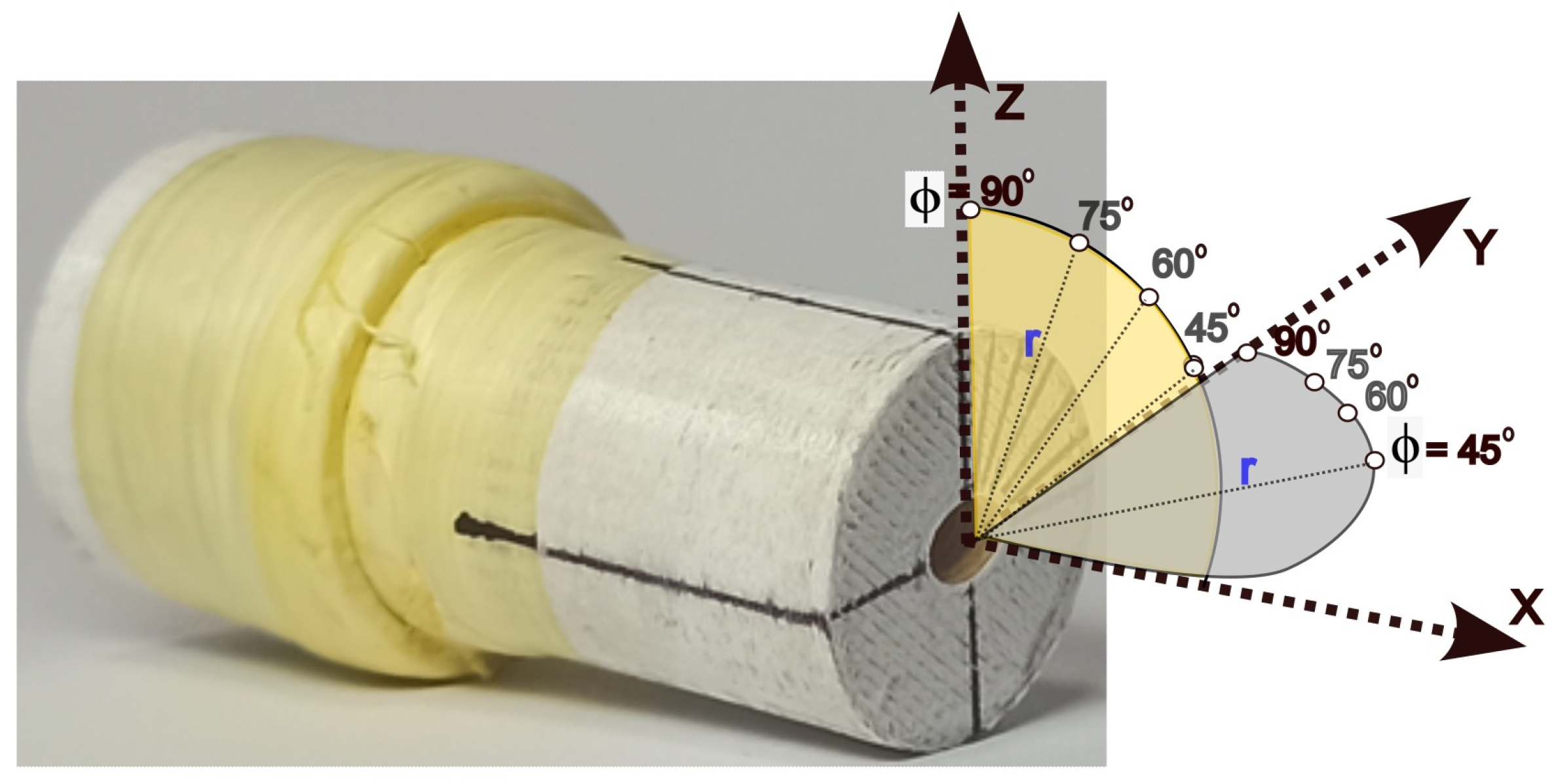

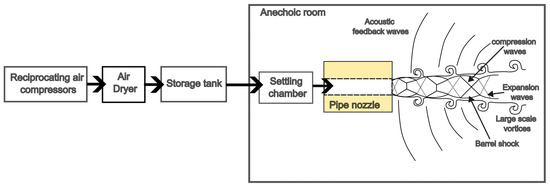

The 3D-printed elliptic pipe is made up of acrylonitrile butadiene styrene (ABS). The dimensions of the elliptic pipe can be found in Table 1. For a circular jet, acoustic measurement in one plane is sufficient. However, for elliptic jets with two planes, the major plane (X-Y) and minor plane (X-Z) are considered for acoustic measurements. The jet spread is different along the two planes. The jet noise produced along the two planes also differs. The microphone locations or emission angles (ϕ) are varied from 45° to 90° at an interval of 15° each in both planes, as seen in Figure 2. The minimum angle ϕ = 45° is chosen, such that the microphone is at a safe distance from the jet. Large-scale turbulence noise is dominant from ϕ = 45° to 60° and fine-scale turbulence noise is dominant from ϕ = 60° to 90° [22]. The screech propagates in the upstream direction and can be captured at ϕ = 90°.

Table 1.

Operating conditions of the jet.

Figure 2.

Elliptic pipe and microphone locations along measurement planes.

The jet noise is acquired through a pre-polarized condenser microphone (PCB 378C01, PCB Piezotronics, Inc., Depew, NY, USA), which is kept inside the anechoic room. The 6.35 mm free field microphone with sensitivity S = 2 mV/Pa, with a range of 3 Hz to 100 kHz (+2/−3 dB), measures the maximum sound pressure level (SPL) up to 165 dB. A 4-channel signal conditioner (PCB 482C54, PCB Piezotronics, Inc., Depew, NY, USA) powers the microphone and receives the signal from the microphone; it conditions and sends it to a data card (PicoLog 1012, St Neots, Cambridgeshire, UK). The data card is a 12-channel DAQ connected to a computer via a USB cable. The data card is controlled using Picoscope 6.0, a PC-based software program. The sound signals are acquired at an FFT length equal to 4096, with a bandwidth of 24.41 Hz. The sound spectrum ranges from 630 Hz to 100 kHz, where 630 Hz is the cut-off frequency of the anechoic room. The speed of sound is assumed constant at at a standard reference temperature of 25 °C. The density of air is 1.225 kg/m3, and the atmospheric pressure at reference conditions is Pa = 101.325 kPa. The temperature ratio (settling chamber temperature/ambient temperature) is taken as = 1, indicating that it is a cold jet.

