Recent Trends in Computer Vision for Cheese Quality Evaluation †

Abstract

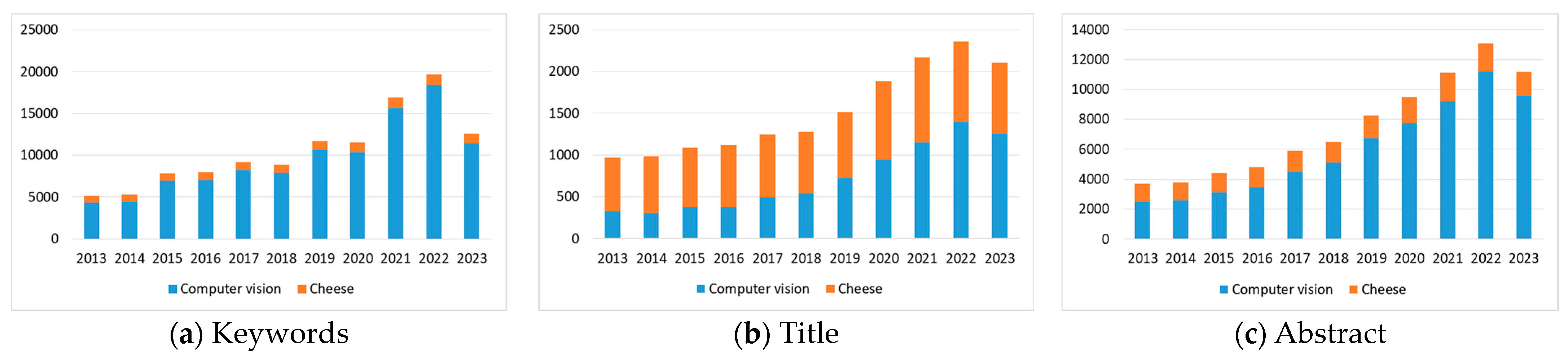

1. Introduction

2. Computer Vision Systems’ (CVS) Application in Cheese Quality Evaluation

2.1. Using Ultrasound for Cheese Quality Evaluation

2.2. Using NIR for Cheese Quality Evaluation

2.3. Using MRI for Cheese Quality Evaluation

2.4. Using Digital Images for Cheese Quality Evaluation

3. Discussion and Future Trends

4. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Belyaeva, M.; Kitova, O.; Popov, A.; Chernikova, E. Innovative technologies in food production processes. IOP Conf. Series Earth Environ. Sci. 2021, 937, 032044. [Google Scholar] [CrossRef]

- XingYuan, L.; Wang, Y.; Li, X.; Liu, Y. Application of Computer Information Technology in Food Safety Control. J. Phys. Conf. Ser. 2021, 1915, 032068. [Google Scholar] [CrossRef]

- Dadhaneeya, H.; Nema, P.K.; Arora, V.K. Internet of Things in food processing and its potential in Industry 4.0 era: A review. Trends Food Sci. Technol. 2023, 139, 104109. [Google Scholar] [CrossRef]

- Sen, P.; Mardinogulu, A.; Nielsen, J. Selection of complementary foods based on optimal nutritional values. Sci. Rep. 2017, 7, 5413. [Google Scholar] [CrossRef] [PubMed]

- Kwak, H.S.; Ganesan, P.; Hong, Y.H. Nutritional Benefits in Cheese, Cheese: Types, Nutrition and Consumption; Nova Science Publishers Inc.: New York, NY, USA, 2011; pp. 269–289. ISBN 978-1-61209-828-9. [Google Scholar]

- Hassoun, A.; Garcia-Garcia, G.; Trollman, H.; Jagtap, S.; Parra-López, C.; Cropotova, J.; Bhat, Z.; Centobelli, P.; Aït-Kaddour, A. Birth of dairy 4.0: Opportunities and challenges in adoption of fourth industrial revolution technologies in the production of milk and its derivatives. Curr. Res. Food Sci. 2023, 7, 100535. [Google Scholar] [CrossRef] [PubMed]

