Development of Jaw Controlled Wireless Navigation Governing System for Wheelchair to Empower Person with Impaired Upper Limb †

Abstract

1. Introduction

2. The Proposed Wheelchair Control System

- Data collection unit;

- Data processing unit and source;

- Mechanical unit.

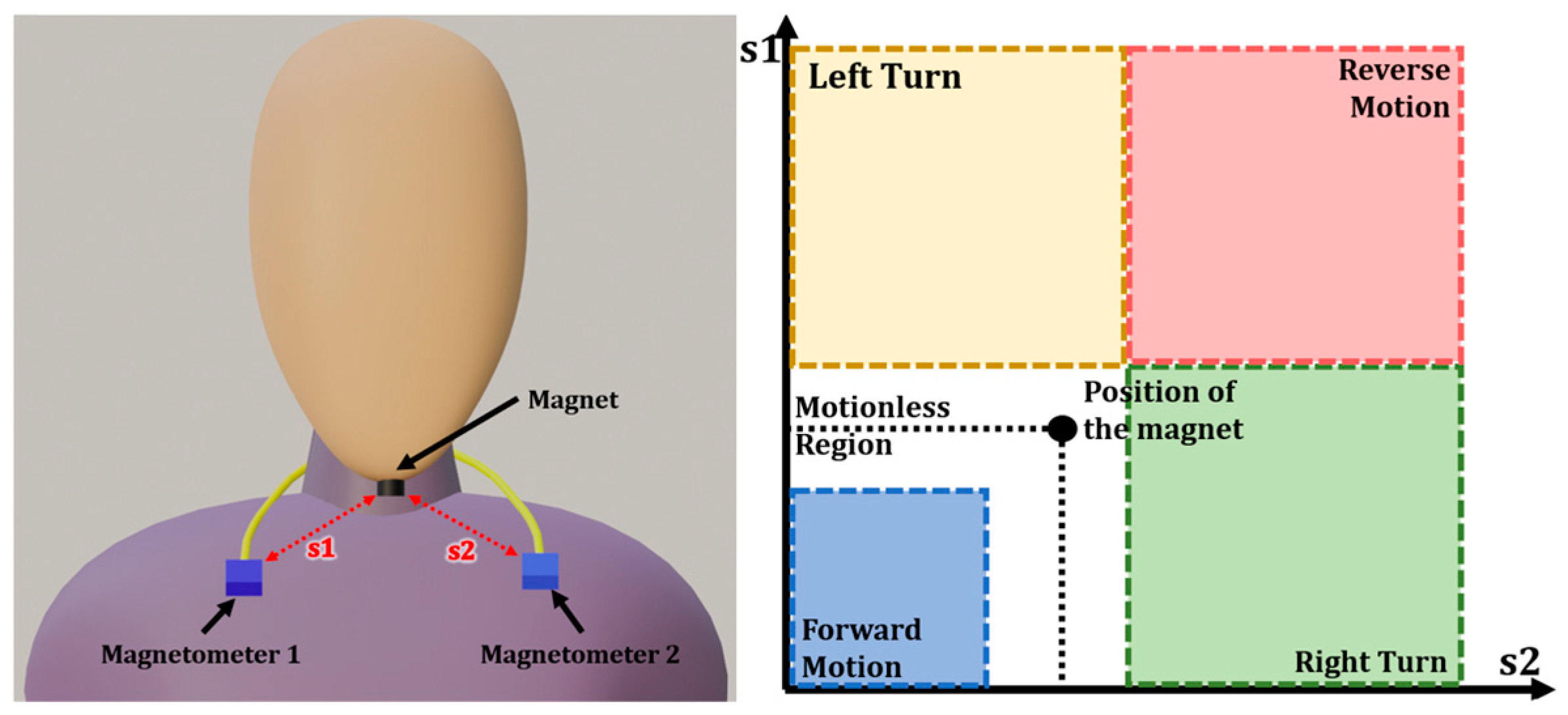

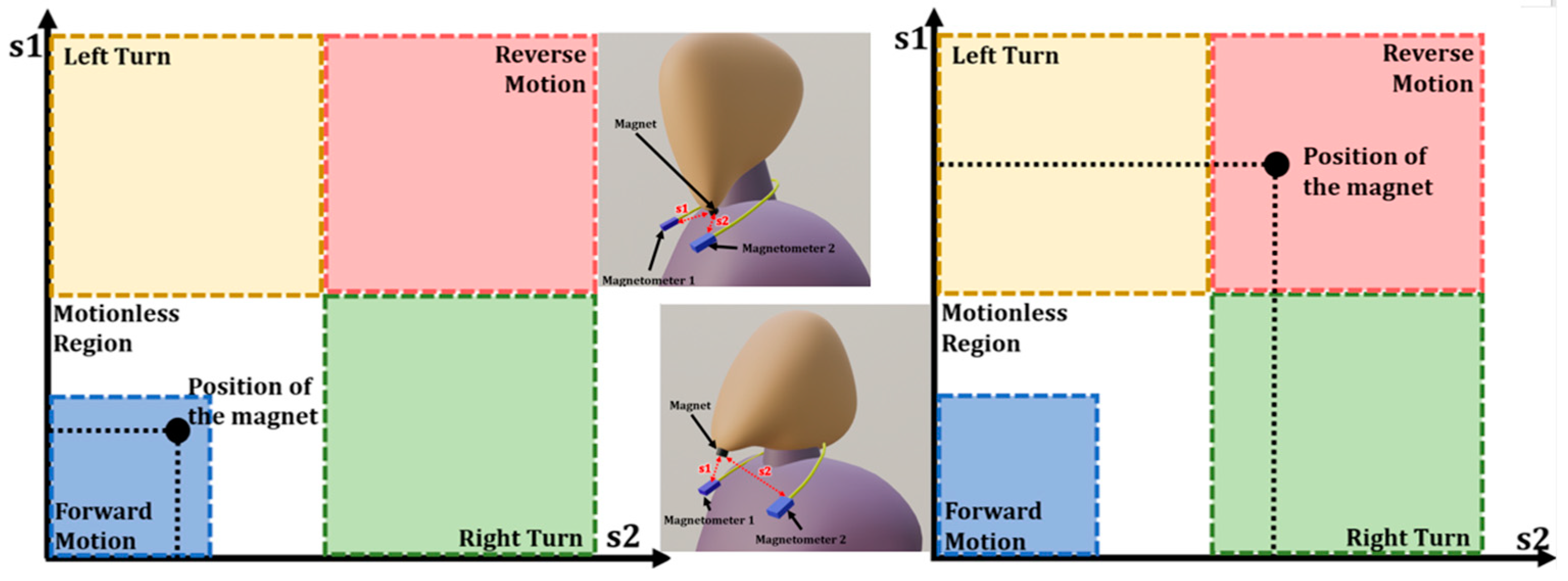

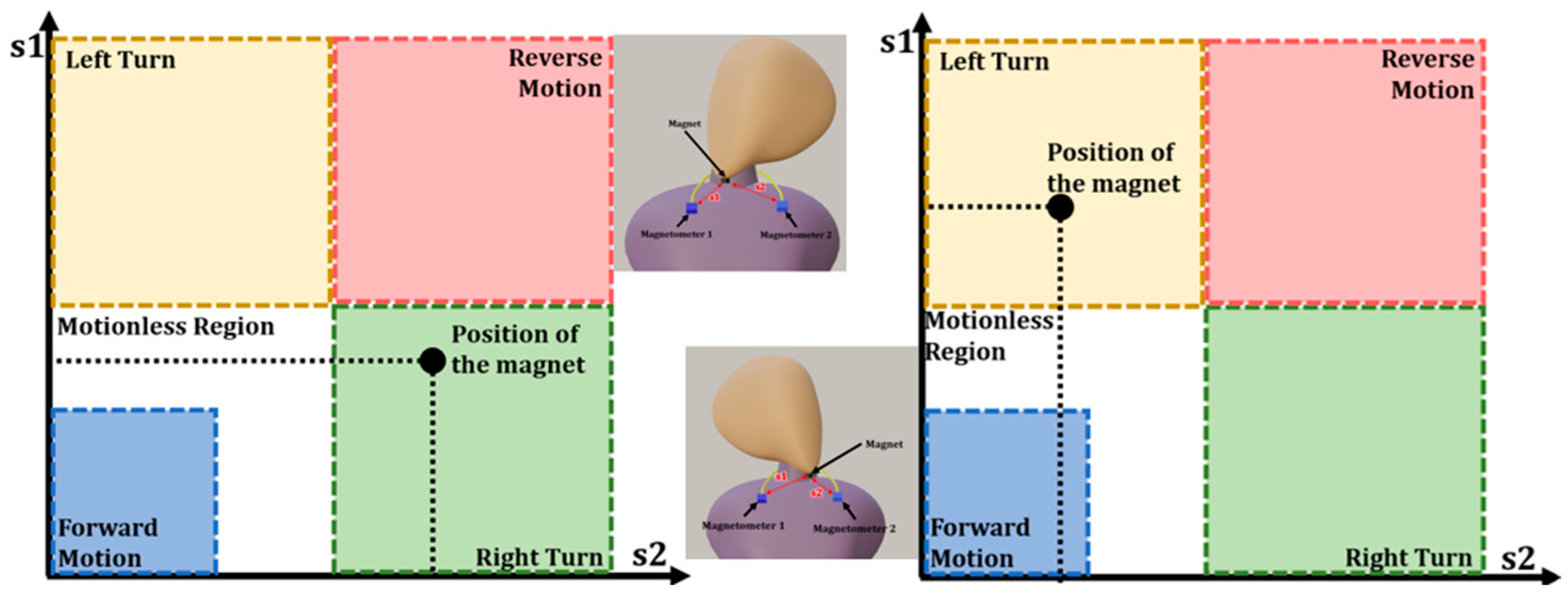

2.1. Data Collection Unit

2.2. Data Processing Unit and Source

2.3. Mechanical Unit

3. Working Process of the Proposed Wheelchair Control System

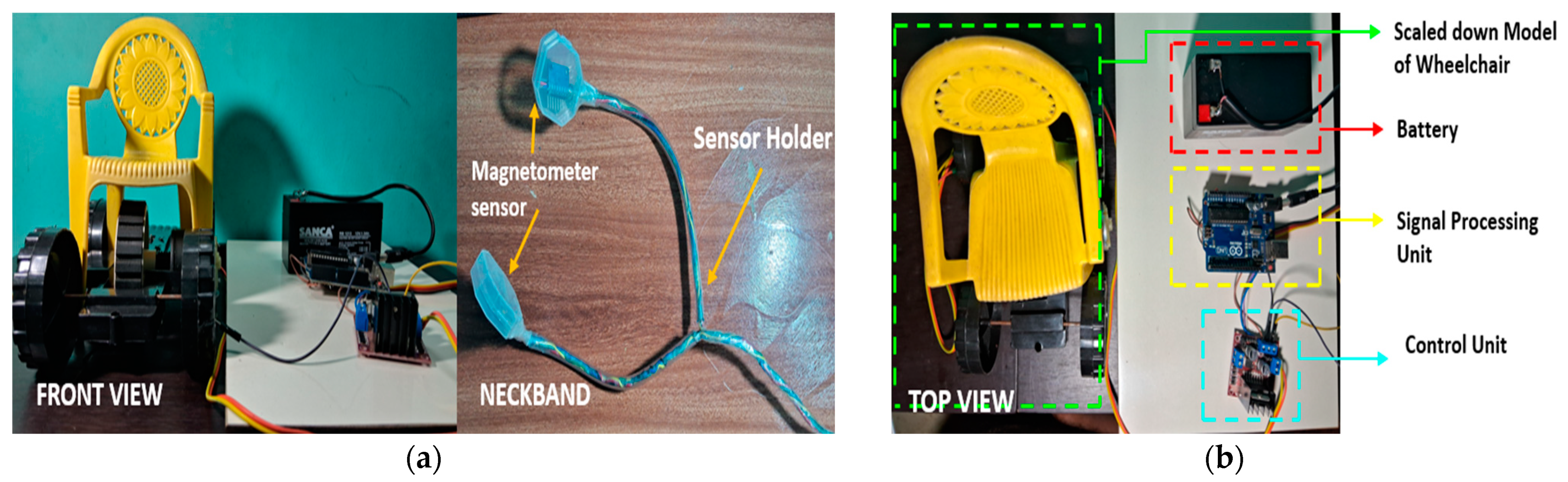

4. Hardware Setup for the Proposed Control System

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gottipati, P.; Dobzhanskyi, O.; Mendrela, E.A. In-wheel brushless DC motor for a wheel chair drive. In Proceedings of the 2010 Joint International Conference on Power Electronics, Drives and Energy Systems & 2010 Power India, New Delhi, India, 20–23 December 2010; pp. 1–4. [Google Scholar] [CrossRef]

