Untethered Flight of a 5 cm Micro Vehicle Powered by an Onboard Capacitor †

Abstract

1. Introduction

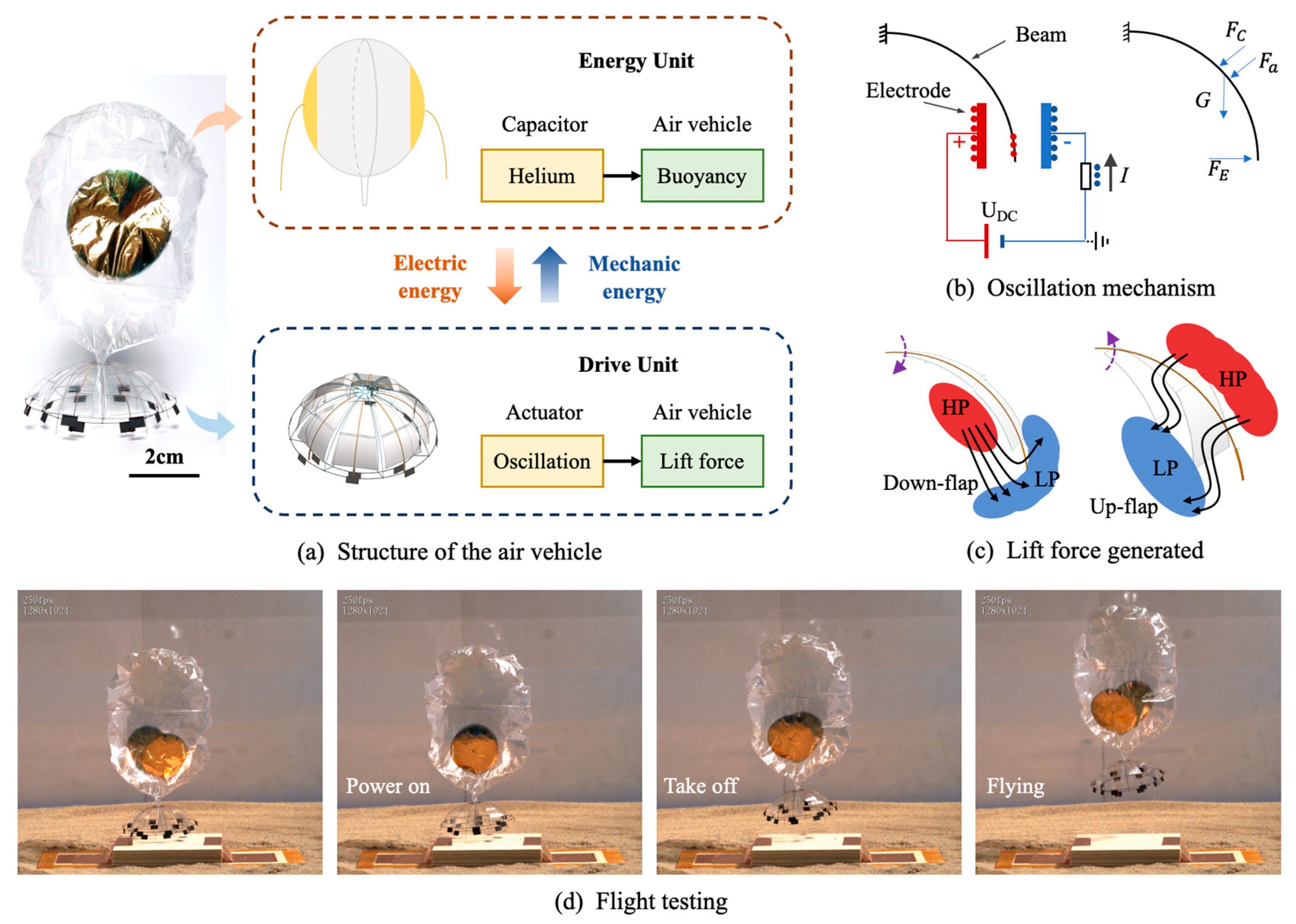

2. General Design of the Air Vehicle

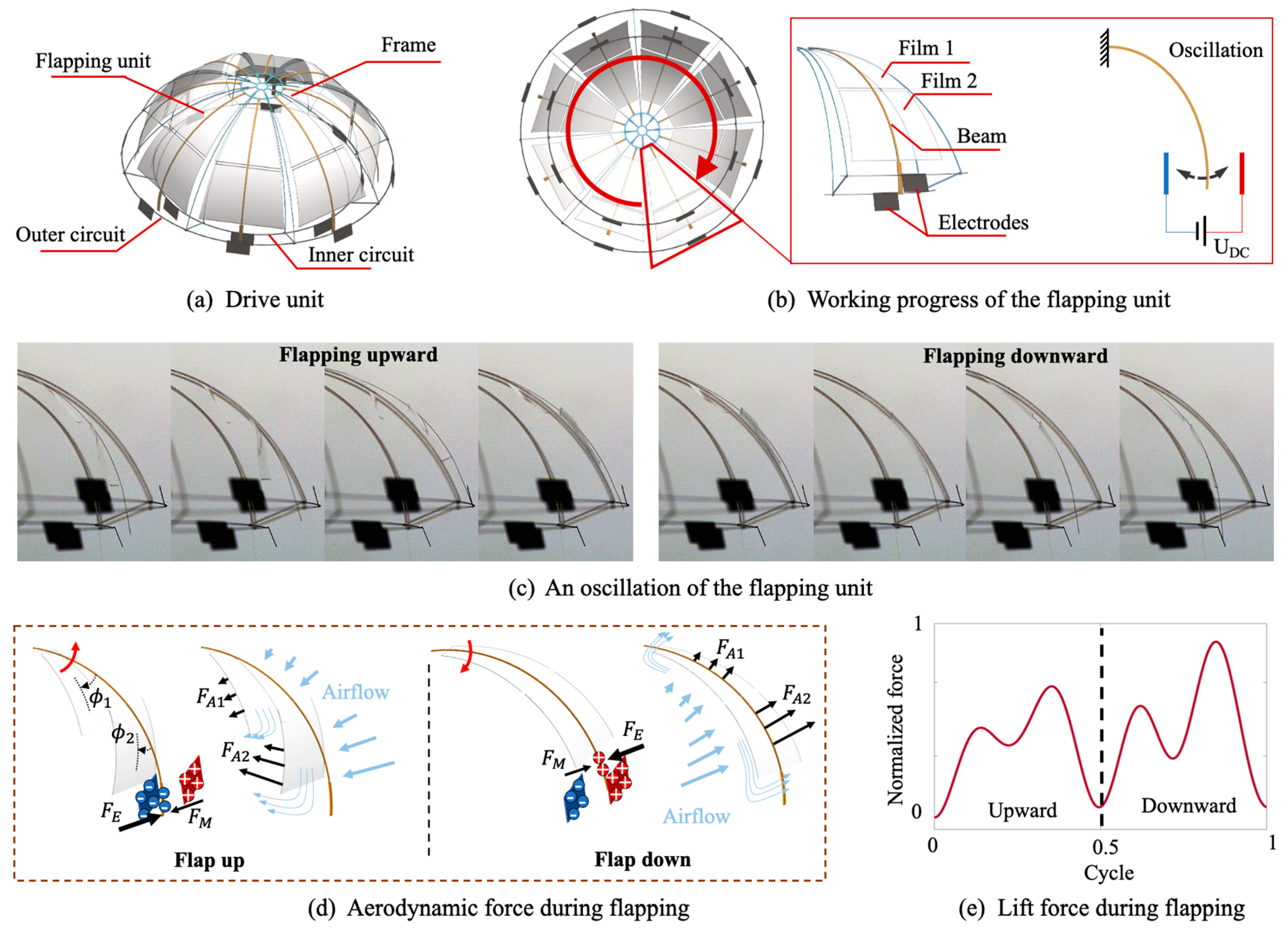

3. Drive Unit

3.1. Actuator Structural Design

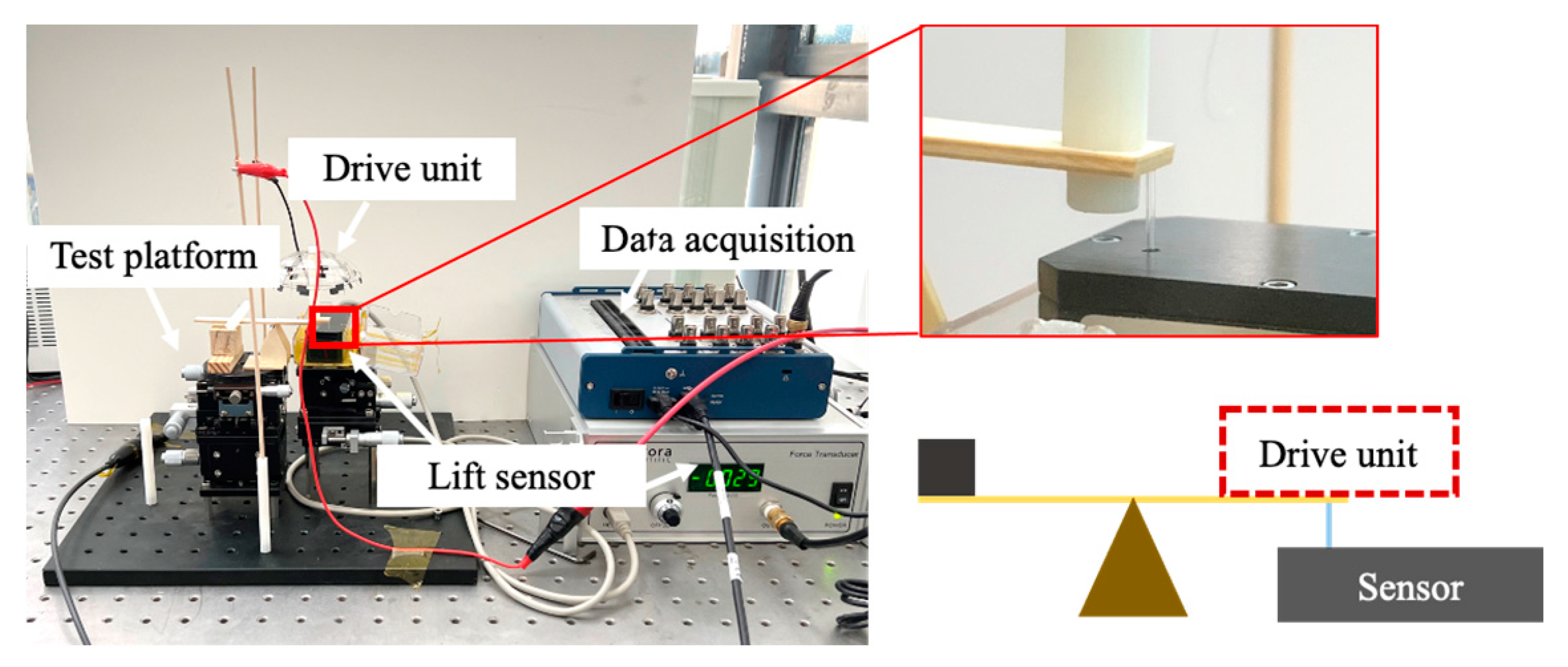

