Abstract

Biobased polyester materials and their nanocomposites have gained significance within the field of engineering materials due to their suitability for many industrial uses. As they reduce our dependence on fossil fuels and non-renewable resources, they reduce environmental impacts and greenhouse gas emissions and enhance sustainability. In addition, biobased polyester has good mechanical and thermal properties, formability, and biodegradation. Consequently, the recycling of these polyester materials has gained a lot of attention lately, as it contributes to resource conservation and reduces waste, the impact on the environment, and energy use. Our study aimed to investigate the physical recyclability of biobased nanocomposites. After multiple extrusion, test specimens made of polylactic acid (PLA) with and without montmorillonite (MMT) were prepared. The viscosity was characterized by a rotational rheometer, DSC (differential scanning calorimetry) was used to examine the crystallinity, and Izod impact tests, 3-point bending, and DMA (dynamic mechanical analysis) were used to measure mechanical characteristics. The results demonstrated that the characteristics of pure PLA and PLA/MMT nanocomposites changed with an increasing number of reprocessings.

1. Introduction

Because it is a biodegradable polyester made from renewable resources, PLA (polylactic acid) is a popular material choice for applications in biomedical devices, auto-motive components, packaging, and various other industries that need more sustainable and ecologically friendly materials [1,2,3]. However, the mechanical properties and processing of PLA can be a limitation [4]. To overcome these obstacles, PLA is often combined with nanofillers such as montmorillonite (MMT) to form PLA/MMT nanocomposites, which can enhance the properties of the material [5]. For example, the results showed that adding MMT in small amounts, up to 6%, led to good dispersion and an increase in the crystallization rate because it acted as a strong nucleating agent [6,7,8]. By adding 3% of MMT, the tensile strength increased by 16%, the Young modulus by about 77%, the storage modulus by 70% [6,9], and the impact and flexural strength by about 10.43% and 6.08%, respectively at 1 wt.% of MMT because of the strong adhesion that exists between MMT and the PLA matrix [9]. The increase in elongation at break reached 133% when adding 3% of MMY and by 100% when adding 5% of MMT, and the melt viscosity also improved [6,10,11]. In addition, it has been proven that reprocessing PLA significantly affects the viscosity and mechanical properties of its compounds. Previous research showed that the restricted mobility of molecular chains and their shortening as a result of reprocessing improved the recycled nanocomposite’s hardness [11].

Overall, understanding these effects is critical in developing effective recycling strategies and ensuring that the recycled materials will maintain the desired performance characteristics. Thus, to improve the sustainability and potential applications of PLA and PLA/MMT nanocomposites in different industries, we investigate in this work how reprocessing affects the mechanical properties and viscosity of PLA and PLA/MMT.

2. Experimental Section

2.1. Materials

The base material for this work was PLA biobased polyester (Ingeo 3100HP-Natureworks, London, OH, USA at 210 °C/2.16 kg; MFI, 24 g/10 min). As a reinforcing agent, MMT (montmorillonite) Nanomer (I.30P, Nanocor, Hoffman Estates, IL, USA) coated with octadecyl-ammonium (about 28–32%) was applied. The polyester (PLA) was tested with and without 6% MMT reinforcement.

2.2. Preparation of Nanocomposite Samples (PLA/MMT)

To ensure the necessary quality, the PLA was dried in an oven for 5 h at 90 °C. This occurred before the processing steps. A Labtech 26–44 type twin screw extruder, produced by Labtech Engineering in Thailand, was used to add MMT to PLA. The screw diameter was 26 mm, the melt temperature was about 195–200 °C, the L/D ratio was about 48, and the screw speed was 52 rpm. For the reprocessed samples, this phase was carried out twice (2× extr). After that, an injection moulding machine (Mitsubishi, Aichi, Japan) with the following parameters was used: injection speed, 60 mm/s; mould temperature, 60 °C; and maintaining the specific pressure at 50 bar for 10 s to make the test samples (60 × 60 × 2 mm3).

2.3. Test Methods

The rheometric studies were performed at low deformation rates using an ARES G2 type oscillation rheometer (TA Instruments, Inc., New Castle, DE, USA) with a 1 mm gap size setting and a sheet–sheet measurement with head diameter of 25 mm. Compounded granules were used in the experiments. The nanocomposites were subjected to 5% deformation and a frequency range of 0.05–500 rad/s when measured at 190 °C. For each case, two parallel measurements were taken, and the average was determined. After fitting the values using the Carreau–Yasuda model, the resulting complex viscosity values were presented as a function of the frequency.

