1. Introduction

The distributed nature of cyber-physical systems (CPSs) makes them easily expandable and reconfigurable to accept more motors or other components. Scalability and flexibility are further enhanced by this architecture. Industries such as transportation, industrial manufacturing, and solar and wind power benefit greatly from this inherent scalability because operating demands are always changing [

1]. Furthermore, CPSs excel in optimizing energy efficiency and resource use through intelligent control and coordination components [

2]. Using continuous information from sensor devices integrated into each motor unit, CPSs automatically modify operation-related parameters to enhance system performance, save operational costs, and boost efficiency [

3]. Rate of acceleration, power consumption, and top speed are all examples of such metrics.

By combining conventional electric motors together with the enhanced intelligence and connectivity provided by the Internet of Things (IoT), electrical drives have undergone significant change in terms of integration [

3]. Examining how the motor current signature analysis (MCSA) method and real-time data transfer from IoT sensing sites can work together to enhance industrial condition monitoring and fault diagnosis is the focus of this study. This method aims to improve industrial system monitoring efficiency and dependability [

4].

Smart manufacturing and progress in industrial automation are making distributed motor systems (DMSs) popular in many industries. These include robotics, energy, transportation, and manufacturing. These motor systems are the backbone of modern manufacturing’s efficacy and efficiency [

5]. Because these systems are more prone to mistakes and failures as they get larger and more complicated, they can cause downtime, inefficient operations, and even safety hazards. The complexity of many modern distributed motor systems makes it impossible to find problems with them using either simple condition monitoring systems or manual inspections. Intelligent fault detection methods that are more advanced are required so that failures can be anticipated and mitigated. Integrating cyber-physical sensor networks with artificial intelligence (AI) could be a solution to this problem by making dispersed motor systems better at detecting defects.

Recent years have seen widespread industry-wide disruption due to the advent of AI-powered computerized data analysis and decision-making. AI can analyze massive volumes of sensor data in real time, spot irregularities, and reliably forecast breakdowns in decentralized motor systems. This is especially useful for distributed motor systems, where a number of motors work in tandem but are often located in awkward or otherwise unattractive locations. AI can constantly monitor these systems for wear, misalignment, overheating, and other faults that could destroy them. AI fault detection improves system reliability, repair expenses, unexpected downtime, and electric motor life expectancy [

6].

Artificial intelligence’s capability for flaw detection has been greatly improved by the emergence of CPSs. Smart and dynamic networks for continuous control and monitoring are created by CPSs by integrating actuators, sensing devices, and motors with computer systems [

7]. In DMSs, CPSs are crucial because they lay the groundwork for real-time data collecting and transmission. Real-time data collection, processing, and analysis using cyber-physical sensor networks provides a complete picture of the motor system’s condition and efficiency. Because artificial intelligence algorithms may be deployed right to the data streams, they can identify patterns and abnormalities that conventional approaches might overlook, allowing for faster and more accurate defect identification.

As a future-oriented approach to system management, predictive maintenance is made possible by combining AI with CPSs. Rather than waiting for a problem to occur before performing maintenance, predictive maintenance can foresee possible problems and allow operators to take precautions. Improved distributed motor system efficiency is the result of shifting from responsive to proactive maintenance, which involves executing checks only when absolutely necessary and cuts down on interruptions [

8]. In addition, downtime may be minimized and resources allocated efficiently with the help of AI-powered predictive maintenance, which improves repair scheduling.

There are a number of obstacles that prevent AI-driven cyber-physical sensor networks from being effectively used for failure detection in distributed motor systems, despite the fact that they show great potential. Managing the massive volumes of data generated by a multitude of sensors, which can number in the hundreds or even thousands, each continuously emitting streams of information, poses a significant difficulty [

9]. A powerful computer architecture and sophisticated algorithms are required for the real-time processing of this data in order to efficiently remove superfluous data while preserving crucial insights. As an added precaution, it is critical to keep these systems secure and reliable; otherwise, they could be vulnerable to cyberattacks or operational failures.

Private and academic entities have studied and developed wireless sensor networks (WSNs) for industrial machines [

3]. A central computer handles data fusion and extraction in these solutions, which focus on data collection and signal transmission. To enhance data processing efficiency and energy conservation at sensor nodes, some techniques include problem identification at the point of data collection [

10]. Motor fault identification and status monitoring by industrial wireless sensor networks (IWSNs) must consider industrial operations and motor characteristics [

4]. Some industrial applications require high sample rates, fast data transmission, and data reliability, yet IWSNs have limited computational resources, wireless internet access, and lasting power. IWSN resource constraints make system needs challenging to balance.

