Abstract

Subcritical water extraction (SWE) is an eco-friendly technology offering advantages such as green solvent and selectivity, especially for extracting bioactive compounds. Despite its potential, limited data exists on upscaling this process. This study investigates the upscaling of SWE by comparing two systems: a commercially available high-pressure system (ASE 200, 32 mL capacity) and high-volume subcritical water extraction (HVSWE) (1000 mL capacity). Medicinal compounds, 6-gingerol and 6-shogaol, were extracted from ginger using SWE at temperatures ranging from 130 °C to 200 °C, at a constant pressure of 3.5 MPa, for 30 min. High-Performance Liquid Chromatography (HPLC) was employed for quantitative analysis. The optimal extraction temperature for 6-gingerol using the high-volume SWE system was 130 °C, yielding 1741.54 ± 0.96 µg/g, whereas ASE 200 achieved optimal extraction at 140 °C with 1957.22 ± 2.55 µg/g. For 6-shogaol, both systems demonstrated an optimal extraction temperature of 170 °C, with yields of 541.78 ± 3.16 µg/g and 1135.23 ± 1.18 µg/g for the high-volume SWE and ASE 200 systems, respectively. These variations stem from the 35-fold difference in capacity, influencing heat and mass transfer during extraction. Thus, scale-up factors must be carefully considered to enhance the mass transfer efficiency and optimize SWE processes at larger scales.

1. Introduction

Ginger (Zingiber officinale) is well known for its medicinal effects, including its anticancer, antioxidant, inflammation, and anti-tumor properties [1]. The main bioactive compounds responsible for these medicinal properties are gingerols, shogaols, and paradols. Among these, the most significant compounds are 6-gingerol [2] and 6-shogaol [3]. 6-gingerol, the most abundant compound in ginger rhizomes, has been shown to mediate cardiac contractility and exhibit antioxidant, antiproliferative, and apoptosis-inducing activity [2,4]. The proven applications of each ginger compound have promoted the search for green extraction technologies that give the ginger added value. Subcritical water extraction (SWE) is one of the options that can be used for this purpose, and it is attracting interest regarding the extraction of ginger bioactive substances [5,6,7]. This study found that SWE gave promising results, with the bioactive metabolites and antioxidant and anti-inflammatory effects of its extract being comparable with other methods [5]. Therefore, the upscaling of the SWE process needs to be considered, and this needs to involve its main parameter, namely temperature. This is because the process involves high temperatures up to 200 °C. In this study, the effect of temperature during the upscaling process was reported by comparing SWE processes with different scales. Two SWE processes with different scales, namely the commercially available high-pressure system ASE 200 with a capacity of 32 mL and a locally fabricated high-volume SWE process with a capacity of 1000 mL, were employed for the extraction of medicinal compounds from ginger, namely 6-gingerol and 6-shogaol. The effect of temperature on the concentrations of the compounds in both setups was studied from 130 °C to 200 °C at a constant pressure of 3.5 MPa and for a duration of 30 min.

