Factors and Method of Preventing Construction Site Incidents †

Abstract

1. Introduction

2. Methodology

3. Results

3.1. Reliability Test

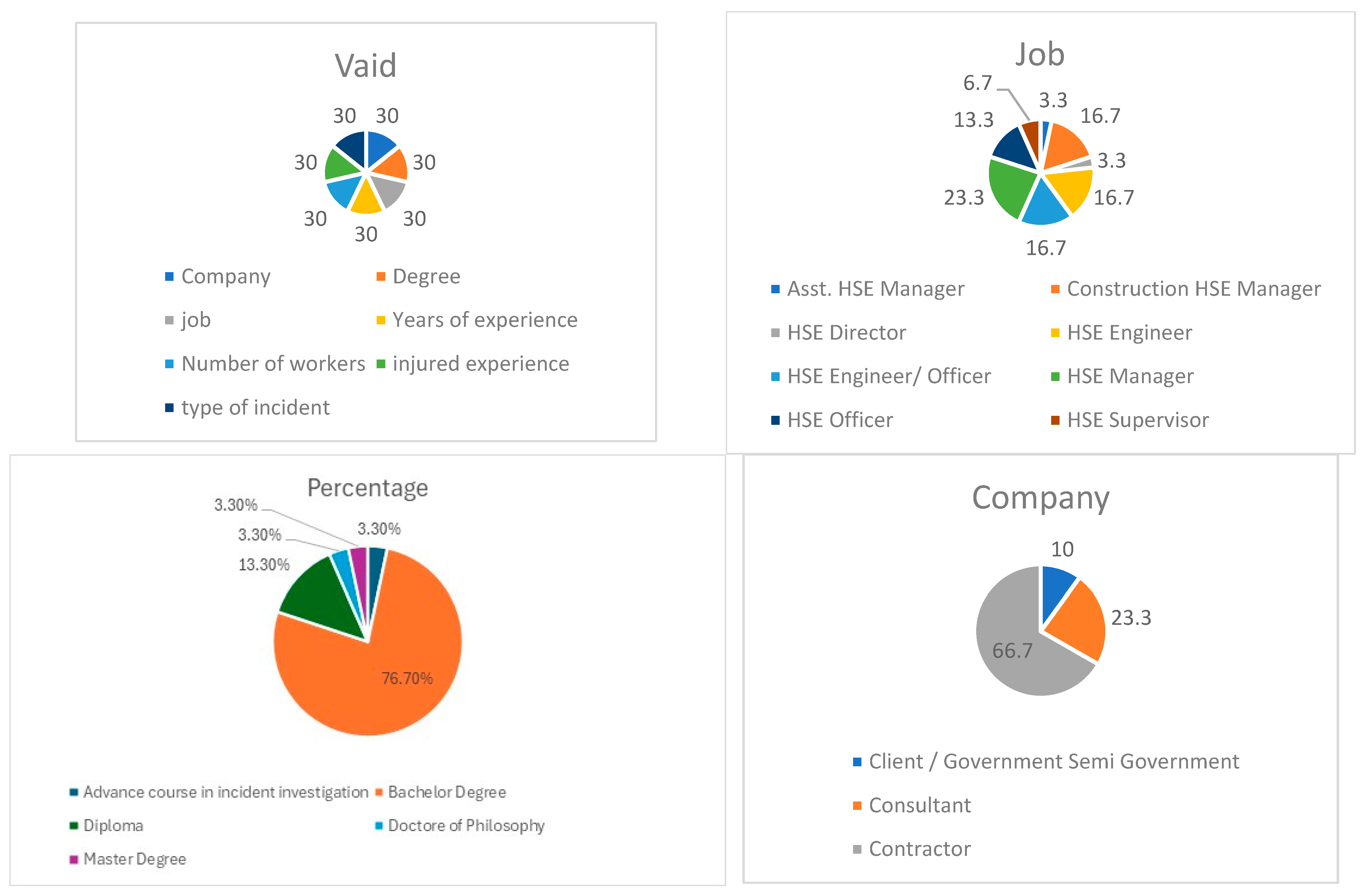

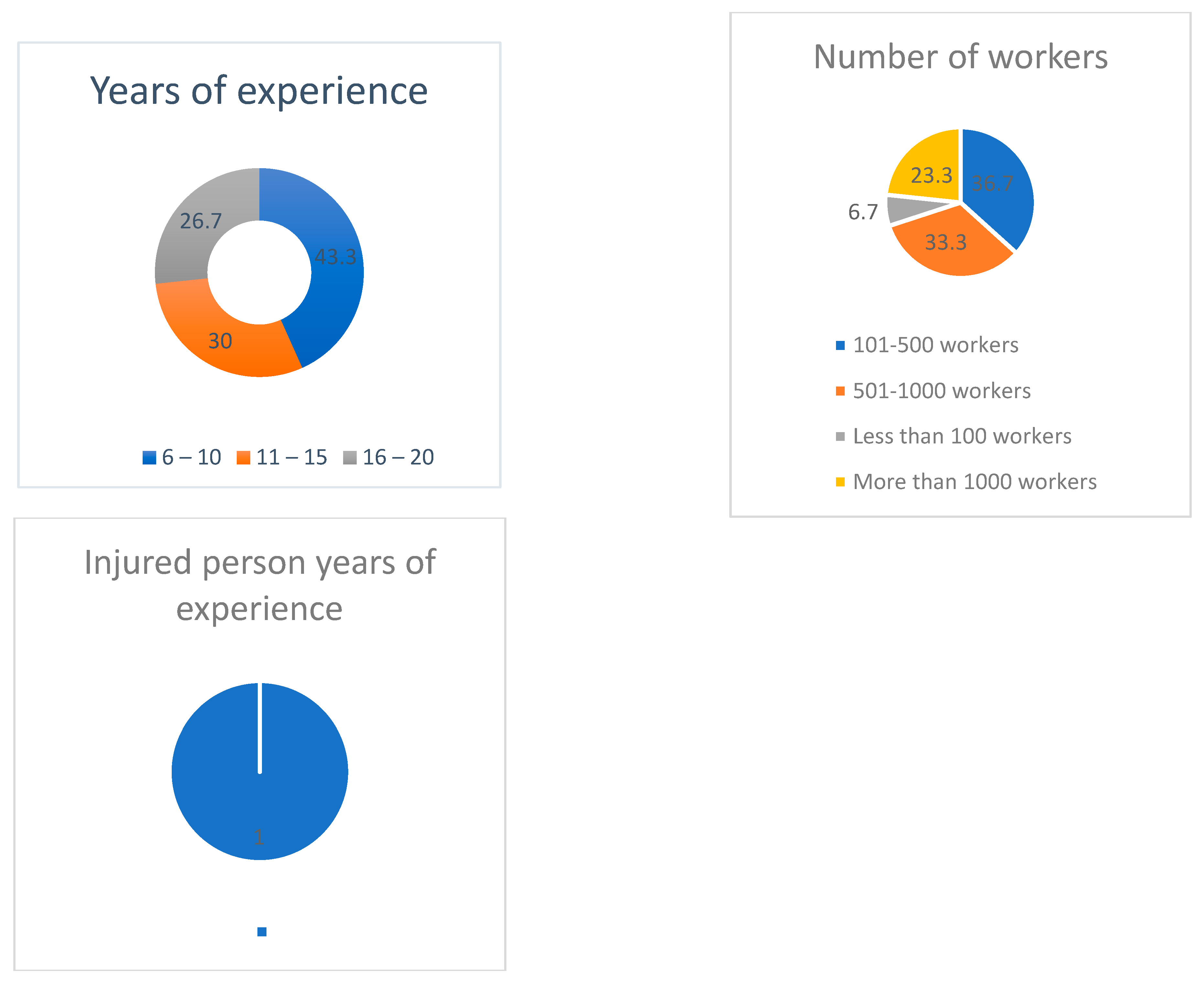

3.2. Descriptive Statistics

3.3. Factors and Preventive Measures

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bilir, S.; Gurcanli, G.E. The New Severity Scale of Occupational Accidents for Construction Projects. In Proceedings of the 5th international Project and Construction Management Conference (Conference Paper), Kyrenia, Cyprus, 16–18 November 2018; Civil Engineering Department, Istanbul Technical University: Istanbul, Turkey, 2018. [Google Scholar]

