Abstract

The rapid advancement of technology has increased our reliance on axial flux permanent magnet machines (AFPMMs), making Printed Circuit Boards (PCBs) essential for modern, lightweight designs. This study reviews PCB roles in AFPMMs for low- and high-power applications by examining research from 2019 to 2024. Using the PRISMA methodology, 38 articles from IEEE Xplore and Web of Science were analyzed. This review focuses on advancements in PCB manufacturing, defect mitigation, winding topologies, software tools, and optimization methods. A structured Boolean search strategy (“Printed Circuit Board” OR “PCB” AND “axial flux permanent magnet machine” OR “AFPM”) guided the literature retrieval process. Articles were meticulously screened using the Rayyan software for titles, abstracts, and content, with duplicate removal performed via the Mendeley software V2.120.0. Findings show significant progress in lightweight AFPMMs with PCBs, improving power quality and performance. Research activity over the 6 years showed inconsistent growth, with concentrated trapezoidal winding emerging as the dominant configuration, followed by distributed winding designs. These configurations were particularly applied in single stator double rotor (SSDR) coreless AFPM machines, characterized by minimal defects, minimal losses, and optimized single-layer winding designs utilizing tools such as ANSYS and COMSOL. Growing interest in double stator single rotor (DSSR) and multi-disk configurations highlights opportunities for innovative designs and advanced optimization techniques.

1. Introduction

The growing need for energy-efficient, compact, and high-performance electric machines has prompted major advancements in design and production [1,2,3]. Among these, coreless axial flux permanent magnet synchronous machines (CAFPMMs) have surfaced as a compelling technology because of their distinctive design and performance benefits. They are brushless AC machines with optimal electromagnetic performances. In contrast to conventional radial flux machines, CAFPMMs do away with a ferromagnetic core in the stator, which greatly decreases core losses, rendering them suitable for situations where efficiency and weight savings are essential [4]. These advantages have positioned CAFPMMs as the preferred option in fields like electric vehicles (EVs) such as solar cars and flywheels, renewable energy, and robotics, where compactness, efficiency, and dependability are crucial [1,3]. A significant development in CAFPM design is the incorporation of Printed Circuit Boards (PCBs) for executing winding configurations. Traditional copper windings, while commonly utilized, present issues concerning manufacturing intricacy, weight, and accuracy. On the other hand, PCBs provide a lightweight, compact, and scalable option, facilitating accurate planar winding arrangements that are simpler to produce [5]. The flat design of PCB windings makes the assembly process easier and allows for more design versatility, especially in attaining an even magnetic field distribution. Additionally, PCBs can support multi-layer configurations, allowing for intricate interconnections and enhanced current density [6].

PCB technology has revolutionized the design of CAFPM generators, pushing the boundaries of compact and efficient energy conversion systems [7]. These innovative devices employ single-layer PCB designs for both the stator and the rotor, creating a lightweight and streamlined configuration. Shaped into circular forms, the stator and rotor are constructed using Flame retardant 4 (FR-4) as the substrate, with radial copper electrodes etched into the copper layer [8]. These innovations emphasize the adaptability of PCB technology, broadening its use well beyond traditional electronics into areas such as renewable energy, intelligent sensing, and autonomous systems. Nonetheless, despite the benefits, incorporating PCBs into CAFPMMs presents various difficulties. These involve concerns regarding thermal management arising from the restricted heat dissipation abilities of PCB substrates, electrical reliability at elevated current densities, and mechanical strength when subjected to dynamic loads [9].

Moreover, challenges in manufacturing, like attaining accurate alignment and lowering expenses for high-performance PCBs, continue to be points of worry. Tackling these challenges necessitates a methodical comprehension of the design principles, material choices, and performance effects of PCB-based CAFPMMs. Through a systematic review of the current literature, as presented in Table 1, this paper seeks to offer perspectives on the advantages, obstacles, and future paths for incorporating PCBs in CAFPM designs. By tackling these goals, this paper seeks to provide a thorough insight into the use of PCBs in CAFPMs, highlighting their transformative capabilities while recognizing the challenges that come with them [10]. This paper is organized as follows: Introduction, Methodology, and Results/Data analysis.

Table 1.

Presentation of some related works.

2. Methodology

2.1. Review Method

A systematic literature review (SLR) utilizes a structured approach that includes the steps of planning, performing, and documenting, as detailed in [14,15]. The process starts with a detailed examination of the most recent improvements in PCB applications for AFPM machines, pinpointing important developments, research inquiries, and pertinent sources. During the conducting phase, definitive inclusion and exclusion criteria are set to guarantee the selection of relevant studies, and subsequently, a strong data extraction method is created to compile essential information and tackle the research questions. The reporting phase includes systematically examining the gathered data, using organized methods to integrate results, and displaying them in a clear format. This method not only emphasizes trends and challenges but also recognizes research gaps, offering important insights for enhancing PCB implementation in lightweight AFPM machines.

2.2. Research Questions

The research questions (RQs), as detailed in Table 1, serve as the guiding compass for this study, shaping the trajectory of the analysis. Spanning diverse domains, these questions delve into the intricate features of Printed Circuit Boards (PCBs), their seamless integration into axial flux permanent magnet machines (AFPMMs), and the innovative winding configurations employed. Furthermore, they explore the evaluation metrics essential for assessing performance, efficiency, and design optimization, offering a comprehensive framework to uncover insights and address critical aspects of PCB applications in modern motor technologies.

- What are the recent advancements in PCB manufacturing or design technology?

- How does the integration of PCBs into AFPM machines affect its performance?

- What are the classifications of PCB-based winding designs?

- How do they minimize the effects of thermal losses experienced?

2.3. Review Strategy

To ensure a high-quality and relevant literature search, we evaluated two prominent databases: IEEE Xplore and Web of Science, both of which offer extensive collections of scholarly content. While Web of Science provides a more comprehensive selection, we selected IEEE for its balanced approach, offering access to a substantial pool of pertinent sources while prioritizing peer-reviewed materials. This strategic selection ensures a robust and reliable foundation for the review, encompassing both breadth and scholarly rigor. The literature search utilized keywords such as Printed Circuit Boards (PCBs), axial flux permanent magnet machines (AFPMMs), winding configurations, electromagnetic performance, and thermal management. Boolean operators (AND/OR) were used to refine search results. The search was filtered to include only peer-reviewed sources, focusing on recent publications relevant to the research objectives.

2.4. Inclusion and Exclusion Criteria

Inclusion criteria focused on peer-reviewed studies related to PCBs in AFPMMs, covering topics such as winding configurations, electromagnetic performance, and thermal management. Exclusion criteria removed studies unrelated to these areas, non-peer-reviewed sources, or those lacking rigorous methodology, ensuring the review included only relevant, high-quality literature. All criteria are presented in Table 2.

Table 2.

Inclusion and exclusion criteria.