3. Results

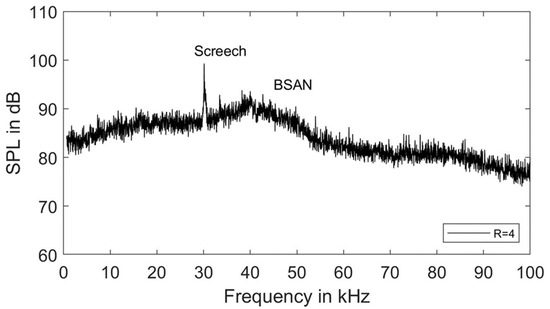

SPL Spectrum

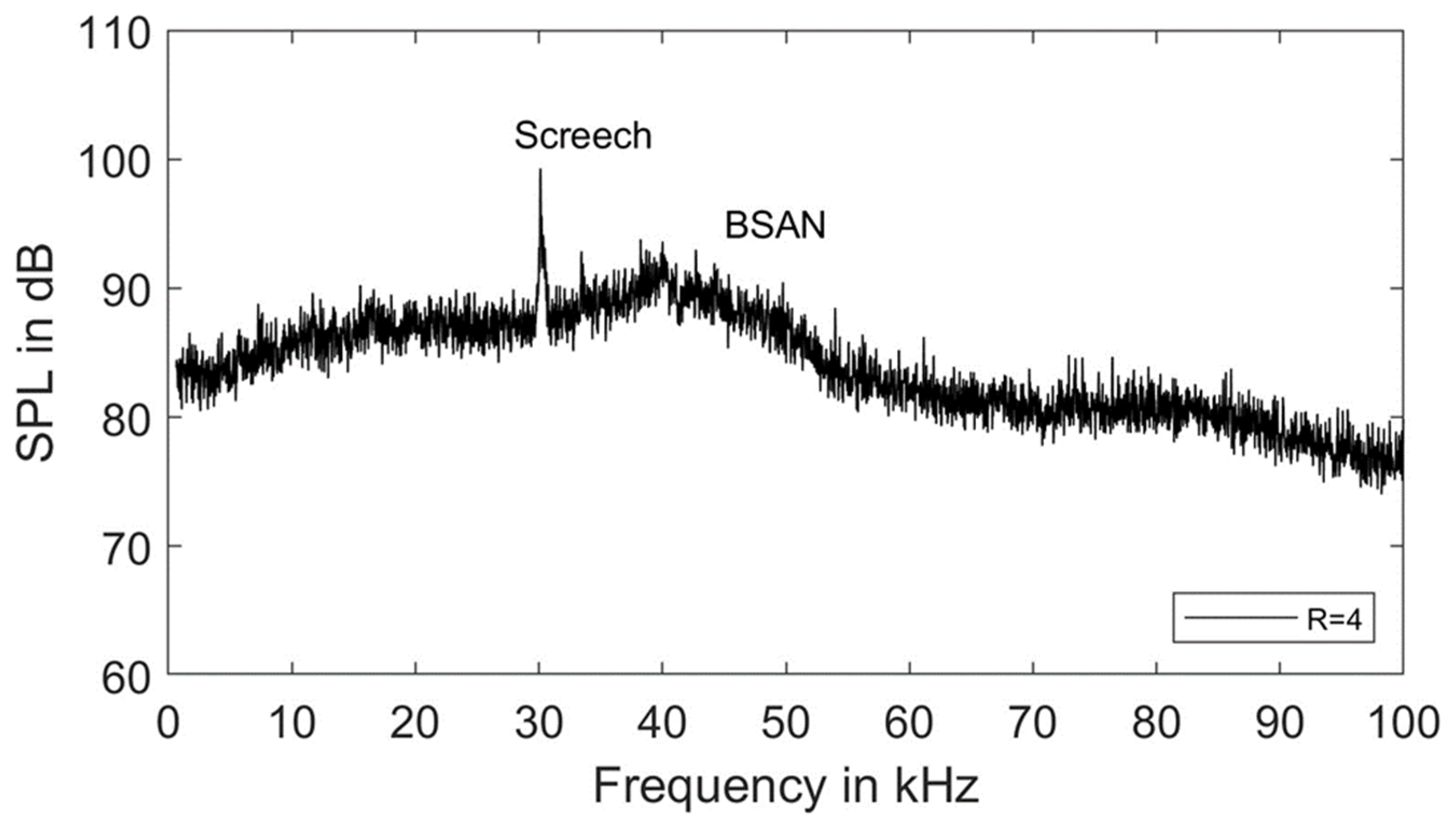

Figure 3 gives the typical sound pressure level (SPL) spectrum of the pipe jet noise for R = 4 at ϕ = 45° in the minor plane. This spectrum is characterized by a screech tone and broadband shock-associated noise (BSAN), as shown in Figure 3. Both of the above noise types are due to shock formation in the compressible jet flow. Noise at the frequency range of up to 20 kHz is low-frequency noise (detectable by the human ear), that from 20 kHz to 50 kHz is mid-frequency noise, and that above 50 kHz is high-frequency noise. The reference sound pressure level is 20 μPa. Large-scale turbulent noise occurs at low frequencies, whereas fine-scale turbulent noise occurs at high frequencies. The screech is high-amplitude tonal noise in the spectrum. Screech tones can be harmonic in nature, consisting of multiple tones. The first one is the fundamental tone (fs or f1) and is analyzed in this paper, while harmonics are not considered. The shock-associated noise is broadband in nature, and, at its unique frequency, it propagates in the upstream direction towards the nozzle exit, as described in [17]; this is called the fundamental screech tone. The harmonics may propagate in other directions depending on the harmonic number (f2, f3 and so on). In the spectrum shown, the BSAN occurs in the mid-frequency range, and screech occurs at around 30 kHz. The SPL is more in the low- and mid-frequency regions than in the high-frequency range.