Using DSC131 EVO equipment (Setaram, Lyon, France), one heating and one cooling ramp were conducted at a rate of 10 °C/min to determine the CRF (initial crystallinity ratio). The samples under examination weighed between 10 and 15 mg. Equation (1) was used to calculate the CRF of the samples. The enthalpy of melting and crystallization, ∆Hm and ∆Hcc, was calculated from the area of each peak, respectively.

In the case of PLA, the reference value associated with the heat of fusion of a 100% crystalline polymer ( is 93 J/g [12], and ΦMMT is the mass fraction of MMT.

A universal mechanical device L3369 (Instron, Norwood, MA, USA) was used to perform flexural testing at a speed of 10 mm/min following the ISO 178 standard [13].

An impact tester of the 5113.10.01 types (Zwick, Ulm, Germany) was used to measure the impact strength at room temperature. Tests were carried out utilizing notched samples (50 × 8 × 2 mm3) with a pendulum energy of 2.75 J according to ISO 179-1 [13].

With a 3-point bending head, DMA (dynamic mechanical analysis) was performed utilizing a Q800 measuring instrument (TA Instruments, Inc., New Castle, DE, USA). The samples were 50 × 10 × 4 mm3.

3. Results and Discussion

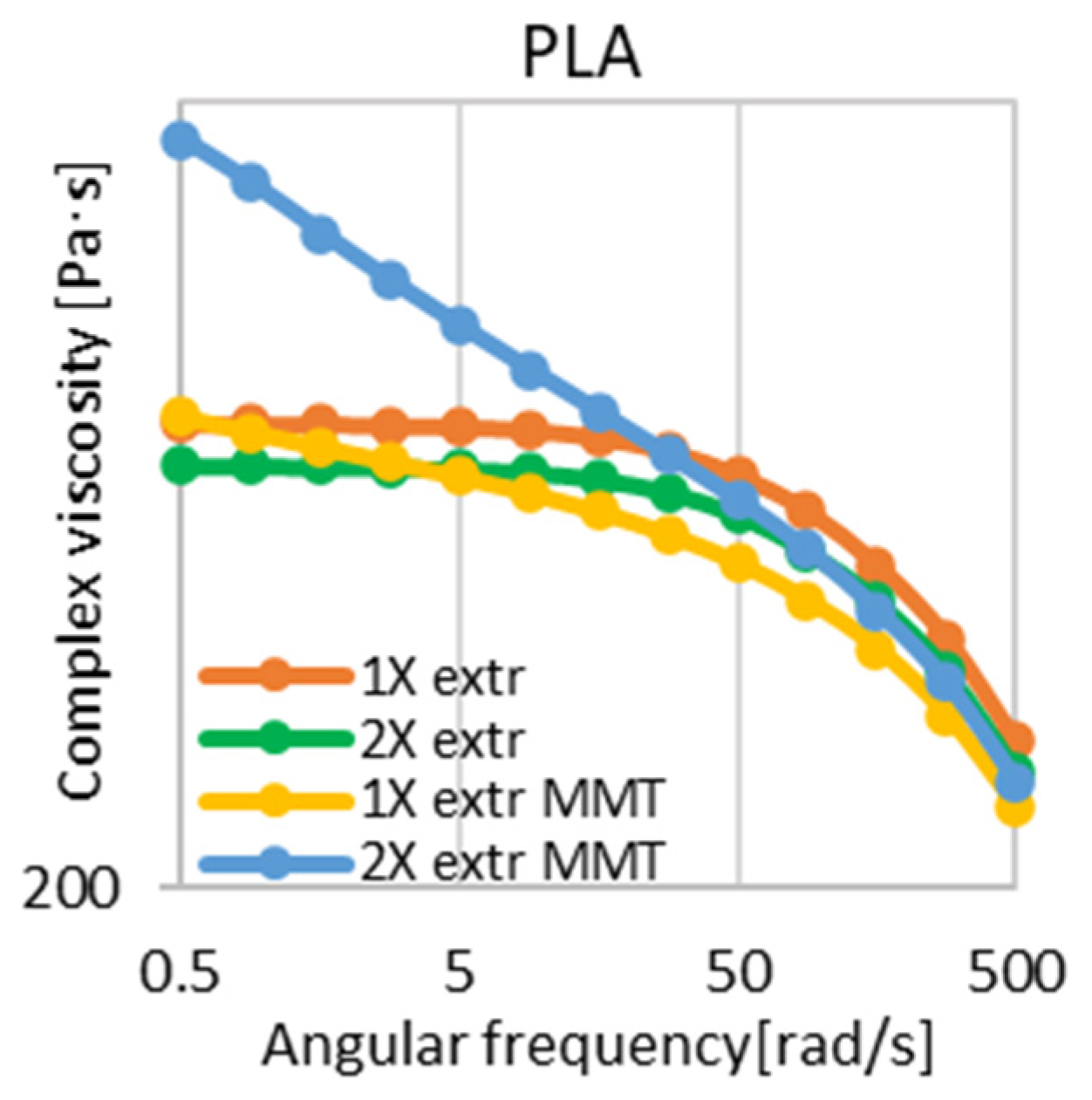