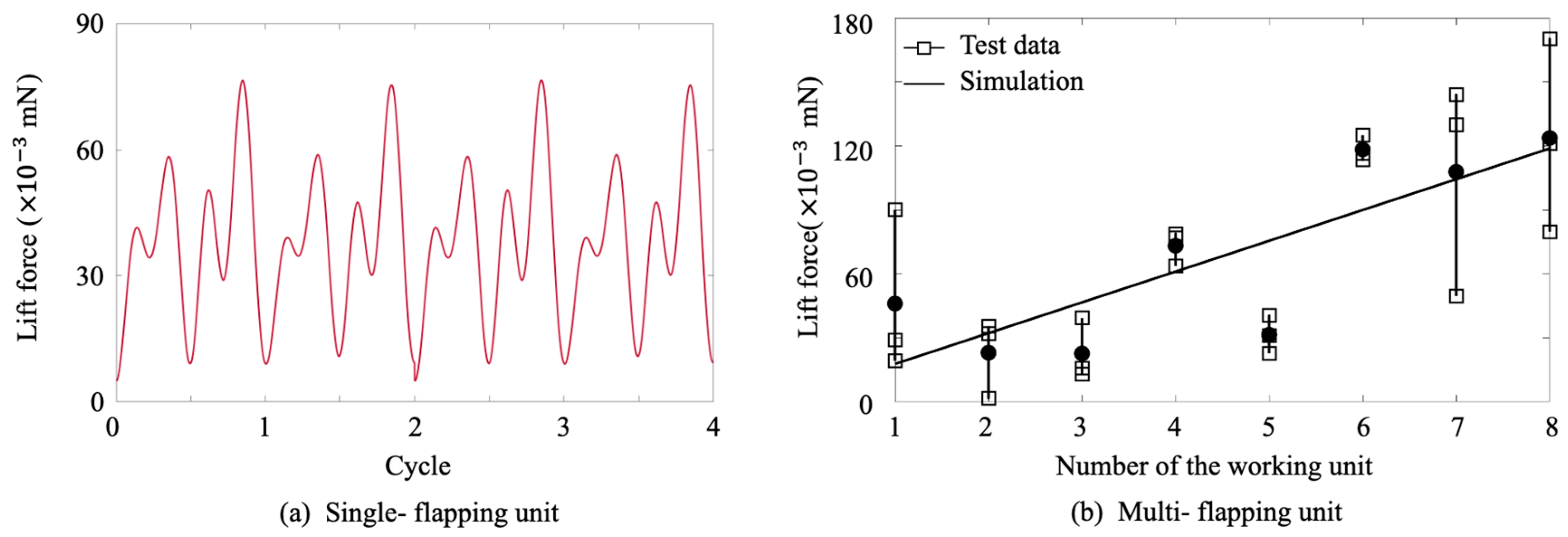

3.2. Thrust Testing

4. Energy Supply Units

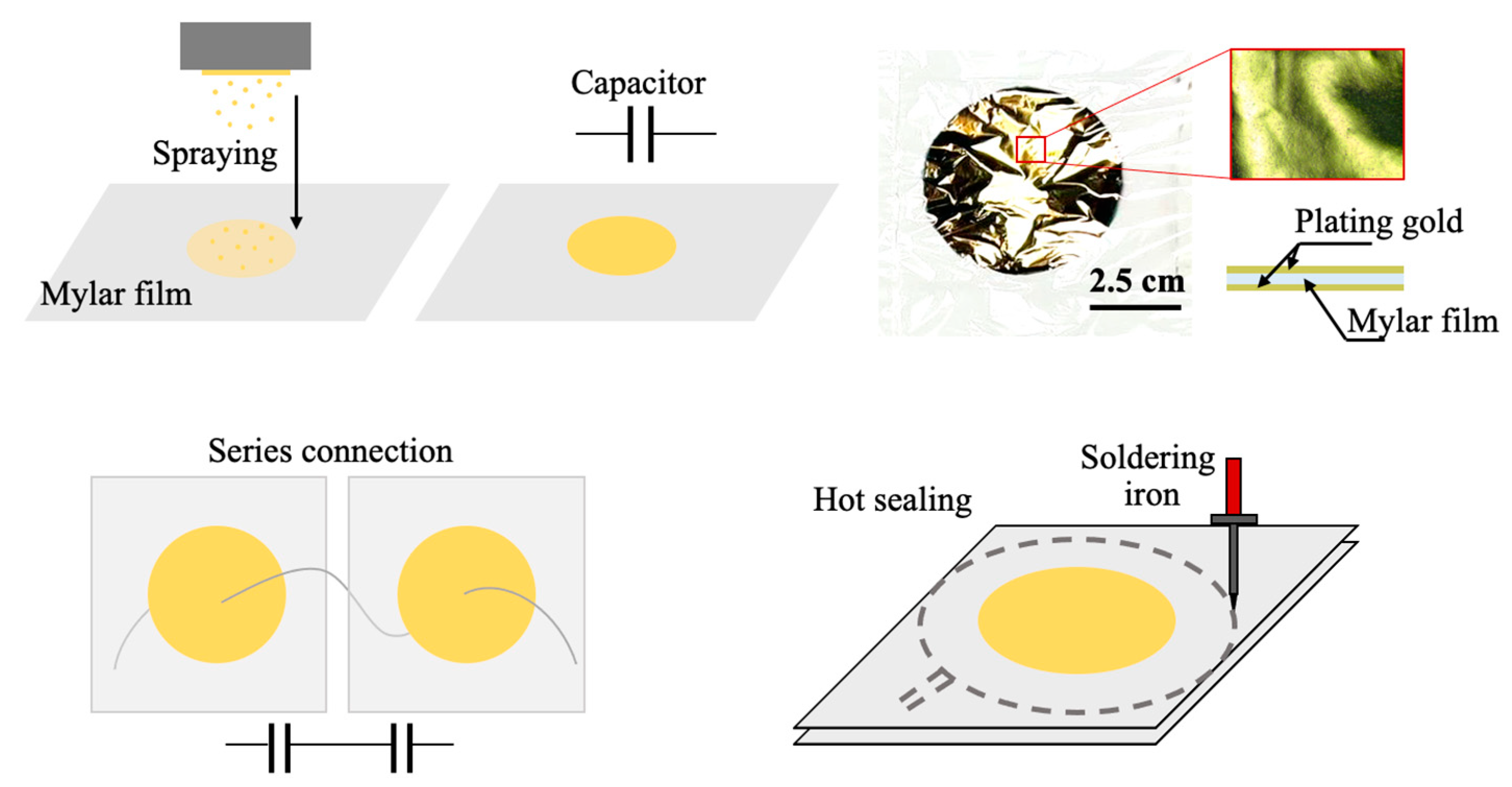

4.1. Energy Storage Capacitor Design

4.2. Energy Supply Analysis

4.3. Flight Motion

4.4. Research Perspectives

5. Discussion and Conclusions

- (1)

- Adopting multiple flapping units gave the driving unit the ability to work stably. The thrust generated by a single flapping unit in one cycle was 0.032 mN, and that generated by multiple flapping units was 0.127 mN, while the mass of the whole drive unit was 105 mg with a thrust-to-weight ratio of 0.123.

- (2)

- The drive unit consumed only 48 nA of current and 0.112 mW of power. The lower power consumption will allow the drive unit to be powered by a structural capacitor or a solar cell in the future due to the energy unit providing the required energy consumption.

- (3)

- Filling the film capacitor with helium provided buoyancy for the micro-vehicle, and the energy stored in the structural capacitor provided energy for the drive unit. The capacitance value of a single capacitor was 12.76 nF, and the breakdown voltage could reach 1300 ± 50 V. The twin capacitors were connected in series to satisfy the working voltage of 2400 V.

