Abstract

Wood flour-paired poly(lactic acid) (PLA)-based biocomposites were fabricated with filler contents of 0, 2.5, 5, 10, and 20 wt.%. The samples were processed through extrusion followed by injection molding. The injection-molded specimens were subjected to tensile tests, impact tests, and water absorption tests. Based on the results, increasing the amount of lignocellulose fibers effectively improved the modulus of PLA from 2.8 to 3.6 GPa at 20 wt.% wood flour loading; however, this came at the cost of strength, which dropped from 55.0 to 48.8 MPa. Additionally, the incorporation of lignocellulose increased the hydrophilicity of the composites, resulting in a threefold increase in water absorption at 10 wt.% filler content. These results provide insight into the effects of embedding lignocellulose fibers into PLA.

1. Introduction

In today’s consumer society, the focus is mainly on manufacturing products with less emphasis on their afterlife. This approach results in an immense accumulation of waste. A substantial portion of waste originates from plastic products; according to estimations, the total weight accumulated by 2020 exceeded 7.4 billion metric tons and is expected to reach 40 billion tons by 2050 [1]. Recycling is considered a potential solution to mitigate this issue; however, despite being aware of the environmental effects, a considerable percentage of society does not follow the guidelines to promote this sustainable method of handling waste [2]. Another alternative is to substitute traditional petrochemical-based plastics with polymers that can decompose over a short period. This way, plastic products could degrade shortly into non-harmful components instead of accumulating.

Biopolymers are classified depending on their source and biodegradability [3]. Non-renewable biopolymers are produced using fossil-based petrochemical sources, while renewable ones are derived from biomass [4]. Nowadays, there is an abundance of literature on the topic of biopolymers [5,6,7]. Among the various bioplastics, poly(lactic acid) (PLA) is by far the most prevalent, making up almost 14% of the global biopolymer production [8]. Its monomer production market share is 3.2 billion USD [9], with predictions indicating a gradual increase in the coming years.

Lactic acid (LA), the main building block of PLA, is a naturally occurring biopolymer; however, its production on a large scale is rather challenging. Most commonly, it is synthesized through microbial fermentation [10]. To obtain PLA, LA has to go through polymerization procedures, such as polycondensation or ring-opening polymerization [11]. Due to the relatively high cost of PLA production, researchers have devoted considerable efforts to reducing these costs. One potential strategy to achieve this goal is to develop composite materials by pairing PLA with reinforcement or filler materials.

Such polymer composites are gaining more and more recognition and are being utilized in many areas, therefore. Single-use plastics and non-load bearing parts are already being substituted with various biopolymer composites, including in the automotive industry. Under-the-hood gears and interior panels, such as dashboards and door panels, have been replaced in many modern vehicles [12]. Currently, researchers are working tirelessly to develop biopolymer composites suitable for industrial purposes [13,14], as they can reduce both the weight and the production costs of parts, and by utilizing natural fillers, their environmental friendliness can be improved, thereby meeting the derivative quotas set by governments and environmental advocates.

Wood flour (WF) is an attractive filler type due to its low cost and easy integration into polymer production. Yu et al. [15] experimented with adding different coupling agents to PLA/WF/poly(butylene succinate) composites to promote adhesion between the components, successfully enhancing the tensile strength by 45% compared to the untreated counterparts. However, due to the use of harmful chemicals, this method challenges the environmentally friendly nature of the composite. Other researchers have also attempted to prepare complex mixtures, which makes it challenging to determine the specific effects of the incorporated WF.

In this study, PLA was mixed with WF-based lignocellulose fibers at various weight percentages (0–20 wt.%) by extrusion, and the prepared composites were injection molded into specimens suitable for characterization. The mechanical properties were assessed through tensile tests and Charpy impact tests, and their water uptake was also determined by submerging the specimens in deionized water and measuring their weight increase.