- Rafindadi, A.D.; Shafiq, N.; Othman, I.; Ibrahim, A.; Aliyu, M.M.; Mikić, M.; Alarifi, H. Data mining of the essential causes of different types of fatal construction accidents. Heliyon 2023, 9, E13389. [Google Scholar] [CrossRef]

- Umair, K.; Amrit, S.S.; Benachir, M. Safety Management System (SMS) framework development—Mitigating the critical safety factors affecting Health and Safety performance in construction projects. Saf. Sci. 2021, 143, 105402. [Google Scholar]

- Duryan, M.; Smyth, H.; Roberts, A.; Rowlinson, S.; Sherratt, F. Knowledge transfer for occupational health and safety: Cultivating health and safety learning culture in construction firms. Sci.—Accid. Anal. Prev. 2020, 139, 105496. [Google Scholar] [CrossRef] [PubMed]

- Peng, J.L.; Liu, X.; Peng, C.; Shao, Y. Comprehensive factor analysis and risk quantification study of fall from height accidents. Heliyon 2023, 9, e22167. [Google Scholar] [CrossRef]

- Frederico, G.P.M.; Camila, P.D.; Oliveira, C.A.F. Workplace accidents and the probabilities of injuries occurring in the civil construction industry in Brazilian Amazon: A descriptive and inferential analysis. Saf. Sci. 2024, 173, 9. [Google Scholar]

- Weiyan, J.; Wong, K.W.J. Embedding Corporate Social Responsibility into the Construction Process: A Preliminary Study. In ICCREM 2015: Environment and the Sustainable Building, Proceedings of the 2015 International Conference on Construction and Real Estate Management, Lulea, Sweden, 11–12 August 2015; Wang, Y., Olofsson, T., Shen, G.Q., Bai, Y., Eds.; American Society of Civil Engineers (ASCE): Reston, VA, USA, 2015; Volume 11–12, p. 37. [Google Scholar]

- Behm, M. Linking construction fatalities to the design for construction safety concept Review. U. S. Saf. Sci. 2005, 43, 589–611. [Google Scholar] [CrossRef]

- Asanka, W.A.; Singapore, M.R. Study on the impact of Accidents on construction projects. In Proceedings of the 6th International Conference on Structural Engineering and Construction Management, Kandy, Sri Lanka, 11–13 December 2015; Conference Paper: ICSECM, 2015. [Google Scholar]

- Hinze, J.; Gambatese, J. Factors Influencing Safety Performance of Specialty Contractors. J. Constr. Eng. Manag. 2003, 129, 159–164. [Google Scholar] [CrossRef]

- Hinze, J.; Wiegand, F. Role of Designers in Construction Worker Safety. J. Constr. Eng. Manag. 1992, 118, 677–684. [Google Scholar] [CrossRef]

- Zarooni, A.; Awad, M.; Alzaatreh, A. Confirmatory factor analysis of work-related accidents in UAE. Saf. Sci. 2022, 153, 105813. [Google Scholar] [CrossRef]

- Celal, G. Safety sign comprehension of fiberboard industry employees. Heliyon 2023, 9, 5. [Google Scholar]

- Winge, S.; Albrechtsen, E.; Mostue, B.A. Causal factors and connections in construction Accidents. Saf. Sci. 2018, 112, 130–141. [Google Scholar] [CrossRef]

- Abdelhamid, T.S.; Everett, J.G. Identifying Root Causes Of Construction Accidents. J. Constr. Eng. Manag. 2000, 126, 52–60. [Google Scholar] [CrossRef]

- Dwyer, T.; Raftery, A.E. Industrial Accidents Are Produced by Social Relations of Work: A Sociological Theory of Industrial Accidents. Appl. Ergon. 1991, 22, 167–178. [Google Scholar] [CrossRef]

- Woolley, M.; Goode, N.; Read, G.; Salmon, P. Have we reached the organisational ceiling? a review of applied accident causation models, methods and contributing factors in construction. J. Theor. Issues Ergon. Sci. 2019, 20, 533–555. [Google Scholar] [CrossRef]