- (4)

- The maximum flight speed of the vehicle reached 16.67 cm/s in a confined space; the vehicle had good flight performance and low working noise; and the stable flight time was more than 60 s when powered by the capacitor.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Phan, H.V.; Park, H.C. Insect-inspired, tailless, hover-capable flapping-wing robots: Recent progress, challenges, and future directions. Prog. Aerosp. Sci. 2019, 111, 100573. [Google Scholar] [CrossRef]

- Helbling, E.F.; Wood, R. A Review of Propulsion, Power, and Control Architectures for Insect-Scale Flapping-Wing Vehicles. Appl. Mech. Rev. 2018, 70, 010801. [Google Scholar] [CrossRef]

- Zhang, C.; Rossi, C. A review of compliant transmission mechanisms for bio-inspired flapping-wing micro air vehicles. Bioinspir. Biomim. 2017, 12, 025005. [Google Scholar] [CrossRef]

- Xiao, S.; Hu, K.; Huang, B.; Deng, H.; Ding, X. A Review of Research on the Mechanical Design of Hoverable Flapping Wing Micro-Air Vehicles. J. Bionic Eng. 2021, 18, 1235–1254. [Google Scholar] [CrossRef]

- Holness, A.E.; Bruck, H.A.; Gupta, S.K. Characterizing and modeling the enhancement of lift and payload capacity resulting from thrust augmentation in a propeller-assisted flapping wing air vehicle. Int. J. Micro Air Veh. 2018, 10, 50–69. [Google Scholar] [CrossRef]

- Nguyen, Q.V.; Chan, W.L. Development and flight performance of a biologically-inspired tailless flapping-wing micro air vehicle with wing stroke plane modulation. Bioinspir. Biomim. 2019, 14, 016015. [Google Scholar] [CrossRef]

- Tijmons, S.; Karásek, M.; Croon, G.D. Attitude control system for a lightweight flapping wing MAV. Bioinspir. Biomim. 2018, 13, 056004. [Google Scholar] [CrossRef] [PubMed]

- Karasek, M.; Muijres, F.T.; De Wagter, C.; Remes, B.D.W.; de Croon, G. A tailless aerial robotic flapper reveals that flies use torque coupling in rapid banked turns. Science 2018, 361, 1089–1094. [Google Scholar] [CrossRef] [PubMed]

- Wagter, C.D.; Karásek, M.; Croon, G.D. Quad-thopter: Tailless Flapping Wing Robot with 4 Pairs of Wings. In Proceedings of the 9th International Micro Air Vehicles Conference and Flight Competition 2017, Toulouse, France, 18–21 September 2017. [Google Scholar]

- Phan, H.V.; Park, H.C. Mechanisms of collision recovery in flying beetles and flapping-wing robots. Science 2020, 370, 1214–1219. [Google Scholar] [CrossRef] [PubMed]

- Zufferey, R.; Ancel, A.O.; Farinha, A.; Siddall, R.; Armanini, S.F.; Nasr, M.; Brahmal, R.V.; Kennedy, G.; Kovac, M. Consecutive aquatic jump-gliding with water-reactive fuel. Sci. Robot. 2019, 4, eaax7330. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.F.; Wang, H.Q.; Helbling, E.F.; Jafferis, N.T.; Zufferey, R.; Ong, A.; Ma, K.; Gravish, N.; Chirarattananon, P.; Kovac, M.; et al. A biologically inspired, flapping-wing, hybrid aerial-aquatic microrobot. Sci. Robot. 2017, 2, eaao5619. [Google Scholar] [CrossRef]

- Chukewad, Y.M.; Singh, A.T.; James, J.M.; Fuller, S.B.; Kosecka, J. A New Robot Fly Design That is Easier to Fabricate and Capable of Flight and Ground Locomotion. In Proceedings of the 2018 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Madrid, Spain, 1–5 October 2018; pp. 4875–4882. [Google Scholar]

- Tu, Z.; Fei, F.; Zhang, J.; Deng, X. An At-Scale Tailless Flapping-Wing Hummingbird Robot. I. Design, Optimization, and Experimental Validation. IEEE Trans. Robot. 2020, 36, 1511–1525. [Google Scholar] [CrossRef]

- Festo. Taking a Close Look at Wings in Nature; Festo: Hongkong, China, 2018. [Google Scholar]

- Chen, J.; Pakdel, E.; Xie, W.; Sun, L.; Xu, M.; Liu, Q.; Wang, D. High-Performance Natural Melanin/Poly(vinyl Alcohol-co-ethylene) Nanofibers/PA6 Fiber for Twisted and Coiled Fiber-Based Actuator. Adv. Fiber Mater. 2020, 2, 64–73. [Google Scholar] [CrossRef]

