1. Introduction

Gray cast iron, renowned for its excellent mechanical properties and ease of production, has played a pivotal role in the development of industrial components such as engine blocks, brake discs, and machine beds. Its superior castability, thermal conductivity, and vibration-damping capabilities make it indispensable in engineering applications [

1]. The microstructure of gray cast iron, dominated by graphite flakes embedded within a metallic matrix, is a key determinant of its performance characteristics. This microstructure is heavily influenced by the cooling rate during casting, which governs the size, distribution, and morphology of the graphite and matrix phases [

2].

Traditional sand molds, long favored for their flexibility and cost-effectiveness, dominate the casting industry. These molds are particularly advantageous for producing complex geometries and large components. However, the cooling rates achieved with sand molds are relatively low, leading to coarser microstructures and, in some cases, suboptimal mechanical properties. In contrast, metal molds, with their higher thermal conductivity, enable faster cooling rates, resulting in finer microstructures and improved hardness [

3]. As a newer technique, metal molds offer potential advantages for specific applications but need to be explored in detail in order to optimize their benefits for gray cast iron casting [

4].

The cooling rate during casting is a critical factor in determining the microstructural characteristics and, consequently, the mechanical properties of cast metals. In gray cast iron, higher cooling rates promote the formation of pearlite over ferrite in the matrix and refine graphite flakes, enhancing hardness and strength. This sensitivity to the cooling rate underpins the importance of understanding the interplay between the mold type, casting thickness, and material inoculation to tailor properties for industrial needs [

5].

Exploring the effects of thickness-dependent cooling dynamics in gray cast iron castings is crucial for advancing casting technologies. Variations in thickness influence heat dissipation, creating localized differences in cooling rates, which can lead to non-uniform properties within a single casting. Developing a comprehensive understanding of these effects is essential for optimizing component design and manufacturing processes [

6].

2. Materials and Methods

2.1. Materials

The material used in this study was gray cast iron conforming to ASTM A-48 standards [

7]. To enhance its properties, the gray cast iron was inoculated with 3.5% FeSi and 2.5% FeMn by weight during the liquid state. A CE Meter test was utilized to validate the liquid state and confirm the cast iron’s composition and characteristics before pouring.

2.2. Experimental Setup

The casting process employed green sand molds designed in an inverted triangular configuration, with each side measuring 100 mm in length. To monitor the cooling dynamics, three thermocouple probes were strategically installed on the inner surface of the mold. These probes recorded the temperature profile of the molten metal during solidification, as illustrated in

Figure 1.

2.3. Microstructure Analysis

To investigate the microstructural characteristics of the cast samples, metallographic examinations were conducted. The areas around the thermocouple installation points were sampled for analysis. The samples were observed under an Olympus Metallurgical Microscope (Olympus Corporation, Center Valley, CA, USA) at 200× magnification, adhering to the ASTM E3 standard [

8] for microstructural preparation and examination. This analysis provided insights into the effects of cooling rates on the microstructure.

2.4. Chemical Composition Testing

Chemical composition testing was performed to quantify the percentage of alloying elements present in the gray cast iron. This analysis ensured that the desired inoculation levels of FeSi and FeMn were achieved and that the chemical composition met the required specifications.

2.5. Hardness Testing

The Vickers hardness test was carried out to determine the hardness values of the cast samples, following ASTM E92 standards [

9]. The test locations were carefully selected, to ensure consistent and accurate measurements across different regions of the samples. This evaluation provided a correlation between cooling rates and the mechanical properties of the material.

3. Results and Discussions

3.1. Chemical Composition Analysis

The chemical composition analysis of inoculated and non-inoculated gray cast iron samples, presented in

Table 1, reveals significant differences in alloying elements. The inoculated samples show elevated levels of silicon (Si) and carbon (C), with Si increasing from 2.027% to 3.572% and C rising from 3.785% to 4.476%. This increase is attributed to the inoculation with 3.5% FeSi and 2.5% FeMn. Silicon acts as a graphite stabilizer, enhancing the formation of graphite over cementite, while also reducing the phosphorus (P) content by mitigating its reaction with iron. Consequently, the inoculated samples exhibit improved solidification characteristics, essential for refining the graphite morphology and enhancing the mechanical properties.

