1. Introduction

Companies and organizations worldwide are focused on the creation of projects on saving energy to reduce CO

2 emissions. Among these efforts is replacing conventional electricity generation with renewable energy production [

1,

2]. Although this trend is not new, alternative approaches continue to be developed that focus on optimizing photovoltaic solar energy systems in both their design and sizing [

3,

4]. The optimal sizing of a photovoltaic (PV) system determines the appropriate capacity by balancing the number and arrangement of PV panels, the energy storage, and the electrical infrastructure to maximize energy generation and overall system efficiency while ensuring cost-effectiveness [

5]. The functionality, economic viability, and sustainability of a PV system depend on its optimal sizing, which requires a meticulous assessment of factors such as geographical location, solar resource availability, energy consumption patterns, financial considerations, and environmental impact. Oversizing the system can lead to unnecessary costs and underutilization of generated energy, while undersizing can result in unmet energy needs and unrealized potential. Thus, a holistic and informed approach is essential to strike the right balance [

4,

5].

Ecuador’s geographic location on the equinoctial line offers high levels of solar potential; the data related to solar radiation within the Ecuadorian territory show consistency and homogeneity in the records during the year. Due to the variety of natural resources, these can be used as an approach to clean energy production, thus obtaining electricity supply throughout the country and promoting a change in the environmentally friendly energy matrix, positioning the use of generators based on petroleum derivatives and fuels as a secondary form of energy supply [

6,

7]. Estimates of energy capacity based on alternative sources (solar, geothermal, hydraulic, wind, primary biomass) indicate that its potential contribution will increase by ten, with the possibility of reaching 10 or 15 TW/year. Consequently, the growth of renewable energy will lie in the operational values, taxes on non-renewable energy sources, and energy policies of the country [

7].

The poultry sector in the country must maintain partial or complete control over key environmental conditions using ventilation, heating, cooling, and lighting equipment to ensure optimal production performance. This necessity results in high energy costs, particularly for the feeding and lighting systems in chicken barns [

8]. Although the methods of implementation of photovoltaic systems are well established in domestic and industrial areas, there is a need to venture into the application of these sources of energy generation for the poultry environment. This requires the use of equipment with the capacity to cover the energy requirement under conditions of viable cost and simple design.

To address this need, we designed a model for a photovoltaic system capable of reducing electricity costs and promoting energy independence through alternative sources. The system is intended to optimize solar energy usage by analyzing the area’s energy demand, peak solar times, equipment dimensions, electrical conductors, and protection mechanisms, ultimately achieving a sustainable, environmentally responsible, and affordable alternative that can meet the energy consumption needs of chicken barns.