2.5. Data Extraction and Analysis

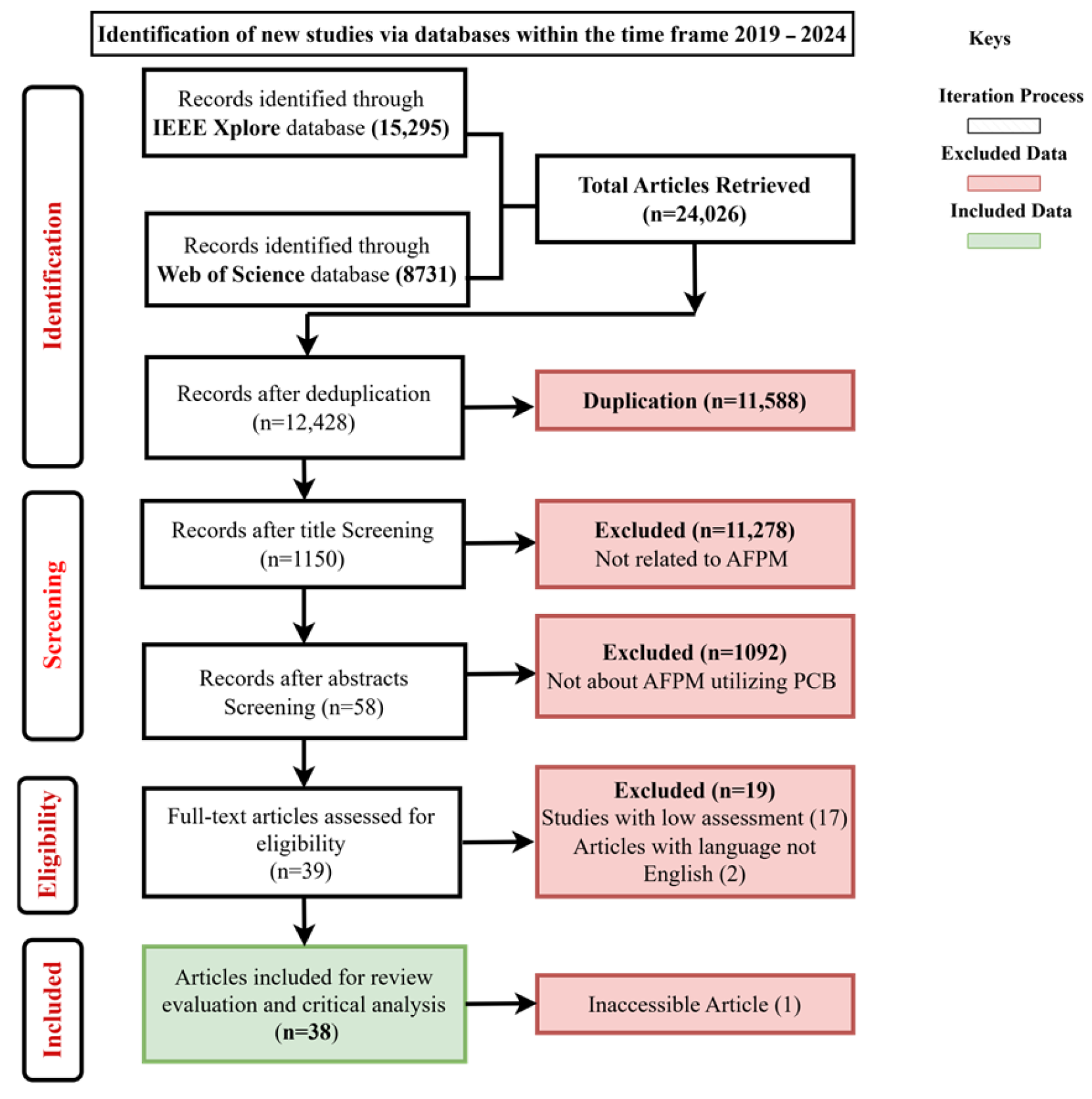

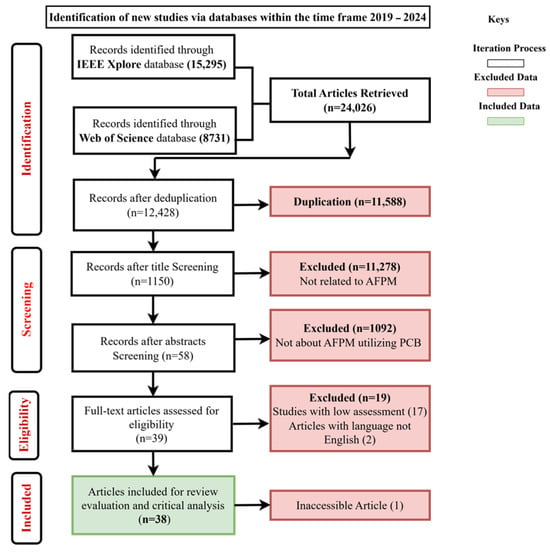

Figure 1 outlines a systematic review process conducted from 2019 to 2024, following the PRISMA framework guideline, to identify relevant studies on the utilization of PCBs in axial flux permanent magnet machines (AFPMs). Initially, 24,026 articles were retrieved from IEEE Xplore (15,295) and Web of Science (8731). After removing 11,598 duplicates, 12,428 unique articles remained. Title screening excluded 11,278 articles unrelated to AFPMs, leaving 1150 for abstract review, where a further 1092 articles unrelated to PCBs in AFPMs were removed. The full-text assessment of 58 articles excluded 19 due to low quality (17) or non-English language (2), resulting in 38 articles selected for critical analysis. One article was inaccessible, but the process ensured the inclusion of high-quality and relevant studies. To refine the analysis and ensure its precision, we adopted a meticulous filtering process, guided by well-defined criteria, as illustrated in Figure 1. This approach narrowed our focus to a curated collection of 38 papers, each directly contributing to the exploration of PCB utilization in AFPMMs, ensuring relevance and quality throughout the review.

Figure 1.

PRISMA.

3. Results for Data Synthesis

3.1. Advancements in PCB Manufacturing

Recent progress in Printed Circuit Board (PCB) manufacturing has greatly changed the design and production of windings in axial flux machines (AFMs), improving their efficiency and compactness [16]. A key innovation is the introduction of flex-PCBs and rigid-flex PCBs, which allow for complex and space-efficient designs for AFM windings. Flex-PCBs, made from pliable materials, facilitate straightforward integration into small motor designs, whereas rigid-flex PCBs merge the durability of rigid boards with the adaptability of flex-PCBs [17]. By utilizing materials such as PTFE or ceramics, these PCBs guarantee that electrical signals retain their quality during high-frequency operations, a property essential for accuracy and performance in electric machines. For AFPMMs, these materials facilitate excellent current conduction and better electromagnetic performance, minimizing losses and boosting efficiency [18].

The emergence of high-density interconnect (HDI) PCBs and miniaturization methods has transformed AFM winding production. HDI PCBs, featuring narrower traces, stacked microvias, and greater circuit density, allow for the fabrication of super-slim and compact PCBs [19]. This enables CAFPMMs to deliver greater torque and power in smaller sizes, catering to the need for lightweight and compact designs. Miniaturization has resulted in the creation of micro-PCBs that enable exact control over winding configurations and decrease the total weight of the machine, thereby enhancing the motor’s efficiency and portability [20]. Advances in 3D printing and new materials have opened additional possibilities for CAFPMMS winding production [21]. Three-dimensional printing technologies enable the rapid prototyping of custom PCB designs, allowing manufacturers to experiment with complex and innovative winding geometries [22]. Additive manufacturing, which eliminates traditional etching processes, offers flexibility and faster production cycles, enhancing the adaptability of PCB designs. Furthermore, the exploration of alternatives to copper, such as graphene and carbon nanotubes, has introduced lighter and more thermally efficient materials into PCB manufacturing [9]. These advancements collectively enable axial flux machines: single stator single rotor (SSSR), single stator double rotor (SSDR), double stators single rotor (DSSR), multi stator multi rotor (MSMR), to achieve unprecedented levels of performance, reliability, and design flexibility, aligning with the evolving needs of electric machine technology [4,23].