3.2. Cooling Rate Analysis

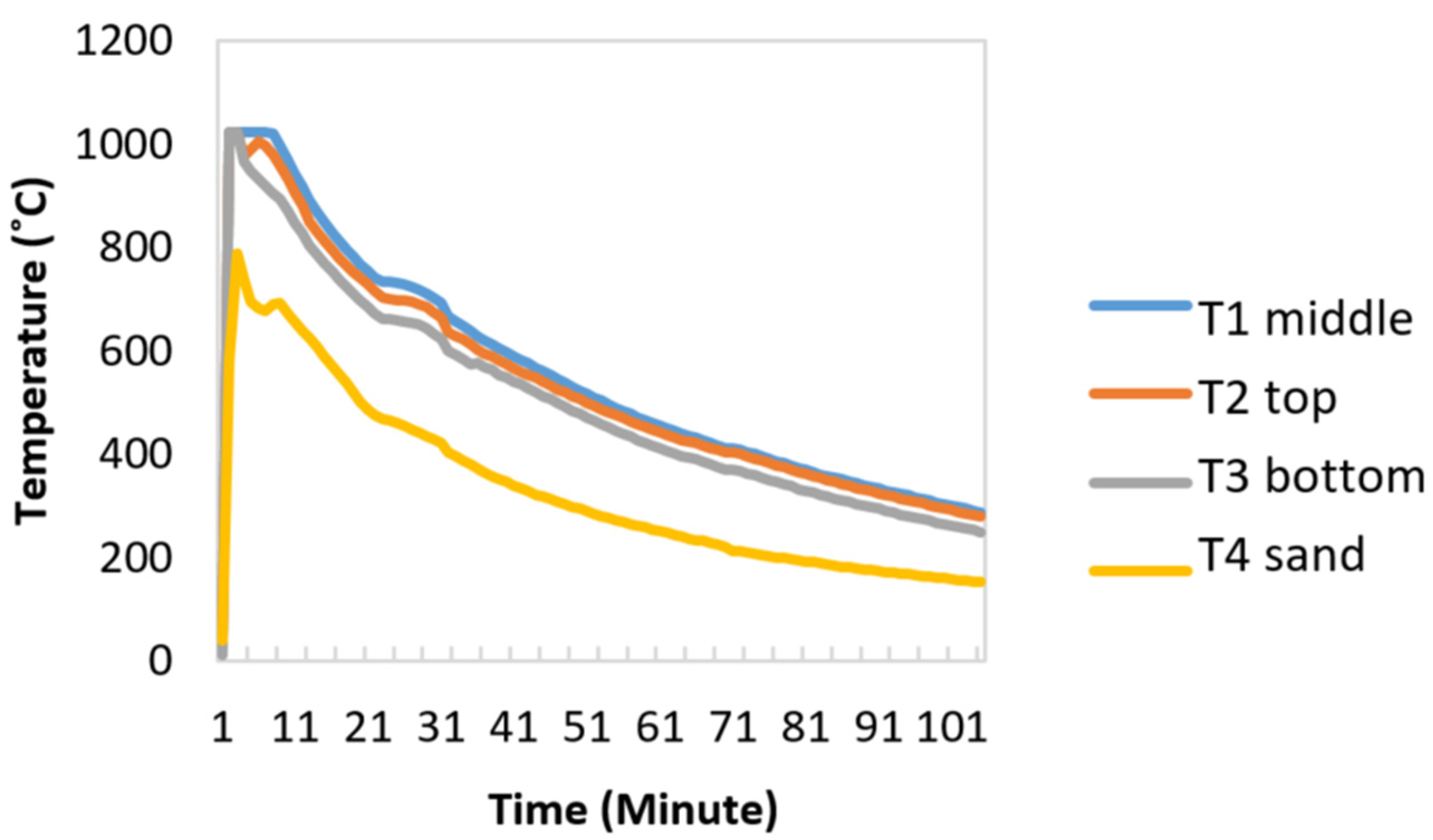

The cooling rate was monitored using thermocouples at three different thicknesses within the mold, as shown in

