Determination of Properties of Meat Products with Plant Supplements †

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Production of Control Samples of Minced Meat Products and Samples with Plant Supplements

2.3. Proximate Analysis

2.4. Determination of Iron Content in the Semi-Finished Minced Meat Products

2.5. Study of the Stability of Minced Meat Emulsions, the Water-Holding Capacity, and the Fat-Holding Capacity

2.6. Statistical Analysis

3. Results and Discussion

3.1. Determination of Proximate Composition of Minced Meat Products

3.2. Determination of Iron Content in the Minced Meat Semi-Finished Products

3.3. Study of the Stability of Minced Meat Emulsions, the Water-Holding Capacity, and the Fat-Holding Capacity

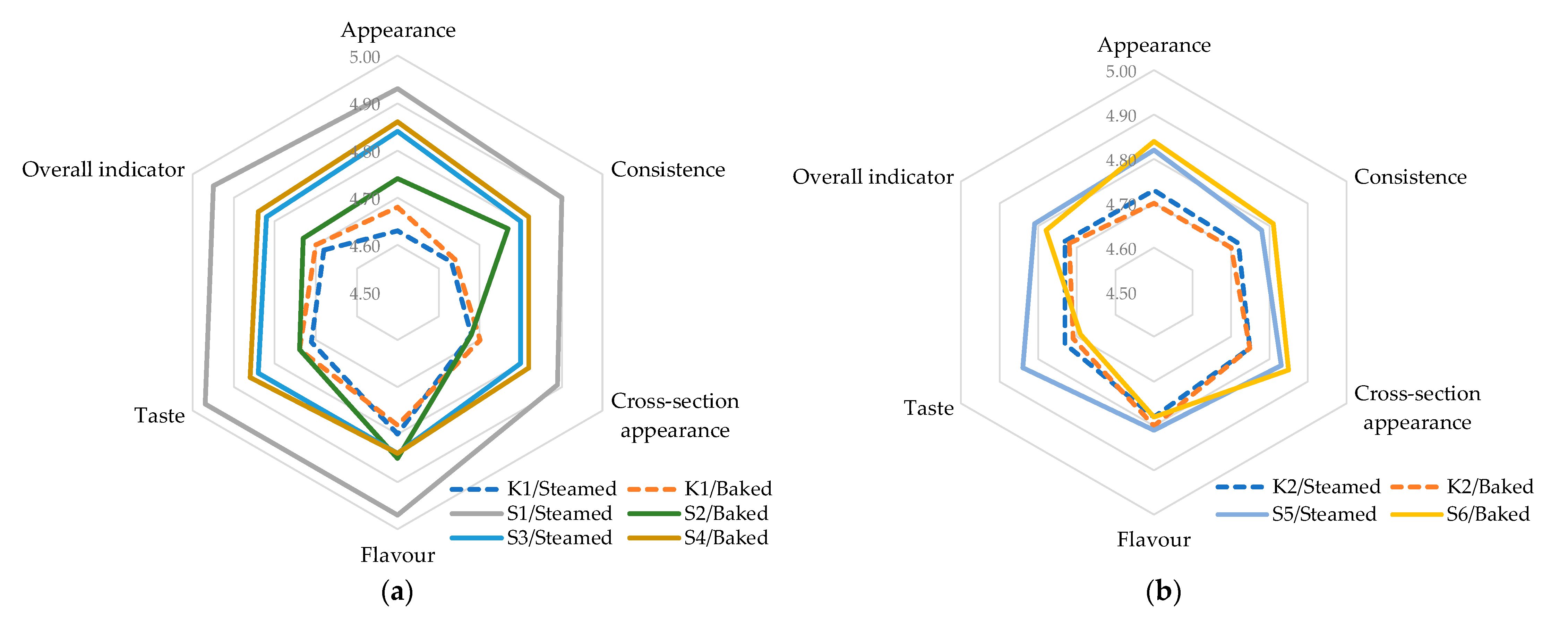

3.4. Study of Post-Heat-Treatment Losses and Sensory Evaluation of Minced Meat Products

4. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| DLBC | Dried leaves of black currant |