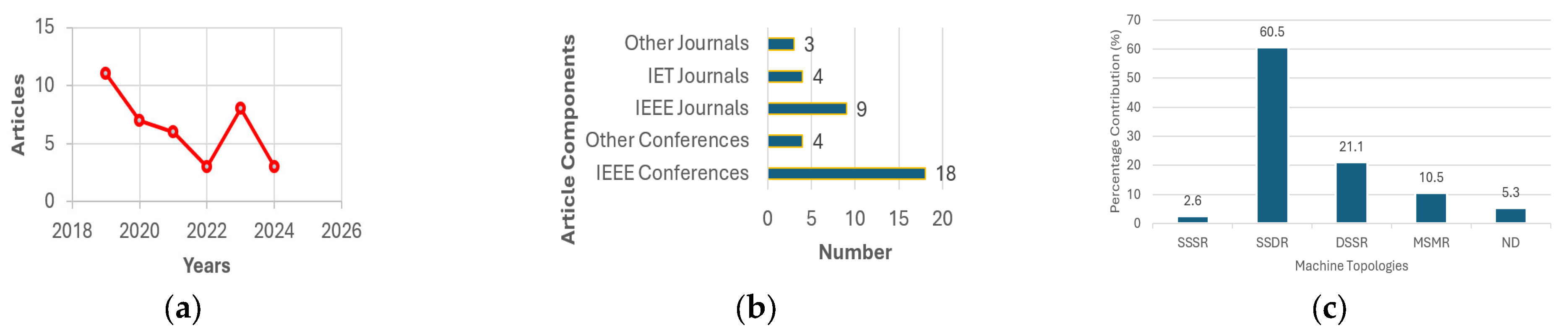

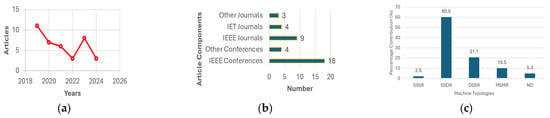

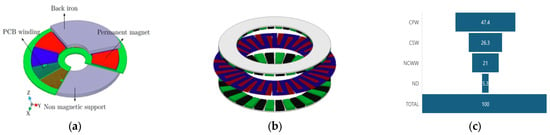

Figure 2a shows that the research activity from 2019 to 2024 demonstrates a fluctuating trend in scholarly interest and output. The year 2019 marked the peak with 11 publications, indicating significant momentum and attention in the field. However, this was followed by a decline, with seven studies in 2020 and six in 2021, suggesting a gradual reduction in research efforts. The downward trend continued into 2022, with only three publications, marking the lowest point during the period. Interestingly, 2023 saw a resurgence with eight studies, reflecting renewed interest or advancements in the field. Despite this uptick, 2024 recorded just three publications, mirroring the output of 2022. This pattern highlights the dynamic nature of research priorities, possibly influenced by a maturing field that requires more targets. Figure 2b highlights the distribution of research contributions across various publication platforms. IEEE conferences lead significantly with eighteen contributions, followed by IEEE journals with nine, showcasing a strong preference for IEEE-affiliated articles. IET journals and other conferences contribute equally, with four publications each, while other journals account for the smallest share at three. This distribution indicates a clear emphasis on IEEE platforms for disseminating research, particularly through conferences, reflecting their importance in the research community.

Figure 2.

(a) Segment of research content. (b) Research progress and article component contribution. (c) AFPMM contributions.

Figure 2c presents the percentage contributions of different machine topologies: SSSR, SSDR, DSSR, MSMR, and ND (not defined). Among these, the SSDR topology dominates, with the highest contribution at 60.5%, indicating its substantial importance due to the symmetrical rotor design eliminating unbalanced axial forces and improving cooling, power, and torque density. DSSR follows as the second most significant topology with 21.1% having symmetrical stator design, enhanced torque and power density, and structural complexity, while MSMR and ND contribute more modestly at 10.5% and 5.3%, respectively. However, MSMR further increases electromagnetic performance but comes with design and manufacturing complexity. SSSR has the smallest impact, contributing only 2.6% as a result of distortion from unbalanced axial forces. These data highlight the overwhelming influence of the SSDR topology compared to the others, particularly the minimal role played by SSSR.

3.2. Defect Mitigation Strategies

Flaws in PCBs pose a serious issue for CAFPMM winding designs, as they can greatly impact the machine’s performance, efficiency, and reliability [18]. These machines depend greatly on PCB windings for compact size, accuracy, and enhanced power density, rendering flawless PCB production a necessity. As the use of multi-layered and adaptable PCBs grows, the likelihood of defects like incomplete circuits, short circuits, or misaligned patterns has emerged as a challenge [13,24]. These flaws may cause irregular current distribution, higher thermal losses, and the deterioration of electromagnetic performance, ultimately affecting the machine’s overall efficiency and longevity. Avoiding PCB defects in the winding designs necessitates a strong strategy throughout the design and production stages [24]. By adhering to Design for Manufacturability (DFM) guidelines, designers can verify that the PCB’s layout, trace width, and spacing conform to the machine’s specifications and the capabilities of the fabrication process [25]. Moreover, a meticulous choice of materials, especially for insulation and copper layers, is crucial to endure the thermal and electromagnetic stresses faced during machine operation, minimizing the chances of defects such as delamination or warping.

Automated optical inspection (AOI) systems integrated with X-ray analysis are utilized to identify problems like incomplete vias, misaligned parts, or soldering faults that might affect the winding’s efficiency [26]. Functional testing tailored to the electrical and magnetic specifications of AFPMMs guarantees that the PCBs can withstand the necessary current density and magnetic flux without failing [27]. Innovative manufacturing processes, including additive technologies and laser drilling, also improve the accuracy and dependability of the PCB windings, making them more resistant to defects and more appropriate for challenging operating environments [8,28]. By tackling potential flaws and implementing strong manufacturing methods, the quality and efficiency of PCBs in AFPMMs can be greatly enhanced. Kanygina et al. [18] highlighted the importance of optical and electrical testing to address common defects such as open circuits and shorts caused by etching and inclusions. Tokuda et al. [29] explored flexible PCB (FPCB) design challenges in high-density hard disk drives, focusing on specification optimization and reliable mounting processes. These studies collectively underscore the critical role of innovative manufacturing, inspection, and optimization in advancing PCB technology.

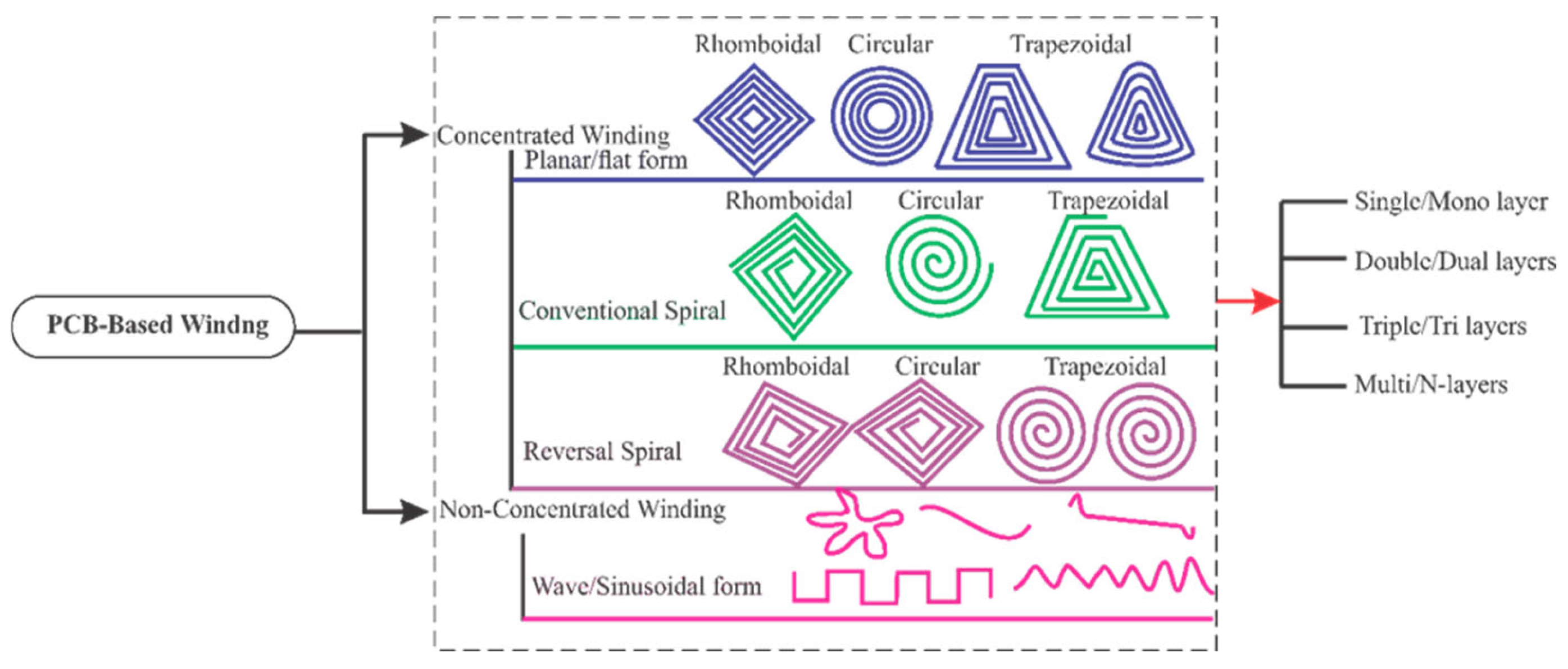

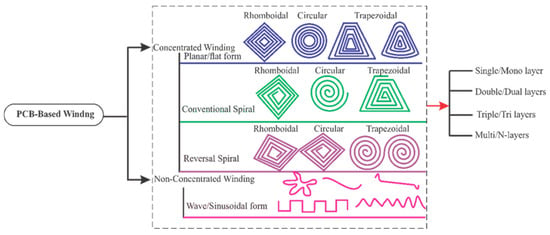

3.3. PCB-Based Winding Configurations

PCB-based winding designs have risen as a groundbreaking method in the creation of CAFPMMs. These setups utilize the accuracy, compactness, and adaptability of PCBs to create efficient and high-performing winding structures. In contrast to traditional copper wire windings, PCB windings incorporate conductive traces directly on the board, allowing for intricate and accurate shapes that enhance current flow and magnetic field arrangement [30]. This approach increases the machine’s productivity, minimizes material waste, and streamlines the assembly process. When utilizing PCB stator windings in AFPM machines, selecting an optimal winding pattern is crucial for achieving the desired performance and efficient use of the limited board area [31]. Winding configurations are primarily categorized into concentrated and non-concentrated windings, each suited to specific operational demands, as depicted in Figure 3. Windings that use PCB technology are generally constructed in flat layers, which enables multi-layer stacking to enhance coil density and attain greater power outputs. Patterns like spiral and wave configurations are frequently used. These designs also allow for improved thermal management, since the flat shape of the PCB promotes effective heat dissipation. Moreover, the capability to modify the arrangement of traces offers enhanced flexibility in fine-tuning winding factors, minimizing eddy current losses, and increasing torque density.

