Abstract

Correct implementation of circular economy measures is essential for achieving sustainable development criteria with a growing share of the world’s population and global product consumption. This article examines the problem of ensuring a quality life for residents in the city of Ruse by increasing the efficiency of the water supply based on IoT and blockchain technologies. For the application of the technology, the regulatory, technical, socio-economic, and financial areas are classified, which must be updated according to the functionality of the water supply system. The current state of the automated water supply system has been studied. The digitization of a dispatcher is proposed for working IoT. Hyperledger Fabric is selected as a suitable DLT platform. A communication scheme is proposed for sharing data with citizens, repair companies, and regulatory bodies in the event of an accident.

1. Introduction

Water is one of the most important natural resources without which life on earth is impossible. The main sources of drinking water are rivers, lakes, reservoirs, springs, and groundwater. The underground piped water supply system has the highest relative share in urbanized areas. In addition to drinking needs, it is widely used both in industrial production and in households, agricultural production, and construction. The set goals for sustainable development (SDGs) require the implementation of various measures for the environmentally friendly use of available natural resources and the provision of sufficient resources for future generations to ensure the well-being of the population and its security in economic, ecological, and social terms, as well as with the adverse consequences of climate change (mainly drought) [1,2]. These include the reduction in hunger and equal access to education, health care, and renewable energy sources with strict observance of the principles of the circular economy regarding the protection of natural resources and the environment. Despite the apparent heterogeneity of the listed measures, the common goal is to achieve optimal use of resources without waste. Achieving this common goal requires developing and implementing new production processes and technologies, training people and specialized personnel, capabilities to remotely manage and control domestic and industrial applications, etc. [3].

It is known that a significant part of the waste of natural resources is due to poor and/or unmaintained infrastructure. This leads to increased losses in material, ecological, and social terms. They can have direct and indirect impacts on water resources. For example, bad roads lead to increased fuel consumption, more frequent vehicle breakdowns, prerequisites for traffic jams, increased levels of fine dust particles, soil, water pollution, etc. Another example of an indirect impact on the water supply system is the state of the power transmission system [3]. It is an extremely important element of the country’s infrastructure because the modern economy, people’s lives, and electrical equipment in general are directly related to its functional condition and suitability. System overloads, the influence of temperature and mechanical loads on overhead power lines, unmaintained infrastructure, and others are the cause of damage to transformers and power lines, which can lead to loss of human life, material losses (damage to pumps for water supply and irrigation systems), and often to environmental problems (current in the ground, leading to stray current and, accordingly, corrosion of the underground water supply, gas transmission, and other infrastructure) [4,5]. All this requires a qualitative analysis of the condition of pipeline systems. A major difficulty in its implementation is determining the function, size, cause, and location of the accident. Damaged pipelines lead to loss of fluid (water, gas, oil), the possibility of explosion in two of the cases, environmental pollution, deterioration of people’s health, stoppage of fuel or water supply for households and industry, increase in prices, etc. [6]. Therefore, the efficient and trouble-free functioning of water supply systems and the quality of water, especially for drinking purposes, is of primary importance, which is also the topic of this article.

One of the ways to improve the functionality of the water supply system is by reducing losses through timely detection of violations of normal operation and deteriorated quality of drinking water available in the underground water transmission network. In this regard, several normative documents have been adopted in Bulgaria in accordance with the Guidelines of the World Health Organization and the EU Directives regarding the quality of water intended for human consumption. They regulate the implementation of consistent policies and efforts of the country related to increasing the quality of water supply and sewerage services in the implementation of the Strategy for the Development of the Water Sector and the commitments undertaken by the Republic of Bulgaria in connection with the “Plan for Development and Sustainability” and the fight against climate change.