Figure 3.

SPL spectrum for R = 4 at microphone location (ϕ) = 45 deg in minor plane.

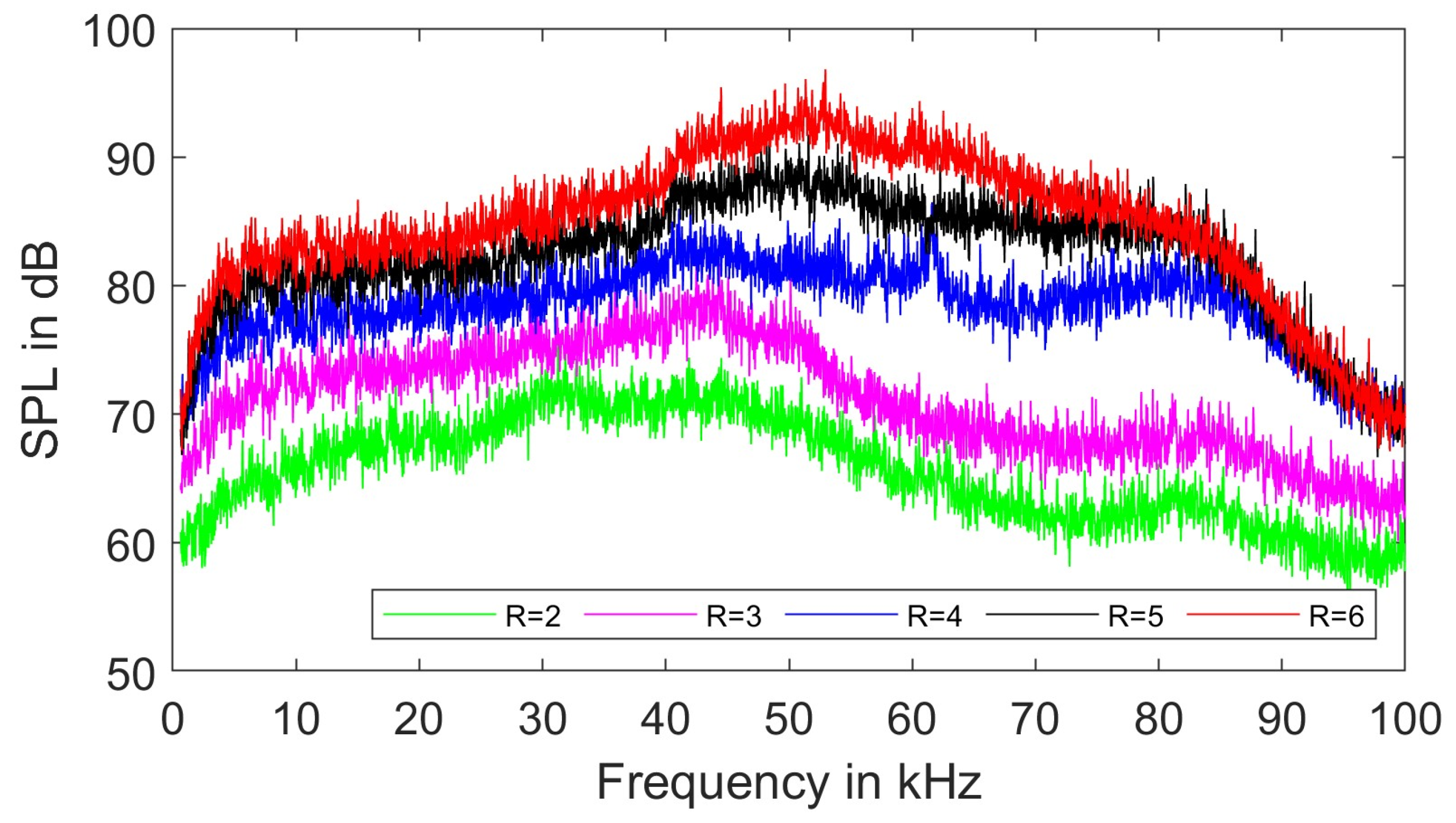

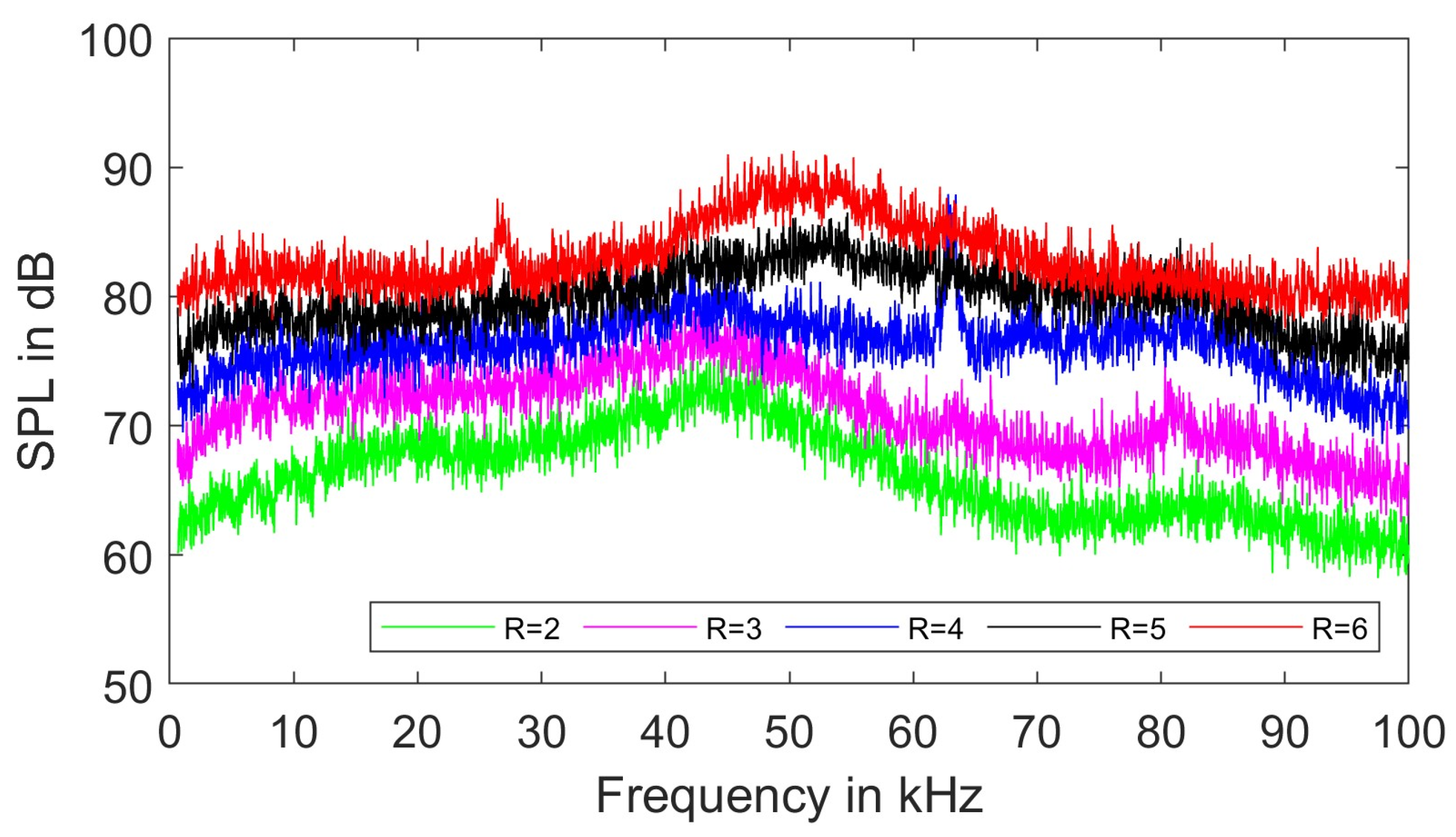

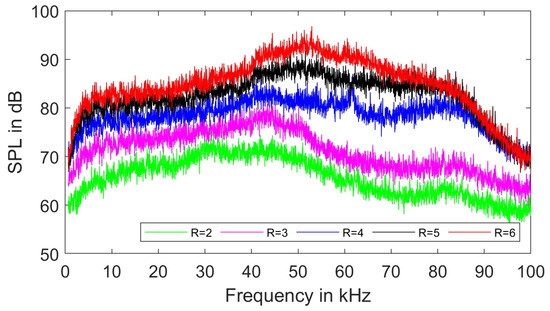

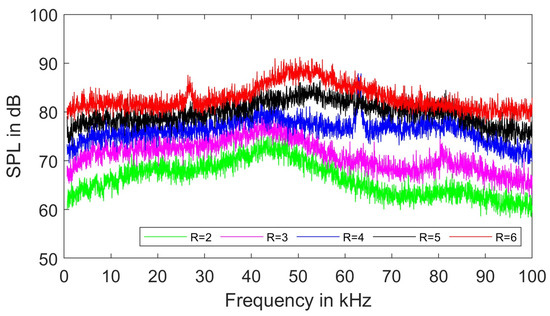

Figure 4 and Figure 5 give the SPL spectra in both planes at ϕ = 90° (sideline to nozzle exit). The spectra for R = 2 and 3 are similar for both axes. For R = 4, a screech tone is present in the spectra of the major and minor axes at around 63 kHz and has a higher amplitude of 1.5 dB more in the minor axis. A screech tone is also present at R = 6 at around 26 kHz (87.59 dB) only in the minor axis. It can be said that the minor axis has more tones. The spectra for R = 4 to 6 are also very similar for both axes, except for frequencies f < 10 kHz and f > 90 kHz. The peak values of the spectrum are larger in the major plane than the minor plane for higher values of R.

Figure 4.

SPL spectra for various pressure ratios (R) at microphone location (ϕ) = 90 deg in major plane.

Figure 5.

SPL spectra for various pressure ratios (R) at microphone location (ϕ) = 90 deg in minor plane.