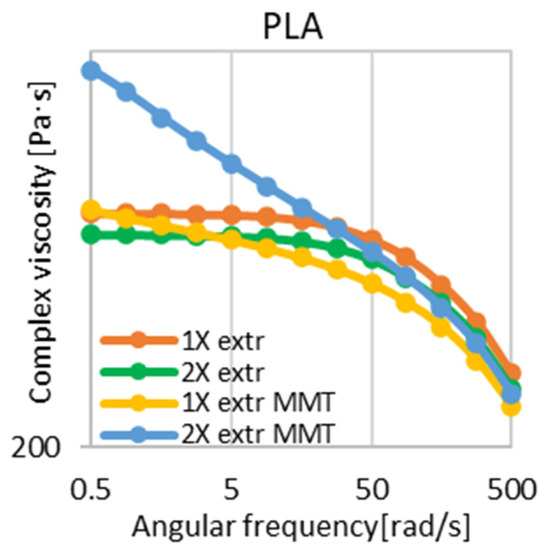

The complex viscosity of the single (1× extr) and double (2× extr) extrusion of PLA/MMT nanocomposites and pure PLA at various angular frequencies is shown in Figure 1. With increasing angular frequency, the complex viscosity decreased for all samples as they showed shear thinning behaviour. The pure PLA’s viscosity decreased as a result of recycling due to either degradation during the recycling process, which reduced the molecular weight and led to lower viscosity, or the improvement of the polyester chain alignment [14]. The addition of MMT to the polymer matrix at high frequencies resulted in a decrease in viscosity due to the presence of MMT agglomerates [15]. However, recycling the PLA/MMT helped disperse MMT better, which enhanced its reinforcing effect, and thus viscosity increased significantly despite the degradation of the polymer [16]. This is consistent with MMT providing more flow resistance as it forms a network structure within the PLA matrix [17]. At low angular frequencies, the effect of MMT was more pronounced, indicating that the network structure formed by MMT was more effective at lower shear rates.

Figure 1.

Complex viscosity for PLA and PLA/MMT nanocomposite as a function of frequency.