Figure 3.

PCB-based winding.

Nevertheless, utilizing PCB-based winding configurations introduces difficulties, such as the compromises between electrical conductivity and thermal performance, especially when selecting PCB materials such as FR4 or polyimide. The restricted current-carrying capacity of thin copper layers, in contrast to conventional wires, necessitates meticulous design to prevent overheating and guarantee dependable performance under high power demands. PCB windings in AFPMMs enable higher current densities with improved thermal performance [32] and facilitate low-profile, high-torque designs, with trapezoidal windings showing superior torque production [33]. Innovations in winding patterns, such as radial and parallel configurations, further reduce losses and enhance performance [8]. Manufacturing processes are also evolving, with intelligent optimization systems improving PCB assembly efficiency and yield [34]. Advanced conductor technologies, including Litz wire and PCB windings, mitigate eddy current losses in coreless AFPM designs, optimizing power density and reducing copper losses [35].

3.3.1. Concentrated Planar Windings (CPWs)

Planar windings are a specialized configuration of coil arrangements, typically fabricated using PCB or similar flat substrates, offering a compact and efficient alternative to traditional wire windings [36]. These windings are characterized by their flat, 2D design, where conductive traces replace conventional wires, enabling precise geometric patterns that optimize electromagnetic performance. In CAFPMMs, planar windings significantly enhance performance by reducing the coil’s end lengths, which minimizes resistance and copper losses. This design contributes to higher power density and efficiency. Moreover, the precision of planar windings ensures the uniform distribution of the magnetic field, reducing undesired harmonics and improving machine stability [37]. Thermal management is another advantage, as the flat configuration facilitates better heat dissipation, reducing the risk of hotspots. The use of planar windings also streamlines manufacturing, offering repeatability and scalability, particularly in applications requiring lightweight and compact designs [38]. Planar windings are increasingly favored in advanced electrical machines due to their ability to integrate seamlessly with PCB technologies.

3.3.2. Concentrated Spiral Windings (CSPs)

Spiral configurations are innovative winding approaches used in modern electrical machines, including coreless axial flux permanent magnet machines (CAFMs), to enhance performance and efficiency. These configurations leverage unique geometries to optimize electromagnetic properties and streamline machine designs. Spiral configurations, often implemented using planar or PCB-based technologies, feature concentric or spiral patterns of conductive traces [23]. These patterns maximize the use of the available space while reducing the copper losses associated with conventional winding techniques. The precise geometry of spiral windings also ensures a well-distributed magnetic field, leading to improved torque generation and reduced harmonic distortions [8,30]. The ability to integrate seamlessly with thermal management systems further enhances their applicability in high-performance machines, paving the way for more efficient and sustainable machine designs.

3.3.3. Non-Concentrated Wave Windings (NCWWs)

Wave windings are specialized configurations aimed at optimizing the performance of the machine’s stator winding [11]. These windings are particularly effective in applications requiring smooth sinusoidal electromotive force (EMF) generation and reduced harmonic distortion for achieving high efficiency. In CAFPMMs, wave windings are typically implemented by routing the winding pattern in a continuous, wave-like path across multiple poles [39]. This design allows the winding to span a larger area of the stator while maintaining a sinusoidal EMF profile. The overlapping arrangement of conductors ensures consistent magnetic interaction with the rotor’s permanent magnets, making wave winding particularly suitable for multi-pole designs, where smooth torque and low cogging are desired. Furthermore, wave windings provide a relatively uniform current distribution, which helps minimize hotspots and improve thermal performance [40]. However, implementing wave windings also presents challenges. Their complex layout requires precise PCB design and manufacturing processes, particularly in multi-layer PCB configurations. Additionally, wave windings may increase the total length of copper traces, which can lead to higher copper losses compared to more compact winding configurations like concentrated windings.

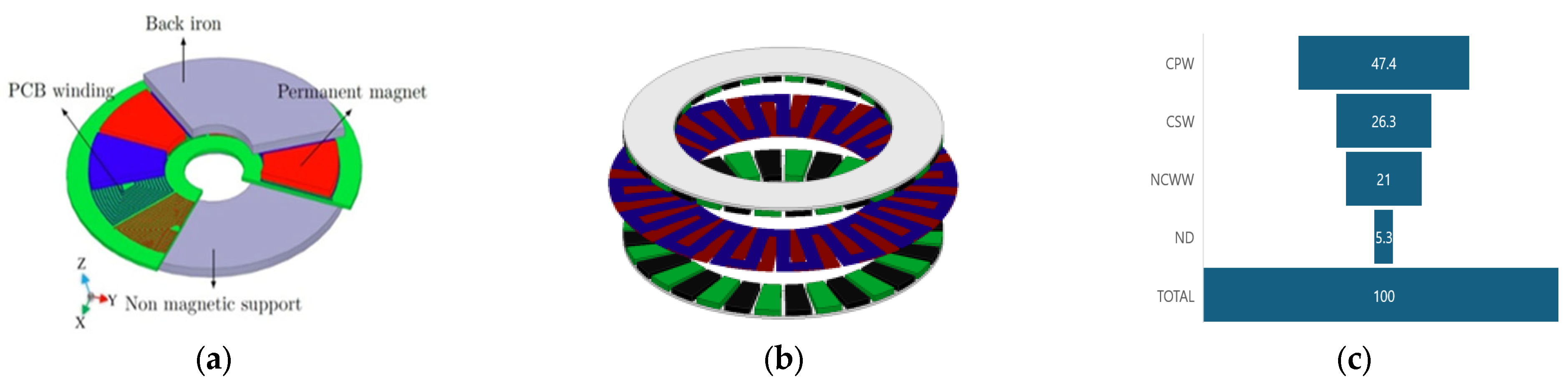

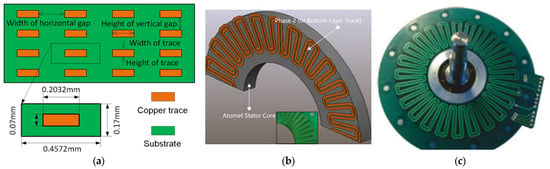

Despite these challenges, wave winding remains a promising option for applications prioritizing low harmonic distortion and smooth operation. Studies, including those by [40,41] explored innovative winding designs like wave and spiral topologies, multi-layer configurations, and unequal-width windings, optimizing power density, efficiency, and torque through finite element analysis (FEA). Hybrid analytical and numerical methods, such as those by [30], have proven effective in estimating losses and optimizing conductor paths. Thermal modeling, as examined by [12], is critical for managing temperature rise in PCB stators, with design strategies like increasing conductor linewidth improving heat dissipation. Additionally, comparative analyses by [42] revealed that slotted machines excel in torque density, while non-slotted ones reduce torque ripple, making each suitable for specific applications. Overall, these advancements in PCB winding design and multiphysics optimization pave the way for high-performance AFPM machines in compact, efficient, and versatile configurations. Figure 4a,b showcase the simulated model of a CAFPMM utilizing the PCB winding configuration.

Figure 4.

(a) AFPM machine with concentrated winding [11]. (b)AFPM with PCB wave windings [35]. (c) Contribution per winding configuration.

