Contrast Enhancement in 2D Nanomaterial SEM Images †

Abstract

1. Introduction

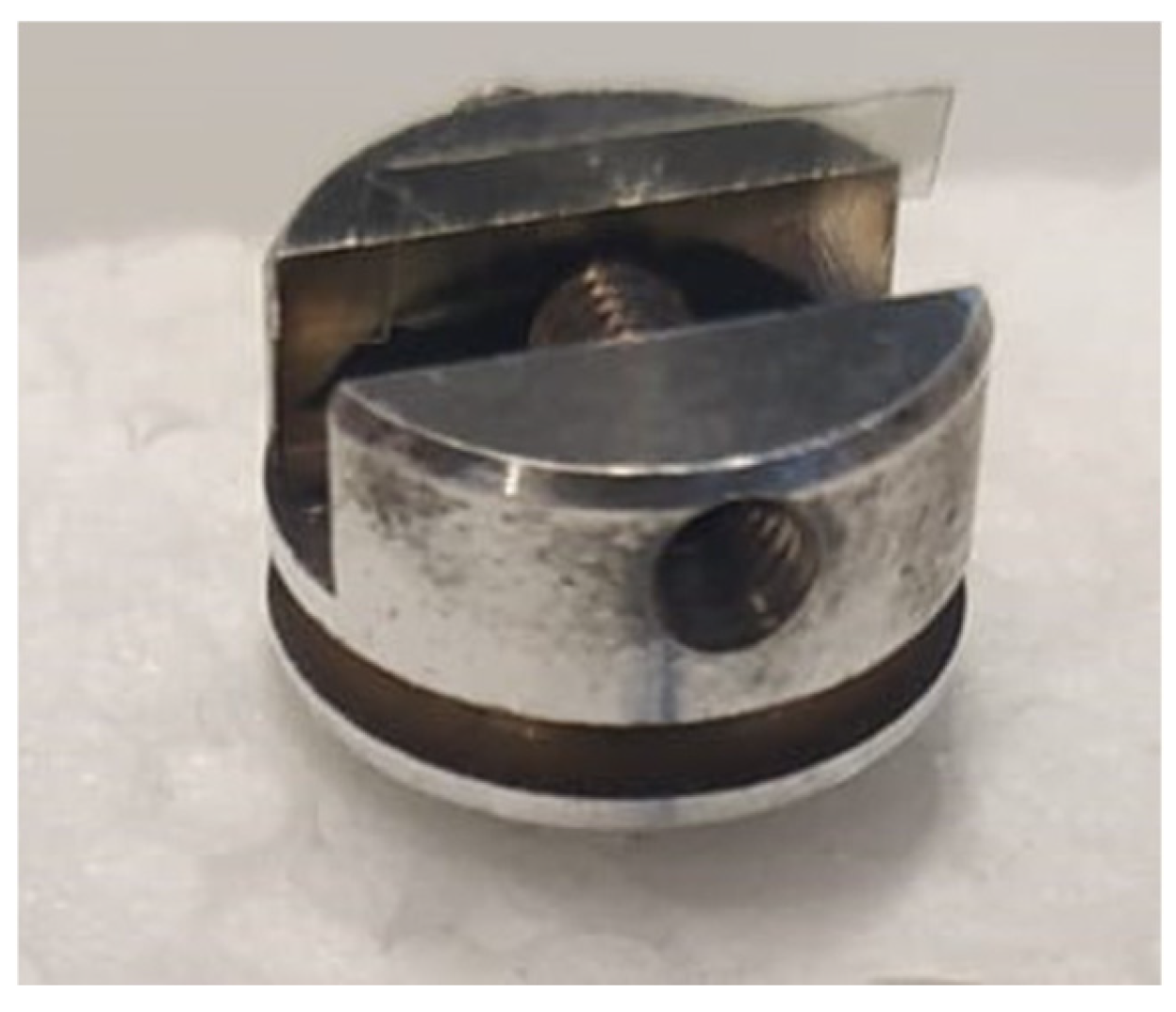

2. Materials and Methods

3. Results and Discussion