2. Methodology

2.1. Material and Chemical

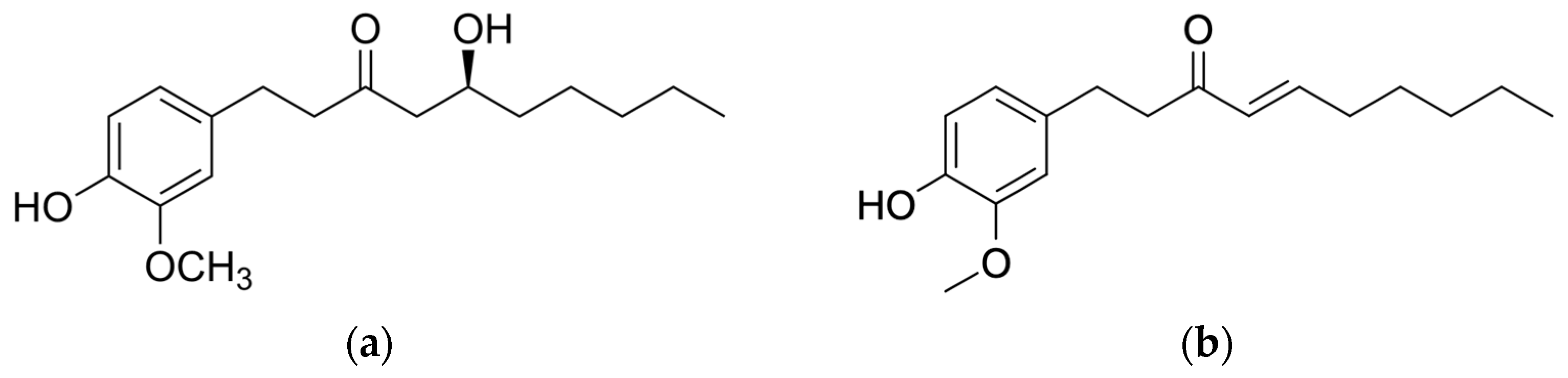

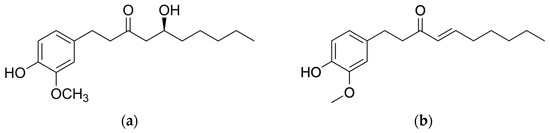

Dried and ground ginger was supplied by a local supplier from Ranau, Sabah, East Malaysia. The ginger standards of 6-gingerol (85.8% w/w) and 6-shogaol (96.4% w/w) were purchased from ChromoDex Inc., Los Angeles, CA, USA. Acetonitrile and methanol were of High-Performance Liquid Chromatography (HPLC) grade and supplied by MERCK, Darmstadt, Germany. Distilled water was used for both SWE processes. The structure of 6-gingerol and 6-shogaol is shown in Figure 1.

Figure 1.

(a) 6-gingerol and (b) 6-shogaol.

