1. Introduction

The automotive industry of today is rapidly changing. The increasing spread of highly electrified vehicles (hybrid and full-battery electric vehicles) and the application possibility of e-fuels (fuel from sustainable sources) are the two main driving forces in the automotive industry of today, and this rapid process provides a significant number of new challenges for the subsystems of these drivetrains [

1]. The lubrication of the engines, transmissions, and other machines is becoming increasingly vital for providing humanity with a cleaner and more sustainable future. As lubricants can significantly impact the overall energy losses of the used machines, optimizing these liquids can save a vast amount of energy. It is a common tendency for these liquids to be prepared with lower viscosity values to decrease the internal friction between the lubricant molecules. Still, the role of surface-protecting additives is increasing because of the thinner separation layer between the contacting surfaces. One possible technical solution can be the application of nanoscale particles inside the lubricants to ensure the smooth operation of the machines by decreasing the frictional losses and providing a longer component lifetime by minimizing the wear losses [

2].

Nanoscale particles are usually made of ceramic materials because of their excellent mechanical and chemical properties. Their shape is diverse, typically spherical, and their average particle diameter is below 100 nm [

3]. There is considerable diversity in the material composition of nanoscale additives: metal oxides (TiO

2, CuO, Fe

3O

4, ZnO, Co

3O

4, Al

2O

3, etc.), metal sulfides (MoS

2, WS

2, FeS, etc.), nanocomposites (Cu/CeO

2, Al

2O

3/SiO

2, ZrO

2/SiO

2, etc.), and rare earth compounds (cerium, yttrium, and lanthanum compounds) [

4].

The size of the nanoparticles can strongly influence the operation behavior of the nanoparticles. Peña-Parás et al. [

5] published evidence of a correlation between the average particle size and the average roughness parameters of the contacting surfaces: nanoparticles can only positively influence the tribosystem if their size is smaller than the surface roughness. Otherwise, they form larger micron-scale clusters, increasing the three-body abrasion effect and worsening the investigated system's tribological parameters. Different nanoparticle types and compounds can provide different working mechanisms to the rubbing surfaces according to [

6]; rolling, mending, polishing, and protective film-forming mechanisms were published. One of the biggest challenges is the homogenization of the nanoparticles into the used liquid because the particles become sedimented by the liquid molecules; the only question unanswered is when this occurs. A proper homogenization method can delay this saturation effect. Akl et al. [

2] compared one- and two-step homogenization methods using an ultrasonic homogenizer and magnetic stirrer to produce a homogeneous nanoparticle mixture. The authors developed a unique homogenization method [

7] to provide nanolubricant samples with a saturation time of multiple weeks. This method prepares a modified coating layer on the surface of each nanoparticle from ethyl oleate, and this layer increases the stable dispersion-producing effect of the nanoparticles and hydrocarbon-based oils used for the vehicles of today.

Zinc oxide nanoparticles (NPs) are chemicals with at least one dimension less than 100 nm. Nanoscale zinc oxide occurs in closed compositional phases only. The α, β, and γ polytypes are the most common ones. Their structures are based on the hexagonal closest packing of oxygen atoms, with Zn atoms occupying one-third of the close-packed planes. The α polytype can exist in brass as a naturally occurring mineral. These morphologies present features such as spherical shapes, different morphologies, and hierarchical structures [

8,

9,

10]. Nanoscale zinc oxide is a versatile material with widespread applications in various sectors of technological progress. It is used in transparent UV-blocking coatings, pigment inks, transparent conductive oxide thin films, varistors and gas sensors, piezoelectric devices, different types of devices for water purification, and the textile industry. The appearance of nanoscale zinc oxide has been greatly motivated by the needs of the semiconductor industry, optoelectronics, and photonic crystals [

11].

Zinc oxide nanoparticles were investigated by Hernández Battez et al. [

12]; nearly spherical particles (hexagonal, 20 nm average diameter) were homogenized in a PAO 6 base oil at three different concentrations (0.5, 1, and 2 wt%), and the authors presented the best tribological results in the case of the 0.5 wt% concentration. Alves et al. [

13] have investigated the tribological effects of ZnO nanoparticles (average diameter 11.71 nm) in four different base oil variations (mineral, PAO synthetic, sunflower, and soybean oil). The results showed that the friction coefficient was only reduced in the case of mineral and synthetic base oils by 5 and 12%, respectively. They suggested that the positive effect of the nanoparticles can only be achieved if they are used in a proper base liquid. Otherwise, the protective film-forming mechanism cannot be established and the three-body abrasion friction and wear process increases the tribological properties of the tested tribosystem.