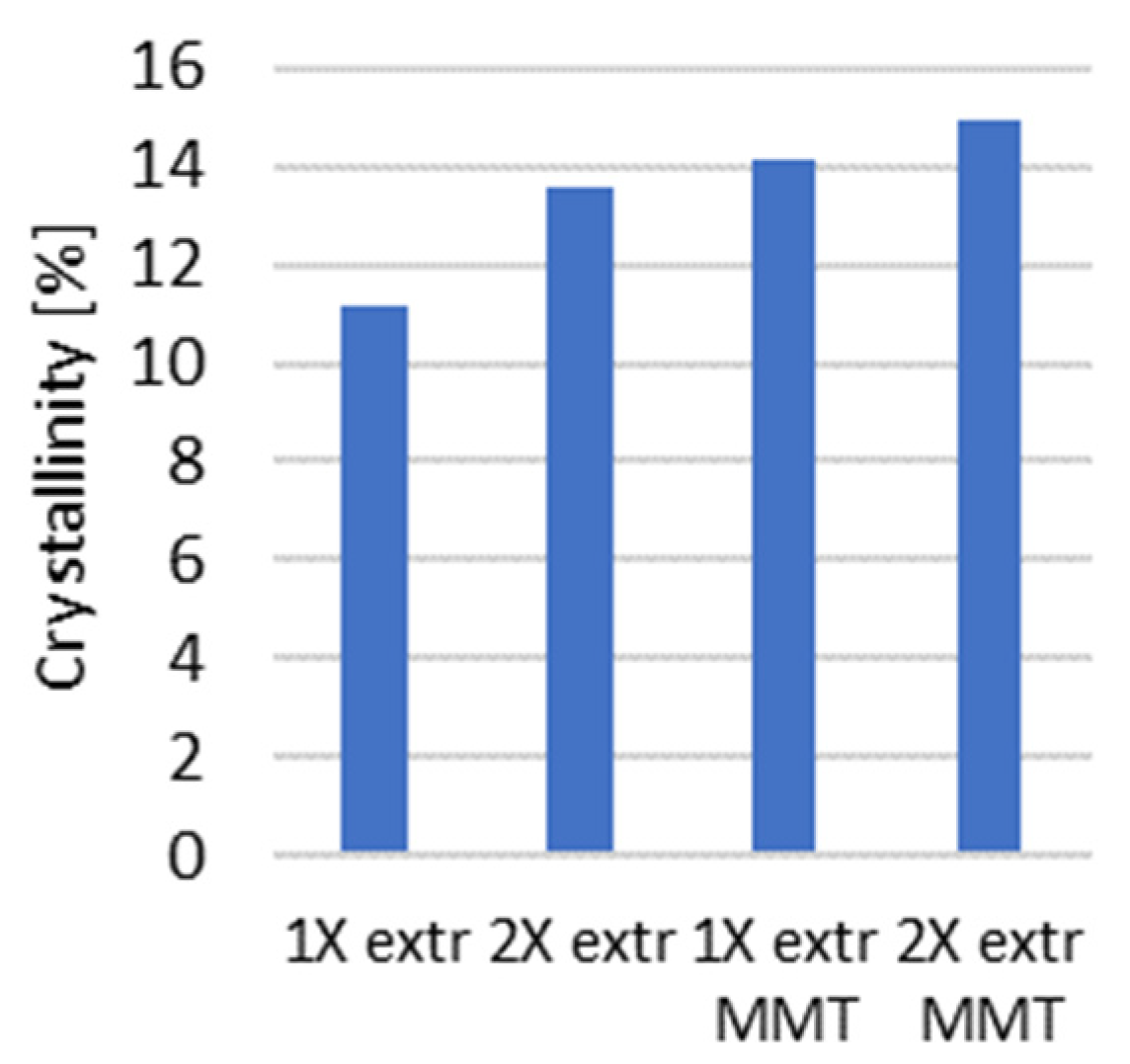

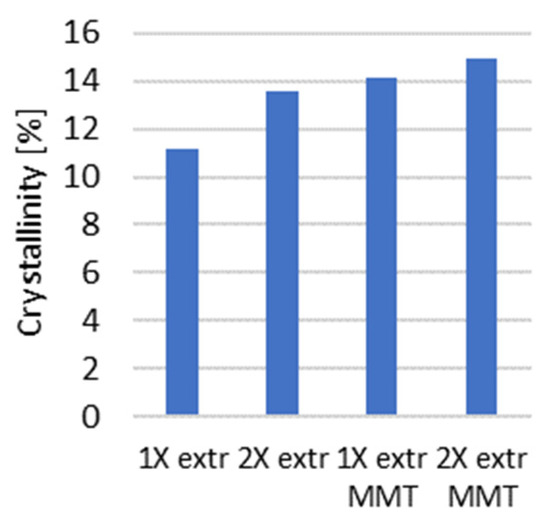

When DSC was used to determine the initial crystallinity of the injection moulded specimens shown in Figure 2, it was found that recycling pure PLA led to an increase in its crystallinity by 21%. This suggests that recycling may promote more ordered arrangement in the polymer chains, which would increase crystallinity. Also, the crystallization rate increased in the presence of MMT because it acted as a nucleating agent [18,19]. MMT continued to enhance crystallization during the recycling process of PLA/MMT nanocomposites because of its good dispersion inside the polymer matrix, thus improved the crystallinity.

Figure 2.

Effect of recycling on the initial crystallinity of PLA and PLA/MMT nanocomposite.