2.2. SWE Process

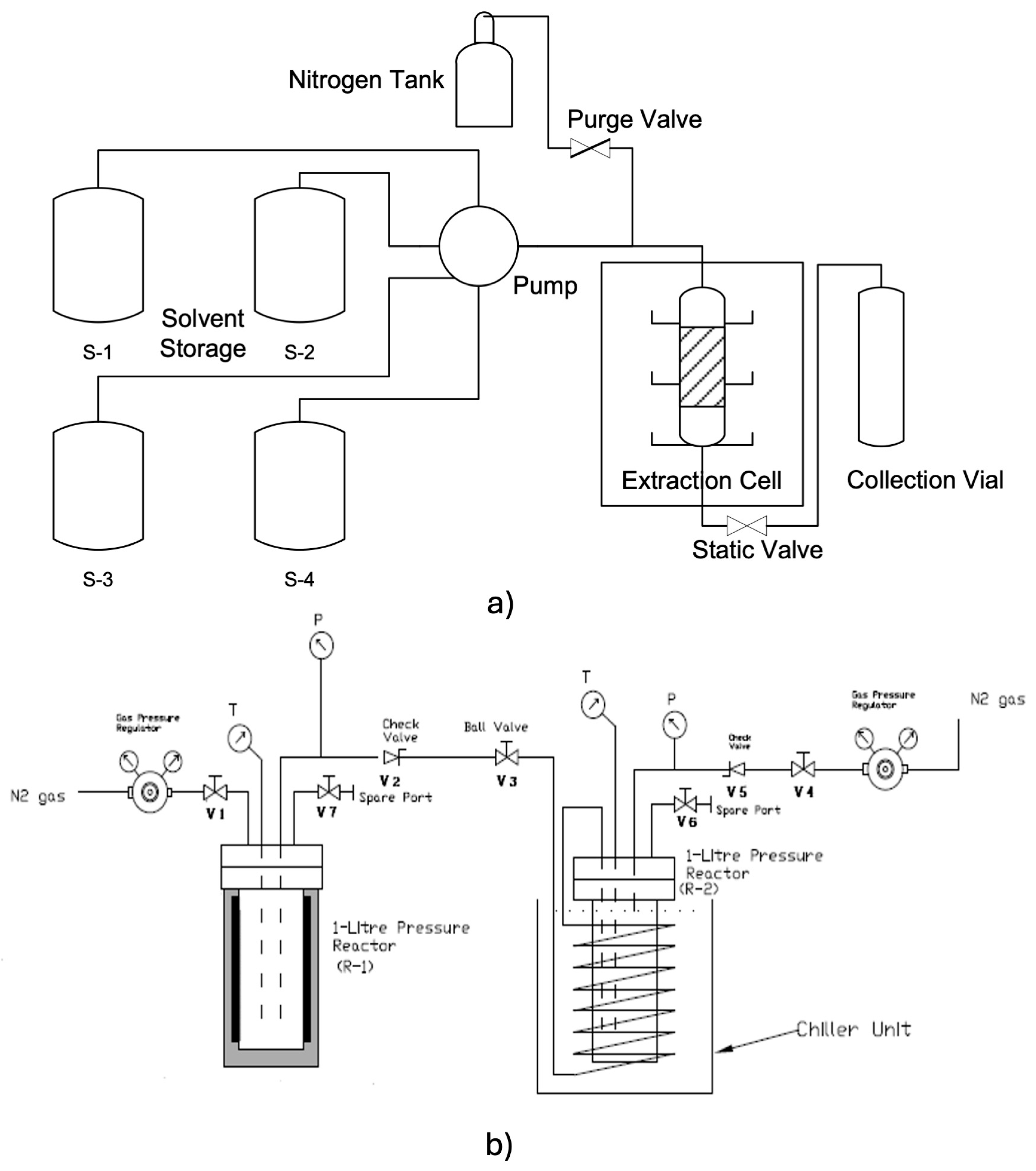

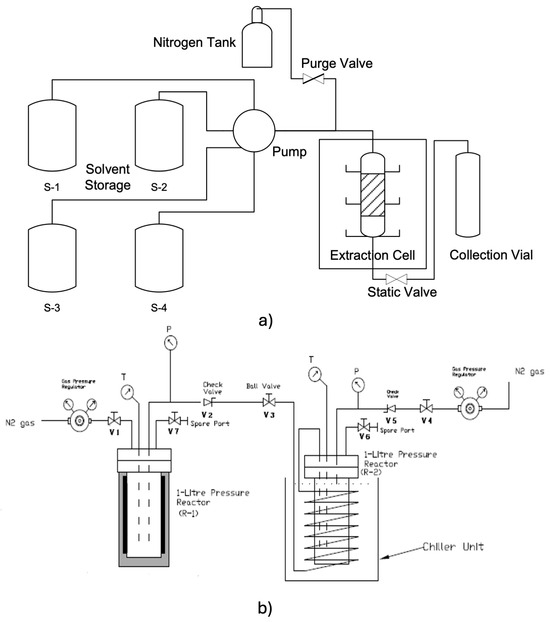

In this study, two types of SWE experimental rig were used to evaluate the effect of upscaling on the process. (1) Accelerated solvent extraction system (ASE 200, Dionex, Sunnyvale, CA, USA) and (2) High-volume subcritical water extraction (HVSWE) system with a 1000 mL capacity.

2.2.1. Accelerated Solvent Extraction System (ASE 200)

As shown in Figure 2a, ASE 200 was utilized for a SW process with a small volume (32 mL). The ASE 200 consisted of a four-feed tank, a 32 mL extraction cell and a collection vessel, as shown in Figure 2a. The experiment was conducted at temperatures ranging from 130 °C to 200 °C, under a constant pressure of 3.5 MPa, and with an extraction time of 30 min. For all experimental conditions, the flushing process was carried out at 60% of the volume for 60 s, and the heating time was 7 min. The experimental procedure for the equipment was as follows. (1) A 3 ± 0.01 g sample was weighed and installed in the extraction cell. (2) The operating condition was loaded into the system. (3) The extraction process took 30 min. (4) The ginger extract was collected from the extraction vial.