Figure 2. The data reveal subtle variations in cooling rates across the mold. The middle section, with a medium thickness, exhibited the highest cooling rate. This phenomenon is likely due to optimal heat dissipation in the medium-thickness region, whereas the thickest section experienced slower cooling due to a reduced surface area-to-volume ratio, and the thinnest section faced rapid cooling but lacked sufficient thermal mass to retain efficient heat transfer.

The cooling rates directly impact the microstructure, as the faster cooling rates in the medium section create finer microstructures, contributing to increased hardness. The comparison between sand molds and metal molds highlights that the latter provides higher cooling rates overall, which is beneficial for achieving more uniform and refined microstructures in gray cast iron.

3.3. SEM-EDS Results Analysis

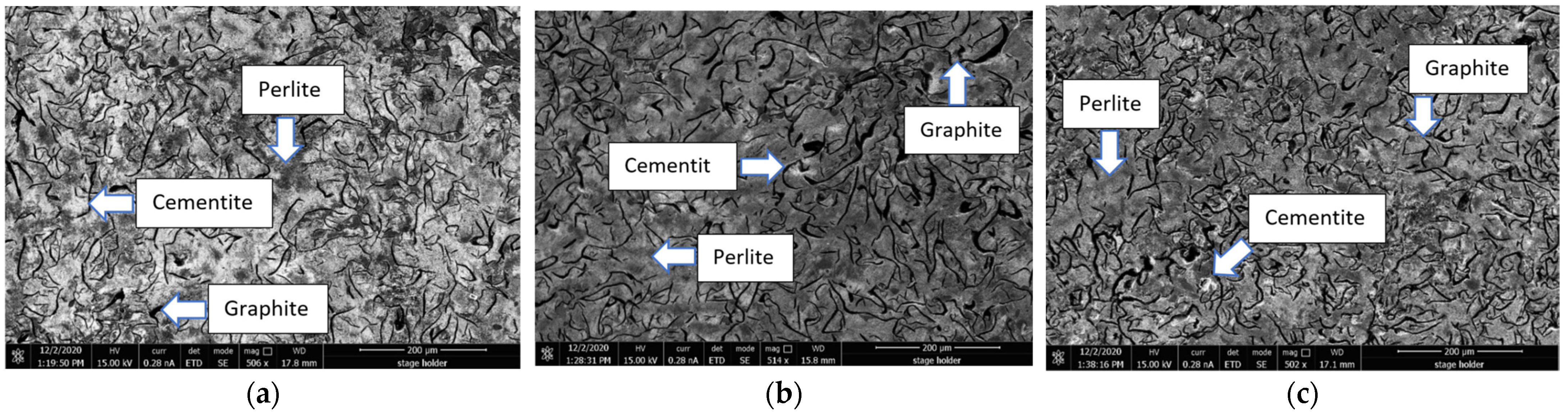

The SEM-EDS analysis of the cast samples demonstrated distinct variations in the morphology and distribution of graphite across different thicknesses.

Figure 3 illustrates these findings. The thinnest section (

Figure 3a) showed elongated graphite flakes with a higher number of thinner flakes, likely due to the faster cooling rates limiting graphite growth. In contrast, the medium-thickness section (

Figure 3b) exhibited thicker graphite flakes in reduced quantities, a characteristic of intermediate cooling rates. The thickest section (

Figure 3c) displayed shorter graphite flakes, attributed to slower cooling rates that allowed more time for graphite nucleation and growth.

The EDS analysis further confirmed elemental variations corresponding to these microstructural changes.

Table 2 (thinnest section/bottom),

Table 3 (medium section/middle), and

Table 4 (thickest section/top) detail the elemental compositions. The medium section, with higher cooling rates, showed slightly lower carbon and silicon contents compared to the thickest section, aligning with the observed microstructural refinement.

