Abstract

Electrocardiography (ECG) is one of the most widely used diagnostic methods to examine heart situations. This paper focuses on the development of a textile-based electrode and the study its ECG-detecting performance. We developed silver-printed textile electrodes via a the flat-screen printing of silver ink on knitted polyester fabric. The silver-printed PET fabric stayed reasonably conductive after washing and stretching, which makes it suitable for wearable applications. Moreover, the ECG measurements in static condition showed that the signal quality collected before and after washing was comparable with standard Ag/AgCl electrodes.

1. Introduction

Traditionally, textile clothing is used for protecting the wearer from different weather conditions and is expected to have a good fit and comfort. However, nowadays, we demand a lot from our clothing to make our life easy, and this is becoming possible due to the rapid emergence of new types of materials and the miniaturization of electronic components which have led to the development of smart textile materials [1,2].

Textile-based electrocardiogram (ECG) sensors are one application area of smart wearable healthcare textiles. Silver/silver chloride (Ag/AgCl) gelled electrodes are the most commonly used types of electrodes for ECG monitoring because of their ability to capture a high-quality signal. However, the gel employed in such electrodes can cause skin irritation and dries out during prolonged recordings, which causes deterioration of the signal quality [3,4]. This makes gelled electrodes unsuitable for wearable systems.

Textile electrodes are ideal for building wearable health monitoring devices due to their inherent flexibility and softness [5]. Conductive textiles can be used for this application by fixing them to an elastic band or tight garment, which creates good contact of the electrode with the skin of the user. Recently, many textile-based ECG electrodes have been developed. Yokus and Jur [6] developed fabric electrodes screen-printing Ag/AgCl conductive inks on nonwoven fabrics encircled with an adhesive sheet, and they reported that the printed electrode yielded comparable ECG signals to wet electrodes. However, they did not investigate comfortability, washability, and durability.

In this study, a silver-printed textile electrode was created for ECG detection. The electrode was developed by the screen printing of polyester knitted fabric with silver ink. Knitted fabric is preferred because of its flexibility and ability to fit to the body. ECG test results showed that the developed electrodes have a capacity to acquire ECG signals.

2. Experimental

2.1. Materials and Sample Preparation

Knitted polyester fabric weighing 140 g/m2 and with a thickness of 0.49 mm was used to fabricate electrodes. High-performance silver ink (Metalon HPS-FG32) with a solid content of 75% and particle size of 1.5 microns was provided by Novacentrix. Screen printing was used to develop conductive textile with electrode sizes of 6 cm2 (3 × 2 cm) to be used as ECG electrodes. Stainless-steel screen mesh with a mesh count of 90 was used to develop the screen. The silver ink was stirred thoroughly before use to achieve good dispersion. Three samples were printed and cured at 120 °C for 30 min according to the manufacturer’s recommendation. A metallic snap connector was attached to the textile electrode in order to connect to the wires of an ECG recording module.

2.2. Electrical Conductivity Measurement

The surface resistance of the silver-printed electrodes was measured with the four-point method, using an MR-1 surface measuring instrument (Schuetz Messtechnik). This method is more accurate compared to the two-point method [7]. In the four-point method, there are four contacts: the current, I, is supplied via the two outer contacts, and the voltage, V, is measured through the two middle contacts. Ten readings were taken and recorded to compute the mean and standard deviation. The surface image of the fabric before and after printing was studied by scanning electron microscopy (SEM-FEI Quanta 200 FFE) with an acceleration voltage of 20 kV.

To investigate the wash stability, the textile electrodes were washed with 4 g/L non-ionic detergent and 1 g/L sodium carbonate at 40 °C for 30 min, according to the ISO norm 105-C06-A1S, 2010 standard method. The effect of stretching on the conductivity of the textile electrodes was also studied by stretching the textile electrodes on a light-duty drill vice modified for this purpose, as shown in (Figure S1a). The samples were stretched from 5% to 40% of their original length with 5% intervals, and the surface resistance was recorded at different stretching percentages of the sample using a two-point probe method with a Fluke 87 multimeter. The increase in surface resistance was calculated as follows:

where Ri is the surface resistance at different stretching levels, and R0 is the original surface resistance when not stretched.