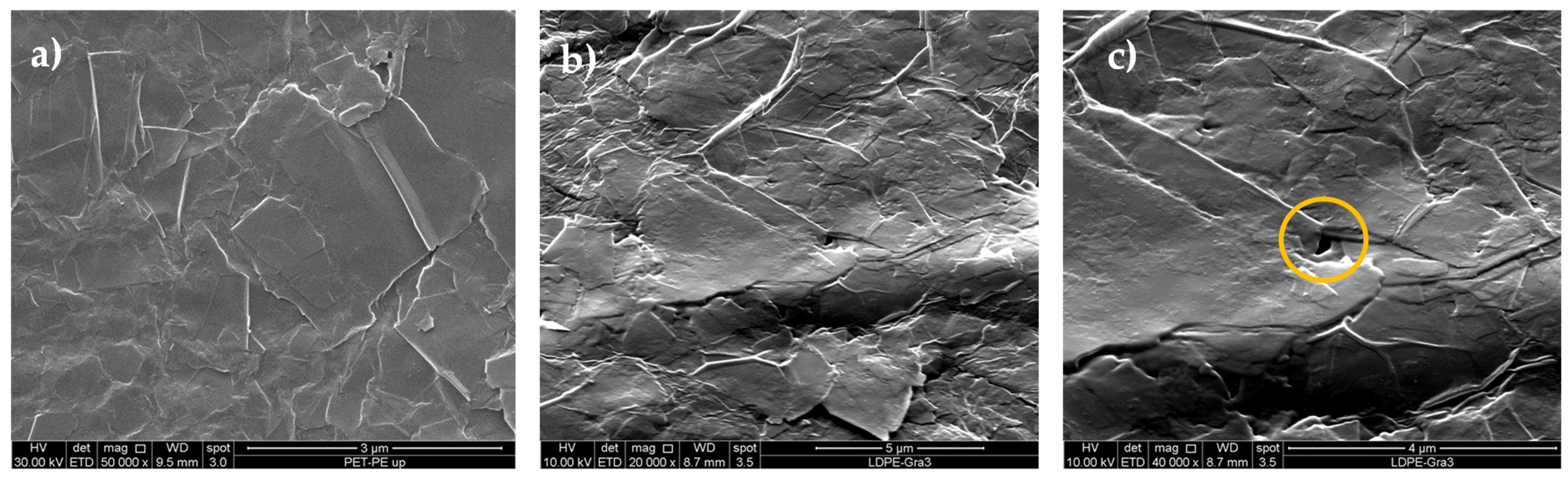

3.1. SEM Characterization of GNP Coatings on LD-PE

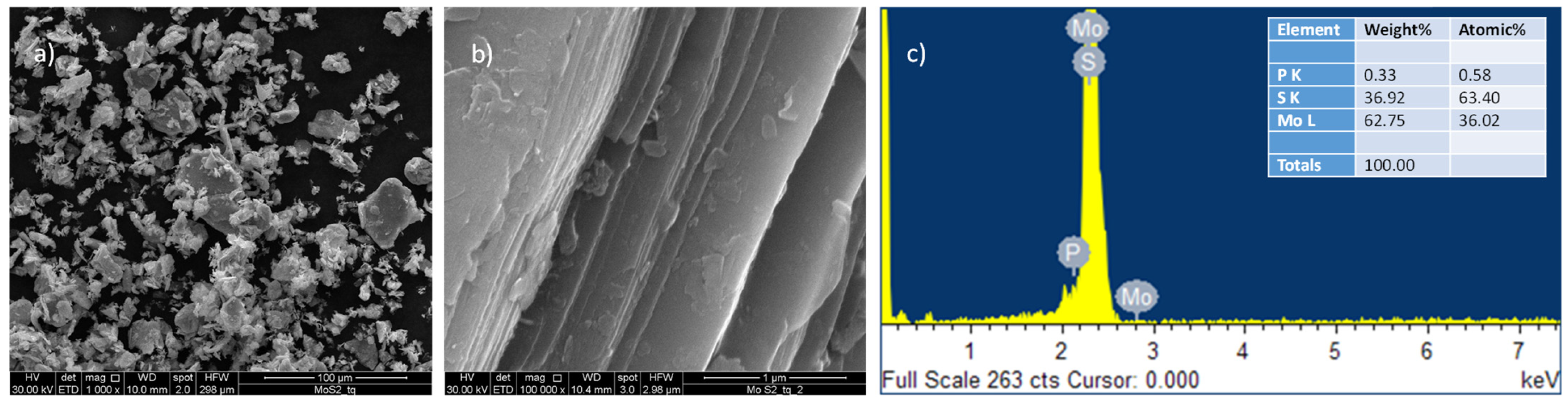

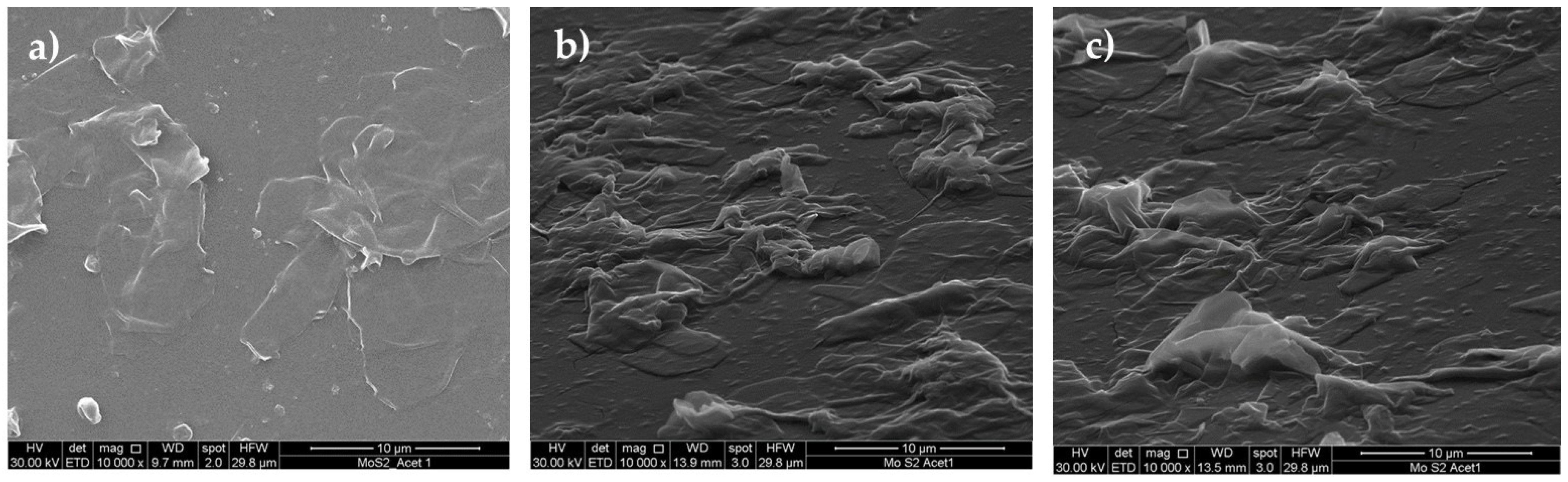

3.2. SEM-Characterization of MoS2 Coatings on Glass