The main statement of the results of the previously presented literature is that the synergies between the nanoparticles, base oils, and contacting surfaces are among the critical factors for achieving the possible lowest tribological losses. It is common in the literature that there is no worldwide accepted general testing method and equipment used for these experiments, complicating the comparison of different nanolubricants. This article aims to investigate a nanoscale spherical zinc oxide particle in base oils used in the automotive industry. The authors aim to investigate the applicability of widely known nanoparticles with the same methodology. This manuscript is part of a big research project which aims to support the lubrication industry in developing a lubricant with better overall performance.

2. Materials and Methodology

For the investigation, nanoscale spherical zinc oxide particles (CAS-No: 1314-13-2) were purchased from Reanal Laborvegyszer Kereskedelmi Kft (Budapest, Hungary), with an average particle diameter of lower than 50 nm BET and with 97% purity. The nanoparticles were surface-activated by ethyl oleate [

7], which produced a coating on the outer surface of the nanoparticles. The surface-activated nanoparticles were homogenized into a neat Group-III-type base oil (kinematic viscosity of 4 cSt measured on 100 °C, provided by MOL-LUB Ltd., Almásfüzitő, Hungary) at 5 different NP concentrations between 0.1 and 0.5 wt%, with an increasing step of 0.1 wt%. A unique, three-step homogenization method was used to prepare the nanolubricant variations: the surface-activated particles were firstly added into the Group III base oil by using a magnetic stirrer for 15 minutes under laboratory temperature conditions, followed by an ultrasonic homogenization procedure for 15 minutes at 70 °C to loosen the bounding forces between each nanoparticle, and the samples were stirred afterward until they filled the oil circuit of the investigation machine to ensure the most homogeneous and coherent status of the nanolubricant variation at each measurement. The kinematic viscosity and the density of the prepared nanolubricants were measured by using an Anton Paar SVM 3001 viscometer (Anton Paar GmbH., Graz, Austria), enabling us to analyze the viscosity influencing the effect of the nanoparticles.

An Optimol SRV

®5 type tribometer (Optimol Instruments GmbH., Munich, Germany) was used for the experiment, which was located in the Tribological Laboratory of the Széchenyi István University, the Department of Propulsion Technology in Győr, Hungary. The nanolubricant variations were tested with the ball-on-disc module of the tribometer. The ball and the disc specimens correlate with the ISO 19291:2016 international standards [

14], made of 100Cr6 steel (1.3505). The 10 mm diameter ball specimens were polished at an Ra value of 0.025 ± 0.005 µm and had a hardness value of 60 ± 2 HRC. In comparison, the disc specimens (ø 24 mm × 6.9 mm) were vacuum arc remelted, and through heat treatment, they were spheroidized and annealed. The flat surfaces were grinded and lapped (62 ± 1 HRC, Ra = 0.035–0.05 µm). The testing specimens were cleaned in an ultrasonic bath (50 °C temperature, 15-minute duration) using brake disc cleaner to remove the dust and contamination from their surface and ensure the same starting conditions for the whole tribosystem. A three-step tribological testing program was used to measure the frictional coefficient established between the contacting surfaces of the testing specimens: a preheating step to ensure the starting conditions (50 N preload and 100 °C heating temperature), a 30-second lasting run-in phase to ensure the required tribofilm between the surfaces (50 N load), and a 2 h test where the protective properties of the nanolubricants were tested (150 N load). During the test, a predefined sinusoidal oscillation movement pattern was applied (1 mm stroke and 50 Hz frequency), and the testing temperature was kept constant. A separately preheated external oil circuit was realized with the help of a peristaltic oil pump (100 °C temperature and 225 mL/h oil flow rate) to ensure the proper oil flow toward the contacting surfaces and to ensure the local overheat protection of the tiny contacting surfaces. The integral average of the measured friction coefficient values was calculated automatically by the controlling computer of the tribometer, which was recorded with a 1 s data-saving frequency.

The worn surfaces were analyzed with digital (Keyence VHX-1000, Keyence International, Mechlin, Belgium) and confocal (Leica DCM 3D, Leica Camera AG, Wetzlar, Germany) microscopes to measure the mean wear scar diameter (MWSD) according to ISO 19291:2016 [

14] (measuring the diameter of the circular wear pattern parallel and perpendicular to the sliding direction and calculating their average value) and calculate the missing volume of the surface (digitalizing the surface including a predefined non-worn surface area, placing a virtual plane on the non-worn surface points by using the least squares method, and calculating the volume under this plane inside the worn area of the surface). Furthermore, a Hitachi S-3400N (Hitachi Ltd., Chiyoda, Tokyo, Japan) scanning electron microscope was also used to define the characteristic wear marks on the surface and the distribution of zinc oxide nanoparticles on the surface.