In order to better detect faults in distributed motor systems, this research aims to investigate how cyber-physical sensor networks driven by AI can do just that. This study intends to contribute to the growing pool of literature on intelligent defect detection by investigating the potential benefits and drawbacks of integrating AI with sensor networks. The following sections will explore the most recent developments in artificial intelligence (AI) and cyber-physical systems (CPSs), the limitations of traditional fault detection methods, and the benefits of integrating AI-powered solutions into DMSs. By delving into the ways AI can revolutionize problem detection and maintenance procedures, this investigation will shed light on how to build industrial systems that are more resilient and efficient. The literature is lacking in several key areas:

Many studies have focused on comparing healthy and malfunctioning motors to diagnose their condition and performance. However, distributed multi-motor systems, whose interconnected motors may send incorrect signals throughout the network, have not been studied.

Problems with analysis owing to non-linear interference from industrial noise signals and the fact that problem symptoms in power-line networks are similar across machines make fault detection difficult to implement in dispersed motor networks.

Few studies have examined how load fluctuations affect fault frequency component amplitudes under healthy and defective situations.

The rest of the article is structured as follows: The proposed framework is in

Section 2. In

Section 3, we offer the experimental results and accompanying remarks. In

Section 4, we conclude the study and suggest directions for further research.

2. Framework for Distributed Motor Network Signature Analysis and Fault Type Diagnosis

A typical industrial multi-motor power-line network’s structural arrangement is examined to show how fault signals spread and can be identified along the main power bus. As signals travel through the network, their closeness influences how other motors respond. The arrangement of various measurement sites used to track motor activity takes a number of aspects into account when connecting induction motors over a common supply bus. Connected motors, categorized bus bars, and a primary power bus make up the model. Multiple measurement sites are assumed at important points to monitor distinct motor behaviors inside a particular bus system. This allows us to measure the performance of fault diagnostics by evaluating our findings at each point.

The main objective of this research is to demonstrate how well fault signal detection at the node level may work by examining the corresponding spectrum. Important considerations to consider while diagnosing power-line network issues include the background noise, fault signal propagation, numerous routes of interference from surrounding nodes, and the incidence of similar failures across different nodes. There must also be accurate fault localization in the power-line network.

Figure 1 depicts the research framework used for fault diagnosis in this study, which is a distributed framework for multi-motor designs that incorporates wireless sensor network (WSN) connectivity.

Figure 1 presents the concept of distributed signature analysis, where electric current signals from multiple sensing points are observed to enhance fault diagnosis accuracy. By leveraging data from various points, this approach clarifies fault symptoms affected by network noise. It focuses on identifying faulty motors within the power-line network, analyzing signal attenuation, and understanding fault signal propagation paths. Wireless sensor network (WSN) nodes play a key role in data collection, fault diagnosis, noise identification, and monitoring neighboring nodes, with alerts sent to the coordinator when faults are suspected. This framework offers a more reliable solution, especially when direct measurement methods are unavailable.

3. Experimental Testbed Setup and Results

Experimental motor networks were created and tested by researchers at AUT’s SeNSe lab to show how fault signals can be transmitted throughout a power-line structure and to identify various types of faults. Two different-sized single-phase induction motors were connected to a primary power bus. A multi-motor network was replicated using a total of nine induction motors, which were spread among three sub-buses, as illustrated in

Figure 2.

In

Figure 3, we can see the experimental configuration of the Arduino system. It contains a current sensor that takes readings from the ground and sends them to the Arduino for processing.

To demonstrate the theory and show how a fault signal can influence the properties of neighboring motors based on their distance from the source, a case study was conducted, as shown in

Figure 2. Two similarly sized motors (Motor 5 and Motor 9) from buses 2 and 3 were selected to observe the impact of faulty signals on other motors within the same or different buses. Additionally, a high-power motor (Motor 1) was chosen to introduce a stronger faulty signal for better fault discrimination. Three sensing points were used to measure the fault signal strength at different locations within the motor network. Electric current spectra and amplitude values from all motors are examined in

Figure 4 and

Figure 5. A failure signal for eccentricity occurred at the same harmonic point, as shown in

Figure 5, although the magnitude of the signal varied with motor magnitude and distance from Motor 1. From Motors 5 and 9, BRB faults spread with different intensities. Distance made Motor 1 less impacted by BRB faults, yet its eccentricity fault caused a large amplitude.