2.3. ECG Measurement

ECG performance of the electrodes was tested by placing three electrodes on the skin of a healthy volunteer: one on the right wrist, one on the left wrist, and the third one, i.e., the reference electrode, on the back of the left forearm (Figure S1b). The electrodes were wrapped on the wrist using an elastic strap to ensure the electrodes remained in the correct position. Once all electrodes were placed in the right spot, the electrodes were connected to a portable ECG device (PC-80B easy ECG monitor purchased from Shanghai Lishen Scientific Equipment, China). For comparison of the performance of the developed electrodes with standard Ag/AgCl electrodes, an asynchronous ECG recording method, i.e., two electrodes fixed at the same place and a signal recorded at a different time, was implemented. We collected data from both the textile and standard electrodes in the following conditions: sitting down on a chair, with two arms on the table for 3 min, and walking on a smooth surface for 3 min. Collected ECG signals were uploaded to a computer for analysis using the ECG viewer manager software provided by the manufacturer of the device. This software enabled determination of the amplitude of P, QRS, and T waveforms, as well as beats per minute (bpm).

3. Results

Conductivity is one factor that affects the ECG detection performance of textile electrodes. The silver-printed polyester electrodes had a surface resistance of 1.78 ± 0.2 Ω/Sq, which showed that they have acceptable conductivity to be used as ECG electrodes. After washing, the sheet resistance of the electrodes increased to 3.77 Ω/Sq (2.12 times greater than the original value). This increase in resistance is due to the washing away of silver particles which are loosely attached to the fabric surface. Kazani et al. have also reported that silver-printed textiles show a considerable increase in resistance after ten washes [7]. The SEM image (Figure S2a) shows that the silver flakes coated on the fabric and gaps between adjacent loops filled with silver particles, which made the fabric conductive. The stretch test results (Figure S2b), on the other hand, show that resistance increased linearly with stretching up to 40%. The increase in surface resistance at 5% stretch was around 6%, which increased to only 18.28% at 40% stretch. This reveals that even at 40% stretching, the conductivity of the electrodes is not affected in a way that would make signal acquisition problematic.