- Hines, L.; Petersen, K.; Lum, G.Z.; Sitti, M. Soft Actuators for Small-Scale Robotics. Adv. Mater. 2017, 29, 1603483. [Google Scholar] [CrossRef] [PubMed]

- Ilami, M.; Bagheri, H.; Ahmed, R.; Skowronek, E.O.; Marvi, H. Materials, Actuators, and Sensors for Soft Bioinspired Robots. Adv. Mater. 2021, 33, 2003139. [Google Scholar] [CrossRef] [PubMed]

- Guo, G.; Wu, Q.; Liu, F.; Yin, J.; Wu, Z.L.; Zheng, Q.; Qian, J. Solvent-Cast-Assisted Printing of Biomimetic Morphing Hydrogel Structures with Solvent Evaporation-Induced Swelling Mismatch. Adv. Funct. Mater. 2022, 32, 2108548. [Google Scholar] [CrossRef]

- Li, Z.; Ye, Z.; Han, L.; Fan, Q.; Wu, C.; Ding, D.; Xin, H.L.; Myung, N.V.; Yin, Y. Polarization-Modulated Multidirectional Photothermal Actuators. Adv. Mater. 2021, 33, 2006367. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Wang, J.; Ikeda, T.; Jiang, L. Liquid-Phase Super Photoactuator through the Synergetic Effects of a Janus Structure and Solvent/Thermal/Photo Responses. Adv. Funct. Mater. 2021, 31, 2105728. [Google Scholar] [CrossRef]

- Chung, H.-J.; Parsons, A.M.; Zheng, L. Magnetically Controlled Soft Robotics Utilizing Elastomers and Gels in Actuation: A Review. Adv. Intell. Syst. 2021, 3, 2000186. [Google Scholar] [CrossRef]

- Wood, R.J. The first takeoff of a biologically inspired at-scale robotic insect. IEEE Trans. Robot. 2008, 24, 341–347. [Google Scholar] [CrossRef]

- Karpelson, M.; Wei, G.Y.; Wood, R.J. Driving high voltage piezoelectric actuators in microrobotic applications. Sens. Actuators A-Phys. 2012, 176, 78–89. [Google Scholar] [CrossRef]

- Pulskamp, J.S.; Polcawich, R.G.; Rudy, R.Q.; Bedair, S.S.; Proie, R.M.; Ivanov, T.; Smith, G.L. Piezoelectric PZT MEMS technologies for small-scale robotics and RF applications. MRS Bull. 2012, 37, 1062–1070. [Google Scholar] [CrossRef]

- Chirarattananon, P.; Ma, K.Y.; Wood, R.J. Adaptive control of a millimeter-scale flapping-wing robot. Bioinspir. Biomim. 2014, 9, 025004. [Google Scholar] [CrossRef] [PubMed]

- Fuller, S.B.; Karpelson, M.; Censi, A.; Ma, K.Y.; Wood, R.J. Controlling free flight of a robotic fly using an onboard vision sensor inspired by insect ocelli. J. R. Soc. Interface 2014, 11, 20140281. [Google Scholar] [CrossRef] [PubMed]

- Lok, M.; Helbling, E.F.; Zhang, X.; Wood, R.; Brooks, D.; Wei, G.Y. A Low Mass Power Electronics Unit to Drive Piezoelectric Actuators for Flying Microrobots. IEEE Trans. Power Electron. 2018, 33, 3180–3191. [Google Scholar] [CrossRef]

- Chen, Y.; Zhao, H.; Mao, J.; Chirarattananon, P.; Wood, R.J. Controlled flight of a microrobot powered by soft artificial muscles. Nature 2019, 575, 324–329. [Google Scholar] [CrossRef] [PubMed]