| SE | Stability of minced meat emulsions |

| WHC | Water-holding capacity |

| FHC | Fat-holding capacity |

| MMPs | Minced meat products |

| ANOVA | Analysis of variance |

References

- Nair, M.S.; Nair, D.V.T.; Johny, A.K.; Venkitanarayanan, K. Chapter 12—Use of food preservatives and additives in meat and their detection techniques. Meat Quality Analysis. In Advanced Evaluation Methods, Techniques, and Technologies; Academic Press: Cambridge, MA, USA, 2020; pp. 187–213. [Google Scholar] [CrossRef]

- Santamaria-Echart, A.; Fernandes, I.P.; Silva, S.C.; Rezende, S.C.; Colucci, G.; Dias, M.M.; Barreiro, M.F. New Trends in Natural Emulsifiers and Emulsion Technology for the Food Industry. In Natural Food Additives; Lage, M.Á.P., Otero, P., Eds.; Intech Open: London, UK, 2021; pp. 5–17. [Google Scholar] [CrossRef]

- Stadnik, J. Nutritional Value of Meat and Meat Products and Their Role in Human Health. Nutrients 2024, 16, 1446. [Google Scholar] [CrossRef] [PubMed]

- Campbell, J.A.; Honikel, K.O. Minced meats. In Encyclopedia of Meat Sciences, 3rd ed.; Elsevier: Amsterdam, The Netherlands, 2024; pp. 446–452. [Google Scholar] [CrossRef]

- Patel, N.; Bergamaschi, M.; Magro, L.; Petrini, A.; Bittante, G. Relationships of a Detailed Mineral Profile of Meat with Animal Performance and Beef Quality. Animals 2019, 9, 1073. [Google Scholar] [CrossRef] [PubMed]

- Xiong, Y.L. Chemical and physical characteristics of meat protein functionality. In Encyclopedia of Meat Sciences; Elsevier: Amsterdam, The Netherlands, 2024; pp. 419–428. [Google Scholar] [CrossRef]

- Nollet, L.M.L.; Toldrá, F. Safety of Meat and Processed Meat; Springer Science + Business Media: Berlin/Heidelberg, Germany, 2009; 704p. [Google Scholar]

- Toldrá, F.; Nollet, L.M.L. Advanced Technologies for Meat Processing, 2nd ed.; CRC Press/Taylor & Francis Group: Boca Raton, FL, USA, 2018; p. 722. [Google Scholar] [CrossRef]

- Toldrá, F. Handbook of Meat Processing; Blackwell Publishing: Ames, IA, USA, 2010; p. 568. [Google Scholar]

- Murlykina, N.; Yancheva, M. Theory and Practice of the Use of Acylglycerol Emulsifiers in the Technology of Meat Products: Monograph; КHSUFТ: Kharkiv, Ukraine, 2015; 207p. [Google Scholar] [CrossRef]

- Rebellato, A.P.; Siqueira Silva, J.G.; Probio de Moraes, P.; Trajano, B.; Pallone, J.A.L. Static in vitro digestion methods for assessing essential minerals in processed meat products. Food Res. Int. 2022, 155, 111121. [Google Scholar] [CrossRef] [PubMed]

- Omezzine, F.; Bouaziz, M.; Daami-Remadi, M.; Simmonds, M.S.J.; Haouala, R. Chemical composition and antifungal activity of Trigonella foenum-graecum L. varied with plant ploidy level and developmental stage King Saud University. Arab. J. Chem. 2017, 10, S3622–S3631. [Google Scholar] [CrossRef]

- Sun, Q.; Wang, N.; Xu, W.; Zhou, H. Genus Ribes Linn. (Grossulariaceae): A comprehensive review of traditional uses, phytochemistry, pharmacology and clinical applications. J. Ethnopharmacol. 2021, 276, 114166. [Google Scholar] [CrossRef]