- Rodrigues, F.; Coutinho, A.; Cardoso, C.V. Correlation of causal factors that influence construction safety performance: A Model. Work 2015, 51, 721–730. [Google Scholar] [CrossRef] [PubMed]

- Rowlinson, S.; Jia, Y.A. Construction Accidents causality: An institutional analysis of heat illness Accidents on site. Saf. Sci. 2015, 78, 179–189. [Google Scholar] [CrossRef]

- Hale, A.A.B.; Walker, D.C.; Walters, N.D.; Bolt, H.E. Developing the understanding of underlying causes of construction fatal Accidents. Saf. Sci. 2012, 50, 2020–2027. [Google Scholar] [CrossRef]

- Leedy, P.D. Practical Research: Planning and Design; Prentice-Hall: Saddle River, NJ, USA, 1993. [Google Scholar]

- Memon, A.H. Structural Modelling of Factors Causing Cost Overrun in Construction Industry. Ph.D. Thesis, Universiti Tun Hussein Onn Malaysia, Parit Raja, Malaysia, 2013. [Google Scholar]

- Yang, J.-B.; Peng, S.-C. Development of a Customer Satisfaction Evaluation Model for Construction Project Management. Build. Environ. 2008, 43, 458–468. [Google Scholar] [CrossRef]

- Connelly, L.M. Pilot studies. Medsurg Nurs. 2008, 17, 411–412. [Google Scholar]

- Hill, R. What Sample Size Is Enough in Internet Survey Research. Interpers. Comput. Technol. Electron. J. 21st Century 1998, 6, 1–10. [Google Scholar]

- Isaac, S.; Michael, W.B. Handbook in Research and Evaluation: A Collection of Principles, Methods, and Strategies Useful in the Planning, Design, and Evaluation of Studies in Education and the Behavioral Sciences, 3rd ed.; EdITS Publishers: San Diego, CA, USA, 1995. [Google Scholar]

- Gerald, v.B. Statistical Rules of Thumb; John Wiley & Sons: Hoboken, NJ, USA, 2002. [Google Scholar]

- Mathers, N.; Fox, N.; Hunn, A. Surveys and Questionnaires; The NIHR RDS for the East Midlands/Yorkshire & the Humber Nottingham: Sheffield, UK, 2007; p. 12. [Google Scholar]

- Szolnoki, G.; Hoffmann, D. Online, face-to-face and telephone surveys—Comparing different sampling methods in wine consumer research. Wine Econ. Policy 2013, 2, 57–66. [Google Scholar] [CrossRef]

- Bechhofer, F.; Paterson, L. Principles of Research Design in the Social Sciences, 1st ed.; Routledge: London, UK, 2012. [Google Scholar] [CrossRef]

- Frances, R.; Coughlan, M. Interviewing in qualitative research. Int. J. Ther. Rehabil. 2009, 16, 309–314. [Google Scholar] [CrossRef]

- Michaelidou, N.; Dibb, S. Using email questionnaires for research: Good practice in tackling non-response. J. Target. Meas. Anal. Mark. 2006, 14, 289–296. [Google Scholar] [CrossRef]

- Zeller, R.A. Measurement Error, Issues and Solutions. In Encyclopedia of Social Measurement; Elsevier: Amsterdam, The Netherlands, 2005; pp. 665–676. [Google Scholar]

| Q | Part B: What is Your Scale for the Following Management System Factors that Cause the Incident Do You Experience? | Q48 | Excessive Noise Exposure |

|---|---|---|---|

| Q1 | Inadequate training | Q49 | Radiation exposure |

| Q2 | Inadequate/missing procedure | Q50 | Equipment failure |

| Q3 | Inadequate purchasing/material handling | What is your scale for the following nature of incident do you experience? | |

| Q4 | Inadequate tool/ marital | Q51 | Abrasions/Bruising (Scratches) |

| Q5 | Inadequate risk assessment/management | Q52 | Amputation—Traumatic |

| Q6 | Inadequate contractor management | Q53 | Burn |

| Q7 | Inadequate management of change | Q54 | Crush Cuts/Laceration/Open Wound |

| Q8 | Inadequate leadership/supervisor | Q55 | Electric Shock |

| Q9 | Inadequate incident investigation/analysis | Q56 | Foreign Body under Skin |