4. Discussion

Fundamental Screech Frequency and Amplitude

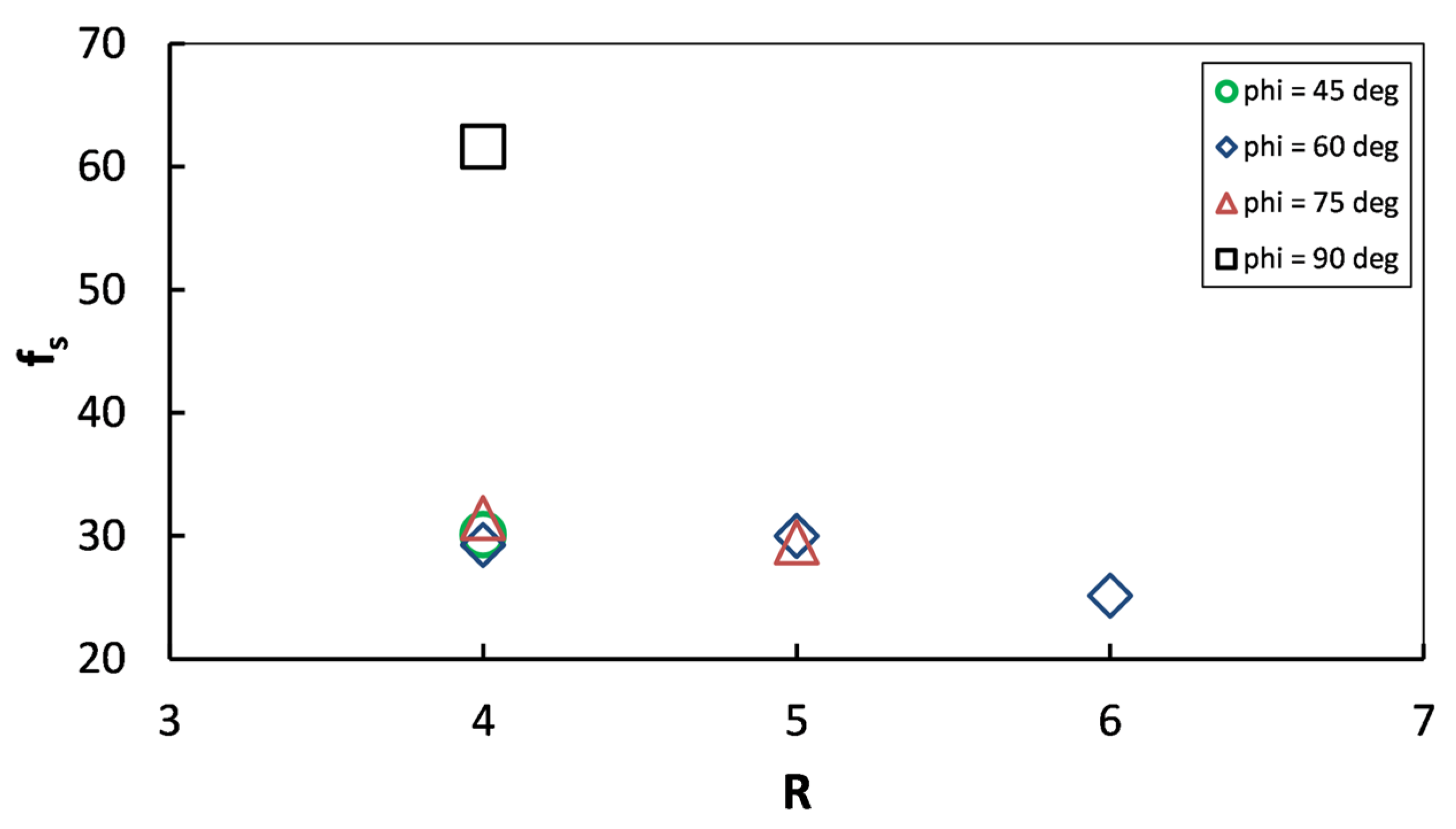

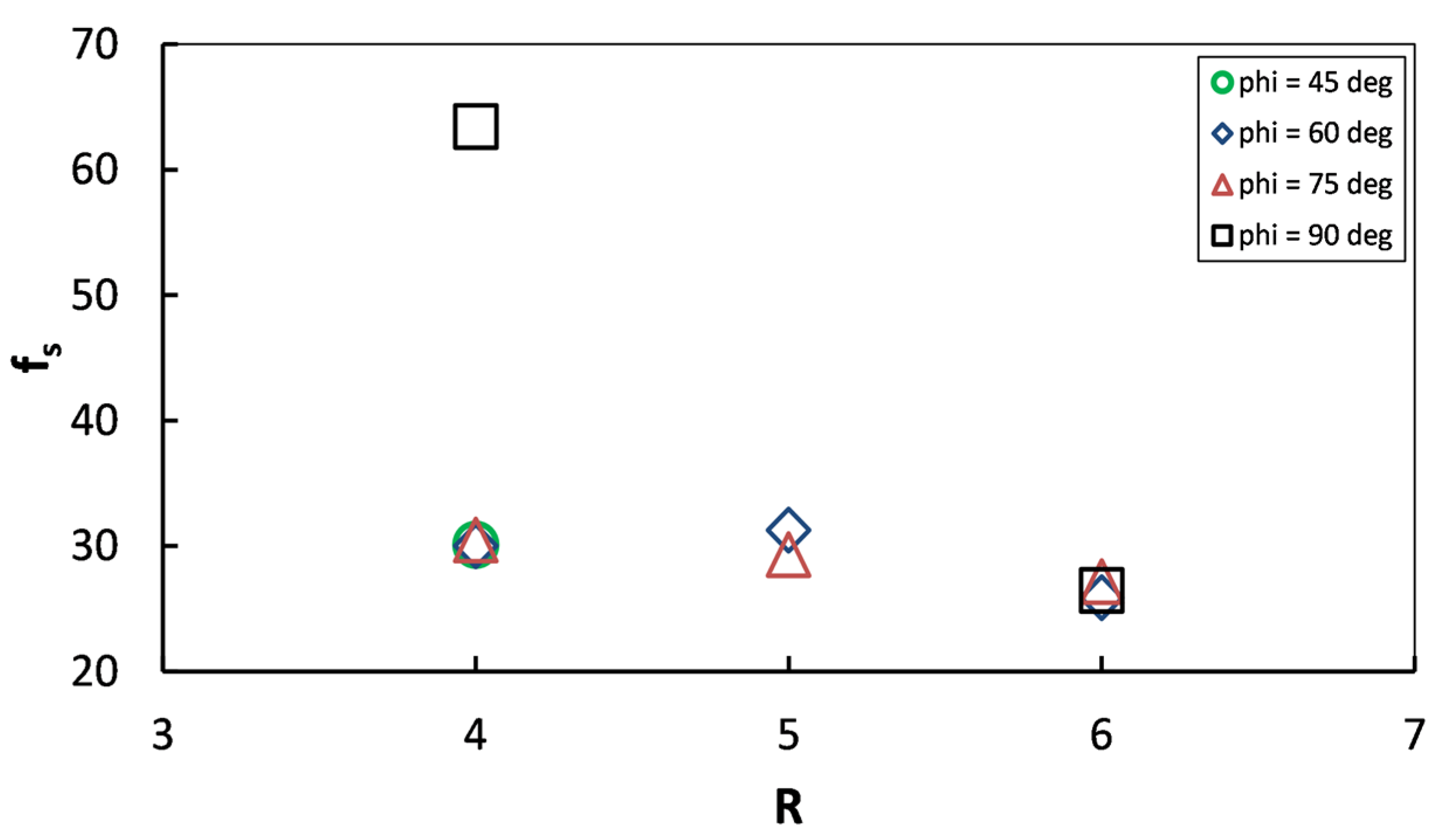

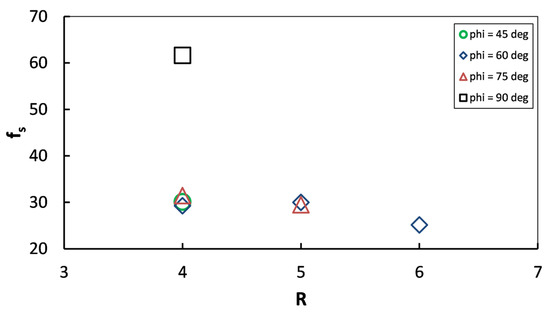

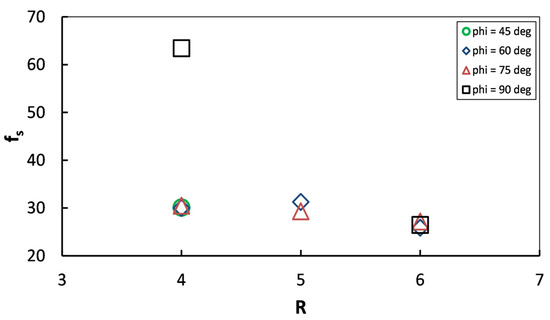

The fundamental screech frequency (fs) as a function of the emission angle (ϕ) is given for various pressure ratios (R). Figure 6 gives the screech tone frequency for the major plane and Figure 7 for the minor plane. Although the sound spectrum is captured for all pressure ratios (R) and all emission angles (ϕ), the screech tone is found to appear from R = 4 onwards. The screech frequency and its amplitudes are obtained from the spectrum and plotted against R for various values of ϕ.

Figure 6.

Fundamental screech frequency as function of pressure ratio for different emission angles in major plane.

Figure 7.

Fundamental screech frequency as function of pressure ratio for different emission angles in minor plane.

In the major plane in Figure 6, the screech frequency tends to decrease with R, which can be seen for ϕ = 60° and 75°. For ϕ = 90°, the screech tone appears at a high frequency (61.621 kHz) at R = 4, and no other screech is seen after the pressure ratio (R). At ϕ = 45°, a screech tone appears at R = 4 but not for higher R values. In the minor plane in Figure 7, more screech tones are present than in the major plane. Here, again, as R increases, the screech frequency decreases, which can be seen for ϕ = 60° and 75°. At ϕ = 45°, only one screech tone is present at R = 4, which is also present in the major axis. At ϕ = 90°, for R = 4, the second harmonic tone (63.428 kHz) is seen, and, at R = 6, a screech tone (26.465 kHz) is present. In general, the value of the frequency at which the screech occurs tends to decrease with the pressure ratio, as seen in [12,15,17].

- ϕ = 45°—the emission angle at which screech tones are the least produced, occurring only at R = 4;

- ϕ = 60°—fs occurs for R = 4, 5, and 6 in both planes;

- ϕ = 75°—fs occurs for R = 4, 5, and 6 in the minor plane and R = 4 and 5 in the major plane;

- ϕ = 90°—screech at the second harmonic occurs at around 63 kHz for R = 4 only.