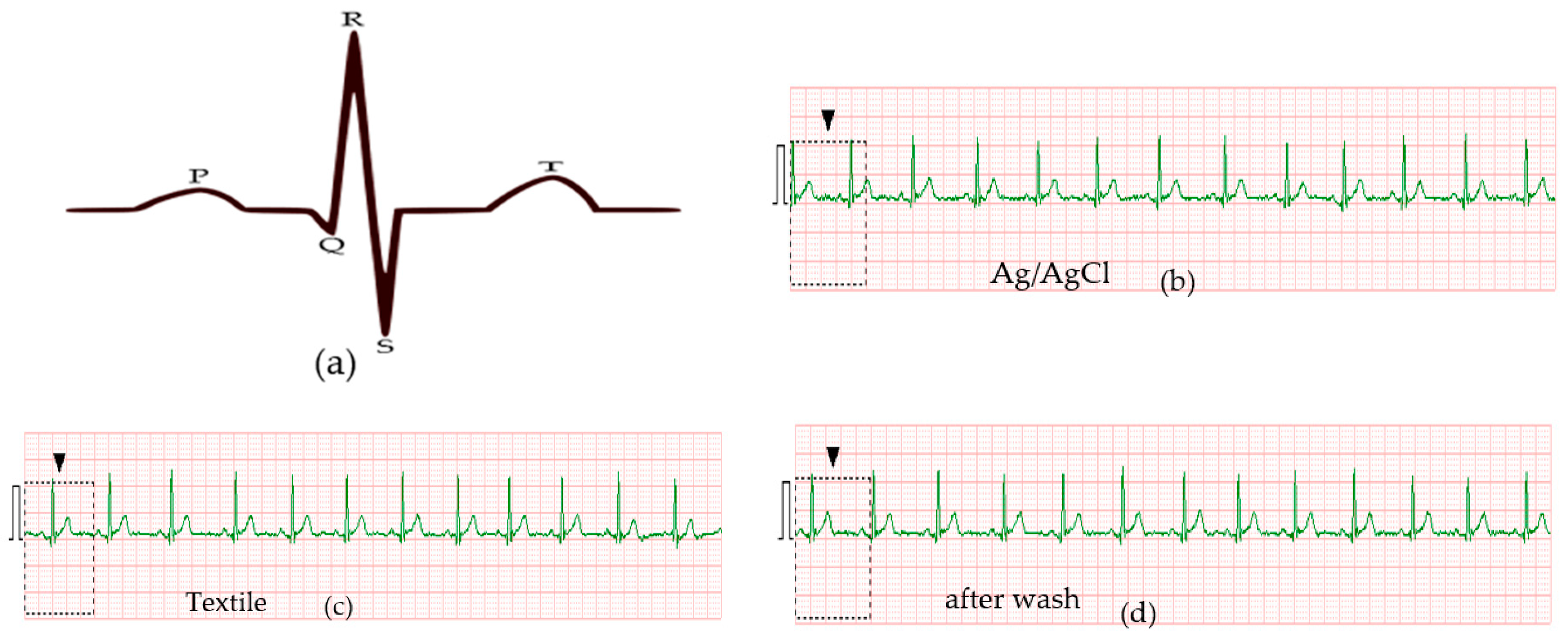

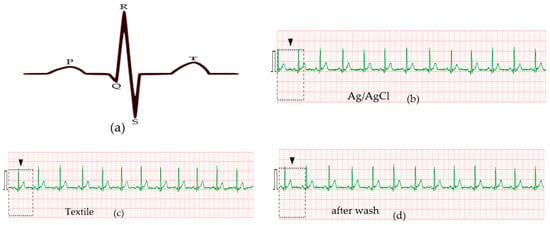

A typical ECG signal contains three main components i.e., P wave, T waves, and QRS complex, as shown in Figure 1a. An ECG waveform is acceptable if the major picks are clearly visible, with no missing R-peaks or falsely detected R-peaks in the QRS complex [8]. Figure 1b shows the ECG signal collected using standard Ag/AgCl electrodes, and Figure 1c shows the signals acquired using printed textile electrodes in a static position. The major peaks were visible in both waveforms. Visual examinations of the test results demonstrated that ECG signals collected using the printed textile electrode were consistent with signals collected using the standard electrodes. In the signal collected using textile electrodes, the P, QRS, and T waves are recognizable with signal amplitudes of 0.09, 1.20, and 0.30 mV, respectively, and their R-peak waves are approximately the same. The P, QRS, and T waves of the signals collected using Ag/AgCl electrodes were 0.10, 1.21, and 0.30 mV, respectively. The heartbeat results were 72 bpm and 76 bpm for the polyester electrode and the standard electrodes during asynchronous measurement, respectively, which is sufficiently similar to allow comparison. As shown in Figure 1d, the ECG signals collected by the textile electrodes after washing still contained clearly visible P, QRS, and T waves, with amplitudes of 0.08, 1.13, and 0.27 mV, respectively, and the heartbeat was 77 bpm, signals which are comparable to those acquired before washing.

Figure 1.

(a) Components of an ECG signal, (b) signal collected using the Ag/AgCl electrode, (c) signal collected using the textile electrode, and (d) signal collected using the textile electrode after washing. All signals were collected in static conditions.

For better ECG signal detection, there should be stable contact between the electrode and the body. During movement, the skin–textile contact slides slightly; hence, the electrodes cannot capture the electric current as accurately, which leads to the deterioration of signal quality. A solution could be to fit the band more tightly to the body, but this would negatively affect the comfort of the user. Signals collected while walking using textile electrodes (Figure S3a) gave lower signal quality compared to signals collected using Ag/AgCl electrodes (Figure S3b), which could be due to an unstable contact of the electrodes with skin when moving. P, QRS, and T peaks were not clear enough in the signals from the textile electrode, but were sufficient to determine beats per minute. Work is in progress to improve the signal quality of the textile electrode in motion.