- Jafferis, N.T.; Helbling, E.F.; Karpelson, M.; Wood, R.J. Untethered flight of an insect-sized flapping-wing microscale aerial vehicle. Nature 2019, 570, 491–495. [Google Scholar] [CrossRef]

- Shen, W.; Peng, J.; Ma, R.; Wu, J.; Li, J.; Liu, Z.; Leng, J.; Yan, X.; Qi, M. Sunlight-powered sustained flight of an ultralight micro aerial vehicle. Nature 2024, 631, 537–543. [Google Scholar] [CrossRef]

- James, J.; Iyer, V.; Chukewad, Y.; Gollakota, S.; Fuller, S.B. Liftoff of a 190 mg Laser-Powered Aerial Vehicle: The Lightest Wireless Robot to Fly. In Proceedings of the 2018 IEEE International Conference on Robotics and Automation (ICRA), Brisbane, Australia, 21–25 May 2018; pp. 3587–3594. [Google Scholar]

- Ozaki, T.; Ohta, N.; Jimbo, T.; Hamaguchi, K. A wireless radiofrequency-powered insect-scale flapping-wing aerial vehicle. Nat. Electron. 2021, 4, 845–852. [Google Scholar] [CrossRef]

- Hines, L.; Campolo, D.; Sitti, M. Liftoff of a Motor-Driven, Flapping-Wing Microaerial Vehicle Capable of Resonance. IEEE Trans. Robot. 2014, 30, 220–232. [Google Scholar] [CrossRef]

- Chin, D.D.; Lentink, D. Flapping wing aerodynamics: From insects to vertebrates. J. Exp. Biol. 2016, 219, 920–932. [Google Scholar] [CrossRef] [PubMed]

- Dickinson, M.H.; Lehmann, F.O.; Sane, S.P. Wing rotation and the aerodynamic basis of insect flight. Science 1999, 284, 1954–1960. [Google Scholar] [CrossRef] [PubMed]

- Sane, S.P.; Dickinson, M.H. The control of flight force by a flapping wing: Lift and drag production. J. Exp. Biol. 2001, 204, 2607–2626. [Google Scholar] [CrossRef] [PubMed]

- Fry, S.N.; Sayaman, R.; Dickinson, M.H. The aerodynamics of hovering flight in Drosophila. J. Exp. Biol. 2005, 208, 2303–2318. [Google Scholar] [CrossRef]

| Name | Unit |

|---|---|

| Lift force | 0.127 mN |

| Mass | 105 mg |

| Consumption power | 0.112 mW |

| Thrust-to-weight ratio | 0.123 |

| Thrust-to-power ratio | 1.134 N/W |

| Name | Parameter |

|---|---|

| Spray radiul, Rc | 22.5 mm |

| Spray area, S | 1590 mm2 |

| Capacitance, C | 12.76 nF |

| Stored charge, Q | 16.828 μC |

| Endurance, T | 60 s |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yun, R.; Zhou, L.; Wang, R.; Bao, J.; Zhou, J. Untethered Flight of a 5 cm Micro Vehicle Powered by an Onboard Capacitor. Eng. Proc. 2024, 80, 8. https://doi.org/10.3390/engproc2024080008

Yun R, Zhou L, Wang R, Bao J, Zhou J. Untethered Flight of a 5 cm Micro Vehicle Powered by an Onboard Capacitor. Engineering Proceedings. 2024; 80(1):8. https://doi.org/10.3390/engproc2024080008

Chicago/Turabian StyleYun, Ruide, Long Zhou, Ruiwen Wang, Junbo Bao, and Jian Zhou. 2024. "Untethered Flight of a 5 cm Micro Vehicle Powered by an Onboard Capacitor" Engineering Proceedings 80, no. 1: 8. https://doi.org/10.3390/engproc2024080008

APA StyleYun, R., Zhou, L., Wang, R., Bao, J., & Zhou, J. (2024). Untethered Flight of a 5 cm Micro Vehicle Powered by an Onboard Capacitor. Engineering Proceedings, 80(1), 8. https://doi.org/10.3390/engproc2024080008