- Wang, Q.; Chen, H.; Wu, W.; Jin, H.Y.; Heng, P.A. Real-Time Mandibular Angle Reduction Surgical Simulation With Haptic Rendering. IEEE Trans. Inf. Technol. Biomed. 2012, 16, 1105–1114. [Google Scholar] [CrossRef] [PubMed]

- Tang, T.; Zhu, M.; Chen, C.; Xu, Y. A Design of Mandibular Motion Tracking System Based on Video Processing. In Proceedings of the 2019 IEEE 4th Advanced Information Technology, Electronic and Automation Control Conference (IAEAC), Chengdu, China, 20–22 December 2019; pp. 1370–1374. [Google Scholar] [CrossRef]

- Shahin, M.K.; Tharwat, A.; Gaber, T.; Hassanien, A.E. A wheelchair control system using human-machine interaction: Single-modal and multimodal approaches. J. Intell. Syst. 2019, 28, 115–132. [Google Scholar] [CrossRef]

- Bokolo, A.J. Inclusive and safe mobility needs of senior citizens: Implications for age-friendly cities and communities. Urban Sci. 2023, 7, 103. [Google Scholar] [CrossRef]

- Huo, X.; Wang, J.; Ghovanloo, M. Wireless control of powered wheelchairs with tongue motion using tongue drive assistive technology. In Proceedings of the 2008 30th Annual International Conference of the IEEE Engineering in Medicine and Biology Society, Vancouver, BC, Canada, 20–25 August 2008; pp. 4199–4202. [Google Scholar]

- Krishnamurthy, G.; Ghovanloo, M. Tongue drive: A tongue operated magnetic sensor based wireless assistive technology for people with severe disabilities. In Proceedings of the 2006 IEEE international symposium on circuits and systems, Kos, Greece, 21–24 May 2006; p. 4. [Google Scholar]

- Acosta, D.; Fariña, B.; Toledo, J.; Sanchez, L.A. Low Cost Magnetic Field Control for Disabled People. Sensors 2023, 23, 1024. [Google Scholar] [CrossRef] [PubMed]

- Faria, B.M.; Reis, L.P.; Lau, N. A survey on intelligent wheelchair prototypes and simulators. In New Perspectives in Information Systems and Technologies; Springer International Publishing: Berlin/Heidelberg, Germany, 2014; Volume 1, pp. 545–557. [Google Scholar]

- Caltenco, H.A.; Breidegard, B.; Andreasen Struijk, L.N. On the tip of the tongue: Learning typing and pointing with an intra-oral computer interface. Disabil. Rehabil. Assist. Technol. 2014, 9, 307–317. [Google Scholar] [CrossRef] [PubMed]

- Dar, R.A.; Khatoon, S.; Saleem, B.; Khan, H. IOT Based Smart Wheelchair for Elderly Healthcare Monitoring. In Proceedings of the 2023 International Conference on Power, Instrumentation, Energy and Control (PIECON), Aligarh, India, 10–12 February 2023; pp. 1–6. [Google Scholar]

- Al Shabibi, M.A.K.; Kesavan, S.M. Iot based smart wheelchair for disabled people. In Proceedings of the 2021 International Conference on System, Computation, Automation and Networking (ICSCAN), Puducherry, India, 30–31 July 2021; pp. 1–6. [Google Scholar]