2. Methodology

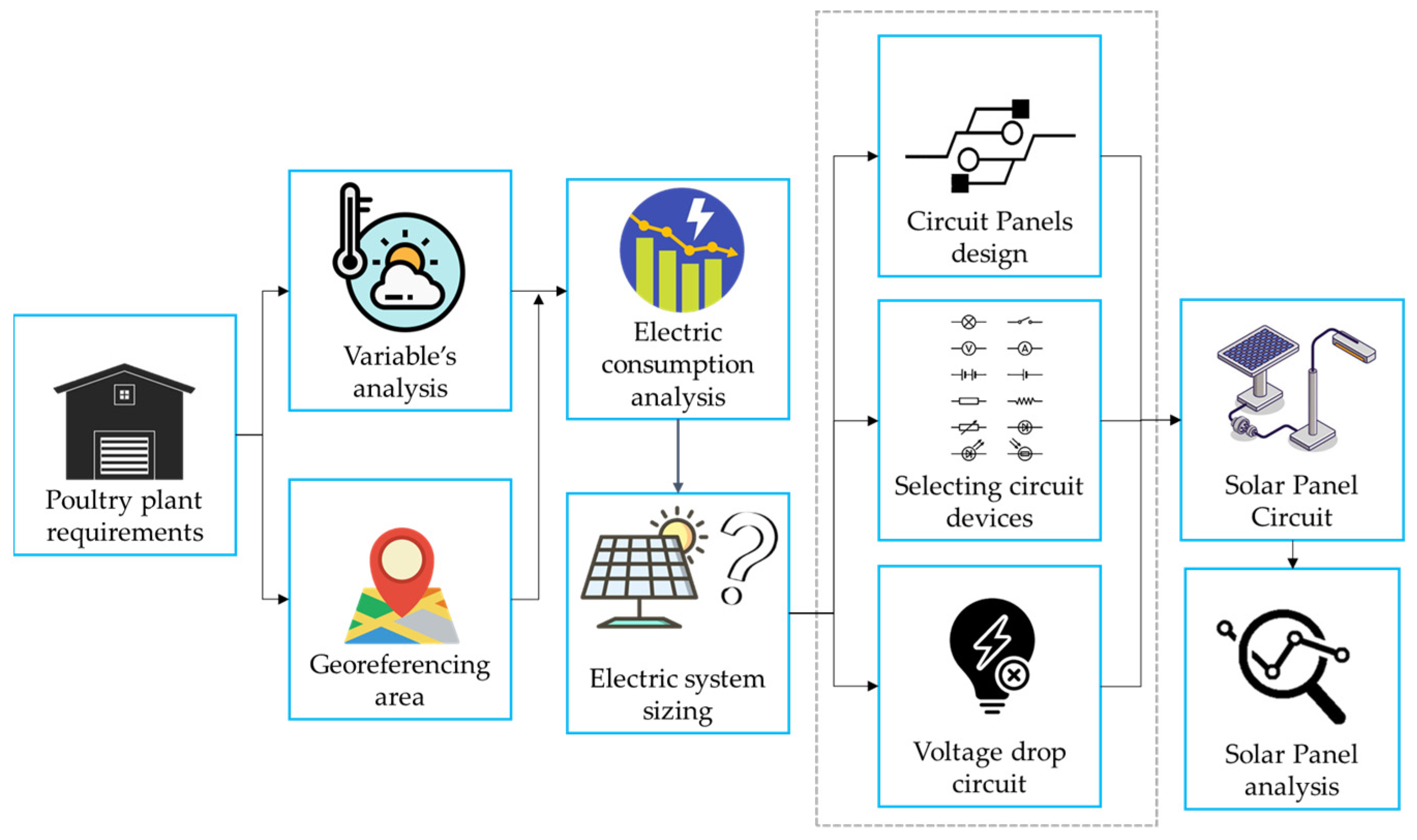

To design the model of the photovoltaic system, we followed the workflow sequence illustrated in

Figure 1, where the energy requirements of the poultry plant were analyzed, including calculations of energy needs. Subsequently, we identified the key variables, such as environmental factors, solar radiation, and associated costs. Data on electrical consumption were compiled to appropriately size the system, and then we proposed an optimal modular system.

2.1. Georeferencing of the Area

The poultry plant is located in Mulalillo, Cotopaxi (lat: ; long: ), with average ambient temperature of 11.7 °C, atmospheric pressure of 71 kPa, wind speed average of 2.5 m/s, relative humidity of 89.1%, and average water precipitation of 3.3. With these geographical characteristics, it is possible to characterize the conditions with maximum solar exposure for an optimal installation of the photovoltaic system. The poultry plant takes up a space of 50,332 m2, where the study area is composed of 11 chicken barns (A and B) that store up to 20,000 laying birds in each. The chicken barn area has food distribution and water supply systems, directly associated with energy consumption; a single-phase motor is used for food and a three-phase motor is used for the water supply. Both feeding and hydration in the poultry plant are carried out twice a day with a duration of 60 to 90 min for each process.