2. Materials and Methods

2.1. Materials and Processing Techniques

Ingeo 3052D PLA of NatureWorks (Plymouth, MN, USA) was used as the matrix material for the fabricated polymer composites. This PLA grade has a density of 1.24 g/cm3 and a crystalline melting temperature of 145–160 °C. Its glass transition temperature is between 55 and 60 °C, and its melt flow rate is 14 g/10 min (2.16 kg/210 °C). Lignocel S 150 TR-grade commercial WF, kindly supplied by J. Rettenmaier & Söhne GmbH (Rosenberg, Germany), was utilized as the natural fiber. According to the supplier, it is derived from untreated softwood and has a fiber length of 70–150 μm.

Before composite fabrication, both components were dried for 4 h at 80 °C in a Faithful WGLL 125 BE drying chamber (Cangzhou, China). Afterward, PLA and WF were mixed to prepare dry mixtures with previously optimized [16] component ratios, as summarized in Table 1.

Table 1.

Designation and composition of the fabricated samples.

After manual premixing, the components were periodically added into a LabTech Scientific LTE 20–44 twin-screw extruder (Samutprakarn, Thailand). The temperature of the extruder barrel, from feeder to die along the separate heating zones, was set as follows: 155–160–160–165–170–170–175–180–185–185–185 °C. The extruded strings were cooled by air on a conveyor belt using ventilation units. The cooling was followed by grinding the composites using a Labtech LZ120 pelletizer (Samutprakarn, Thailand).

After extrusion, the obtained granules were dried under the conditions as before. Subsequently, they were fed into an Arburg Allrounder 420C injection molding machine (Lossburg, Germany). The parameters of the injection molding procedure are summarized in Table 2. A1-type multipurpose specimens, according to EN ISO 527–2 [17], were manufactured this way.

Table 2.

Injection molding parameters used for processing PLA, and PLA/WF composite specimens.

2.2. Characterization

The composite specimens were characterized one month after production for their mechanical and physical properties. An Instron 5582 testing machine (Norwood, MA, USA) was used to measure the tensile strength and Young’s modulus, following the ISO 527 standard [18]. During the tensile tests, the crosshead speed was set to 1 mm/min until 0.3% elongation was reached, after which it was increased to 5 mm/min. The clamping distance was set to 100 mm.

Impact strength was measured according to the ISO 179 standard [19]. For this purpose, unnotched specimens of 80 mm length were cut from the parallel section of the injection-molded samples. The test was conducted using a Ceast 6545 pendulum-based machine (Torino, Italy) equipped with a 2 J hammer.

The water uptake of the samples was also examined. Small specimens measuring 10 × 10 × 4 mm3 were submerged in distilled water for 28 days. Prior to this, they were dried at 40 °C until an equilibrium weight was reached, which took approximately 24 h. Water uptake was measured until the saturation of all samples was reached, and it was quantified by calculating the weight gain (mt) of the specimens using Equation 1:

where mr is the weight measured after a specific soaking time, and m0 is the dry weight of the specimens before submersion.

3. Results and Discussion

3.1. Tensile Tests

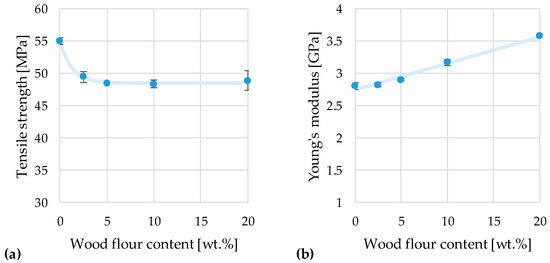

Figure 1 summarizes the results of the tensile tests. As evidenced by Figure 1a, PLA has a tensile strength of 55.0 MPa and exhibits a Young’s modulus of 2.8 GPa, both of which are in good accord with the literature [20,21]. With the incorporation of WF fibers, the tensile strength slightly decreased to 49.4 MPa, while Young’s modulus did not change substantially (2.8 GPa). At 5 wt.% wood flour content, a further decrease in tensile strength was observed (48.4 MPa), but there was an increase in modulus (2.9 GPa). With further WF loading, the tensile strength did not show any noticeable changes (48.9 MPa for PLA_S150TR_20). At the same time, the modulus values exhibited a gradually increasing tendency, peaking at 3.6 GPa in the case of sample PLA_S150TR_20. The decreased strength can be attributed to the improper compatibility between the components. The reason for the modulus still increasing is that it is determined during the early stage of the test, where interfacial adhesion does not play a significant role [22].