- Chávez-Martínez, A.; Reyes-Villagrana, R.A.; Rentería-Monterrubio, A.L.; Sánchez-Vega, R.; Tirado-Gallegos, J.M.; Bolivar-Jacobo, N.A. Low and High-Intensity Ultrasound in Dairy Products: Applications and Effects on Physicochemical and Microbiological Quality. Foods 2020, 9, 1688. [Google Scholar] [CrossRef]

- Eskelinen, J.; Alavuotunki, A.; Hæggström, E.; Alatossava, T. Structural Quality Control of Swiss-Type Cheese with Ultrasound. AIP Conf. Proc. 2007, 894, 1328–1331. [Google Scholar]

- Benedito, J.; Carcel, J.; Sanjuan, N.; Mulet, A. Use of ultrasound to assess Cheddar cheese characteristics. Ultrasonics 2000, 38, 727–730. [Google Scholar] [CrossRef]

- Crespo, A.; Martín, A.; Ruiz-Moyano, S.; Benito, M.J.; Rufo, M.; Paniagua, J.M.; Jiménez, A. Application of ultrasound for quality control of Torta del Casar cheese ripening. J. Dairy Sci. 2020, 103, 8808–8821. [Google Scholar] [CrossRef]

- Shopov, N.; Bosakova-Ardenska, A.; Topalov, I.; Panayotov, P.; Boyanova, P. Ultrasound method for classification of Bulgarian white brined sheep and cow cheese. In Proceedings of the XXIX International Scientific Conference Electronics (ET), Sozopol, Bulgaria, 16–18 September 2020. [Google Scholar]

- Petrova, P.; Ivanov, I.; Tsigoriyna, L.; Valcheva, N.; Vasileva, E.; Parvanova-Mancheva, T.; Arsov, A.; Petrov, K. Traditional Bulgarian Dairy Products: Ethnic Foods with Health Benefits. Microorganisms 2021, 9, 480. [Google Scholar] [CrossRef]

- Teneva-Angelova, T.; Balabanova, T.; Boyanova, P.; Beshkova, D. Traditional Balkan fermented milk products. Eng. Life Sci. 2018, 18, 807–819. [Google Scholar] [CrossRef] [PubMed]

- Solberg, L.E.; Wold, J.P.; Dankel, K.; Øyaas, J.; Måge, I. In-Line Near-Infrared Spectroscopy Gives Rapid and Precise Assessment of Product Quality and Reveals Unknown Sources of Variation—A Case Study from Commercial Cheese Production. Foods 2023, 12, 1026. [Google Scholar] [CrossRef] [PubMed]

- Baycheva, S.; Zlatev, Z.; Veleva, P. Influence of unregulated storage conditions on physico-chemical, organoleptic and NIR spectral characteristics of yellow cheese. BIO Web Conf. 2023, 58, 01006. [Google Scholar] [CrossRef]

- Ayvaz, H.; Mortas, M.; Dogan, M.A.; Atan, M.; Tiryaki, G.Y.; Yuceer, Y.K. Near- and mid-infrared determination of some quality parameters of cheese manufactured from the mixture of different milk species. J. Food Sci. Technol. 2020, 58, 3981–3992. [Google Scholar] [CrossRef] [PubMed]

- Yaman, H.; Aykas, D.P.; Rodriguez-Saona, L.E. Monitoring Turkish white cheese ripening by portable FT-IR spectroscopy. Front. Nutr. 2023, 10, 1107491. [Google Scholar] [CrossRef] [PubMed]

- Soto-Barajas, M.C.; González-Martín, M.I.; Salvador-Esteban, J.; Hernández-Hierro, J.M.; Moreno-Rodilla, V.; Vivar-Quintana, A.M.; Revilla, I.; Ortega, I.L.; Morón-Sancho, R.; Curto-Diego, B. Prediction of the type of milk and degree of ripening in cheeses by means of artificial neural networks with data concerning fatty acids and near infrared spectroscopy. Talanta 2013, 116, 50–55. [Google Scholar] [CrossRef] [PubMed]