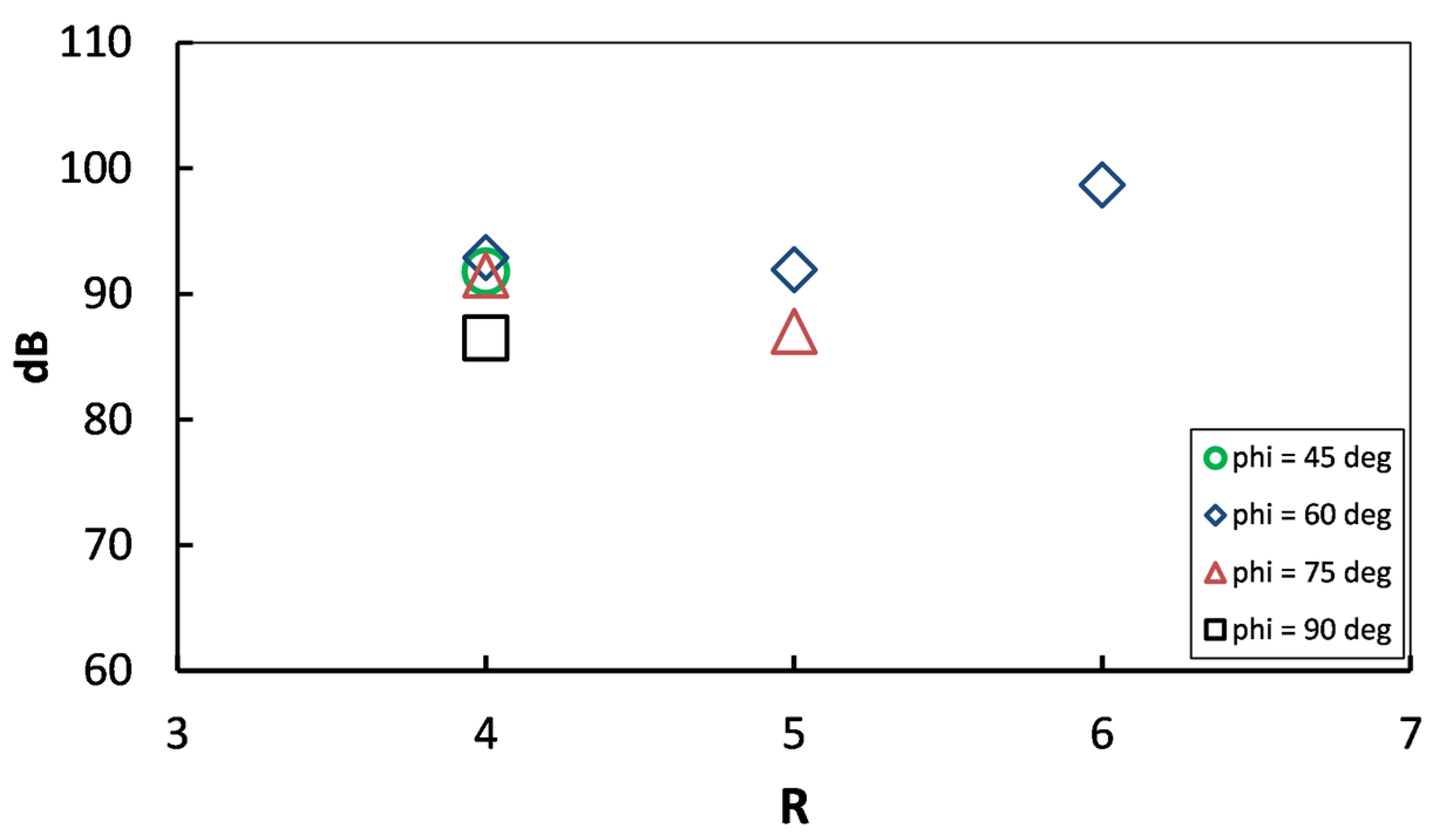

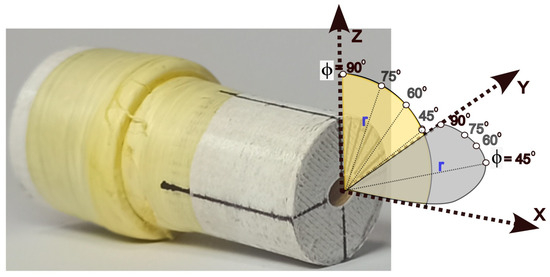

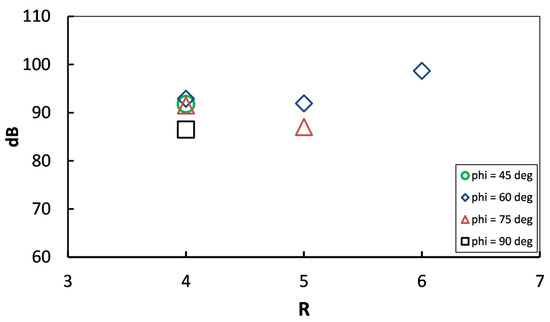

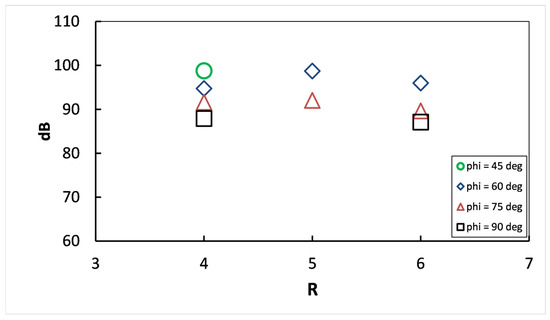

Figure 8 gives the amplitude of the fundamental screech tone against the pressure ratio (R). At ϕ = 60°, the magnitude slightly decreases, and it then increases from R = 4 to 6. The initial decreasing trend can also be found for ϕ = 75°. Figure 9 corresponds to the amplitude variations in the minor plane. The trend of magnitude variation in the minor plane is different from that in the major plane. The magnitude initially increases and then decreases with respect to R, which can be seen at ϕ = 60° and 75°, respectively. The tone is more dominant at a lower emission angle at ϕ = 45° to 75° and less pronounced at a sideline angle ϕ = 90°.

Figure 8.

Amplitude of fundamental screech variation with pressure ratio for different emission angles in major plane.

Figure 9.

Amplitude of fundamental screech variation with pressure ratio for different emission angles in minor plane.

The screech starts at a pressure ratio R = 4 and is seen up to R = 6. The elliptic pipe jet does not exhibit screech at lower underexpansion levels of R = 2 to 3. The screech is dominant at R = 4. The second harmonic (63.43 kHz) is seen at an emission angle ϕ = 90°, as stated in [17]. The screech of an elliptic jet is similar to that of an underexpanded circular jet, but its directivity is different in both planes. Screech radiation is dominant in the minor axis plane.

5. Conclusions

The acoustic analysis of an elliptic pipe jet shows that screech occurs at R = 4 and can be found up to a maximum of R = 6 in the case under consideration. The screech frequency is found to decrease with the pressure ratio and is evident in both planes. The SPL spectrum shows the screech and BSAN along with mixing noise. The SPL spectrum is different among the planes for R = 4 to 6. A high-frequency second harmonic tone can be found for R = 4 at ϕ = 90° only. The screech amplitudes are dominant at ϕ = 45° and 60° as compared to 75° and 90°. Overall, the screech behavior is found to be similar to that of a circular jet, but the directivity is different among the two planes.

Author Contributions

Conceptualization, R.K.S. and B.T.K.; methodology, R.K.S. and B.T.K.; software, R.K.S. and B.T.K.; validation, R.K.S. and B.T.K.; formal analysis, R.K.S. and B.T.K.; investigation, R.K.S. and B.T.K.; resources, R.K.S. and B.T.K.; data curation, R.K.S. and B.T.K.; writing—original draft preparation, R.K.S. and B.T.K.; writing—review and editing, R.K.S. and B.T.K.; visualization, R.K.S. and B.T.K.; supervision, R.K.S. and B.T.K.; project administration, R.K.S. and B.T.K.; funding acquisition, R.K.S. and B.T.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Dataset available on request from the authors.