4. Conclusions

A textile ECG electrode was developed by the screen printing of silver ink on knitted polyester fabric. The surface resistance of the printed electrodes was 1.78 Ω/Sq. After washing, the sheet resistance of the electrodes increased by 2.12 times but increased only slightly while stretching up to 40%. The ECG signals acquired using textile electrodes were comparable with signals from standard Ag/AgCl electrodes. The P, QRS, and T waves were recognizable with signal amplitudes of 0.09, 1.20, and 0.30 mV for signals collected using textile electrodes, whereas 0.10, 1.21, and 0.30 mV were obtained, respectively, for signals collected from Ag/AgCl electrodes during asynchronous measurements. Even though the sheet resistance of the electrode increased after washing, they were able to capture signals with acceptable quality.

Supplementary Materials

The presentation file is available at https://www.mdpi.com/article/10.3390/I3S2021Dresden-10139/s1.

Author Contributions

A.B.N. conducted the experiment, analyzed results, and wrote the paper; B.M. and D.A.M. analyzed the results and edited the paper; L.V.L. supervised and administered the project. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the CoE project funded through KFW project No. 51235 ((PE 479—Higher Education) under grant number MBZ/201166305 in collaboration with the Ethiopian government.

Institutional Review Board Statement

The study was conducted following the Declaration of Helsinki, and the protocol was approved by the Institutional Review Board of EiTEX, Bahir-Dar University under the reference number EiTEX-PGPDO/37/2020.

Informed Consent Statement

All subjects gave their informed consent for inclusion before they participated in the study.

Data Availability Statement

Data sharing is not applicable to this article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Wang, Y.; Deepu, C.J.; Lian, Y. A Computationally Efficient QRS Detection Algorithm for Wearable ECG Sensors. In Proceedings of the Annual International Conference of the IEEE Engineering in Medicine and Biology Society, Boston, MA, USA, 30 August–3 September 2011; pp. 5641–5644. [Google Scholar]

- Koncar, V. Smart Textiles and Their Applications; Woodhead Publishing: Sawston, UK, 2016; ISBN 9780081005835. [Google Scholar]

- Abu-Saude, M.; Morshed, B.I. Characterization of a Novel Polypyrrole (PPy) Conductive Polymer Coated Patterned Vertical CNT (PvCNT) Dry ECG Electrode. Chemosensors 2018, 6, 27. [Google Scholar] [CrossRef] [Green Version]

- Xu, P.J.; Zhang, H.; Tao, X.M. Textile-Structured Electrodes for Electrocardiogram. Text. Prog. 2008, 40, 183–213. [Google Scholar] [CrossRef]

- Yapici, M.K.; Alkhidir, T.E. Intelligent Medical Garments with Graphene-Functionalized Smart-Cloth ECG Sensors. Sensors 2017, 17, 875. [Google Scholar] [CrossRef] [Green Version]

- Yokus, M.A.; Jur, J.S. Fabric-Based Wearable Dry Electrodes for Body Surface Biopotential Recording. IEEE Trans. Biomed. Eng. 2016, 63, 423–430. [Google Scholar] [CrossRef]

- Kazani, I.; Hertleer, C.; de Mey, G.; Schwarz, A.; Guxho, G.; van Langenhove, L. Electrical Conductive Textiles Obtained by Screen Printing. Fibres Text. East. Eur. 2012, 90, 57–63. [Google Scholar]

- Taji, B.; Shirmohammadi, S.; Groza, V.; Bolic, M. An ECG Monitoring System Using Conductive Fabric. In Proceedings of the 2013 IEEE International Symposium on Medical Measurements and Applications (MeMeA), Gatineau, QC, Canada, 4–5 May 2013; pp. 309–314. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).