- Behl, T.; Bungau, S.; Kumar, K.; Zengin, G.; Khan, F.; Kumar, A.; Kaur, R.; Venkatachalam, T.; Tit, D.M.; Vesa, C.M.; et al. Pleotropic Effects of Polyphenols in Cardiovascular System. Biomed. Pharmacother. 2020, 130, 110714. [Google Scholar] [CrossRef]

- Evlash, V.; Aksenova, O.; Murlykina, N.; Piliugina, I.; Gazzavi, L.; Gubsky, S.; Upatova, O. Scientific and Practical Aspects of Technologies of Dietary Products for People with Impaired Metabolism: A Monograph; SBTU: Kharkiv, Ukraine, 2022; 282p. [Google Scholar]

- Akoh, C.C.; Min, D.B. Food Lipids. Chemistry, Nutrition, and Biotechnology, 4th ed.; CRC Press, Taylor & Francis Group, LLC: Boca Raton, FL, USA, 2017. [Google Scholar]

- Casillas-Vargas, G.; Ocasio-Malavé, C.; Medina, S.; Morales-Guzmán, C.; del Valle, R.G.; Carballeira, N.M.; Sanabria-Ríos, D.J. Antibacterial fatty acids: An update of possible mechanisms of action and implications in the development of the next-generation of antibacterial agents. Prog. Lipid Res. 2021, 82, 101093. [Google Scholar] [CrossRef]

- López-López, I.; Bastida, S.; Ruiz-Capillas, C.; Bravo, L.; Larrea, M.T.; Sánchez-Muniz, F.; Cofrades, S.; Jiménez-Colmenero, F. Composition and antioxidant capacity of low-salt meat emulsion model systems containing edible seaweeds. Meat Sci. 2009, 83, 492–498. [Google Scholar] [CrossRef]

- López-López, I.; Cofrades, S.; Yakan, A.; Solas, M.T.; Jiménez-Colmenero, F. Frozen storage characteristics of low-salt and low-fat beef patties as affected by Wakame addition and replacing pork backfat with olive oil-in-water emulsion. Food Res. Int. 2010, 43, 1244–1254. [Google Scholar] [CrossRef]

- Shashikumar, J.N.; Champawat, P.S.; Mudgal, V.D.; Jain, S.K.; Deepak, S.; Mahcsh, K. A review: Food, medicinal and nutraceutical properties of fenugreek (Trigonella foenum-graecum L.). Int. J. Chem. Stud. 2018, 6, 1239–1245. [Google Scholar]

- Ahmad, A.; Alghamdi, S.S.; Mahmood, K.; Afzal, M. Review. Fenugreek a multipurpose crop: Potentialities and improvements. Saudi J. Biol. Sci. 2016, 23, 300–310. [Google Scholar] [CrossRef] [PubMed]

- Khole, S.; Chatterjee, S.; Variyar, P.; Sharma, A.; Devasagayam, T.P.A.; Ghaskadbi, S. Bioactive constituents of germinated fenugreek seeds with strong antioxidant potential. J. Funct. Foods 2014, 6, 270–279. [Google Scholar] [CrossRef]

- Mukthamba, P. Dietary fenugreek (Trigonella foenum-graecum) seeds and garlic (Alliumsativum) alleviates oxidative stress in experimental myocardial infarction. P. Mukthamba, K. Srinivasan. Food Sci. Hum. Wellness 2017, 6, 77–87. [Google Scholar] [CrossRef]

- Wankhedea, S. Beneficial effects of fenugreek glycoside supplementation in male subjects during resistance training: A randomized controlled pilot study. Sachin Wankhedea, Vishwaraman Mohan, Prasad Thakurdesai. J. Sport Health Sci. 2016, 5, 176–182. [Google Scholar] [CrossRef]

- Wani, S.A. Fenugreek: A review on its nutraceutical properties and utilization in various food products / Sajad Ahmad Wani, Pradyuman Kumar. J. Saudi Soc. Agric. Sci. 2018, 17, 97–106. [Google Scholar] [CrossRef]

- Gomathi, G.K.; Parameshwari, S. Evaluation of buckwheat flour addition on the sensory, nutritional and materialistic properties analysis of Indian flat bread. Mater. Today Proc. 2022, 66, 988–995. [Google Scholar] [CrossRef]