Figure 2.

Schematic diagram for SWE. (a) ASE 200. (b) HVSWE.

2.2.2. HVSWE

HVSWE was conducted using the fabricated SWE experimental rig, as shown in Figure 2b. This was located at Universiti Teknologi Malaysia (UTM). The fabricated equipment consisted of two vessels, each with a one-liter volume: the extraction and the cooling cells were connected by a 1/4-inch stainless steel pipeline. Then, 75 g of ground ginger was weighed and loaded into a covered stainless steel mesh cylinder before being placed into the extraction cell. Next, 700 mL of distilled water was added into the cell. The cell was then securely covered with a stainless steel lid. N2 gas was then passed through the cell for 2 min to purge out air and dissolved oxygen. Excess pressure was relieved through the release valve. The temperature was set according to the required experiment. The electrically jacketed extraction cell took 3–5 min to achieve the desired temperature. The extraction time started once the set temperature was achieved, as indicated by the temperature indicator in the extraction cell. No stirrer was included in the extraction vessel.

2.3. Compound Identification

The identification of the bioactive compounds of ginger, namely 6-gingerol and 6-shogoal, was performed using High-Performance Liquid Chromatography (Waters Corporation, Milford, MA, USA) with a Proto Iodide Detector (Waters Corporation, Milford, MA, USA) in FRIM, Kepong using Lichrocart 250-4, and using a 6 Purospher Star RP-8E (5 Mym) column by Merck (Rahway, NJ, USA). A 20 min run time analysis and 8 min next injection delay were implemented in this method. The two mobile phases used were acetonitrile (Merck, Rahway, NJ, USA) and methanol (Merck, Rahway, NJ, USA). The percentage of mixture in the mobile phase increased gradually during the analysis from 20% acetonitrile to 50% acetonitrile. The standard for the ginger bioactive compounds, namely 6-gingerol and 6-shogoal, was provided by Chromodex, UK. The single concentrations of each standard were injected into the HPLC system to identify the retention time, RT. RT identification using a single-concentration injection was only the preliminary procedure used before the actual RT identification. Then, an equal mixture of the standard was injected into the system for precise and accurate RT identification [8].

2.4. Statistical Analysis

All the experimental work was conducted in triplicate. The reproducibility of the process was calculated based on the average absolute deviation, AAD, which was applied for each set of experiments using Equation (1).

where i, n is the number of runs for one experimental condition; N is the total number of runs; xi is the data for one experimental condition; and x is the average for one experimental condition.

3. Result and Discussion

3.1. Effect of Temperature on the 6-Gingerol Concentration

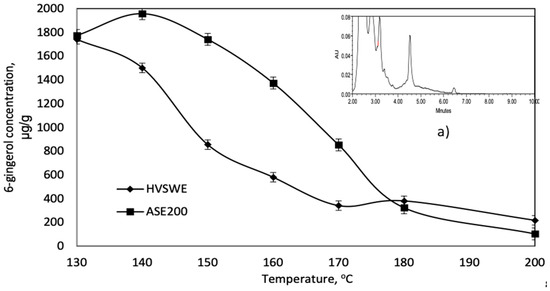

Figure 1 shows the effect of the temperature on the 6-gingerol concentration using high-volume subcritical water extraction and ASE 200.