- Onea, A.; Collewet, G.; Fernandez, C.; Vertan, C.; Richard, N.; Mariette, F. Quality analysis of blue-veined cheeses by MRI: A preliminary study. In Proceedings of the SPIE 5132, Sixth International Conference on Quality Control by Artificial Vision, Gatlinberg, TN, USA, 19–22 May 2003. [Google Scholar] [CrossRef]

- Musse, M.; Challois, S.; Huc, D.; Quellec, S.; Mariette, F. MRI method for investigation of eye growth in semi-hard cheese. J. Food Eng. 2014, 121, 152–158. [Google Scholar] [CrossRef]

- Anedda, R.; Melis, R.; Curti, E. Quality Control in Fiore Sardo PDO Cheese: Detection of Heat Treatment Application and Production Chain by MRI Relaxometry and Image Analysis. Dairy 2021, 2, 270–287. [Google Scholar] [CrossRef]

- Lukinac, J.L.; Jukić, M.J.; Mastanjević, K.M.; Lučan, M.L. Application of computer vision and image analysis method in cheese-quality evaluation: A review. Ukr. Food J. 2018, 7, 192–214. [Google Scholar] [CrossRef]

- Dias, J.; Lage, P.; Garrido, A.; Machado, E.; Conceição, C.; Gomes, S.; Martins, A.; Paulino, A.; Duarte, M.F.; Alvarenga, N. Evaluation of gas holes in “Queijo de Nisa” PDO cheese using computer vision. J. Food Sci. Technol. 2020, 58, 1072–1080. [Google Scholar] [CrossRef]

- Minz, P.S.; Saini, C.S. Comparison of computer vision system and colour spectrophotometer for colour measurement of mozzarella cheese. Appl. Food Res. 2021, 1, 100020. [Google Scholar] [CrossRef]

- Jeliński, T.; Du, C.-J.; Sun, D.-W.; Fornal, J. Inspection of the distribution and amount of ingredients in pasteurized cheese by computer vision. J. Food Eng. 2007, 83, 3–9. [Google Scholar] [CrossRef]

- Ganchovska, V.; Bosakova-Ardenska, A.; Andreeva, H.; Danev, A.; Panayotov, P.; Boyanova, P. Automatic mold analysis in blue cheese. J. Hyg. Eng. Des. 2022, 39, 252–258. [Google Scholar]

- Danev, A.; Bosakova-Ardenska, A.; Boyanova, P.; Panayotov, P.; Kostadinova-Georgieva, L. Cheese quality evaluation by image segmentation: Image segmentation algorithm for broken surface evaluation of Bulgarian white cheese in brine. In Proceedings of the CompSysTech’19: The 20th International Conference on Computer Systems and Technologies, Ruse, Bulgaria, 21–22 June 2019. [Google Scholar] [CrossRef]

- Bosakova-Ardenska, A.; Kutryanska, M.; Boyanova, P.; Panayotov, P. Application of images segmentation and median filter for white brined cheese structure evaluation. AIP Conf. Proc. 2022, 2570, 020014. [Google Scholar] [CrossRef]

- Bosakova-Ardenska, A.; Danev, A.; Boyanova, P.; Panayotov, P. Application of image analysis techniques for quality assessment of Swiss-type of cheese. In Proceedings of the 35th International Conference on Information Technologies, Varna, Bulgaria, 16–17 September 2021; pp. 27–30. [Google Scholar] [CrossRef]

- Barreto, A.; Cruz-Tirado, J.; Siche, R.; Quevedo, R. Determination of starch content in adulterated fresh cheese using hyperspectral imaging. Food Biosci. 2018, 21, 14–19. [Google Scholar] [CrossRef]

- Farrugia, J.; Griffin, S.; Valdramidis, V.P.; Camilleri, K.; Falzon, O. Principal component analysis of hyperspectral data for early detection of mould in cheeselets. Curr. Res. Food Sci. 2021, 4, 18–27. [Google Scholar] [CrossRef]