2.2. Availability of Solar Energy Resource

The data on solar radiation were provided by ARCONEL [

9], INAHMI [

10], and NASA [

11]. To check and collect data, the free version of RETScreen software (Version 8.1) was used [

12]. The peak solar hours according to the Ecuadorian construction standard establishes the calculation by application of the equation

[

13], where HSP is the value of peak solar hours, H is the average irradiation in the poultry plant, and I is the variable irradiance of the Earth’s surface. The climatic factors of the area during the year were analyzed using the Weather Spark web application [

14].

2.3. Energy Consumption and Demand

To estimate the energy consumption and demand, the barns were divided into two types, A and B, since the time value changes between both types according to the number of laying birds that have the installation, which influences the hours of use of the elements that use electrical energy. The data of the electrical consumption of the poultry plant were obtained from electrical spreadsheets where there are the data on the real energy cost for the period of 2018 to 2022; this time period was chosen for data source comparison purposes. The calculation of daily electricity consumption is determined by equations that relate the effect of each device with the maximum operating time per hour of daily production; the energy consumed is calculated by the equation , where is the power of the equipment and is the maximum time of use of the equipment.

2.4. Design of the Photovoltaic System

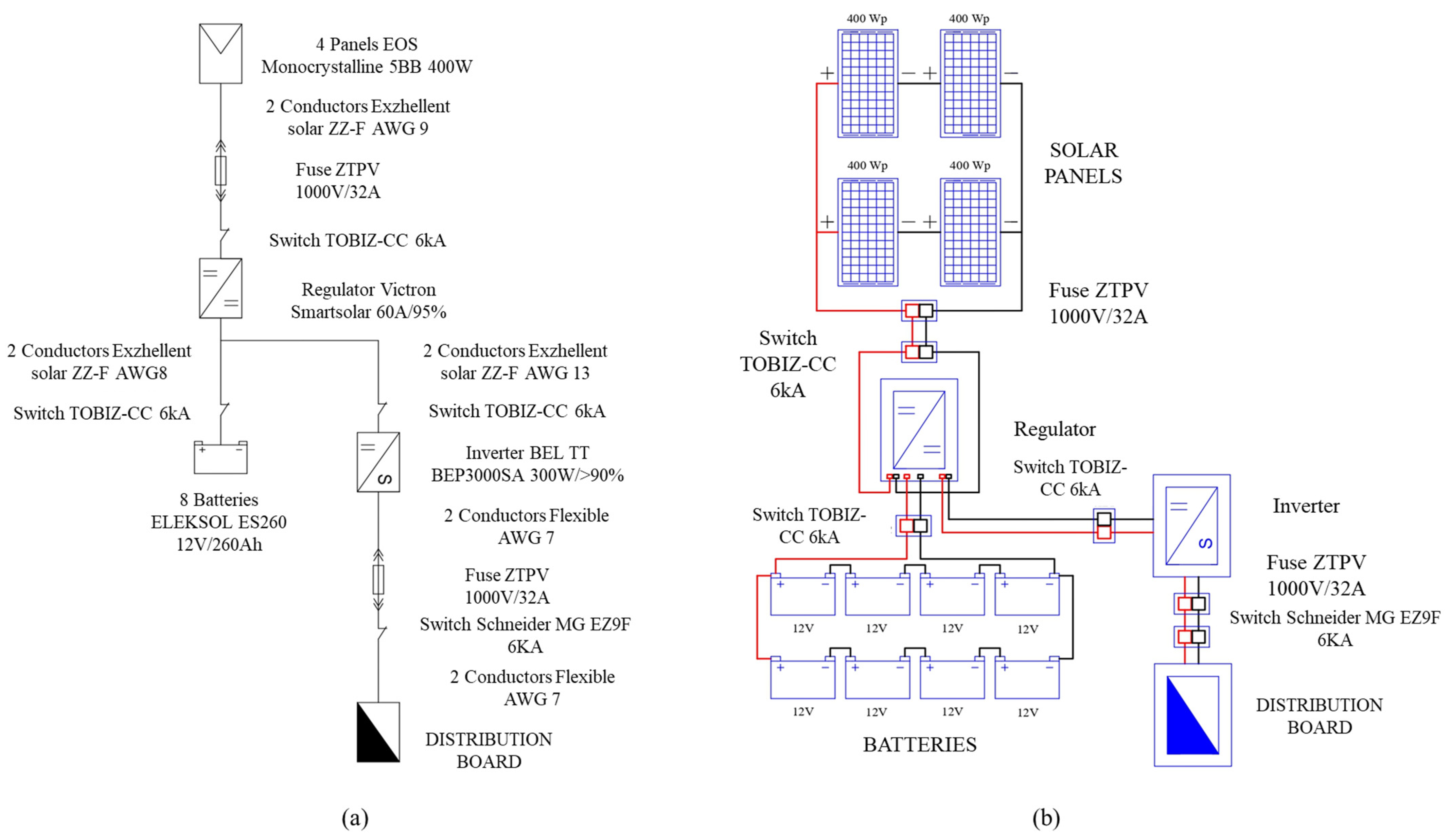

The design of the photovoltaic system was determined by the number of solar panels, regulators, and batteries and inverters, and the length of the conductor used. The performance of the different components determines the ideal operation to supply energy to the area under study. For this, the distribution of components and connections was established through CAD tools that allow single-line and general structure diagrams of the designed photovoltaic system to be drawn.

3. Results and Discussion

3.1. Solar Energy Resource

Due to the location of Ecuador, the solar radiation remains constant throughout the year. The maximum solar radiation was detected in the range of 5 Kwh/m

2/d for June, the minimum was detected in April with measures under 4.6 Kwh/m

2/d, and the average was 4.8 Kwh/m

2/d, as shown in

Figure 2. The solar radiation is high in this zone compared with zones located in the northern and southern hemispheres [

15,

16].