3.4. Hardness Analysis

The Vickers hardness test results, shown in

Table 5, indicate that the medium section achieved the highest hardness value (168.85 HV), while the thickest section recorded the lowest (123.83 HV). This trend correlates directly with the cooling rates and resultant microstructure. Faster cooling rates in the medium section facilitated the formation of finer graphite and pearlite structures, leading to improved hardness. Conversely, the thickest section, with slower cooling rates, experienced coarser microstructures and lower hardness.

The findings highlight the pivotal effect of the mold design, cooling rate, and inoculation on the microstructure and mechanical properties of gray cast iron. The addition of FeSi and FeMn inoculants significantly enhanced the chemical composition, particularly increasing the silicon and carbon levels, which promoted graphite stabilization and reduced the interference of phosphorus during solidification [

10]. This aligns with prior research emphasizing the importance of inoculants in refining the morphology of graphite and improving the performance of cast iron [

11].

The cooling rate, a critical factor in determining the microstructure, was highest in the medium-thickness region. This observation supports earlier studies showing that moderate thicknesses optimize heat dissipation, enabling finer microstructure formation and enhanced mechanical properties [

12]. In contrast, the thickest section, with slower cooling rates, exhibited coarser microstructures and reduced hardness, consistent with heat transfer principles and their impact on solidification dynamics [

13].

The SEM-EDS analysis provided valuable insights into the distribution and morphology of graphite, with notable differences across thicknesses. The medium-thickness region demonstrated the most desirable microstructural characteristics, including finer graphite flakes and a balanced matrix structure, attributed to the optimized cooling conditions. This further corroborates the relationship between the cooling rate, microstructure, and hardness in cast materials [

5,

13].

Overall, this study underscores the importance of controlling various casting parameters, including the mold type, thickness, and inoculation, to tailor the properties of gray cast iron for specific applications. The findings contribute to the development of more efficient casting practices and materials with superior performance characteristics.

4. Conclusions

The study demonstrates that inoculation with FeSi and FeMn significantly enhances the silicon (Si) content in gray cast iron, which in turn reduces the reactivity of phosphorus (P) with iron (Fe). This leads to an increase in carbon (C) levels during solidification, contributing to a more stable graphite structure and improved material properties. The chemical modifications induced by inoculation are critical for achieving desirable microstructural characteristics in the cast material.

The findings further reveal that the casting thickness plays a pivotal role in determining the cooling rate and resultant mechanical properties. Among the analyzed sections, the medium-thickness region exhibited the highest cooling rate, attributable to optimized heat dissipation. This led to the formation of finer microstructures, characterized by a refined graphite morphology and enhanced pearlite content, which significantly improved the hardness compared to the thinnest and thickest sections. These results underscore the importance of controlling the mold design, casting parameters, and thickness to achieve a superior performance in gray cast iron components.

This study highlights the synergistic effects of inoculation and cooling dynamics in optimizing the microstructure and mechanical properties of gray cast iron, providing valuable insights for advancing casting technologies and material design.

Author Contributions

The following are the author’s contributions: A.Y. prepared the materials and instruments, P.P. analyzed the data, A.D.A. composed the text, and N. carried out the experimental methods. All authors have read and agreed to the published version of the manuscript.

Funding

The Innovation and Research Office of Universitas Muhammadiyah Surakarta provided significant financial support for the study project under the Hibah Integrasi Tridharma (HIT), contract number 228/A.3-III/FT/VI/2022, for which the authors are grateful. They would like to express their gratitude to Universitas Muhammadiyah Surakarta’s Material Laboratory, Mechanical Engineering Department, and Engineering Faculty for their important contributions to the project.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

No new data were created or analyzed in this study. Data sharing is not applicable to this article.