Figure 1.

Tensile strength (a) and Young’s modulus (b) values of PLA and its composites containing 10 and 20 wt.% wood flour.

3.2. Impact Tests

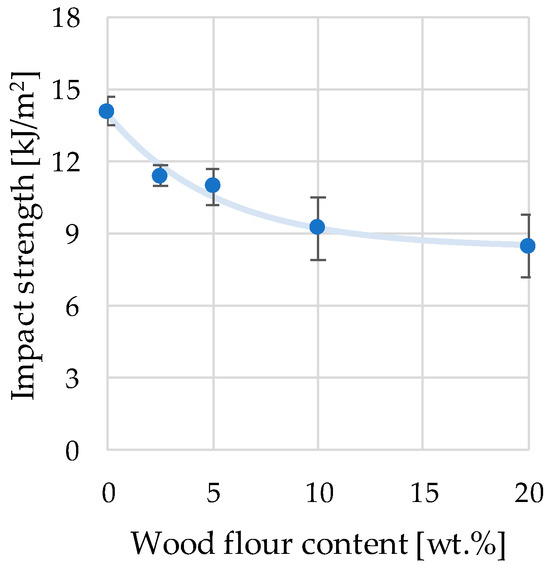

The impact test results are depicted in Figure 2. Similar to tensile strength, even at the lowest WF content, PLA exhibited a significant reduction in impact resistance, decreasing from 14.1 kJ/m2 to 11.4 kJ/m2 for sample PLA_S150TR_2.5. This drop can be explained by the limited adhesion between the PLA and WF [23], which facilitates the failure of the specimens when exposed to impact loads. Further increases in WF content reduced the impact strength of PLA even further, down to 8.5 kJ/m2 for sample PLA_S150TR_20.

Figure 2.

Impact strength of PLA and its composites containing 10 and 20 wt.% wood flour.

3.3. Water Absorption Tests

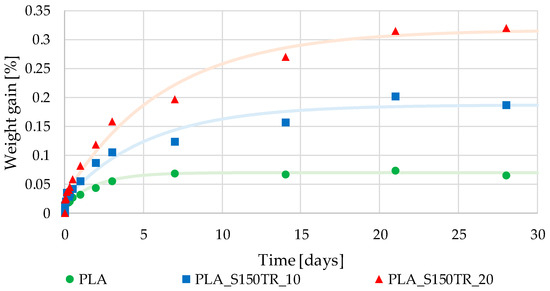

A water absorption test was carried out on samples PLA, PLA_S150TR_10, and PLA_S150TR_20, and the results are summarized in Figure 3. Due to the hydrophobic nature of PLA, it only absorbed a relatively low amount of water (0.07%), and its weight remained constant after reaching saturation at the end of the first week. Meanwhile, the composites absorbed a higher amount of water, which can be attributed to the hydrophilicity of WF. Their mass continued to increase even after the end of the second week. This is in good accordance with findings in the literature, which report an increasing water absorption rate with the growing amount of vegetable fiber-based fillers [24,25]. Specifically, sample PLA_S150TR_10 reached saturation at 0.20% water content, while PLA_S150TR_20 absorbed 0.32% after 3 weeks of submersion.

Figure 3.

Water absorption of PLA and its composites containing 10 and 20 wt.% wood flour.

4. Conclusions

Investigating the effect of incorporating lignocellulosic fibers such as WF into PLA is worthwhile in achieving cost-effective manufacturing while retaining the polymer matrix’s most essential properties. In this study, PLA/WF biocomposites were prepared and characterized. Based on the findings, the following conclusions can be drawn:

- The incorporation of WF effectively improves the modulus of PLA; however, this comes at the cost of strength (both tensile and impact), which decreases with growing WF content.