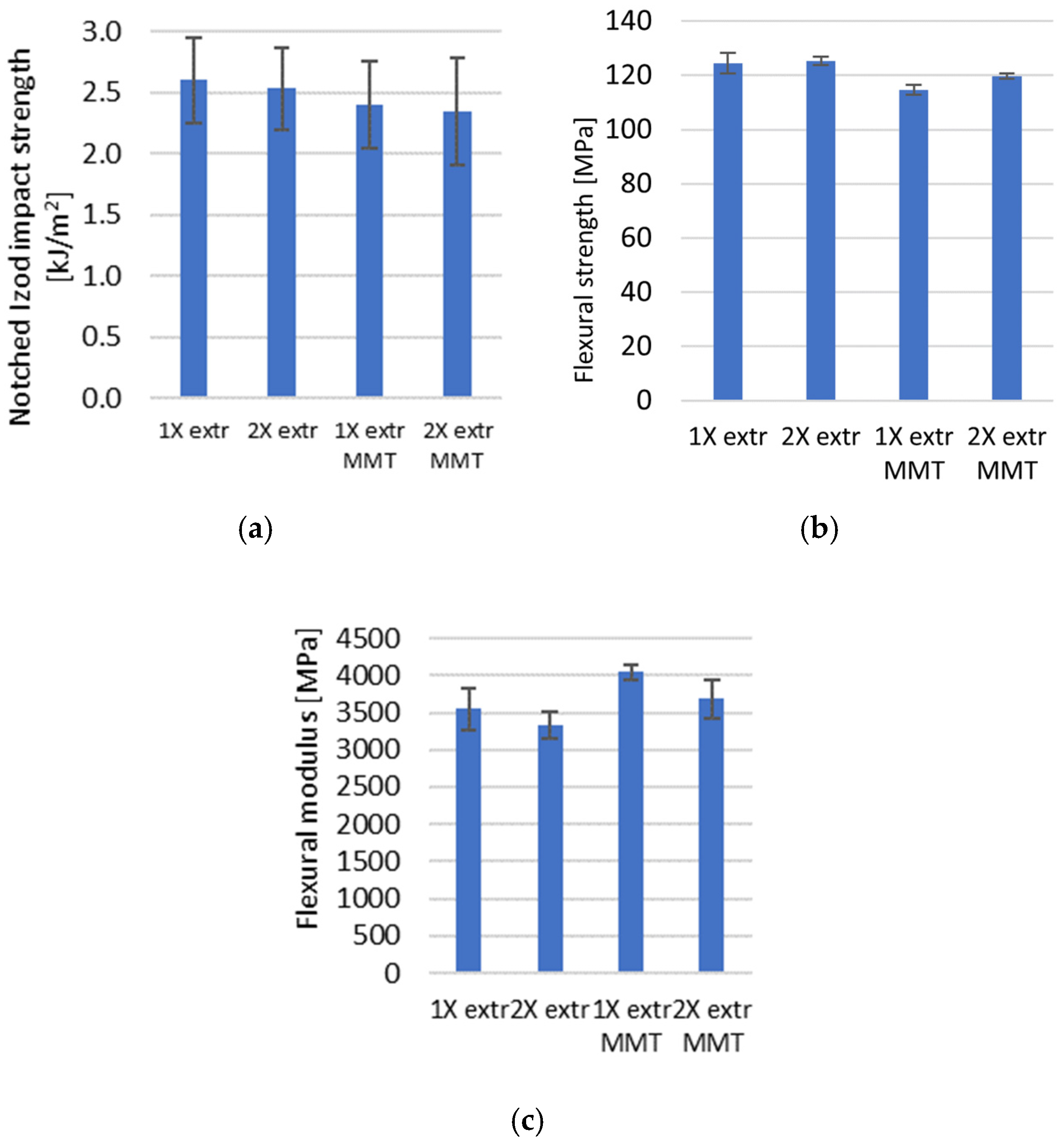

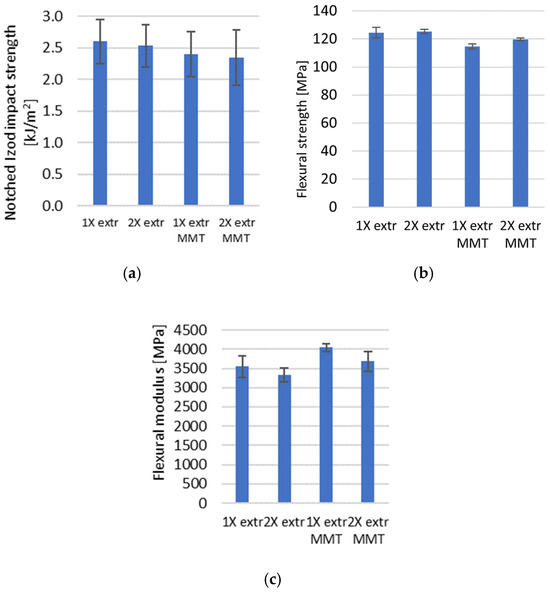

The impact strength of both PLA and its nanocomposites was reduced by reprocessing. Compared to pure polyester, the reduction in the nanocomposites was more significant, suggesting that the application of MMT did not reduce the degradation effects, as shown in Figure 3a.

Figure 3.

(a) Impact strength; (b) flexural strength; (c) flexural modulus of PLA and PLA/MMT nanocomposites with multiple extrusion.

Regarding the flexural properties (Figure 3b,c), recycling caused a slight increase (about 10%) in flexural strength and a slight decrease in flexural modulus, indicating that it had no significant effect on pure PLA. The flexural modulus increased by about 14%, and the flexural strength decreased by 8% with the addition of MMT, suggesting noticeable effects on both properties. Because of the enhanced interfacial adhesion between PLA and MMT, which promoted load distribution, PLA/MMT achieved greater stiffness than pure PLA [7,20]. It can also be seen that recycling in the presence of MMT improved the flexural modulus due to the better dispersion of its particles. In addition, repeated extrusion helped restore flexural strength slightly when MMT was present, but it still did not reach the strength levels of PLA without MMT.