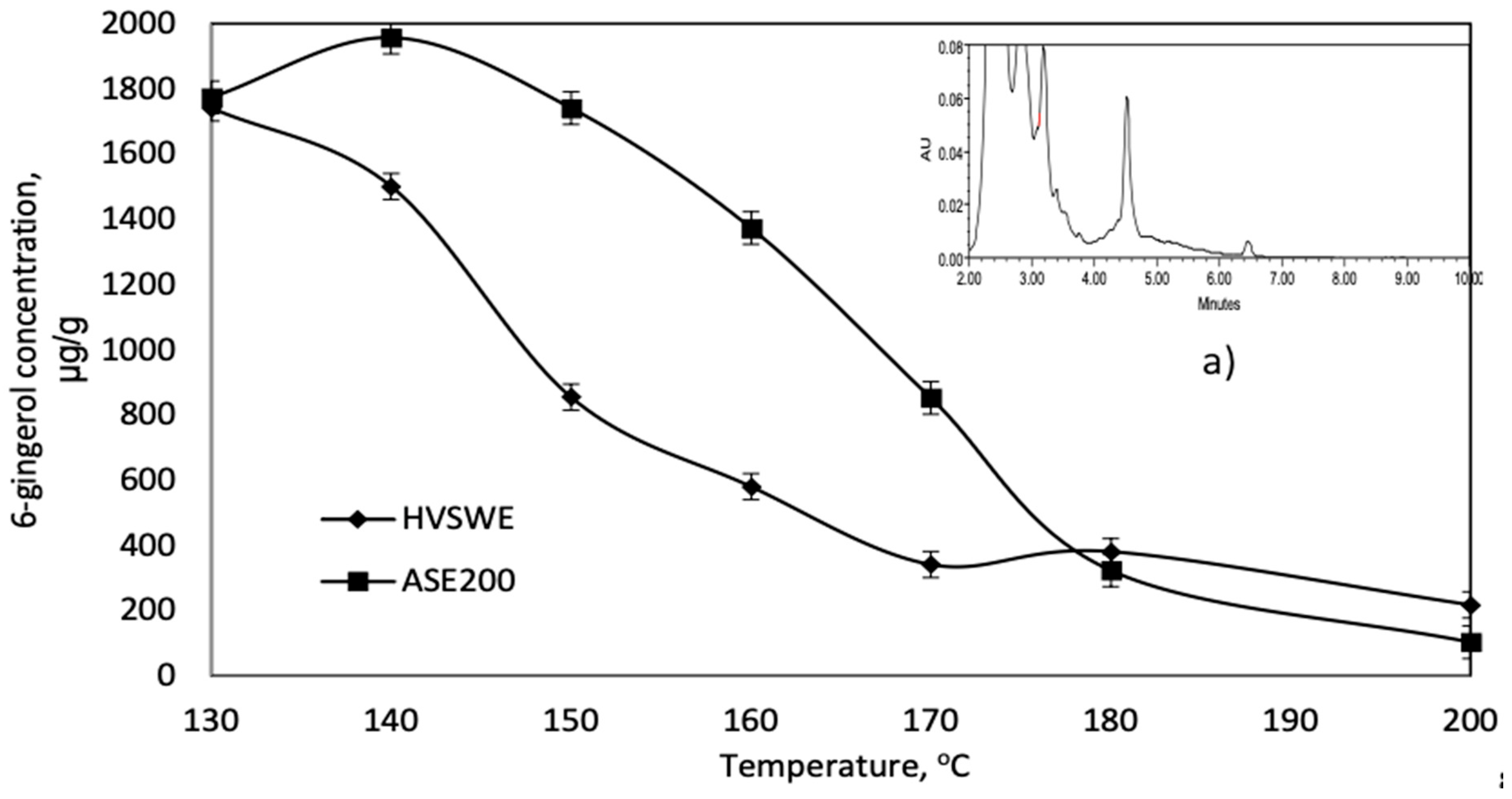

Figure 3 illustrates the effect of temperature on the concentration of 6-gingerol during subcritical water extraction using both the HVSWE and ASE 200 systems. In the HVSWE process, the 6-gingerol concentration decreased markedly from 1741.54 ± 2.19 µg/g at 130 °C to 102.98 ± 2.19 µg/g at 200 °C. Conversely, the ASE 200 system exhibited an initial increase in concentration, rising from 1773.93 ± 2.55 µg/g at 130 °C to a peak of 1957.22 ± 2.55 µg/g at 140 °C, followed by a gradual decline to 102.49 ± 2.55 µg/g at 200 °C.

Figure 3.

Effect of temperature on 6-gingerol concentration using HVSWE and ASE 200. (a) HPLC chromatogram for HVSWE sample at 130 °C.