- Biocomposites exhibit more hydrophilic behavior than neat PLA, which, along with the potential gaps and voids on the interphase of the components, result in a higher water absorption.

Author Contributions

Conceptualization, L.L.; methodology, S.K.J., V.L.B. and L.L.; validation, S.K.J., V.L.B. and L.L.; formal analysis, S.K.J. and V.L.B.; investigation, S.K.J. and V.L.B.; resources, L.L.; writing—original draft preparation, S.K.J.; writing—review and editing, L.L.; visualization, S.K.J.; supervision, L.L.; project administration, L.L.; funding acquisition, L.L. All authors have read and agreed to the published version of the manuscript.

Funding

L.L. is grateful for the support of the János Bolyai Research Scholarship of the Hungarian Academy of Sciences.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Acknowledgments

The authors are grateful to J. Rettenmaier & Söhne GmbH for providing the wood flour used in this research.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Korley, L.T.J.; Epps, T.H.; Helms, B.A.; Ryan, A.J. Toward polymer upcycling—Adding value and tackling circularity. Science 2021, 373, 66–69. [Google Scholar] [CrossRef]

- Steinhorst, J.; Beyerl, K. First reduce and reuse, then recycle! Enabling consumers to tackle the plastic crisis—Qualitative expert interviews in Germany. J. Clean. Prod. 2021, 313, 127782. [Google Scholar] [CrossRef]

- Shlush, E.; Davidovich-Pinhas, M. Bioplastics for food packaging. Trends Food Sci. Technol. 2022, 125, 66–80. [Google Scholar] [CrossRef]

- Shaikh, S.; Yaqoob, M.; Aggarwal, P. An overview of biodegradable packaging in food industry. Curr. Res. Food Sci. 2021, 4, 503–520. [Google Scholar] [CrossRef] [PubMed]

- Backes, E.H.; Harb, S.V.; Beatrice, C.A.G.; Shimomura, K.M.B.; Passador, F.R.; Costa, L.C.; Pessan, L.A. Polycaprolactone usage in additive manufacturing strategies for tissue engineering applications: A review. J. Biomed. Mater. Res. B Appl. Biomater. 2022, 110, 1479–1503. [Google Scholar] [CrossRef]

- Popa, M.S.; Frone, A.N.; Panaitescu, D.M. Polyhydroxybutyrate blends: A solution for biodegradable packaging? Int. J. Biol. Macromol. 2022, 207, 263–277. [Google Scholar] [CrossRef] [PubMed]

- Coppola, G.; Gaudio, M.T.; Lopresto, C.G.; Calabro, V.; Curcio, S.; Chakraborty, S. Bioplastic from Renewable Biomass: A Facile Solution for a Greener Environment. Earth Syst. Environ. 2021, 5, 231–251. [Google Scholar] [CrossRef]

- Goel, V.; Luthra, P.; Kapur, G.S.; Ramakumar, S.S.V. Biodegradable/Bio-plastics: Myths and Realities. J. Polym. Environ. 2021, 29, 3079–3104. [Google Scholar] [CrossRef]

- Kim, J.; Kim, Y.M.; Lebaka, V.R.; Wee, Y.J. Lactic Acid for Green Chemical Industry: Recent Advances in and Future Prospects for Production Technology, Recovery, and Applications. Fermentation 2022, 8, 609. [Google Scholar] [CrossRef]

- Yu, J.; Xu, S.; Liu, B.; Wang, H.; Qiao, F.; Ren, X.; Wei, Q. PLA bioplastic production: From monomer to the polymer. Eur. Polym. J. 2023, 193, 112076. [Google Scholar] [CrossRef]

- Grillo, A.; Rusconi, Y.; Alterio, M.C.; De Rosa, C.; Talarico, G.; Poater, A. Ring Opening Polymerization of Six- and Eight-Membered Racemic Cyclic Esters for Biodegradable Materials. Int. J. Mol. Sci. 2024, 25, 1647. [Google Scholar] [CrossRef] [PubMed]