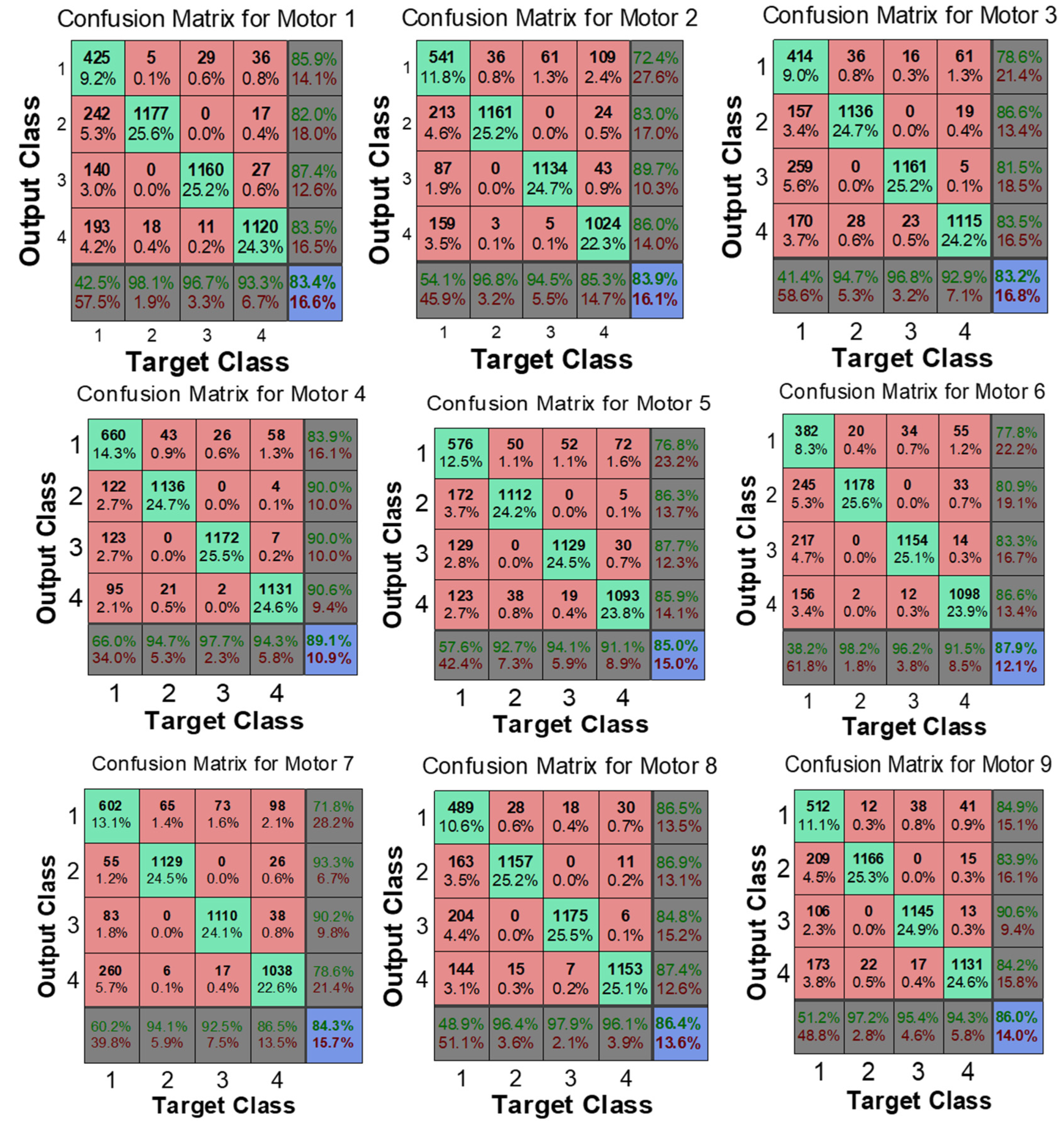

Figure 6 presents the confusion matrices for the three phases of training, testing, and validation of each motor, respectively.

Table 1 shows that satisfactory accuracy, ranging from 83% to 89%, was achieved in fault detection within the feature vector. This indicates the efficiency of the ANN network in handling multiple faults, even when similar fault types appear in other motor spectrums, causing ambiguity in identifying the fault source.

4. Conclusions and Future Directions

This research explored fault detection in distributed motors using the Internet of Electric Drives (IoED) concept, proposing a cyber-physical system architecture for accurate fault identification. The system combined a distributed Internet of Things (DIoT) approach with FFT for signal processing and an ANN for fault detection. FFT extracted frequency features, while the ANN enhanced accuracy through pattern recognition. Experimental results showed real-time fault classification capabilities. The system successfully modeled two motor faults (BRB and ECE) based on existing spectrum patterns, accounting for motor size differences and fault signal propagation. A wireless sensor network (IWSN) using XBee modules simulated an industrial multi-motor environment. Output data demonstrated close accuracy between simulated and real-time sensor measurements. However, signal complexity in the distributed network caused interference and misclassification. This study also developed a decision-level fusion for more efficient and complex fault diagnosis.

This research lays a foundation for future work, but several areas need further exploration: optimizing cyber-physical system architecture for scalability, enhancing simulations for fault detection in induction motors, expanding fault analysis to other fault types, exploring advanced diagnostic methods like fuzzy logic and Bayesian inference, ensuring compatibility with diverse IoT platforms, and developing adaptive fault detection mechanisms for evolving operational conditions and new fault types in distributed motor systems.