Figure 4c’s funnel chart illustrates the proportional contributions of four categories, totaling 100%. CPW dominates with 47.4%, nearly half of the total, followed by CSW at 26.3% and NCWW at 21%, representing moderate contributions. ND accounts for the smallest share at 5.3%. This distribution highlights CPW as the most significant contributor, with CSW and NCWW playing notable roles, while ND has a minimal impact. However, their individual contributions are presented in Table 3.

Table 3.

Comparative analysis of PCB-based windings [23,40,43].

3.4. Optimization of Design Utilizing Software Tools

The optimization of PCB-based winding designs in CAFPMMs is essential for attaining peak performance, efficiency, and reliability. Sophisticated software applications are crucial in simplifying the design workflow, guaranteeing accurate simulations, and enhancing overall machine efficiency [30]. These instruments help in examining electromagnetic properties, refining winding arrangements, and tackling thermal and mechanical issues. A key goal of utilizing software tools is to enhance the winding pattern, which directly influences the machine’s torque density, efficiency, and thermal characteristics [44]. Programs like ANSYS Maxwell, COMSOL Multiphysics, and ALTAIR Flux facilitate in-depth electromagnetic simulations to assess various winding configurations, including wave winding, planar concentrated windings, and spiral windings. These simulations offer an understanding of the magnetic flux distribution, EMF waveform quality, and torque ripple, enabling engineers to optimize their designs for particular applications [45]. Additionally, software applications such as MATLAB/Simulink, Motor-CAD, and Altium Designer offer a unified platform for co-simulating the electrical, thermal, and mechanical features.

3.5. PCB Winding Wiring Strategy

Particularly in CAFPMMs and other synchronous permanent magnet machines, the PCB wiring strategy for variant windings requires a careful consideration of electrical, thermal, and mechanical factors. Currently, FR4 materials serve as the optimal substrate for PCB designs as they have a small loss tangent, implying that the power loss due to the material is negligible at a temperature gradient of ≥170 °C [5]. Effectively controlling high currents and lowering resistive losses require choosing the right values for the following parameters: PCB thickness, copper thickness, trace clearance, trace width, number of layers and turns, vias design, and core thickness. The requirements of the Institute of Printed Circuits (IPC-2221) for trace width and spacing should be followed to ensure adequate current-carrying capacity without undue heating. Employing many vias for interlayer connections is advised to further improve performance [46]. To accomplish the necessary turns while retaining the ideal current density, high-power PCBs require several winding layers (top and bottom) or tracks. Wider traces are required to manage high currents due to the limited copper thickness. PCB windings can be efficiently designed and modified using professional tools, and to optimize current flow, through-hole vias require proper overlap between successive turns, thereby allowing multiple vias to handle maximum current efficiently.

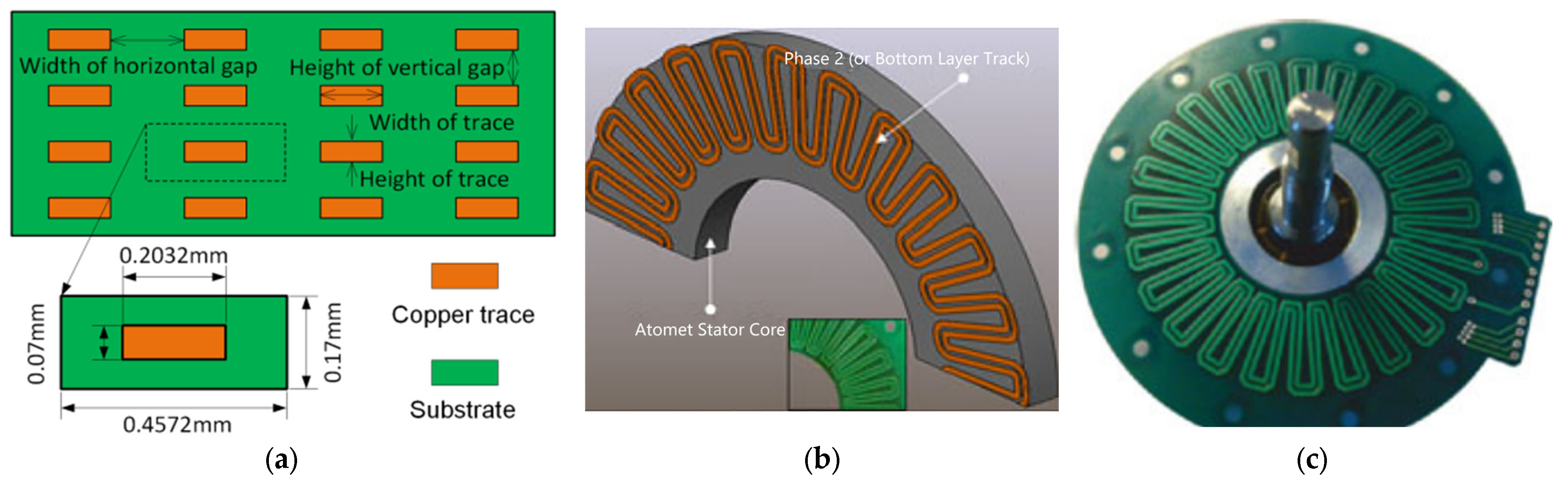

Performance and size must be balanced by optimizing certain aspects of the parameters. To satisfy DC bus voltage requirements and reduce circulating currents, either CPW, or NCWW winding designs incorporate many coupled traces. Variations in PCB thickness have an impact on the design, affecting the fill factor due to manufacturer-defined trace dimensions and spacing [5]. Effective layout techniques improve performance while maintaining manufacturability, such as optimizing route density. The voltage and current constraints of the system should determine whether to use series or parallel winding configurations, with careful end-turn length optimization to reduce copper losses [44]. To enhance durability and conductivity, an appropriate surface finish like ENIG (electroless nickel immersion gold) ought to be used. Following these design approaches allows PCB-based windings to attain improved efficiency, greater reliability, and optimized performance in contemporary machine applications. A schematic representation, a quasi-3D schematic, and a full 3D model design of NCWW on a PCB substrate are shown in Figure 5a–c.

Figure 5.

(a) A 2D representation of a PCB on a substrate [46]. (b) PCB wave winding design with dimensions. (c) Prototype of the winding [5].

3.6. PCB-Based Winding and Their Practical Applications

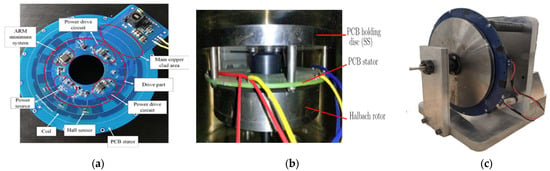

This section underscores the authors’ specialized expertise and contributions. A critical aspect of their work involves addressing PCB manufacturing tolerances, particularly the selection of appropriate trace widths [47]. The inadequate selection of PCB manufacturing tolerances, such as specifying narrow traces, leads to higher electrical resistance and power loss, thereby reducing machine efficiency. The strong correlation between simulation models and experimental results, with negligible error margins, underscores the robustness of their methodologies for various applications as presented in Table 4. By adopting a methodically simplified equivalent three-dimensional finite element analysis (FEA) model, many of these challenges are effectively addressed. This approach not only enhances computational efficiency but also maintains high accuracy in the analysis of complex systems. Research by [48] optimized CAFPMMs for vertical-axis wind turbines using the NSGA-II algorithm, demonstrating the importance of air gap adjustments to minimize eddy current losses and mechanical stress, with results validated via 3D finite element analysis (FEA). Matin [49] proposed an AFPM motor for electric aircrafts, optimizing its coreless structure for high power density and efficiency while addressing fault tolerance and thermal management using evolutionary algorithms and FEA.

Table 4.

Comparative analysis of PCB-based windings.