3. Experimental Results

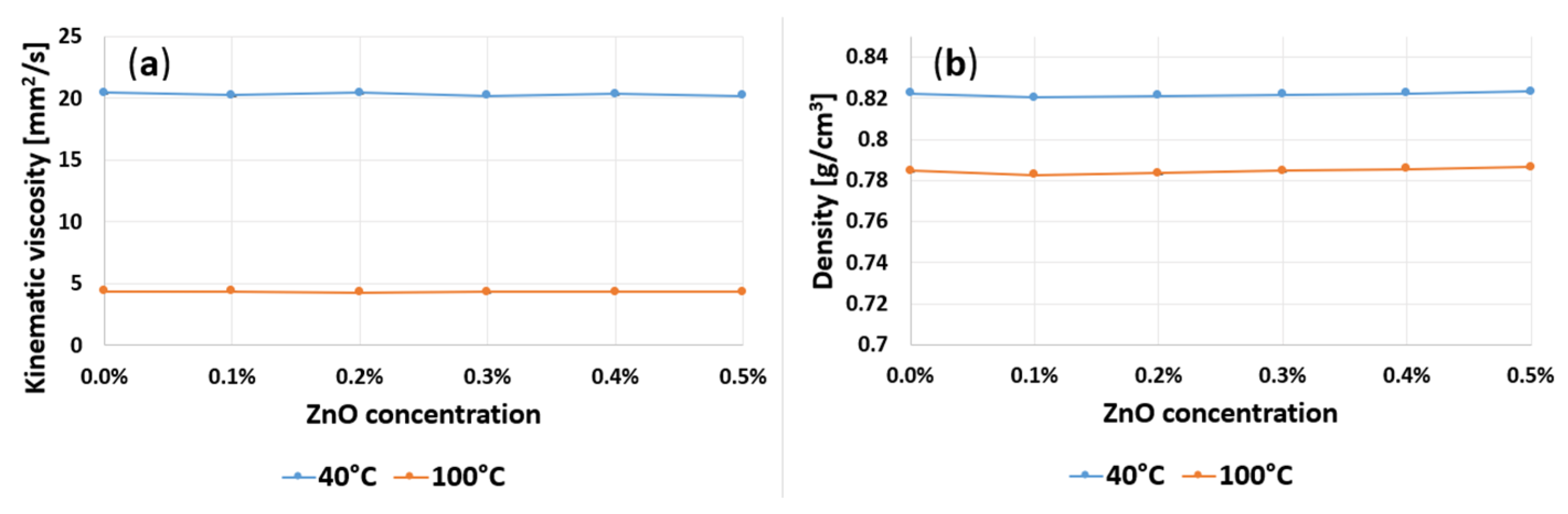

The kinematic viscosity and density values measured at 40 and 100 °C with the Anton Paar SVM 3001 viscometer are presented in

Figure 1. It is noticeable that the purchased Group-III-type base oil (0% NP content) has a slightly higher kinematic viscosity at 100 °C than stated in the documentation of the oil (4.3 mm

2/s was measured instead of 4). Furthermore, the results state that there is no significant difference in the viscosity or density values (lower than 1% compared to the reference value) when different concentrations of nanoparticles are added.

Figure 2a presents the measured friction coefficient values of the tribological measurements in the case of each lubricant sample with different nanoparticle concentrations. It is visible that the friction coefficient has approximately doubled in the case of smaller amounts of nanoparticle concentrations (up to 0.3 wt%). However, the measured values are decreased with the 0.4 and 0.5 wt% NP concentrations by 11–13%, respectively. The measured mean wear scar diameter (MWSD) values are presented in

Figure 2b. The tendency shows that adding a minor amount (0.1 wt%) of zinc oxide into the base oil increases the MWSD by 17%. Still, the MWSD decreases significantly at 0.2 wt% concentration and decreases with the increasing NP concentration. The highest MWSD decrease is measured at 0.4 and 0.5 wt%, namely 42%. A similar tendency can be observed in

Figure 2c, where the measured wear volumes (WVs) are illustrated as follows: a 3% WV increase is detected at 0.1 wt% concentration, and the wear volumes are decreased in the case of the increasing NP concentration (by 73–87%). The best result is observed with the 0.5 wt% NP concentration sample.