| Q10 | Inadequate engineering/design/control | Q57 | Fracture |

| Q11 | Inadequate maintenance | Q58 | Foreign Body in Eye |

| Q12 | Inadequate communication | Q59 | Heat-Related Illness |

| Q13 | Inadequate planning/inspection | Q60 | Occupational Illness/Disease |

| Q14 | Inadequate emergency response plan | Q61 | Psychological (Stress). |

| What is your scale for the following Personal factors that cause the incident do you experience? | Q62 | Poisoning/Toxic Effect—Inhalation | |

| Q15 | Physical capability | Q63 | Strain/Sprain |

| Q16 | Mental state | Q64 | Respiratory Disease |

| Q17 | Behavior | Q65 | Skin Irritation/Disease |

| Q18 | Human error | What is your scale for the following mechanism of incident/injury that causes the incident do you experience? | |

| Q19 | Physical condition | Q66 | Human–Human |

| Q20 | Skill level | Q67 | Confined Space |

| Q21 | Mental stress | Q68 | Environmental Conditions |

| What is your scale for the following unsafe acts that cause the incident do you experience? | Q69 | Fixed Machinery | |

| Q22 | Failure to secure its | Q70 | Infectious Agent |

| Q23 | Failure to warn | Q71 | Materials or Chemical Substances |

| Q24 | Remove/Defeating safety device | Q72 | Mobile Plant/Equipment |

| Q25 | Failure to use PPE | Q73 | Non-Powered Equipment/Tools/Appliances |

| Q26 | Operation at improper speed | Q74 | Scaffolding or Ladders |

| Q27 | Lack of awareness/knowledge | Q75 | Powered Equipment/Tools/Appliances |

| Q28 | Lack of attention concentration | Q76 | Road Transport/Vehicles at site |

| Q29 | Violation/taking shortcuts | Q77 | Sharps/Scalpels/Needles/etc. |

| Q30 | Operation equipment without authority | Q78 | Trench or Excavations |

| Q31 | Service equipment in operation | What is your scale for the following body parts that was affected incident do you experience? | |

| Q32 | Using defective equipment/tools | Q79 | Head |

| Q33 | Using equipment improperly | Q80 | Spine, Pelvis, and Back |

| Q34 | Improper lifting/ lading/placement | Q81 | Fingers and Thumb |

| Q35 | Improper position for task | Q82 | Toe, Foot, and Ankle |

| Q36 | Horseplay | Q83 | Heat-Related and Occupational Illness |

| What is your scale for the following unsafe conditions that cause the incident do you experience? | Q84 | Eye | |

| Q37 | Inadequate guards or barriers | What is your scale for the following top hazard in construction site do you experience? | |

| Q38 | Inadequate wiring system or notice | Q85 | Unsafe working at height |

| Q39 | Inadequate ventilation | Q86 | Unsafe lifting operation |

| Q40 | Fire and explosive hazard | Q87 | Open shafts & edges |

| Q41 | High/low temperature exposure | Q88 | Unsafe machine/equipment/tools |

| Q42 | Hazardous gases/dust/vapors/fumes | Q89 | Housekeeping/site store |

| Q43 | Defective tools, equipment or material | Q90 | Unsafe working platforms/ladder/cantilever/scaffolds |

| Q44 | Inadequate or improper protective equipment | Q91 | Unsafe excavation |

| Q45 | Inadequate or excess illumination | Q92 | Unsafe electrical equipment/connection |

| Q46 | Congestion/ restricted action/poor access | Q93 | What is the probability of incident do you experience? |

| Q47 | Poor housekeeping, disorder | Q94 | What is the severity of consequence of the incident do you experience? |

| How do you scale the following managing incident prevention factors? | Part C: What is your scale for the following incident prevention method (task factors) do you experience?? | ||

| Q95 | Top management commitments, leadership, and lead by example policy | Q109 | Use of safe work procedure |

| Q96 | Sufficient training (induction, orientation, awareness and specific training) | Q110 | Applying work safe monitoring procedure |

| Q97 | Safe work procedures being enforced for implementation | Q111 | Safety devices exciting (human error prevention method) |