- Torbica, A.; Hadnadev, M.; Dapčević, T. Rheological, textural and sensory properties of gluten-free bread formulations based on rice and buckwheat flour. Food Hydrocoll. 2010, 24, 626–632. [Google Scholar] [CrossRef]

- Eren, E.; Reis Akkaya, M. Effect of different forms of buckwheat addition on the physicochemical and sensory properties of bread. Czech J. Food Sci. 2024, 42, 216–223. [Google Scholar] [CrossRef]

- Murlykina, N.; Yancheva, M. The use of emulsifiers in the technologies of meat products. East. Eur. J. Enterp. Technol. 2014, 6, 44–49. [Google Scholar] [CrossRef][Green Version]

- Ruiz-Capillas, C.; Herrero, A.M.; Pintado, T.; Delgado-Pando, G. Sensory Analysis and Consumer Research in New Meat Products Development. Foods 2021, 10, 429. [Google Scholar] [CrossRef]

- AACC International. Approved Methods of the American Association of Cereal Chemists, 11th ed.; The American Association of Cereal Chemists: St. Paul, MN, USA, 2010; Available online: https://www.cerealsgrains.org/resources/methods/Pages/default.aspx (accessed on 3 January 2025).

- ISO 1871:2009; Food and Feed Products—General Guidelines for the Determination of Nitrogen by the Kjeldahl Method. International Organization for Standardization: Geneva, Switzerland, 2009. Available online: https://www.iso.org/standard/41320.html (accessed on 3 January 2025).

- ISO 1443:1973; Meat and Meat Products—Determination of Total Fat Content. International Organization for Standardization: Geneva, Switzerland, 2022. Available online: https://www.iso.org/standard/6038.html (accessed on 3 January 2025).

- Forouzesh, A.; Forouzesh, F.; Foroushani, S.S.; Forouzesh, A. A New Method for Calculating Fat Content and Determining Appropriate Fat Levels in Foods. Iran. J. Public Health 2023, 52, 1038–1047. [Google Scholar] [CrossRef]

- Carpenter, C.E.; Ward, R.E. Iron Determination by Ferrozine Method. In Food Analysis Laboratory Manual, 3rd ed.; Food Science Text Series; Springer: Cham, Switzerland; Boston, MA, USA, 2017; 249p. [Google Scholar] [CrossRef]

- Nielsen, S.S. Food Analysis Laboratory Manual, 3rd ed.; Food Science Texts Series; Springer: Boston, MA, USA; Cham, Switzerland; New York, NY, USA, 2017; 249p. [Google Scholar] [CrossRef]

- Sullivan, G.A.; Venzor, L.G.; Mandigo, R.W. Emulsions and batters: Theory and practice. In Encyclopedia of Meat Sciences; Elsevier: Amsterdam, The Netherlands, 2024; pp. 352–359. [Google Scholar] [CrossRef]

- Nollet, L.M.L.; Toldra, F. (Eds.) Handbook of Food Analysis—Two Volume Set, 3rd ed.; CRC Press, Taylor & Francis Group, LLC: Boca Raton, FL, USA, 2015; 1568p. [Google Scholar] [CrossRef]

- Ismail, B.P.; Nielsen, S.S. Nielsen’s Food Analysis, 6th ed.; Food Science Text Series; Springer: Cham, Switzerland; New York, NY, USA, 2024; 614p. [Google Scholar] [CrossRef]

| Ingredient | K1 | S1 DLBC 0.75% | S2 DLBC 1.85% | S3 Fenugreek 0.75% | S4 Fenugreek 1.85% | K2 | S5 Fenugreek 1.70% | S6 Fenugreek 3.40% |