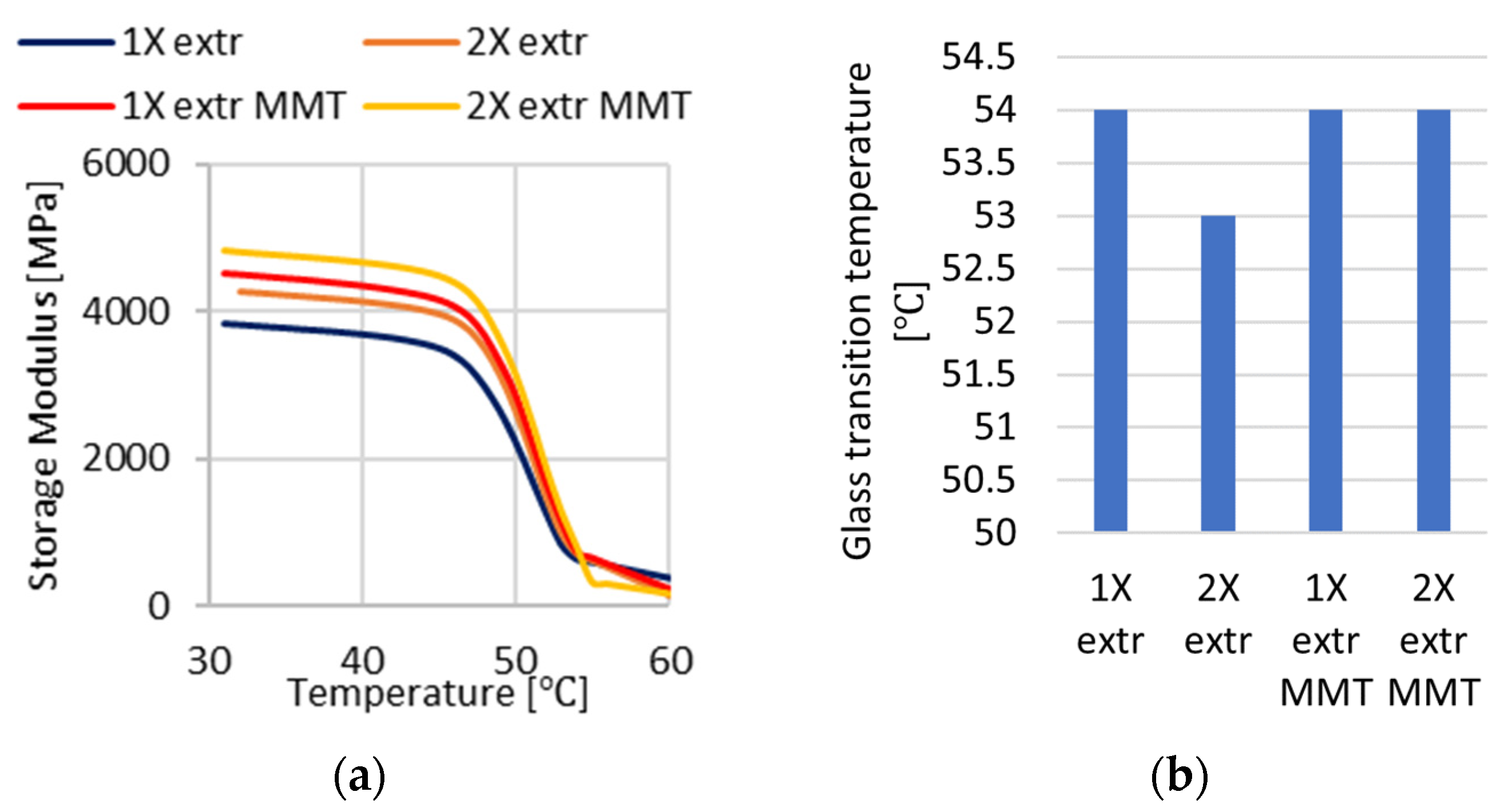

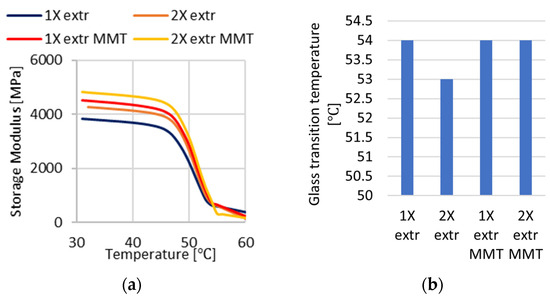

The storage modulus and the glass transition temperature (Tg) were determined as part of the DMA analysis of pure PLA and its nanocomposites at production and after recycling, as indicated in Figure 4. The results revealed that recycled PLA/MMT had the highest storage modulus, as a result of the combined effect of recycling and MMT addition, whereas pure PLA had the lowest storage modulus under the Tg. The storage modulus values were high for all samples at low temperatures, then a sharp decrease occurred in the temperatures range from 50 to 55 °C, which indicates that at higher temperatures, a phase transition and a change in the characteristics of the material occurred. The storage modulus values for all samples converged and became similar at high temperatures (above 55 °C). Additionally, the results showed that recycling enhanced the storage modulus of PLA and PLA/MMT nanocomposites. This suggests that recycling improved the characteristics of the material, either by reducing voids or enhancing MMT’s dispersion in the PLA matrix [20,21].

Figure 4.

(a) Storage modulus and (b) Tg (glass transition temperature) of PLA and PLA/MMT nanocomposites (1× extr and 2× extr).

The measured glass transition temperature (Tg) of the injection-moulded specimens is shown in Figure 4b. It was found that recycling pure PLA led to a slight decrease in Tg due to polymer chain scission, causing molecular degradation. MMT restricted the movement of PLA chains, thus improving the thermal stability of the nanocomposites (PLA/MMT), which helped maintain Tg during recycling processes [22].

4. Conclusions

The test results indicated that during recycling, the structure, viscosity, and mechanical properties of injection-moulded PLA and PLA/MMT nanocomposites change. The presence of MMT also improved the glass transition temperature and crystallization rate due to its compelling role in nucleation. The influence of recycling on nanocomposites depended on the distribution of MMT particles. As a result of their agglomeration, both impact and flexural strength decreased, while the stiffness increased when recycling PLA/MMT. As a result, this recycling method has the potential to successfully handle the current problem of waste made from plastic and thus can be effectively used in sustainability in mobility and transportation.