Acknowledgments

The authors extend their heartfelt appreciation to Universitas Muhammadiyah Surakarta, especially the Innovation and Research office, for their substantial financial assistance. Furthermore, they extent their gratitude to the Mechanical Engineering Department and Material Laboratory at Universitas Muhammadiyah Surakarta for their significant contributions, which substantially improved our research.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Liao, Z.; Huang, X.; Zhang, F.; Li, Z.; Chen, S.; Shan, Q. Effect of WC mass fraction on the microstructure and frictional wear properties of WC/Fe matrix composites. Int. J. Refract. Met. Hard Mater. 2023, 114, 106265. [Google Scholar] [CrossRef]

- Yu, W.; Wang, Y.; Li, Y.; Qian, X.; Wang, H.; Zhou, C.; Wang, Z.; Xu, G. Texture evolution, segregation behavior, and mechanical properties of 2060 Al-Li (aluminium-lithium) composites reinforced by TiC (titanium carbide) nanoparticles. Compos. Part B Eng. 2023, 255, 110611. [Google Scholar] [CrossRef]

- Zhong, H.; Lin, Z.; Han, Q.; Song, J.; Chen, M.; Chen, X.; Li, L.; Zhai, Q. Hot tearing behavior of AZ91D magnesium alloy. J. Magnes. Alloys 2023, 12, 3431–3440. [Google Scholar] [CrossRef]

- Anil, K.C.; Kumaraswamy, J.; Akash; Sanman, S. Experimental arrangement for estimation of metal-mold boundary heat flux during gravity chill casting. Mater. Today Proc. 2023, 72, 2013–2020. [Google Scholar] [CrossRef]

- Abdellah, M.Y.; Fadhl, B.M.; Abu El-Ainin, H.M.; Hassan, M.K.; Backar, A.H.; Mohamed, A.F. Experimental Evaluation of Mechanical and Tribological Properties of Segregated Al-Mg-Si Alloy Filled with Alumina and Silicon Carbide through Different Types of Casting Molds. Metals 2023, 13, 316. [Google Scholar] [CrossRef]

- Zhang, B.; Hungund, A.P.; Alla, D.R.; Neelakandan, D.P.; Roman, M.; O’Malley, R.J.; Bartlett, L.; Gerald, R.E.; Huang, J. Advancing Aluminum Casting Optimization With Real-Time Temperature and Gap Measurements Using Optical Fiber Sensors at the Metal-Mold Interface. IEEE Trans. Instrum. Meas. 2023, 72, 7008412. [Google Scholar] [CrossRef]

- Available online: https://www.astm.org/a0048_a0048m-22.html (accessed on 10 July 2024).

- Available online: https://www.astm.org/e0003-11r17.html (accessed on 10 July 2024).

- Available online: https://www.astm.org/e0092-17.html (accessed on 10 July 2024).

- Amarulloh, A.; Haikal, H.; Atmoko, N.T.; Utomo, B.R.; Setiadhi, D.; Marchant, D.; Zhu, X.; Riyadi, T.W.B. Effect of power and diameter on temperature and frequency in induction heating process of AISI 4140 steel. Mech. Eng. Soc. Ind. 2022, 2, 26–34. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, L.; Zhang, Y.; Cheng, G.; Wang, Y.; Ren, Y.; Yang, W. Prediction of spatial composition distribution of inclusions in the continuous casting bloom of a bearing steel under unsteady casting. ISIJ Int. 2021, 61, 824–833. [Google Scholar] [CrossRef]

- Zhong, H.; Wang, R.; Han, Q.; Fang, M.; Yuan, H.; Song, L.; Xie, X.; Zhai, Q. Solidification structure and central segregation of 6Cr13Mo stainless steel under simulated continuous casting conditions. J. Mater. Res. Technol. 2022, 20, 3408–3419. [Google Scholar] [CrossRef]

- Wang, F.; Yin, D.; Lv, J.; Zhang, S.; Ma, M.; Zhang, X.; Liu, R. Effect of cooling rate on fluidity and glass-forming ability of Zr-based amorphous alloys using different molds. J. Mater. Process. Technol. 2021, 292, 117051. [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).