- Datta, A.; Nicolaï, B.; Vitrac, O.; Verboven, P.; Erdogdu, F.; Marra, F.; Sarghini, F.; Koh, C. Computer-aided food engineering. Nat. Food 2022, 3, 894–904. [Google Scholar] [CrossRef]

- Lei, T.; Sun, D.-W. Developments of nondestructive techniques for evaluating quality attributes of cheeses: A review. Trends Food Sci. Technol. 2019, 88, 527–542. [Google Scholar] [CrossRef]

- Yoo, W.S.; Kang, K.; Kim, J.G.; Yoo, Y. Image-Based Quantification of Color and Its Machine Vision and Offline Applications. Technologies 2023, 11, 49. [Google Scholar] [CrossRef]

- Krupitzer, C.; Noack, T. DigiFoodTwin: Digital Biophysical Twins Combined with Machine Learning for Optimizing Food Processing. Eng. Proc. 2022, 19, 42. [Google Scholar] [CrossRef]

| Type of Cheese | Quality Indicator | Used Technology | Source | |

|---|---|---|---|---|

| Regional cheese | Torta del Casar | fat and ash content, firmness | Ultrasound | Crespo et al., 2020 [10] |

| Fiore Sardo | internal structure | MRI * | Anedda et al., 2021 [21] | |

| Queijo de Nisa | gas holes area | CV * | Dias et al., 2020 [23] | |

| Cheese with mold | Blue cheese | cavities evolution | MRI * | Onea et al., 2003 [19] |

| mold distribution | CV * | Ganchovska et al., 2022 [26] | ||

| Cheese with holes | Swiss type of cheese | maturation stage | Ultrasound | Eskelinen et al., 2007 [8] |

| eyes distribution | CV * | Bosakova-Ardenska et. al., 2021 [29] | ||

| Semi-hard cheese | eyes volume | MRI * | Musse et al., 2014 [20] | |

| White cheese | Bulgarian white cheese in brine | type of raw milk | Ultrasound | Shopov et al., 2020 [11] |

| presence of “Porcelanov lom” | CV * | Danev et al., 2019 [27] | ||

| structure | CV * | Bosakova-Ardenska et al., 2022 [28] | ||

| Turkish white cheese in brine | organic, free fatty and free amino acids | NIR * | Yaman et al., 2023 [17] | |

| Ezine cheese | protein, fat, salt, dry matter, moister and ash content | NIR * | Ayvaz et al., 2020 [16] | |

| Cheese from milk mixture | fatty acid, type of raw milk | NIR * | Soto-Barajas et al., 2013 [18] | |

| Cheese | Mozzarella | color | CV * | Minz and Saini, 2021 [24] |

| Cheddar | moisture | Ultrasound | Benedito et al., 2000 [9] | |

| Yellow cheese | active acidity | NIR * | Baycheva et al., 2023 [15] | |

| Fresh cheese | starch content | CV (HSI) * | Barreto et al., 2018 [30] | |

| Cheese with vegetable ingredients | amount and distribution of ingredients | CV * | Jeliński et al., 2007 [25] | |

| Gouda | dry matter content | NIR * | Solberg et al., 2023 [14] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bosakova-Ardenska, A. Recent Trends in Computer Vision for Cheese Quality Evaluation. Eng. Proc. 2024, 60, 12. https://doi.org/10.3390/engproc2024060012

Bosakova-Ardenska A. Recent Trends in Computer Vision for Cheese Quality Evaluation. Engineering Proceedings. 2024; 60(1):12. https://doi.org/10.3390/engproc2024060012

Chicago/Turabian StyleBosakova-Ardenska, Atanaska. 2024. "Recent Trends in Computer Vision for Cheese Quality Evaluation" Engineering Proceedings 60, no. 1: 12. https://doi.org/10.3390/engproc2024060012

APA StyleBosakova-Ardenska, A. (2024). Recent Trends in Computer Vision for Cheese Quality Evaluation. Engineering Proceedings, 60(1), 12. https://doi.org/10.3390/engproc2024060012