- Dwivedi, A.; Kumar, R.; Omer, P.; Singh, H.P.; Rahmani, U.; Gupta, K. Electric Wheelchair for Physically Disabled Person. In Proceedings of the 2023 International Conference on IoT, Communication and Automation Technology (ICICAT), Gorakhpur, India, 23–24 June 2023; pp. 1–6. [Google Scholar]

- Sebkhi, N.; Bhavsar, A.; Sahadat, N.; Baldwin, J.; Walling, E.; Biniker, A.; Hoefnagel, M.; Tonuzi, G.; Osborne, R.; Anderson, D.V.; et al. Evaluation of a head-tongue controller for power wheelchair driving by people with quadriplegia. IEEE Trans. Biomed. Eng. 2021, 69, 1302–1309. [Google Scholar] [CrossRef] [PubMed]

- Huang, C.K.; Wang, Z.W.; Chen, G.W.; Yang, C.Y. Development of a smart wheelchair with dual functions: Real-time control and automated guide. In Proceedings of the 2017 2nd International Conference on Control and Robotics Engineering (ICCRE), Bangkok, Thailand, 1–3 April 2017; pp. 73–76. [Google Scholar]

| Specification | Dimensions |

|---|---|

| Length (mm) | 14.8 |

| Width (mm) | 13.5 |

| Height (mm) | 3.5 |

| Weight (mm) | 2 |

| Condition | Motor 1 | Motor 2 | ||

|---|---|---|---|---|

| Direction of Rotation | Speed of the Motor (% of Max Speed) | Direction of Rotation | Speed of the Motor (% of Max Speed) | |

| Forward Motion | Forward | 90 | Forward | 90 |

| Reverse Motion | Reverse | 60 | Reverse | 60 |

| Left Turn | Forward | 40 | Forward | 100 |

| Right Turn | Forward | 100 | Forward | 40 |

| Component Name | Component Description |

|---|---|

| Arduino UNO | Microcontroller |

| HMCL 5883L | Magnetometer Sensor |

| L298N-2A | Isolation/Driver Circuit |

| MY1016 | Motor |

| Samarium Cobalt | Magnet |

| Battery | Lithium-ion battery |

| Specification | Description |

|---|---|

| Output Power | 24 W |

| Supply Voltage | 12 V |

| Rated Speed | 2200 RPM |

| No Load Speed | 2500 RPM |

| Full Load Current | <1.5 A |

| No Load Current | <0.5 A |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ravikumar, D.; Loganathan, V.; Pasumponthangaperumal, N.S.R.; Suresh Kumar, M.; Ponnovian, P.; Balan, B.E. Development of Jaw Controlled Wireless Navigation Governing System for Wheelchair to Empower Person with Impaired Upper Limb. Eng. Proc. 2025, 87, 10. https://doi.org/10.3390/engproc2025087010

Ravikumar D, Loganathan V, Pasumponthangaperumal NSR, Suresh Kumar M, Ponnovian P, Balan BE. Development of Jaw Controlled Wireless Navigation Governing System for Wheelchair to Empower Person with Impaired Upper Limb. Engineering Proceedings. 2025; 87(1):10. https://doi.org/10.3390/engproc2025087010

Chicago/Turabian StyleRavikumar, Dhanasekar, Vijayaraja Loganathan, Narenthira Sai Raam Pasumponthangaperumal, Mirthulaa Suresh Kumar, Pranav Ponnovian, and Benita Evangeline Balan. 2025. "Development of Jaw Controlled Wireless Navigation Governing System for Wheelchair to Empower Person with Impaired Upper Limb" Engineering Proceedings 87, no. 1: 10. https://doi.org/10.3390/engproc2025087010

APA StyleRavikumar, D., Loganathan, V., Pasumponthangaperumal, N. S. R., Suresh Kumar, M., Ponnovian, P., & Balan, B. E. (2025). Development of Jaw Controlled Wireless Navigation Governing System for Wheelchair to Empower Person with Impaired Upper Limb. Engineering Proceedings, 87(1), 10. https://doi.org/10.3390/engproc2025087010