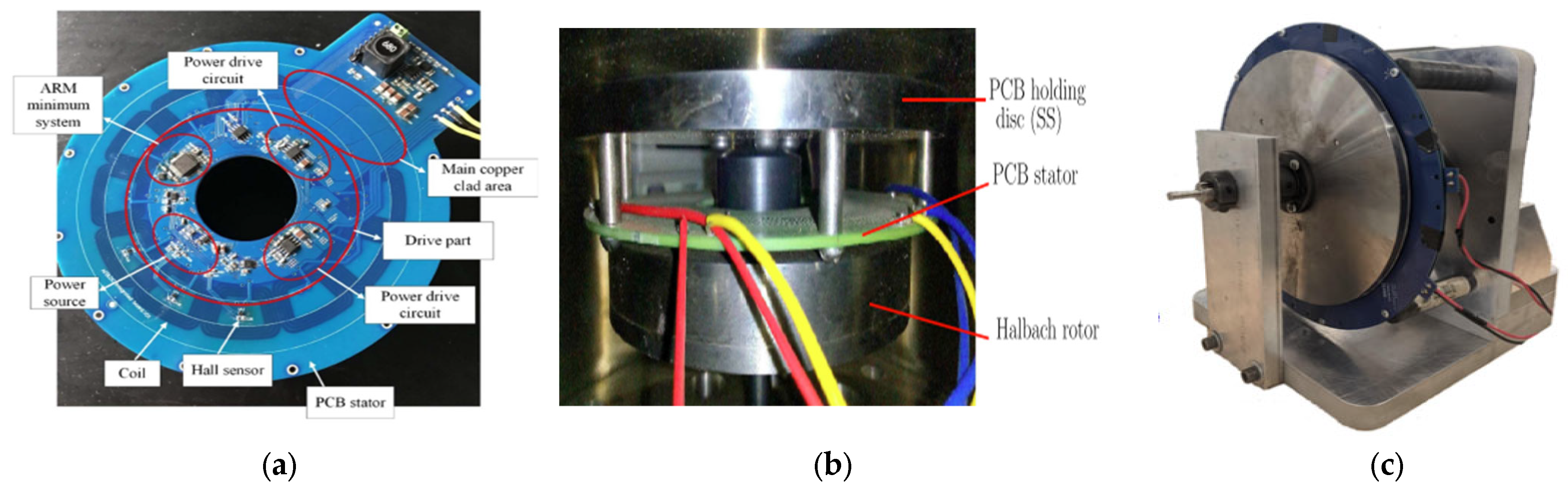

Earlier, Tokgoz [8] demonstrated that PCB windings could address manufacturing challenges in AFPMs by enabling precise and cost-effective mass production. In their extended work in [50], they explored a PCB-stator AFPM with an integrated GaNFET drive, achieving 90% efficiency and effective passive cooling under high-speed operation and introducing methods to measure and mitigate eddy losses. The work conducted by [47] introduces a computationally efficient FEA-based method for large-scale design optimization, leveraging symmetry and simplified models to cut runtime while maintaining accuracy. These studies collectively pave the way for optimized, high-performance CAFPMMs suitable for various applications, balancing efficiency, manufacturing feasibility, and computational scalability. However, based on the analysis records, ANSYS is the most prioritized tool for PCB modeling, accounting for a greater percentage of the usage, followed closely by COMSOL and ALTAIR Flux. Moreover, Figure 6a–c display the validated experimental model, respectively, of the SSDR CAFPMM utilizing PCB stator technology with optimal performances.

Figure 6.

(a) Integrated PCB stator with concentrated winding [27]. (b) SSDR CAFPM motor with PCB winding [7]. (c) SSDR CAFPMM based on concentric PCB winding [49].

3.7. Thermal Control and Related Losses from PCB Winding Arrangements for AFPMM

PCB winding technology has surfaced as a viable substitute for conventional copper windings in axial flux permanent magnet machines (AFPMs) because of its compact size, accuracy, and exceptional reliability. Nonetheless, thermal management becomes an essential design factor when employing PCB windings, as their distinctive arrangement affects heat production and dispersion. Effectively addressing thermal issues linked to PCB winding setups is crucial for maintaining the machine’s performance, efficiency, and durability.

3.7.1. Thermal Management Challenges in PCB Winding Configurations

PCB winding designs are highly compact and often utilize multi-layer configurations to maximize the number of turns per unit volume. While this improves the electromagnetic performance of the CAFPMMs, it increases the risk of heat accumulation due to limited airflow between layers and the insulating properties of the PCB substrate [30]. Furthermore, variations in winding layouts such as spiral, wave, or interleaved configurations affect the distribution of heat within the machine. The axial flux topology itself, with its inherent compactness and limited cooling surfaces, further complicates the dissipation of heat from PCB windings. Inadequate thermal management can lead to performance degradation, reduced efficiency, and even premature failure of the machine [12,27].

- Optimized Winding Design: the careful design of the trace geometry, such as increasing trace width and optimizing the copper fill factor, can reduce resistance and minimize I²R losses.

- Advanced Materials: high-conductivity copper and thermally enhanced PCB substrates, such as ceramic-filled composites, are used to improve heat dissipation.

- Efficient Cooling Mechanisms: Incorporating direct liquid cooling channels into the PCB structure allows for active heat removal. For instance, adding thermal vias within the PCB can enhance vertical heat transfer to external cooling systems.

- Thermal Simulations: these simulations guide the placement of thermal vias and the optimization of trace layouts for uniform heat distribution.

3.7.2. Loss Mitigation

Estimating eddy current losses in PCB traces is a complex yet essential task in the design of high-performance electric machines. These losses can be evaluated using detailed 2D or 3D FEA with other approaches. For CAFPMMs, addressing eddy current losses becomes even more critical during both the design and optimization stages [30]. To overcome this, a hybrid analytical numerical approach is proposed. This innovative method integrates seamlessly with multi-objective optimization algorithms, enabling the efficient and accurate estimation of eddy current losses. The result is a robust, time-saving strategy that preserves the fidelity of loss predictions while accelerating the path to optimized machine designs. PCB stators reduce manufacturing costs and complexities while minimizing losses such as eddy currents and circulating currents, though challenges like limited copper fill factors and AC losses in high-speed applications remain significant [16]. Studies have explored optimized winding layouts, such as wave and spiral designs, to improve efficiency and mitigate loss [46,51,52]. For small-scale applications, novel motor architectures leverage PCB stators to increase torque density and simplify production. Overall, PCB-based CAFPM machines promise scalable, efficient, and lightweight solutions for diverse industries, but overcoming manufacturing and performance trade-offs remains key to unlocking their full potential.

4. Recommendations

The future of PCB manufacturing is driven by the need for faster, smaller, and more efficient electronic systems. The key trends likely to shape the future include the following:

- Nanomaterials: the development of nano-scale materials will enable PCBs with even better performance characteristics, including faster signal transmission, higher thermal conductivity, and improved mechanical strength;

- Artificial Intelligence and Machine Learning: these algorithms can be applied to optimize PCB design and detect defects, enhancing the reliability and lifespan of PCBs;

- Smart PCBs: future PCBs may feature integrated sensors, microprocessors, and wireless communication capabilities, making them more intelligent.

5. Conclusions

This study reviews the role of PCBs in axial flux permanent magnet machines (AFPMMs), analyzing 38 articles from 2019 to 2024 using the PRISMA methodology. PCBs are vital for lightweight AFPMMs, particularly in single stator double rotor (SSDR) configurations, optimized using tools like ANSYS and COMSOL. Concentrated trapezoidal winding is the dominant topology, with growing interest in DSSR and multi-disk designs. The findings highlight advancements in PCB manufacturing, winding optimization, and defect mitigation, emphasizing their evolving role in future AFPMM innovations.