|---|---|---|---|---|---|---|---|---|

| Meat, g | 80.0 | 80.0 | 80.0 | 80.0 | 80.0 | 62.2 | 62.2 | 62.2 |

| Sunflower oil, g | 12.0 | 11.4 | 10.3 | 11.4 | 10.3 | 3.4 | 3.4 | 3.4 |

| Water, g | 6.7 | 6.7 | 6.7 | 6.7 | 6.7 | 18.5 | 18.5 | 18.5 |

| Table salt, g | 1.2 | 1.1 | 1.1 | 1.1 | 1.1 | 0.8 | 0.8 | 0.8 |

| Black pepper, g | 0.1 | 0.05 | 0.05 | 0.05 | 0.05 | 0 | 0 | 0 |

| Buckwheat bread | 0 | 0 | 0 | 0 | 0 | 15.1 | 13.4 | 11.7 |

| Plant Supplements, g | 0 | 0.75 | 1.85 | 0.75 | 1.85 | 0 | 1.7 | 3.4 |

| Total | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 |

| Product Name | Content, % | Energy Value per 100 g of Product, Kcal | ||||

|---|---|---|---|---|---|---|

| Moisture | Proteins | Fats | Carbohydrates | Ash | ||

| Control-1: | ||||||

| semi-finished | 64.1 ± 0.3 | 16.2 ± 0.3 | 17.6 ± 0.2 | 0 * | 2.1 ± 0.2 | 223 |

| steamed | 58.3 ± 0.2 | 19.2 ± 0.3 | 20.3 ± 0.3 | 0 * | 2.2 ± 0.2 | 261 |

| baked | 58.2 ± 0.2 | 19.2 ± 0.3 | 20.4 ± 0.3 | 0 * | 2.2 ± 0.2 | 260 |

| S1 with DLBC (0.75%) | ||||||

| semi-finished | 64.5 ± 0.3 | 16.2 ± 0.3 | 16.8 ± 0.2 | 0.40 ± 0.02 | 2.1 ± 0.2 | 218 |

| steamed | 59.5 ± 0.3 | 18.8 ± 0.2 | 19.1 ± 0.2 | 0.50 ± 0.02 | 2.2 ± 0.2 | 249 |

| S2 with DLBC (1.85%) | ||||||

| semi-finished | 65.1 ± 0.2 | 16.2 ± 0.2 | 15.8 ± 0.2 | 0.80 ± 0.02 | 2.1 ± 0.2 | 210 |

| baked | 61.1 ± 0.2 | 18.3 ± 0.2 | 17.5 ± 0.3 | 0.90 ± 0.02 | 2.2 ± 0.2 | 234 |

| S3 with Fenugreek (0.75%) | ||||||

| semi-finished | 64.2 ± 0.3 | 16.2 ± 0.3 | 17.0 ± 0.2 | 0.50 ± 0.02 | 2.1 ± 0.2 | 220 |

| steamed | 59.1 ± 0.3 | 18.8 ± 0.2 | 19.3 ± 0.2 | 0.60 ± 0.02 | 2.2 ± 0.2 | 251 |

| S4 with Fenugreek (1.85%) | ||||||

| semi-finished | 64.2 ± 0.2 | 16.2 ± 0.3 | 16.3 ± 0.2 | 1.20 ± 0.02 | 2.1 ± 0.2 | 216 |

| baked | 60.2 ± 0.2 | 18.3 ± 0.2 | 18.0 ± 0.3 | 1.40 ± 0.02 | 2.2 ± 0.2 | 244 |

| Control-2: | ||||||

| semi-finished | 69.5 ± 0.3 | 13.9 ± 0.2 | 8.2 ± 0.1 | 7.0 ± 0.1 | 1.5 ± 0.1 | 157 |

| steamed | 63.8 ± 0.2 | 16.7 ± 0.2 | 9.6 ± 0.1 | 8.4 ± 0.1 | 1.6 ± 0.1 | 186 |

| baked | 63.9 ± 0.2 | 16.6 ± 0.2 | 9.6 ± 0.1 | 8.3 ± 0.1 | 1.6 ± 0.1 | 187 |

| S5 with Fenugreek (1.70%) | ||||||

| semi-finished | 68.8 ± 0.3 | 14.3 ± 0.2 | 8.3 ± 0.1 | 7.2 ± 0.1 | 1.5 ± 0.1 | 153 |