| Q98 | Adequate supervision | Q112 | Appropriate tools and materials |

| Q99 | Carry out regular maintenance of equipment. | What is your scale for the following incident prevention method (material) do you experience? | |

| Q100 | Regular safety joint inspections (CEO, Director, GM, PM, CRE, and supervisor) | Q113 | Appropriate equipment and machinery |

| Q101 | Committed to risk assessment and management of change | Q114 | Less hazardous alternative products (possible and available) |

| Q102 | Implementation of Hazard, Near Miss, Incident Reporting, and Investigation. | What is your scale for the following incident prevention method (work environment factors) do you experience? | |

| Q103 | Committed consultation and communication procedure. | Q115 | Poor housekeeping |

| Q104 | Incident investigation led by top management and corrective action implemented. | Q116 | Physical work environment (noise, temperature, light, weather, …) |

| What is your scale for the following incident prevention method (personnel factors) do you experience? | What is your scale for the following incident prevention method (PPE) do you experience? | ||

| Q105 | Implementing competency procedure | Q117 | Use of proper head protection. |

| Q106 | Implementing roles and responsibilities procedure | Q118 | Use of proper coverall protection. |

| Q107 | Physical and mental capability, and workload | Q119 | Use proper foot protection. |

| Q108 | Follow the safe operating procedures | Q120 | Use of proper eye protection. |

| Scale | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| Description of the scale | Not significant (0%) | Slightly significant (25%) | Moderately significant (50%) | Significant (75%) | Very Significant (100%) |

| Likert’s Relevancy Scale | ||||

|---|---|---|---|---|

| Number of Questions | Level of Relevancy | % | Likert’s Relevancy Scale | Number of Answers |

| 120 | Extremely relevant | 100 | 5 | 0 |

| Very Relevant | 75 | 4 | 31 | |

| Moderately Relevant | 50 | 3 | 61 | |

| Slightly Relevant | 25 | 2 | 28 | |

| Not relevant | 0 | 1 | 0 | |

| 120 | ||||

| Cronbach’s Alpha | Cronbach’s Alpha Based on Standardized Items | N of Items |

|---|---|---|

| 0.977 | 0.975 | 126 |

| Q | p Value [Cut off Value Is 0.05] | Mean Score | Level of Relevancy | Q | p Value [Cut off Value Is 0.05] | Mean Score | Level of Relevancy |

|---|---|---|---|---|---|---|---|

| Q1 | 0.197 | 3 | Moderately relevant | Q48 | 0.727 | 2 | Slightly relevant |

| Q2 | 0.997 | 3 | Moderately relevant | Q49 | 0.8.2 | 2 | Slightly relevant |

| Q3 | 0.062 | 3 | Moderately relevant | Q50 | 0.924 | 3 | Moderately relevant |

| Q4 | 0.477 | 3 | Moderately relevant | Q51 | 0.400 | 3 | Moderately relevant |

| Q5 | 0.306 | 3 | Moderately relevant | Q52 | 0.677 | 2 | Slightly relevant |

| Q6 | 0.258 | 3 | Moderately relevant | Q53 | 0.737 | 2 | Slightly relevant |

| Q7 | 0.121 | 3 | Moderately relevant | Q54 | 0.851 | 3 | Moderately relevant |

| Q8 | 0.329 | 4 | Very relevant | Q55 | 0.920 | 2 | Slightly relevant |

| Q9 | 0.691 | 3 | Moderately relevant | Q56 | 0.340 | 2 | Slightly relevant |

| Q10 | 0.508 | 3 | Moderately relevant | Q57 | 0.031 | 3 | Moderately relevant |

| Q11 | 0.510 | 3 | Moderately relevant | Q58 | 0.852 | 2 | Slightly relevant |

| Q12 | 0.192 | 3 | Moderately relevant | Q59 | 0.626 | 3 | Moderately relevant |