Author Contributions

Conceptualization, I.S.; methodology, I.S., E.H.T.W. and R.K.; software, I.S.; validation, I.S., E.H.T.W. and R.K.; formal analysis, I.S.; investigation, I.S.; resources, I.S.; data curation, I.S. and Y.A.S.; writing—original draft preparation, I.S.; writing—review and editing, I.S., E.H.T.W., R.K. and Y.A.S.; visualization, E.H.T.W.; supervision, E.H.T.W. and R.K.; project administration, E.H.T.W. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Acknowledgments

The authors express their gratitude to Universiti Teknologi PETRONAS for providing research resources and technical support. Author Isiaka Shuaibu acknowledges the sponsorship provided by the Petroleum Technology Development Fund (PTDF), Nigeria.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Shuaibu, I.; Wei, E.H.T.; Kannan, R.; Aderinola, M.; Adedayo, H.B.; Samaila, Y.A.; Salisu, H.M.; Adebanjo, A.U. State-of-Art Review of Renewable Energy-Based Systems for Electrical Machine Applications: Prospects and Challenges. IOP Conf. Ser. Earth Environ. Sci. 2024, 1365, 012005. [Google Scholar] [CrossRef]

- Wang, S.; Lin, M. Optimal Slot/Pole Combination of Axial-Field Flux-Modulated Machines With Split Teeth. IEEE Trans. Appl. Supercond. 2024, 34, 5208106. [Google Scholar] [CrossRef]

- Habib, A.; Zainuri, M.A.A.M.; Che, H.S.; Ibrahim, A.A.; Rahim, N.A.; Alaas, Z.M.; Ahmed, M.M.R. A systematic review on current research and developments on coreless axial-flux permanent-magnet machines. IET Electr. Power Appl. 2022, 16, 1095–1116. [Google Scholar] [CrossRef]

- Shuaibu, I.; Wei, E.H.T.; Kannan, R.; Samaila, Y.A. Advancements in axial flux permanent magnet machines utilizing coreless technology: A systematic review. Ain Shams Eng. J. 2024, 15, 103091. [Google Scholar] [CrossRef]

- Marignetti, F.; Volpe, G.; Mirimani, S.M.; Cecati, C. Electromagnetic Design and Modeling of a Two-Phase Axial-Flux Printed Circuit Board Motor. IEEE Trans. Ind. Electron. 2018, 65, 67–76. [Google Scholar] [CrossRef]

- Schafer, J.; Bortis, D.; Kolar, J.W. Novel Highly Efficient/Compact Automotive PCB Winding Inductors Based on the Compensating Air-Gap Fringing Field Concept. IEEE Trans. Power Electron. 2020, 35, 9617–9631. [Google Scholar] [CrossRef]

- Neethu, S.; Nikam, S.P.; Singh, S.; Pal, S.; Wankhede, A.K.; Fernandes, B.G. High-Speed Coreless Axial-Flux Permanent-Magnet Motor With Printed Circuit Board Winding. IEEE Trans. Ind. Appl. 2019, 55, 1954–1962. [Google Scholar] [CrossRef]

- Tokgöz, F.; Çakal, G.; Keysan, O. Comparison of PCB winding topologies for axial-flux permanent magnet synchronous machines. IET Electr. Power Appl. 2020, 14, 2577–2586. [Google Scholar] [CrossRef]

- de Jong, E.; Ferreira, J.; Bauer, P. 3D Integration with PCB Technology. In Proceedings of the Twenty-First Annual IEEE Applied Power Electronics Conference and Exposition, APEC ’06, Dallas, TX, USA, 19–23 March 2006; IEEE: Piscataway, NJ, USA, 2006; pp. 857–863. [Google Scholar] [CrossRef]

- Ratna, S.; Vishwakarma, P.N.; Ojha, M.; Kannojiya, R.; Shubham, P.; Sharma, S. Evaluation of PCB materials for high frequency power applications using MOORA method. J. Phys. Conf. Ser. 2022, 2178, 012021. [Google Scholar] [CrossRef]

- Paul, S.; Farshadnia, M.; Pouramin, A.; Fletcher, J.; Chang, J. Printed Circuit Axial-Flux Permanent Magnet Machines: A Comparative Analysis of Their PCB Topologies and Performance Characteristics. In Proceedings of the 2018 IEEE International Magnetics Conference (INTERMAG), Singapore, 23–27 April 2018; p. 1. [Google Scholar] [CrossRef]

- Wang, X.; Yin, C.; Li, T. Thermal Modeling and Analysis of Axial Flux Permanent Magnet Machine with PCB Stator. In Proceedings of the 2022 International Conference on Electrical Machines and Systems, ICEMS, Chiang Mai, Thailand, 29 November–2 December 2022; pp. 1–5. [Google Scholar] [CrossRef]

- Chen, X.; Wu, Y.; He, X.; Ming, W. A Comprehensive Review of Deep Learning-Based PCB Defect Detection. IEEE Access 2023, 11, 139017–139038. [Google Scholar] [CrossRef]

- Pickering, C.; Byrne, J. The benefits of publishing systematic quantitative literature reviews for PhD candidates and other early-career researchers. High. Educ. Res. Dev. 2014, 33, 534–548. [Google Scholar] [CrossRef]

- Kitchenham, B. Guidelines for performing Systematic Literature Reviews in software engineering. EBSE Technical Report EBSE-2007-01 Guidelines for performing Systematic Literature Reviews in Software Engineering. ICSE 2007, 2021, 1–57. [Google Scholar]

- Marcolini, F.; De Donato, G.; Capponi, F.G.; Caricchi, F. Design of a Printed Circuit Board Axial Flux Permanent Magnet Machine for High Speed Applications. IEEE Trans. Ind. Appl. 2024, 60, 5919–5930. [Google Scholar] [CrossRef]

- Baudart, F.; Dehez, B.; Denies, J.; Markovic, M.; Perriard, Y. Shape optimization of flexible PCB slotless windings in BLDC machines. In Proceedings of the 2013 International Conference on Electrical Machines and Systems (ICEMS), Busan, Republic of Korea, 26–29 October 2013; IEEE: Piscataway, NJ, USA, 2013; pp. 943–948. [Google Scholar] [CrossRef]

- Kanygina, E.D.; Denisova, O.V.; Rastvorova, I.V. Optical and Electrical Control in Printed Circuit Board Manufacturing. In Proceedings of the 2019 IEEE Conference of Russian Young Researchers in Electrical and Electronic Engineering (EIConRus), Saint Petersburg and Moscow, Russia, 28–31 January 2019; pp. 536–538. [Google Scholar] [CrossRef]

- Yee, C.F.; Jambek, A.B.; Al-Hadi, A.A. Advantages and Challenges of 10-Gbps Transmission on High-Density Interconnect Boards. J. Electron. Mater. 2016, 45, 3134–3141. [Google Scholar] [CrossRef]

- Wang, W.; Wang, W.; Mi, H.; Mao, L.; Zhang, G.; Liu, H.; Wen, Y. Study and Optimal Design of a Direct-Driven Stator Coreless Axial Flux Permanent Magnet Synchronous Generator with Improved Dynamic Performance. Energies 2018, 11, 3162. [Google Scholar] [CrossRef]

- Guo, H.; Lv, R.; Bai, S. Recent advances on 3D printing graphene-based composites. Nano Mater. Sci. 2019, 1, 101–115. [Google Scholar] [CrossRef]

- Szabó, L.; Fodor, D. The Key Role of 3D Printing Technologies in the Further Development of Electrical Machines. Machines 2022, 10, 330. [Google Scholar] [CrossRef]

- Shuaibu, I.; Ho, E.T.W. Investigation of a Spiral Planar Coil on Coreless Axial Flux PM Generator for Pico-Hydro Applications. In Proceedings of the 2023 IEEE Conference on Energy Conversion (CENCON), Kuching, Malaysia, 23–24 October 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 58–63. [Google Scholar] [CrossRef]

- Guo, H.; Zhao, H.; Zhao, Y.; Liu, W. PCB defect detection algorithm based on deep learning. Optik 2024, 315, 172036. [Google Scholar] [CrossRef]

- Wang, L.T.N.; Simcoe, M.; Mehrotra, V.; Huda, R.; Lee, Z.C.; McKay, T.; Schroeder, P.; Madhavan, S. Electrical design-for-manufacturability (DFM) checks for reducing layout-induced circuit variability for analog designs. In Design-Process-Technology Co-Optimization XV; Yuan, C.-M., Kim, R.-H., Eds.; SPIE: Pune, Indian, 2021; p. 19. [Google Scholar] [CrossRef]

- Dai, W.; Mujeeb, A.; Erdt, M.; Sourin, A. Soldering defect detection in automatic optical inspection. Adv. Eng. Inform. 2020, 43, 101004. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, Y.; Ma, T.; Liu, X.; Li, J. Losses and Thermal Analysis of an Integrated PCB Coreless Axial Flux PMSM with the Drive System. IEEE Trans. Ind. Electron. 2023, 70, 11022–11032. [Google Scholar] [CrossRef]

- Marcolini, F.; De Donato, G.; Capponi, F.G.; Incurvati, M.; Caricchi, F. On Winding Manufacturing Technologies for Coreless Axial-Flux Permanent-Magnet Machines. In Proceedings of the 2023 IEEE Workshop on Electrical Machines Design, Control and Diagnosis (WEMDCD), Newcastle upon Tyne, UK, 13–14 April 2023; pp. 1–7. [Google Scholar] [CrossRef]