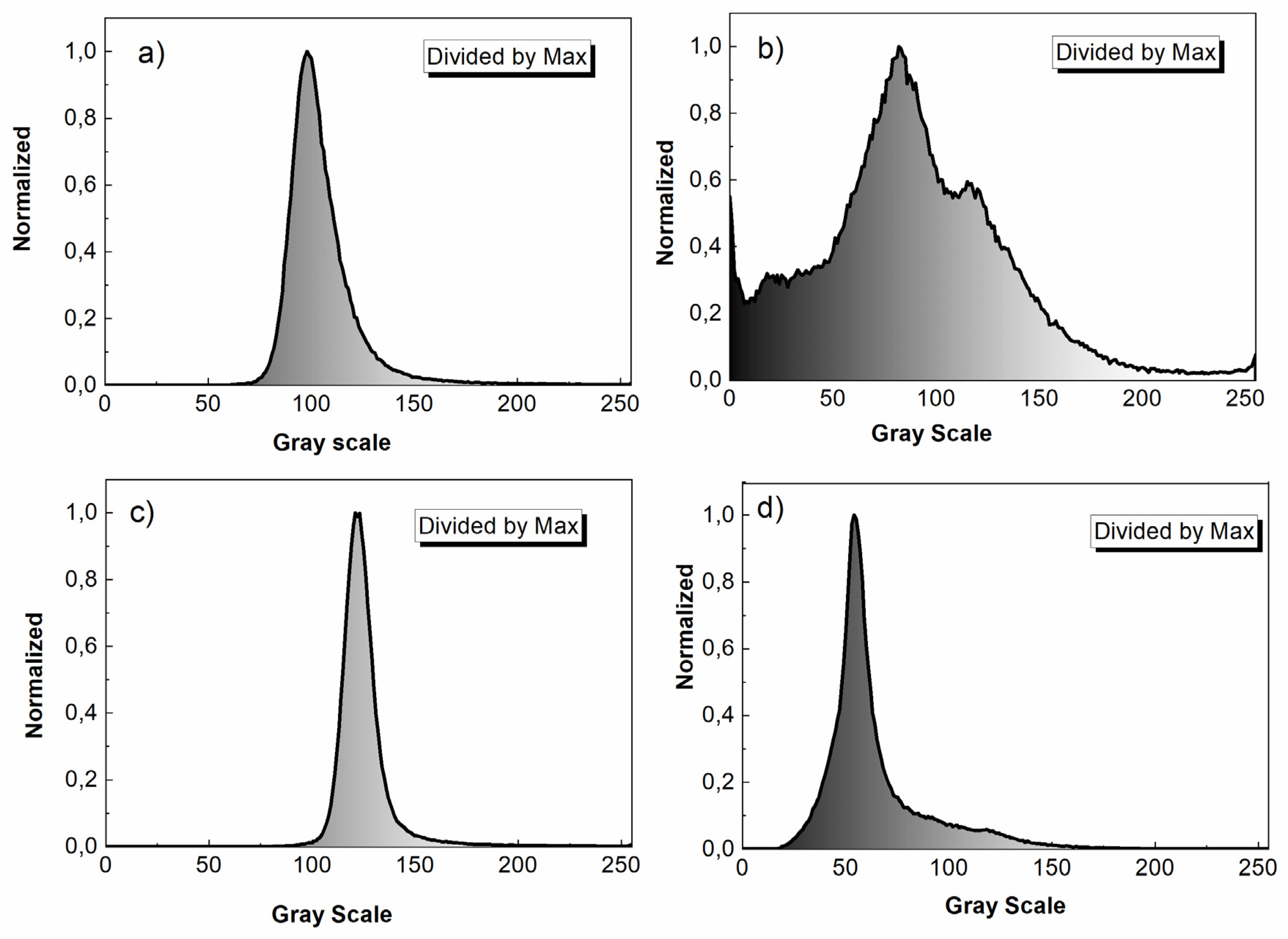

3.3. Quantitative Evaluation of SEM Image Contrast

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Baig, N. Two-dimensional nanomaterials: A critical review of recent progress, properties, applications, and future directions. Compos. Part A Appl. Sci. Manuf. 2023, 165, 107362. [Google Scholar] [CrossRef]