| Q13 | 0.795 | 3 | Moderately relevant | Q60 | 0.525 | 2 | Slightly relevant |

| Q14 | 0.962 | 3 | Moderately relevant | Q61 | 0.132 | 2 | Slightly relevant |

| Q15 | 0.849 | 2 | Slightly Relevant | Q62 | 0.802 | 2 | Slightly relevant |

| Q16 | 0.975 | 2 | Slightly Relevant | Q63 | 0.844 | 2 | Slightly relevant |

| Q17 | 0.643 | 3 | Moderately relevant | Q64 | 0.486 | 2 | Slightly relevant |

| Q18 | 0.820 | 4 | Very relevant | Q65 | 0.390 | 2 | Slightly relevant |

| Q19 | 0.474 | 2 | Slightly relevant | Q66 | 0.258 | 3 | Moderately relevant |

| Q20 | 0.039 | 3 | Moderately relevant | Q67 | 0.780 | 2 | Slightly relevant |

| Q21 | 0.822 | 3 | Moderately relevant | Q68 | 0.203 | 2 | Slightly relevant |

| Q22 | 0.097 | 3 | Moderately relevant | Q69 | 0.062 | 2 | Slightly relevant |

| Q23 | 0.355 | 3 | Moderately relevant | Q70 | 0.368 | 2 | Slightly relevant |

| Q24 | 0.968 | 3 | Moderately relevant | Q71 | 0.259 | 2 | Slightly relevant |

| Q25 | 0.228 | 3 | Moderately relevant | Q72 | 0.337 | 3 | Moderately relevant |

| Q26 | 0.281 | 3 | Moderately relevant | Q73 | 0.207 | 3 | Moderately relevant |

| Q27 | 0.947 | 3 | Moderately relevant | Q74 | 0.073 | 3 | Moderately relevant |

| Q28 | 0.768 | 3 | Moderately relevant | Q75 | 0.333 | 3 | Moderately relevant |

| Q29 | 0.992 | 4 | Very relevant | Q76 | 0.296 | 3 | Moderately relevant |

| Q30 | 0.581 | 3 | Moderately relevant | Q77 | 0.897 | 3 | Moderately relevant |

| Q31 | 0.819 | 3 | Moderately relevant | Q78 | 0.475 | 3 | Moderately relevant |

| Q32 | 0.763 | 3 | Moderately relevant | Q79 | 0.751 | 2 | Slightly relevant |

| Q33 | 0.326 | 3 | Moderately relevant | Q80 | 0.527 | 2 | Slightly relevant |

| Q34 | 0.767 | 3 | Moderately relevant | Q81 | 0.581 | 3 | Moderately relevant |

| Q35 | 0.812 | 3 | Moderately relevant | Q82 | 0.932 | 3 | Moderately relevant |

| Q36 | 0.487 | 3 | Moderately relevant | Q83 | 0.224 | 3 | Moderately relevant |

| Q37 | 0.433 | 3 | Moderately relevant | Q84 | 0.435 | 2 | Slightly Relevant |

| Q38 | 0.458 | 3 | Moderately relevant | Q85 | 0.097 | 4 | Very relevant |

| Q39 | 0.204 | 2 | Slightly relevant | Q86 | 0.579 | 4 | Very relevant |

| Q40 | 0.254 | 2 | Slightly relevant | Q87 | 0.942 | 3 | Moderately relevant |

| Q41 | 0.768 | 3 | Moderately relevant | Q88 | 0.087 | 3 | Moderately relevant |

| Q42 | 0.336 | 2 | Slightly relevant | Q89 | 0.359 | 3 | Moderately relevant |

| Q43 | 0.701 | 3 | Moderately relevant | Q90 | 0.207 | 3 | Moderately relevant |

| Q44 | 0.304 | 3 | Moderately relevant | Q91 | 0.777 | 3 | Moderately relevant |

| Q45 | 0.452 | 2 | Slightly relevant | Q92 | 0.409 | 3 | Moderately relevant |

| Q46 | 0.905 | 3 | Moderately relevant | Q93 | 0.053 | 3 | Moderately relevant |

| Q47 | 0.290 | 3 | Moderately relevant | Q94 | 0.438 | 3 | Moderately relevant |

| Factors | p Value [Cut off Value Is 0.05] | Factors | p Value [Cut off Value Is 0.05] |