In photovoltaic power generation systems, designers avoid obstructing the peripheral environment of the modules, as this variable reduces generation capacity and shortens the panel’s useful life. The loss caused by shadows is analyzed based on the correlation between the total solar radiation that impacts the generating plane, which varies in the presence and absence of shadows [

5,

17,

18].

3.2. Energy Consumption on Demand

The values shown in

Figure 3 represent the energy consumption recorded from 2018 to 2022 to calculate an average. The electrical power and energy consumed by the equipment were analyzed. For the food distribution area, the active power was 1.13 kWh, for the water supply it was 0.77 kWh, and for the entire barn it was 1.9 kWh. Energy consumption was measured for the eleven barns and classified according to their consumption levels. Type A barns had a consumption level of 4.95 kWh, and Type B barns had 5.58 kWh. On average, the barns (Type A and B) use 20,258 kWh per year. The poultry plant consumes a total of 57,313 kWh per year; this amount corresponds to a monthly consumption of 4776 kWh and daily consumption of 159.2 kWh. The greatest consumption of energy quantity corresponds to the barn area with 36%.

The barns have feeding and water supply systems that consume a high percentage of energy due to their constant operation and long action times. The total energy consumption of the devices inside each barn was determined based on the main consumption systems, such as food distribution and water supply. We obtained a performance factor of 0.84. For barn A, the energy consumption was 5.89 kWh, and for barn B it was 6.59 kWh. The calculated energy consumed varies according to the type of barn. According to the range of daily consumption (surplus 4001 Wh), a voltage of 48 V was established.

3.3. Selection and Number of Solar Panels

The proposed model will use monocrystalline solar panels EOS 5BB (1980 × 1002 × 40 mm) with 72 cells, each cell with a dimension of (158.75 × 158.75 mm), working temperature of −45 to 80 °C, and IEC 61,215 certification.

For the calculation of the number of solar panels for the photovoltaic system, the equation

was used for both barns A and B, where

Er = actual energy consumption;

W = nominal power of the panel;

HSP m = solar hour of the worst month (April), where in this case 4.58 h minimum radiation was calculated; and (0.9) represents the global loss factor. We obtained for barn A 3.57 ≈ 4 units, and for barn B 3.98 ≈ 4 units. The connection of the solar panels was established in series and parallel. Calculating the voltage of the system and the nominal voltage of solar module, two panels are connected in series and two panels in parallel in the proposed system, with 24 V and 20.80 A, as shown in

Figure 4.