A comparative assessment between the two systems revealed slight differences, particularly in the 140–170 °C range. However, at both lower (130–140 °C) and higher (180–200 °C) temperatures, similar 6-gingerol concentrations were observed. At the optimal extraction range of 130–140 °C, the ASE 200 system yielded approximately 11% more 6-gingerol than the HVSWE system.

These differences are consistent with the findings reported by Alonso-Riaño in 2023, who observed a 13% higher yield in lab-scale extractions compared to the pilot-scale processes in the context of xylo-oligomer recovery from brewer’s spent grain [9]. Such variations are likely attributed to the complex heat transfer mechanisms inherent to subcritical water extraction, which operates under high-temperature and high-pressure conditions. These conditions significantly alter the physicochemical properties of water, thereby influencing the efficiency of heat transfer and, consequently, the extraction yield at different scales.

Despite these scale-related differences, both systems exhibited a similar extraction profile, with the 130–140 °C range identified as optimal for maximizing 6-gingerol recovery.

3.2. Effect of Temperature on the 6-Shogoal Concentration

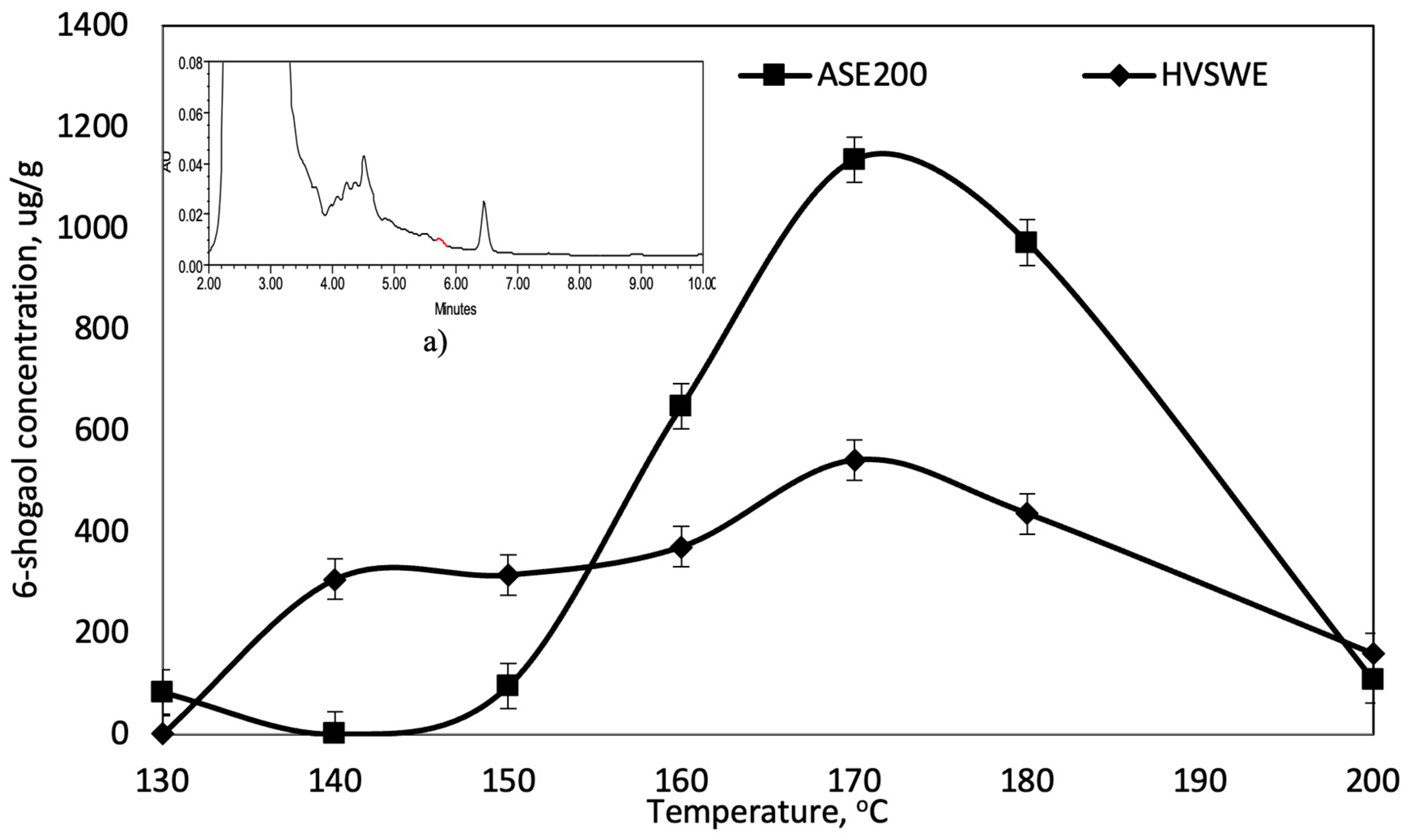

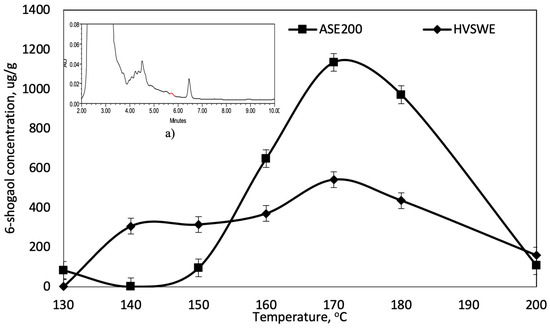

Figure 4 illustrates the effect of temperature on the concentration of 6-shogaol using both High-Volume Subcritical Water Extraction (HVSWE) and ASE 200 systems. As shown, the concentration of 6-shogaol in HVSWE increases from 0 to 541.77 ± 3.16 µg/g as the temperature rises from 130 °C to 170 °C. A similar trend is observed in the ASE 200 system, where the concentration increases from 82.37 ± 1.18 µg/g to 1135.23 ± 1.18 µg/g over the same temperature range.

Figure 4.