Author Contributions

Z.T.T.: Investigation, Methodology, Visualization, Writing—original draft; A.Á.M.: Writing—review and editing, Formal analysis, Resources; F.R.: Conceptualization, Investigation, Methodology, Writing—original draft, Supervision. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data for this study are available upon request from the corresponding author.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Wu, Y.; Gao, X.; Wu, J.; Zhou, T.; Nguyen, T.T.; Wang, Y. Biodegradable Polylactic Acid and Its Composites: Characteristics, Processing, and Sustainable Applications in Sports. Polymers 2023, 15, 3096. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Song, M.; Xu, Y.; Wang, W.; Wang, Z.; Zhang, L. Bio-Based Polyesters: Recent Progress and Future Prospects. Prog. Polym. Sci. 2021, 120, 101430. [Google Scholar] [CrossRef]

- Rabnawaz, M.; Wyman, I.; Auras, R.; Cheng, S. A Roadmap towards Green Packaging: The Current Status and Future Outlook for Polyesters in the Packaging Industry. Green Chem. 2017, 19, 4737–4753. [Google Scholar] [CrossRef]

- Farah, S.; Anderson, D.G.; Langer, R. Physical and Mechanical Properties of PLA, and Their Functions in Widespread Applications—A Comprehensive Review. Adv. Drug Deliv. Rev. 2016, 107, 367–392. [Google Scholar] [CrossRef]

- Sanusi, O.M.; Benelfellah, A.; Bikiaris, D.N.; Aït Hocine, N. Effect of Rigid Nanoparticles and Preparation Techniques on the Performances of Poly(Lactic Acid) Nanocomposites: A Review. Polym. Adv. Technol. 2021, 32, 444–460. [Google Scholar] [CrossRef]

- Othman, S.H.; Ling, H.N.; Talib, R.A.; Naim, M.N.; Risyon, N.P.; Saifullah, M. PLA/MMT and PLA/Halloysite Bio-Nanocomposite Films: Mechanical, Barrier, and Transparency. J. Nano Res. 2019, 59, 77–93. [Google Scholar] [CrossRef]

- Lopes Alves, J.; de Tarso Vieira e Rosa, P.; de Redondo Realinho, V.C.; de Sousa Pais Antunes, M.; Ignacio Velasco, J.; Morales, A.R. Single and Hybrid Organoclay-Filled PLA Nanocomposites: Mechanical Properties, Viscoelastic Behavior and Fracture Toughening Mechanism. J. Appl. Polym. Sci. 2021, 138, 50784. [Google Scholar] [CrossRef]