| steamed | 63.8 ± 0.3 | 16.7 ± 0.2 | 9.5 ± 0.1 | 8.4 ± 0.1 | 1.6 ± 0.1 | 186 |

| S6 with Fenugreek (3.40%) | ||||||

| semi-finished | 68.8 ± 0.2 | 14.7 ± 0.2 | 8.4 ± 0.1 | 7.4 ± 0.1 | 1.5 ± 0.1 | 149 |

| baked | 64.0 ± 0.2 | 16.7 ± 0.2 | 9.3 ± 0.1 | 8.50 ± 0.1 | 1.5 ± 0.1 | 184 |

| Product Name | Fe Content, mg/100 g Dry Mass |

|---|---|

| Control-1 | 1.64 ± 0.03 f |

| S1 with DLBC (0.75%) | 1.73 ± 0.03 e |

| S2 with DLBC (1.85%) | 1.89 ± 0.04 c |

| S3 with Fenugreek (0.75%) | 1.83 ± 0.04 cd |

| S4 with Fenugreek (1.85%) | 2.11 ± 0.03 ab |

| Control-2 | 1.27 ± 0.03 g |

| S5 with Fenugreek (1.70%) | 1.71 ± 0.04 ef |

| S6 with Fenugreek (3.40%) | 2.14 ± 0.04 a |

| Indicator | Control-1 K1 | Control-2 K2 | Plant Supplements (Content, %)/Sample | |||||

|---|---|---|---|---|---|---|---|---|

| DLBC (0.75%)/S1 | DLBC (1.85%)/S2 | Fenugreek (0.75%)/S3 | Fenugreek (1.85%)/S4 | Fenugreek (1.70%)/S5 | Fenugreek (3.40%)/S6 | |||

| Water-holding capacity, % | 64.0 ± 0.3 g | 73.4 ± 0.4 c | 65.7 ± 0.3 f | 66.0 ± 0.3 ef | 66.5 ± 0.3 de | 67.2 ± 0.4 d | 75.8 ± 0.40 b | 77.1 ± 0.3 a |

| Fat-holding capacity, % | 13.9 ± 0.2 d | 15.9 ± 0.3 c | 15.9 ± 0.2 c | 16.8 ± 0.2 b | 16.9 ± 0.2 b | 17.1 ± 0.2 ab | 16.9 ± 0.3 b | 17.5 ± 0.2 a |

| Emulsion stability, % | 83.3 ± 0.3 f | 89.8 ± 0.4 e | 90.1 ± 0.4 e | 91.3 ± 0.4 c | 90.6 ± 0.3 cd | 92.2 ± 0.3 b | 92.5 ± 0.3 b | 94.2 ± 0.4 a |

| Post-heat-treatment losses, % Steamed | 20.8 ± 0.4 a | 15.4 ± 0.3 f | 18.7 ± 0.3 b | 18.1 ± 0.2 c | 17.6 ± 0.3 cd | 16.8 ± 0.2 e | 14.5 ± 0.3 g | 13.8 ± 0.3 h |

| Baked | 20.2 ± 0.3 a | 16.2 ± 0.3 d | 18.2 ± 0.2 b | 16.4 ± 0.3 cd | 16.9 ± 0.3 c | 15.5 ± 0.2 e | 15.4 ± 0.3 e | 15.1 ± 0.3 ef |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Murlykina, N. Determination of Properties of Meat Products with Plant Supplements. Eng. Proc. 2025, 87, 28. https://doi.org/10.3390/engproc2025087028

Murlykina N. Determination of Properties of Meat Products with Plant Supplements. Engineering Proceedings. 2025; 87(1):28. https://doi.org/10.3390/engproc2025087028

Chicago/Turabian StyleMurlykina, Natalia. 2025. "Determination of Properties of Meat Products with Plant Supplements" Engineering Proceedings 87, no. 1: 28. https://doi.org/10.3390/engproc2025087028

APA StyleMurlykina, N. (2025). Determination of Properties of Meat Products with Plant Supplements. Engineering Proceedings, 87(1), 28. https://doi.org/10.3390/engproc2025087028