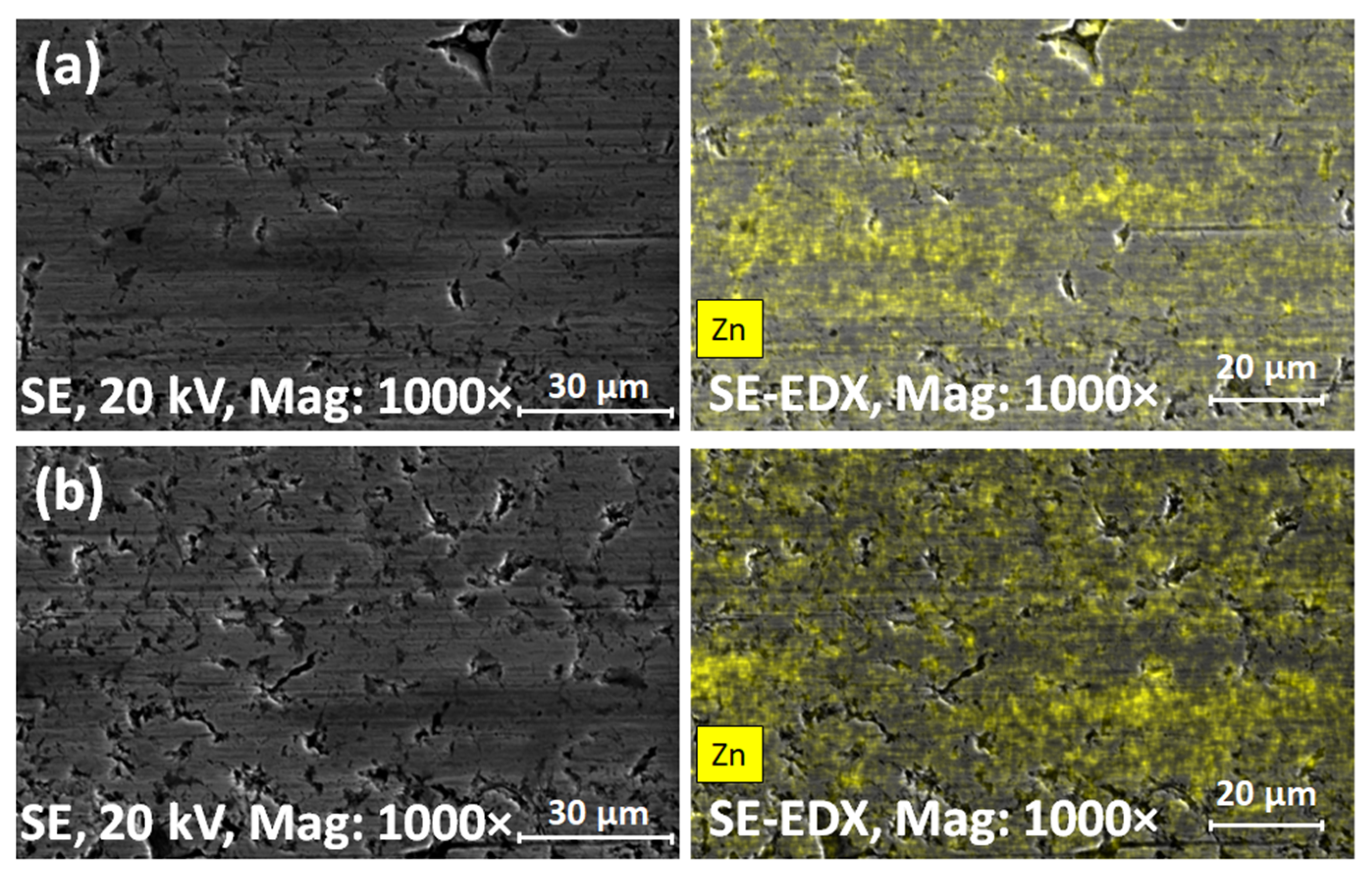

The worn specimen surfaces were analyzed with a scanning electron microscope to define the characteristic wear mechanisms and the distribution of the ZnO nanoparticles on the surface. The investigated specimens were cleaned using an ultrasonic agitator and brake disc cleaner liquid. The acquired images (visible in

Figure 3) define the primary wear mechanism as abrasion; movement-parallel grooves can be found on the surface. The distribution of the Zn element (relating to the ZnO nanoparticles) is doubled: a dark surface area can be identified on the surface, which is rich in ZnO nanoparticles, and Zn-enriched areas can be defined in the bigger surface pores as well, which indicates that the nanoparticles filled the surface pores, resulting in a smoother contacting surface. The quantitative EDX analysis reveals a relatively high amount of Zn on the surface: 5.1 and 5.3 wt% in the middle stroke and the dead center area, respectively.