|---|---|---|---|

| Q95 | 0.533 | Q108 | 0.179 |

| Q96 | 0.903 | Q109 | 0.307 |

| Q97 | 0.689 | Q110 | 0.882 |

| Q98 | 0.376 | Q111 | 0.149 |

| Q99 | 0.616 | Q112 | 0.957 |

| Q100 | 0.550 | Q113 | 0.825 |

| Q101 | 0.340 | Q114 | 0.526 |

| Q102 | 0.326 | Q115 | 0.081 |

| Q103 | 0.781 | Q116 | 0.627 |

| Q104 | 0.387 | Q117 | 0.856 |

| Q105 | 0.372 | Q118 | 0.974 |

| Q106 | 0.530 | Q119 | 0.529 |

| Q107 | 0.110 | Q120 | 0.697 |

| Likert Scale | Management System Factors | Personal Factors | Unsafe Act | Unsafe Condition |

|---|---|---|---|---|

| 1 | N/A | N/A | N/A | N/A |

| 2 | N/A |

| N/A |

|

| 3 |

|

|

|

|

| 4 |

| Human error |

| N/A |

| 5 | N/A | N/A | N/A | N/A |

| Likert Scale | Management | Personal | Task | Material | Work Environment | PPE |

|---|---|---|---|---|---|---|

| 1 | N/A | N/A | N/A | N/A | N/A | N/A |

| 2 | N/A | N/A | N/A | N/A | N/A | N/A |

| 3 | N/A | N/A | N/A | N/A | N/A | N/A |

| 4 | 1—Top management commitments, leadership, and lead by example policy 2—Sufficient training (induction, orientation, awareness and specific training 3—Safe work procedures being enforced for implementation 4—Adequate supervision 5—Carry out regular maintenance of equipment 6—Regular safety joint inspections (CEO, Director, GM, PM, CRE, and supervisor) 7—Committed to risk assessment and management of change 8—Implementation of Hazard, Near Miss, Incident Reporting, and Investigation. 9—Committed consultation and communication procedure. 10—Incident investigation led by top management and corrective action implemented. | 11—Implementing competency procedure 12—Implementing the roles and responsibilities procedure 13—Physical and mental capability and workload 14—Follow the safe operating procedures | 15—Use of safe work procedure 16—Applying work safe monitoring procedure 17—Safety devices exciting (human error prevention method) 18—Appropriate tools and materials | 19—Appropriate equipment and machinery 20—Less hazardous alternative products (possible and available) | 21—Poor housekeeping 22—Physical work environment (noise, temperature, light, weather, …) | 23—Use of proper head protection. 24—Use of proper coverall protection. 25—Use of proper foot protection. 26—Use of proper eye protection. |

| 5 | N/A | N/A | N/A | N/A | N/A | N/A |

| Likert Scale | Top Hazard |

|---|---|

| 1 | N/A |

| 2 | N/A |

| 3 |

|

| 4 |

|

| 5 | N/A |

| Risk Evaluation | |||||

|---|---|---|---|---|---|

| Likert Scale | 1 | 2 | 3 | 4 | 5 |

| Probability | √ | ||||

| Severity | √ | ||||

| Likert Scale | Nature of the Accidents | Mechanism | Body part |

|---|---|---|---|

| 1 | NA | NA | NA |

| 2 |

|

|

|

| 3 |

| Human—Transportable Plant/Equipment

|

|

| 4 | NA | NA | NA |

| 5 | NA | NA | NA |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Medani, A.M.; Rahman, I.B.A.; Hamid, N.A.B.A. Factors and Method of Preventing Construction Site Incidents. Eng. Proc. 2025, 91, 18. https://doi.org/10.3390/engproc2025091018

Medani AM, Rahman IBA, Hamid NABA. Factors and Method of Preventing Construction Site Incidents. Engineering Proceedings. 2025; 91(1):18. https://doi.org/10.3390/engproc2025091018

Chicago/Turabian StyleMedani, Ameir Mohamed, Ismail Bin Abdul Rahman, and Nor Aziati Binti Abdul Hamid. 2025. "Factors and Method of Preventing Construction Site Incidents" Engineering Proceedings 91, no. 1: 18. https://doi.org/10.3390/engproc2025091018

APA StyleMedani, A. M., Rahman, I. B. A., & Hamid, N. A. B. A. (2025). Factors and Method of Preventing Construction Site Incidents. Engineering Proceedings, 91(1), 18. https://doi.org/10.3390/engproc2025091018