- Zhu, B.; Wang, Y.; Liu, H.; Ying, J.; Liu, C.; Shen, C. Effects of Interface Interaction and Microphase Dispersion on the Mechanical Properties of PCL/PLA/MMT Nanocomposites Visualized by Nanomechanical Mapping. Compos. Sci. Technol. 2020, 190, 108048. [Google Scholar] [CrossRef]

- Ramesh, P.; Prasad, B.D.; Narayana, K.L. Effect of MMT Clay on Mechanical, Thermal and Barrier Properties of Treated Aloevera Fiber/PLA-Hybrid Biocomposites. Silicon 2020, 12, 1751–1760. [Google Scholar] [CrossRef]

- Fukushima, K.; Fina, A.; Geobaldo, F.; Venturello, A.; Camino, G. Properties of Poly(Lactic Acid) Nanocomposites Based on Montmorillonite, Sepiolite and Zirconium Phosphonate. Express Polym. Lett. 2012, 6, 914–926. [Google Scholar] [CrossRef]

- Salah, L.S.; Ouslimani, N.; Danlée, Y.; Beltrán, F.R.; Huynen, I.; Ulagares de la Orden, M. Investigation of Mechanical Recycling Effect on Electromagnetic Properties of Polylactic Acid (PLA)—Nanoclay Nanocomposites: Towards a Valorization of Recycled PLA Nanocomposites. Compos. Part C Open Access 2023, 10, 100339. [Google Scholar] [CrossRef]

- Mysiukiewicz, O.; Barczewski, M. Crystallization of Polylactide-Based Green Composites Filled with Oil-Rich Waste Fillers. J. Polym. Res. 2020, 27, 374. [Google Scholar] [CrossRef]

- Bata, A.; Gerse, P.; Slezák, E.; Ronkay, F. Time- and temperature-dependent mechanical and rheological behaviours of injection moulded biodegradable organoclay nanocomposites. Adv. Ind. Eng. Polym. Res. 2024, 7, 482–496. [Google Scholar] [CrossRef]

- Soroudi, A.; Jakubowicz, I. Recycling of Bioplastics, Their Blends and Biocomposites: A Review. Eur. Polym. J. 2013, 49, 2839–2858. [Google Scholar] [CrossRef]

- Andrzejewski, J.; Markowski, M.; Barczewski, M. The Use of Nanoscale Montmorillonite (MMT) as Reinforcement for Polylactide Acid (PLA) Prepared by Fused Deposition Modeling (FDM)—Comparative Study with Biocarbon and Talc Fillers. Materials 2022, 15, 5205. [Google Scholar] [CrossRef]

- He, H.; Liu, B.; Xue, B.; Zhang, H. Study on Structure and Properties of Biodegradable PLA/PBAT/Organic-Modified MMT Nanocomposites. J. Thermoplast. Compos. Mater. 2022, 35, 503–520. [Google Scholar] [CrossRef]

- Sabatini, V.; Farina, H.; Basilissi, L.; Di Silvestro, G.; Ortenzi, M.A. The Use of Epoxy Silanes on Montmorillonite: An Effective Way to Improve Thermal and Rheological Properties of PLA/MMT Nanocomposites Obtained via “in Situ” Polymerization. J. Nanomater. 2015, 2015, 418418. [Google Scholar] [CrossRef]

- Wu, X.; Yuan, J.; Yu, Y.; Wang, Y. Preparation and Characterization of Polylactide/Montmorillonite Nanocomposites. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2009, 24, 562–565. [Google Scholar] [CrossRef]

- Di, Y.; Iannace, S.; Di Maio, E.; Nicolais, L. Poly(Lactic Acid)/Organoclay Nanocomposites: Thermal, Rheological Properties and Foam Processing. J. Polym. Sci. Part B Polym. Phys. 2005, 43, 689–698. [Google Scholar] [CrossRef]

- Ray, S.S.; Yamada, K.; Okamoto, M.; Ueda, K. Biodegradable Polylactide/Montmorillonite Nanocomposites. J. Nanosci. Nanotechnol. 2003, 3, 503–510. [Google Scholar] [CrossRef]

- Sirisinha, K.; Wirasate, S.; Sirisinha, C.; Wattanakrai, N. One-Pot Reactive Melt Recycling of PLA Post-Consumer Waste for the Production of Block Copolymer Nanocomposites of High Strength and Ductility. Polymers 2022, 14, 3642. [Google Scholar] [CrossRef] [PubMed]

- Dittrich, B.; Warting, K.-A.; Mülhaupt, R.; Schartel, B. Flame-Retardancy Properties of Intumescent Ammonium Poly (Phosphate) and Mineral Filler Magnesium Hydroxide in Combination with Graphene. Polymers 2014, 6, 2875–2895. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).