- Tene, T.; Tubon-Usca, G.; Haro-Barroso, C.; Velasco Castelo, G.M.; Vacacela Gomez, C. Two-Dimensional Materials-Based Thin Films and Coatings. Coatings 2024, 14, 1242. [Google Scholar] [CrossRef]

- Satya Prasad, S.V.; Prasad, S.B.; Singh, S. Nanostructured 2D materials as nano coatings and thin films. In Advanced Applications of 2D Nanostructures. Materials Horizons: From Nature to Nanomaterials; Springer: Singapore, 2021; pp. 55–72. [Google Scholar] [CrossRef]

- Coscia, U.; Palomba, M.; Ambrosone, G.; Barucca, G.; Cabibbo, M.; Mengucci, P.; de Asmundis, R.; Carotenuto, G. A new micromechanical approach for the preparation of graphene nanoplatelets deposited on polyethylene. Nanotechnology 2017, 28, 194001. [Google Scholar] [CrossRef] [PubMed]

- Bonavolontà, C.; Aramo, C.; Valentino, M.; Pepe, G.P.; De Nicola, S.; Carotenuto, G.; Longo, A.; Palomba, M.; Boccardi, S.; Meola, C. Graphene–polymer coating for the realization of strain sensors. Beilstein J. Nanotechnol. 2017, 8, 21–27. [Google Scholar] [CrossRef] [PubMed]

- Srinivasan, A.; Han, W.; Zheng, M.; Khursheed, A. Characterization of materials using the secondary electron energy spectromicroscopy technique. Opt. Mater. X 2021, 12, 100121. [Google Scholar] [CrossRef]

- Shi, Q.; Roux, S.; Latourte, F.; Hild, F.; Loisnard, D.; Brynaert, N. Measuring topographies from conventional SEM acquisitions. Ultramicroscopy 2018, 191, 18–33. [Google Scholar] [CrossRef] [PubMed]

- Huang, L.; Zhang, D.; Zhang, F.H.; Huang, Y.D.; Gan, Y. Graphene to graphene, and substrate to substrate: How to reliably differentiate supported graphene from polycrystalline substrates using SEM? Mater. Res. Express 2019, 6, 085604. [Google Scholar] [CrossRef]

- Pachauri, V.; Kern, K.; Balasubramanian, K. Chemically exfoliated large-area two-dimensional flakes of molybdenum disulfide for device applications. APL Mater. 2013, 1, 032102. [Google Scholar] [CrossRef]

- Forsberg, V.; Zhang, R.; Bäckström, J.; Dahlström, C.; Andres, B.; Norgren, M.; Olin, H. Exfoliated MoS2 in water without additives. PLoS ONE 2016, 11, e0154522. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Longo, A.; Palomba, M.; Giubileo, F.; Carotenuto, G. Contrast Enhancement in 2D Nanomaterial SEM Images. Eng. Proc. 2025, 87, 81. https://doi.org/10.3390/engproc2025087081

Longo A, Palomba M, Giubileo F, Carotenuto G. Contrast Enhancement in 2D Nanomaterial SEM Images. Engineering Proceedings. 2025; 87(1):81. https://doi.org/10.3390/engproc2025087081

Chicago/Turabian StyleLongo, Angela, Mariano Palomba, Filippo Giubileo, and Gianfranco Carotenuto. 2025. "Contrast Enhancement in 2D Nanomaterial SEM Images" Engineering Proceedings 87, no. 1: 81. https://doi.org/10.3390/engproc2025087081

APA StyleLongo, A., Palomba, M., Giubileo, F., & Carotenuto, G. (2025). Contrast Enhancement in 2D Nanomaterial SEM Images. Engineering Proceedings, 87(1), 81. https://doi.org/10.3390/engproc2025087081