3.4. Angle of Inclination of the Support Panels

The optimal inclination angle is obtained by the equation , where is the latitude of the company and 10° is a constant value for isolated systems. The calculated inclination angle is 8.899°, which is within the acceptable limit provided by the NEC standard, which indicates that the angle of inclination should be between a minimum of 5° and a maximum of 15°. The orientation of the panels will be directed towards the equinoctial line to take advantage of the sun. Once the angle was calculated, we defined the moorings on the sloping roof, which is recommended to be made of galvanized steel to avoid corrosion.

3.5. Dimensioning and Distribution of the Battery Bank and Charge Controller

The capacity of the battery bank was calculated using the equation

where

Er = real daily energy consumption (A and B); n = day of autonomy of the system; pd = depth of battery discharge 60%; and V system = operating voltage of the system. So, barn A has a battery bank capacity of 206.57 Ah and barn B 218.93 Ah.

The number of batteries for barns A and B was calculated by , where Vs = determined voltage of the system and Vn = nominal voltage of the battery, obtaining an array of four batteries in series for the two barns. The parallel distribution of batteries was calculated by , where Cbat = battery bank capacity; pd = depth of battery discharge, 60%; and In = nominal battery capacity. Barns A and B will have two arrays of batteries in parallel. The distribution of units in series and parallel for barns A and B was determined by . As a result, we obtained eight Eleksol ES260 12 V–260 Ah lead–acid batteries to supply the demand for one day of autonomy of the photovoltaic system, thus ensuring its duration and optimal performance.

3.6. Inverter Sizing

The inverter was dimensioned using the equation

, where

P req = power required by the inverter;

Pnominal = nominal power of the installed equipment; and

Fac.Seg assumes a value of 1.25. The power required for barns A and B is 2386.02 W. The total number of inverters was determined based on the total power of the set of inverters, using the equation

where

PT system = total system power and

P inv = power of the type of inverter selected, so the total number of inverters required for barns A and B is 0.79 ≈ 1 unit. The selected inverter Beltt BEP3000SA (Xindun Power, Foshan, China) pure wave has a power value of 3000 W, so it can supply the needs of the system.

3.7. Unifilar and Distributive Diagram of the Photovoltaic Solar System

The proposed photovoltaic system model utilizes equipment with a useful lifespan of 15 to 25 years. It is expected to yield high energy production due to both technical and geographical factors. Voltage drops are estimated to remain within nominal ranges, representing insignificant values that ensure the longevity and proper operation of the equipment and materials used in the photovoltaic system.