- Shekhar, N.; Mondal, A. Synthesis, properties, environmental degradation, processing, and applications of Polylactic Acid (PLA): An overview. Polym. Bull. 2024, 81, 11421–11457. [Google Scholar] [CrossRef]

- Nirmal Kumar, K.; Dinesh Babu, P. Experimental study of mechanical, morphological and thermal performance of bamboo-reinforced polylactic acid-based montmorillonite clay hybrid composite. Ind. Crops Prod. 2024, 209, 117950. [Google Scholar] [CrossRef]

- Sun, Y.; Wang, Y.; Mu, W.; Zheng, Z.; Yang, B.; Wang, J.; Zhang, R.; Zhou, K.; Chen, L.; Ying, J.; et al. Mechanical properties of 3D printed micro-nano rice husk/polylactic acid filaments. J. Appl. Polym. Sci. 2022, 139, e52619. [Google Scholar] [CrossRef]

- Yu, W.; Sun, L.; Li, M.; Peng, Y.; Wei, C.; Lei, W.; Qiu, R.; Ge, Y. Effect of Modification and Hydrothermal Ageing on Properties of 3D-Printed Wood Flour–Poly(butylene succinate)–Poly(lactic acid) Biocomposites. Polymers 2023, 15, 3697. [Google Scholar] [CrossRef] [PubMed]

- Jakab, S.K.; Singh, T.; Fekete, I.; Lendvai, L. Agricultural by-product filled poly(lactic acid) biocomposites with enhanced biodegradability: The effect of flax seed meal and rapeseed straw. Compos. C Open Access 2024, 14, 100464. [Google Scholar] [CrossRef]

- ISO 527-2; Plastics—Determination of Tensile Properties, Part 2: Test Conditions for Moulding and Extrusion Plastics. ISO: Geneva, Switzerland, 2012.

- ISO 527-1; Plastics—Determination of Tensile Properties, Part 1: General principles. ISO: Geneva, Switzerland, 2019.

- ISO 179-1; Plastics—Determination of Charpy Impact Properties, Part 1: Non-Instrumented Impact Test. ISO: Geneva, Switzerland, 2023.

- Mohammed, M.; Rasidi, M.S.M.; Mohammed, A.; Rahman, R.; Osman, A.; Adam, T.; Betar, B.; Dahham, O. Interfacial bonding mechanisms of natural fibre-matrix composites: An overview. Bioresources 2022, 17, 7031–7090. [Google Scholar] [CrossRef]

- Kannan, G.; Thangaraju, R.; Kayaroganam, P.; Davim, J.P. The Combined Effect of Banana Fiber and Fly Ash Reinforcements on the Mechanical Behavior of Polyester Composites. J. Nat. Fibers 2022, 19, 11384–11403. [Google Scholar] [CrossRef]

- Lendvai, L.; Patnaik, A. The effect of coupling agent on the mechanical properties of injection molded polypropylene/wheat straw composites. Acta Tech. Jaurinensis 2022, 15, 232–238. [Google Scholar] [CrossRef]

- Kuciel, S.; Mazur, K.; Hebda, M. The Influence of Wood and Basalt Fibres on Mechanical, Thermal and Hydrothermal Properties of PLA Composites. J. Polym. Environ. 2020, 28, 1204–1215. [Google Scholar] [CrossRef]

- Al Abdallah, H.; Abu-Jdayil, B.; Iqbal, M.Z. Improvement of mechanical properties and water resistance of bio-based thermal insulation material via silane treatment. J. Clean. Prod. 2022, 346, 131242. [Google Scholar] [CrossRef]

- Ratna Kumari, Y.; Ramanaiah, K.; Ratna Prasad, A.V.; Hemachandra Reddy, K.; Prasad Sanaka, S.; Kalyan Prudhvi, A. Experimental investigation of water absorption behaviour of sisal fiber reinforced polyester and sisal fiber reinforced poly lactic acid composites. Mater. Today Proc. 2021, 44, 935–940. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).