Effect of temperature on 6-shogaol concentration using HVSWE and ASE 200. (a) HPLCchromatogram for HVSWE sample at 170 °C.

Beyond 170 °C, both systems exhibit a decline in the 6-shogaol concentration. At 200 °C, the concentration decreases to 159.23 ± 3.16 µg/g for HVSWE and 106.98 ± 1.18 µg/g for ASE 200. This reduction may be attributed to thermal degradation at higher temperatures.

The need for elevated temperatures in 6-shogaol extraction is well documented. Numerous studies have reported that the hydrolysis of 6-gingerol to 6-shogaol occurs concurrently with extraction when temperatures exceed 150 °C [7]. Both extraction methods show optimal performance at 170 °C, with ASE 200 yielding approximately 52% more 6-shogaol compared to HVSWE.

4. Conclusions

This study investigated the scale-up process of subcritical water extraction (SWE) for the medicinal compounds 6-gingerol and 6-shogaol from ginger, utilizing both a commercially available ASE 200 system and a locally fabricated high-volume SWE (HVSWE) setup. The findings reveal that while both systems exhibited similar extraction trends, notable differences in compound concentrations emerged—particularly within the mid-temperature range (140–170 °C). These disparities are attributed to variations in scale, heat transfer, and mass transfer efficiencies.

For 6-gingerol, the ASE 200 system achieved optimal extraction at 140 °C, yielding a concentration of 1957.22 µg/g. In contrast, the HVSWE system reached its peak concentration of 1741.54 µg/g at 130 °C. Similarly, 6-shogaol showed optimal extraction at 170 °C for both systems; however, the ASE 200 system produced a significantly higher yield. These outcomes underscore the critical influence of scale-up factors, as transitioning from laboratory-scale to pilot-scale systems introduces changes in thermal and mass transfer dynamics that affect extraction performance.