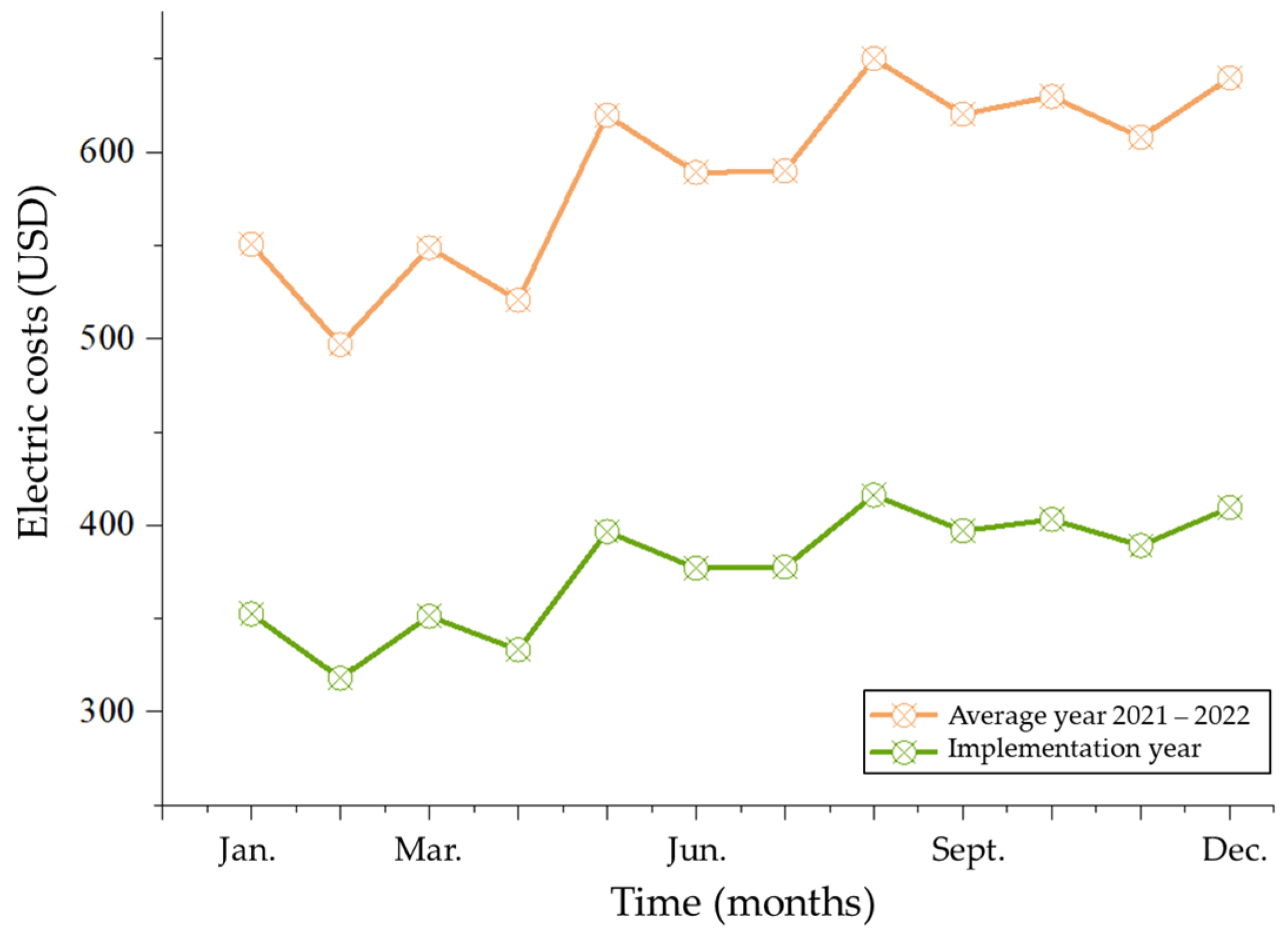

The poultry plant bills approximately USD 7100 per year for electricity costs. Through the implementation of the photovoltaic system, a decrease of 36% in the total is expected; this percentage covers the consumption of the barn area.

Figure 5 analyzes the decrease in electricity costs, considering an average under normal work situations. The photovoltaic system must be configured to work in energy production under standard measurement conditions, as most implementations do not operate under real parameters. That is why the selected inverter must be oversized to 3000 W and present a total capacity greater than the maximum charge of the determined system in order to guarantee standard operation.

4. Conclusions

In this work, we designed a modular photovoltaic system. It addresses the energy demand in the barns of a poultry plant. The main devices are used for supplying feed and hydrating birds. The barns’ consumption was 20,258 kWh per year. The photovoltaic system serves as a renewable energy source, enabling a 36% energy saving in poultry operations. This reduction lowers operating costs and supports a shift in the energy matrix. The geographical analysis of the area shows optimal conditions for solar generation. It has an average annual solar radiation of 4.67 kWh/m2/day and low cloudiness indices. These factors confirm the area’s suitability for solar energy generation. The specific characteristics of the system help ensure constant electricity production during working hours in the chicken barns. The expansion of the photovoltaic system should include an analysis of the distribution of energy loads, weights, and the space required for optimal performance.