- Tokuda, K.; Kaji, K.; Ishizaki, K. High-Density Mounting Technologies for Printed Circuit Boards in Large-Capacity 3.5-inch HDDs. In Proceedings of the 2022 International Conference on Electronics Packaging (ICEP), Sapporo, Japan, 11–14 May 2022. [Google Scholar]

- Chulaee, Y.; Lewis, D.; Mohammadi, A.; Heins, G.; Patterson, D.; Ionel, D.M. Circulating and Eddy Current Losses in Coreless Axial Flux PM Machine Stators With PCB Windings. IEEE Trans. Ind. Appl. 2023, 59, 4010–4020. [Google Scholar] [CrossRef]

- Li, C.; Wang, X.; Lv, H. Performance Improvement by Pattern Optimization of PCB Winding in Coreless Axial Flux Permanent Magnet Motor. In Proceedings of the 2021 IEEE 4th International Electrical and Energy Conference, CIEEC 2021, Wuhan, China, 28–30 May 2021. [Google Scholar] [CrossRef]

- Gao, P.; Zhao, X.; Gu, Y.; Wang, X. Coupled electromagnetic and thermal analysis of an axial flux permanent magnet synchronous machines with printed circuit board winding. Int. J. Appl. Electromagn. Mech. 2020, 63, 449–464. [Google Scholar] [CrossRef]

- Noh, M.D.; Kim, J.; Park, Y.-W. Comparisons of Concentrated Printed-Circuit Stator Windings for Axial Flux Permanent Magnet Machines. In Proceedings of the 2019 IEEE/ASME International Conference on Advanced Intelligent Mechatronics (AIM), Hong Kong, China, 8–12 July 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 229–234. [Google Scholar] [CrossRef]

- Fung, V.W.; Yung, K.C. An intelligent approach for improving printed circuit board assembly process performance in smart manufacturing. Int. J. Eng. Bus. Manag. 2020, 12, 184797902094618. [Google Scholar] [CrossRef]

- Kesgin, M.G.; Han, P.; Taran, N.; Lawhorn, D.; Lewis, D.; Ionel, D.M. Design Optimization of Coreless Axial-flux PM Machines with Litz Wire and PCB Stator Windings. In Proceedings of the 2020 IEEE Energy Conversion Congress and Exposition (ECCE), Detroit, MI, USA, 11–15 October 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 22–26. [Google Scholar] [CrossRef]

- Cupertino, F.; Ettorre, S. Torque production capabilities of electrical machines with planar windings. In Proceedings of the IECON Proceedings (Industrial Electronics Conference), Montreal, QC, Canada, 25–28 October 2012; pp. 2080–2085. [Google Scholar] [CrossRef]

- Wang, X.; Li, X.; Ge, J.; Zhang, G.; Xu, W. Improved Coreless Axial Flux Permanent-Magnet Machine with Nonuniformly Distributed Winding. IEEE Trans. Transp. Electrif. 2023, 9, 2557–2567. [Google Scholar] [CrossRef]

- Ordonez, L.C.; Exposito, A.D.; Cervera, P.A.; Bakic, M.; Wijekoon, T. Optimized Thermal Modelling of High Power Planar PCB Magnetics. In Proceedings of the 2022 IEEE Energy Conversion Congress and Exposition (ECCE), Detroit, MI, USA, 9–13 October 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 1–8. [Google Scholar] [CrossRef]

- Chen, Q.; Liu, G.; Gong, W.; Qu, L.; Zhao, W.; Shen, Y. Design of a spoke-type permanent-magnet motor with optimal winding configuration for electric vehicle applications. J. Appl. Phys. 2012, 111, 07E710. [Google Scholar] [CrossRef]

- Chulaee, Y.; Lewis, D.; Heins, G.; Patterson, D.; Ionel, D.M. Winding Losses in Coreless Axial Flux PM Machines with Wave and Spiral PCB Stator Topologies. In Proceedings of the 2022 IEEE Energy Conversion Congress and Exposition (ECCE), Detroit, MI, USA, 9–13 October 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 1–6. [Google Scholar] [CrossRef]

- Wang, X.; Pang, W.; Gao, P.; Zhao, X. Electromagnetic Design and Analysis of Axial Flux Permanent Magnet Generator with Unequal-Width PCB Winding. IEEE Access 2019, 7, 164696–164707. [Google Scholar] [CrossRef]

- Karabulut, Y.; Mese, E. Torque Performance Comparison Between Slotted and Non-Slotted Axial Flux PCB Winding Machine. In Proceedings of the 2021 IEEE 19th International Power Electronics and Motion Control Conference (PEMC), Gliwice, Poland, 25–29 April 2021; pp. 519–523. [Google Scholar] [CrossRef]

- Wu, M.; Wang, L.; Ahmed, D.; Peng, M.; Mao, L. An Accurate Analytical Model to Evaluate the Winding Loss of A Single-Layer Multi-Turn Planar Air-Core PCB-Inductor. In Proceedings of the 2021 IEEE Energy Conversion Congress and Exposition (ECCE), Vancouver, BC, Canada, 10–14 October 2021; pp. 5483–5487. [Google Scholar] [CrossRef]

- Tokgoz, F.; Cakal, G.; Keysan, O. Design and implementation of an optimized printed circuit board axial-flux permanent magnet machine. In Proceedings of the 2020 International Conference on Electrical Machines, ICEM 2020, Gothenburg, Sweden, 23–26 August 2020; pp. 111–116. [Google Scholar] [CrossRef]

- Lu, Y.; Li, J.; Qu, R.; Ye, D.; Lu, H. Electromagnetic Force and Vibration Study on Axial Flux Permanent Magnet Synchronous Machines With Dual Three-Phase Windings. IEEE Trans. Ind. Electron. 2020, 67, 115–125. [Google Scholar] [CrossRef]

- Han, P.; Lawhorn, D.; Chulaee, Y.; Lewis, D.; Heins, G.; Ionel, D.M. Design Optimization and Experimental Study of Coreless Axial-flux PM Machines with Wave Winding PCB Stators. In Proceedings of the 2021 IEEE Energy Conversion Congress and Exposition, ECCE 2021-Proceedings, Virtual, 10–14 October 2021; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2021; pp. 4347–4352. [Google Scholar] [CrossRef]

- Chulaee, Y.; Ionel, D.M. Ultra-fast finite element analysis of coreless axial flux permanent magnet synchronous machines. IET Electr. Power Appl. 2023, 18, 883–896. [Google Scholar] [CrossRef]

- Wen, Z.; Xiong, B.; Gu, G. Optimization Design of Low Speed Axial Flux Halbach Permanent-Magnet Generator with PCB Winding. In Proceedings of the 2019 22nd International Conference on Electrical Machines and Systems (ICEMS), Harbin, China, 11–14 August 2019. [Google Scholar]

- Vatani, M.; Chulaee, Y.; Mohammadi, A.; Stewart, D.R.; Eastham, J.F.; Ionel, D.M. On the Optimal Design of Coreless AFPM Machines with Halbach Array Rotors for Electric Aircraft Propulsion. In Proceedings of the 2024 IEEE Transportation Electrification Conference and Expo (ITEC), Chicago, IL, USA, 19–21 June 2024; pp. 1–6. [Google Scholar] [CrossRef]

- Tokgoz, F.; Gulsuna, O.; Karakaya, F.; Cakal, G.; Keysan, O. Mechanical and Thermal Design of an Optimized PCB Motor for an Integrated Motor Drive System With GaNFETs. IEEE Trans. Energy Convers. 2023, 38, 653–661. [Google Scholar] [CrossRef]

- Asgari, S.; Saed, N.; Muetze, A. Low-Cost Axial Flux PCB Motor with Ferrite Core and Ferrite Magnet Topology for Fan Applications. In Proceedings of the 2023 IEEE International Electric Machines & Drives Conference (IEMDC), San Francisco, CA, USA, 15–18 May 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 1–5. [Google Scholar] [CrossRef]

- Anvari, B.; Guedes-Pinto, P.; Lee, R. Dual Rotor Axial Flux Permanent Magnet Motor using PCB Stator. In Proceedings of the 2021 IEEE International Electric Machines and Drives Conference, IEMDC 2021, Hartford, CT, USA, 17–20 May 2021; pp. 1–7. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).