This research highlights the necessity of accounting for scale-dependent parameters when designing and optimizing SWE processes. By addressing these challenges, SWE can be further advanced as a green and efficient technology for extracting bioactive compounds, thereby supporting the sustainable exploitation of natural resources like ginger. Future work should aim to refine process parameters, enhance heat and mass transfer mechanisms, and explore a broader spectrum of bioactive compounds to expand SWE’s industrial applications.

Author Contributions

Conceptualization, M.S.M.S. and M.S.H.R.; methodology, M.S.M.S. and N.M.A.N.D.; software, Z.I., A.R.A.B. and A.H.A.A.; validation, M.A.M.Z., A.R.A.B. and Z.I.; formal analysis, M.S.M.S.; investigation, M.S.M.S. and Z.I.; writing—original draft preparation, M.S.M.S.; writing—review and editing, N.M.A.N.D.; visualization, Z.I. and A.H.A.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Acknowledgments

The research infrastructure provide by Universiti Teknologi Malaysia and FRIM is greatly appreciated. Other individuals who have contributed to this research are also duly acknowledged.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Megan, C.; Skye, M.; Wolfgang, M.; Elizabeth, I.; Anna, L. Therapeutic health effects of ginger (Zingiber officinale): Updated narrative review exploring the mechanisms of action. Nutr. Rev. 2023, 81, 1213–1224. [Google Scholar]

- Promdam, N.; Panichayupakaranant, P. [6]-Gingerol: A narrative review of its beneficial effect on human health. Food Chem. Adv. 2022, 1, 100043. [Google Scholar] [CrossRef]

- Bischoff-Kont, I.; Fürst, R. Benefits of Ginger and Its Constituent 6-Shogaol in Inhibiting Inflammatory Processes. Pharmaceuticals 2021, 14, 571. [Google Scholar] [CrossRef] [PubMed]

- Anh, N.H.; Kim, S.J.; Long, N.P.; Min, J.E.; Yoon, Y.C.; Lee, E.G.; Kim, M.; Kim, T.J.; Yang, Y.Y.; Son, E.Y.; et al. Ginger on Human Health: A Comprehensive Systematic Review of Randomized Controlled Trials. Nutrients 2020, 12, 157. [Google Scholar] [CrossRef] [PubMed]

- Razak, A.M.; Zakaria, S.N.A.; Abdul Sani, N.F.; Ab Rani, N.; Hakimi, N.H.; Mohd Said, M.; Tan, J.K.; Gan, H.K.; Mad Nordin, M.F.; Makpol, S. A subcritical water extract of soil grown Zingiber officinale Roscoe: Comparative analysis of antioxidant and anti-inflammatory effects and evaluation of bioactive metabolites. Front. Pharmacol. 2023, 14, 1006265. [Google Scholar] [CrossRef] [PubMed]

- Sulejmanović, M.; Milić, N.; Mourtzinos, I.; Nastić, N.; Kyriakoudi, A.; Drljača, J.; Vidović, S. Ultrasound-assisted and subcritical water extraction techniques for maximal recovery of phenolic compounds from raw ginger herbal dust toward in vitro biological activity investigation. Food Chem. 2024, 437, 137774. [Google Scholar] [CrossRef] [PubMed]

- Yulianto, M.E.; Purwantisari, S.; Hartati, I.; Nisa, Q.A.K. and Nyamiati, R.D. Subcritical reactive extraction of shogaol and gingerol: Effect of time and temperature. Int. Food Res. J. 2022, 29, 857–863. [Google Scholar] [CrossRef]

- Md Sarip, M.S.; Nik Daud, N.M.A.; Mohd Zainudin, M.A.; Ibrahim, L.H.; Saidi, S.A.; Idham, Z.; Anuar, A. Quantitative analysis method for Zingiber officinale water extract using high-performance liquid chromatography. Adv. Mat. Res. 2024, 13, 233–241. [Google Scholar]

- Alonso-Riaño, P.; Ramos, C.; Trigueros, E.; Beltrán, S.; Sanz, M.T. Study of subcritical water scale-up from laboratory to pilot system for brewer’s spent grain valorization. Ind. Crops Prod. 2023, 191 Pt A, 115927. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).