Acknowledgments

The authors express their sincere thanks to Suresh Chandra Khandai, HOD, and Surendra Bogadi, Dept. of Aeronautical Eng., Rajalakshmi Eng. College, Chennai, for their support in conducting the experiments at Anechoic High-Speed Jet Facility in their campus. The authors also acknowledge the facilities, such as the RPT Lab and Advanced Computing Lab (ACL), Dept. of Aerospace Eng., SRM Institute of Science and Technology, Kattankulathur.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Rajesh Kumar, S.; Kannan, B.T. Acoustic Measurements of Compressible Jet Flow from a Pipe Nozzle with Clover Cross-section. In Proceedings of the Eighth International Conference on Science Technology Engineering and Mathematics, Chennai, India, 6–7 April 2023. [Google Scholar] [CrossRef]

- Surendra, B.; Sridhar, B.T.N. Decay of supersonic rectangular jet issuing from a nozzle with diagonal expansion ramps. Therm. Sci. 2019, 23, 3929–3940. [Google Scholar] [CrossRef]

- Surendra, B.; Sridhar, B.T.N. Acoustic characteristics of supersonic rectangular jets issuing from nozzles with diagonal expansion ramps. J. Braz. Soc. Mech. Sci. Eng. 2021, 43, 572. [Google Scholar] [CrossRef]

- Panda, J.; Raman, G.; Zaman, K. Underexpanded screeching jets from circular, rectangular and elliptic nozzles. In Proceedings of the 3rd AIAA/CEAS Aeroacoustics Conference, Atlanta, GA, USA, 12–14 May 1997. [Google Scholar] [CrossRef]

- Verma, S.B.; Rathakrishnan, E. Notches as a candidate for jet noise reduction in low to moderate aspect-ratio elliptic-slot jets. In Proceedings of the 6th Aeroacoustics Conference and Exhibit, Lahaina, HI, USA, 12–14 June 2000. [Google Scholar] [CrossRef]

- Kinzie, K.W.; McLaughlin, D.K. Aeroacoustic properties of supersonic elliptic jets. J. Fluid Mech. 1999, 395, 1–28. [Google Scholar] [CrossRef]

- Quinn, W.R. On mixing in an elliptic turbulent free jet. Phys. Fluids A Fluid Dyn. 1989, 1, 1716–1722. [Google Scholar] [CrossRef]

- Chauhan, V.; Aravindh Kumar, S.M.; Rathakrishnan, E. Mixing Characteristics of Underexpanded Elliptic Sonic Jets from Orifice and Nozzle. J. Propuls. Power 2015, 31, 496–504. [Google Scholar] [CrossRef]

- Chauhan, V.; Aravindh Kumar, S.M.; Rathakrishnan, E. Aspect ratio effect on elliptical sonic jet mixing. Aeronaut. J. 2016, 120, 1197–1214. [Google Scholar] [CrossRef]

- Ahuja, K.; Manes, J.; Massey, K.; Calloway, A. An evaluation of various concepts of reducing supersonic jet noise. In Proceedings of the AIAA 13th Aeroacoustic Conference, Tallahassee, FL, USA, 22–24 October 1990. [Google Scholar]

- Verma, S.B.; Rathakrishnan, E. Experimental study on the flow and noise characteristics of underexpanded notched slot jets. Aeronaut. J. 2001, 105, 267–276. [Google Scholar] [CrossRef]

- Jothi, T.J.S.; Srinivasan, K. Transonic Resonance Tones in Orifice and Pipe Jets. Int. J. Aeroacoust. 2013, 12, 103–121. [Google Scholar] [CrossRef]

- Bellidega, K.C.; Dhamanekar, A.; Srinivasan, K. Acoustic characteristics of annular jets. In Proceedings of the INTERNOISE 2014—43rd International Congress on Noise Control Engineering: Improving the World Through Noise Control, Melbourne, Australia, 16–19 November 2014. [Google Scholar]

- Annu, S.; Rajesh Kumar, S.; Kannan, B.T. Acoustic Measurements for Hexagonal Pipe Jet Flow. In Proceedings of the 2023 IEEE Engineering Informatics, Kolhapur, India, 25–26 November 2023. [Google Scholar] [CrossRef]

- Raman, G. Advances in understanding supersonic jet screech: Review and Prespective. Prog. Aerosp. Sci. 1998, 34, 45–106. [Google Scholar] [CrossRef]

- Aoki, T.; Kweon, Y.H.; Miyazato, Y.; Kim, H.D.; Setoguchi, T. An experimental study of the nozzle lip thickness effect on supersonic jet screech tones. J. Mech. Sci. Technol. 2006, 20, 522–532. [Google Scholar] [CrossRef]

- Tam, C.K.W.; Parrish, S.A.; Viswanathan, K. The harmonics of jet screech tones. In Proceedings of the 19th AIAA/CEAS Aeroacoustics Conference, Berlin, Germany, 17–29 May 2013. [Google Scholar] [CrossRef]

- Jothi, T.J.S.; Srinivasan, K. Surface roughness effects on noise from pipe jets. J. Sound Vib. 2013, 332, 839–849. [Google Scholar] [CrossRef]

- Anureka, R.; Srinivasan, K. The Role of Castellations on Pipe Jet Noise. In Proceedings of the ASME 2018 Noise Control and Acoustics Division Session Presented at INTERNOISE 2018, Chicago, IL, USA, 26–29 August 2018. [Google Scholar] [CrossRef]

- Balakrishnan, P.; Srinivasan, K. Pipe jet noise reduction using co-axial swirl pipe. Aeronaut. J. 2017, 121, 488–514. [Google Scholar] [CrossRef]

- Rathakrishnan, E. Applied Gas Dynamics, 2nd ed.; John Wiley & Sons: Chichester, UK, 2019; p. 414. [Google Scholar] [CrossRef]

- Jothi, T.J.S.; Srinivasan, K. Turbulent Mixing Noise from Underexpanded Non-circular Slot Jets. Acta Acust. United Acust. 2013, 99, 514–523. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).