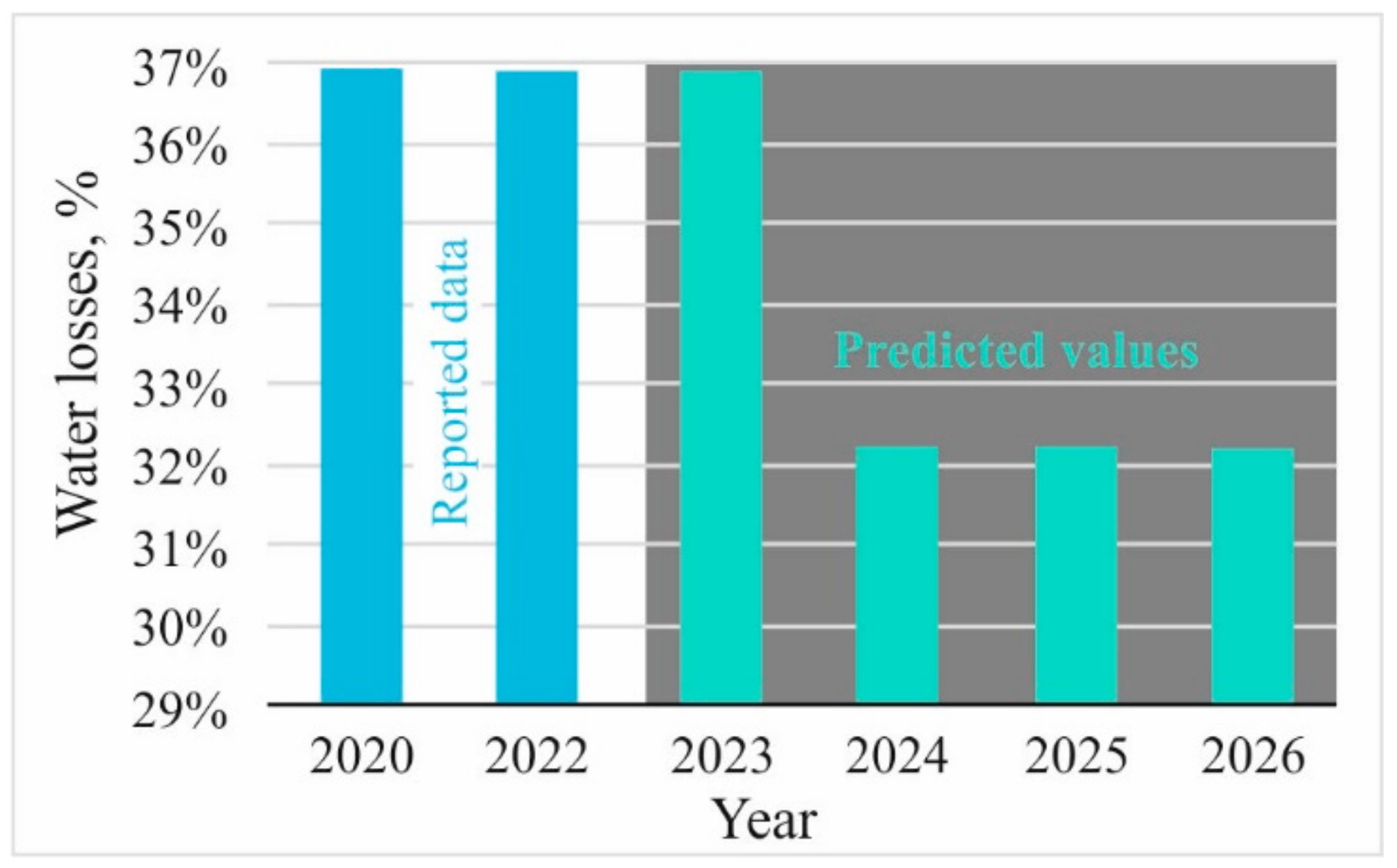

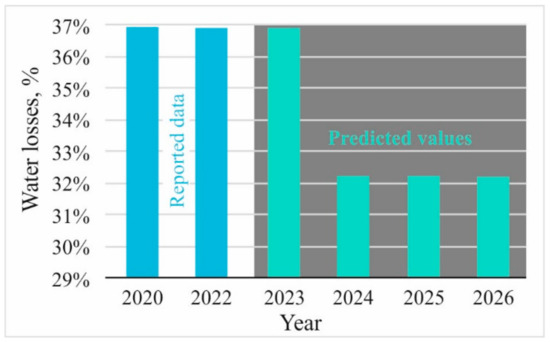

In the territory of Bulgaria, water supply and sewage services are provided by 45 Water Supply and Sanitation (WSS) operators. One of them is WSS Ltd.—Ruse (Ruse, Bulgaria). According to the company’s approved business plan, the amount of actual water losses should decrease by 1% per year in the following years (Figure 1).

Figure 1.

Realized drinking water losses from WSS-Ruse, Bulgaria, and forecast for their reduction.

The significant reduction in water losses in 2024 is expected to be realized after the implementation of a project under the Operational Program Environment to achieve full compliance of the Ruse agglomeration with the requirements of Directive 91/271/EEC and Directive 98/83/EC on ensuring continuity of the water supply, increasing the efficiency of the water supply network and modernization of the disinfection and decontamination system for the city of Ruse, and renovation of the main supply water supply. The total reduction in real water losses for the city of Ruse in 2026 is expected to be 1,769,193 m3 less compared to 2020. However, the level of drinking water losses will remain at a relatively high relative level.

The main goal of this article is to propose solutions to reduce losses in the water supply system of the city of Ruse by improving its functionality by applying modern electrical and communication means. This includes the smart meters and devices in the context of an advanced metering infrastructure to exchange data via IoT, and the company itself to increase its trust and efficiency by building and developing smart networks in the urban environment through blockchain (BC) technologies.

2. Analysis of the Existing Technical State

The company WSS Ltd.—Ruse serves 219 underground water sources: bore wells—105; shaft wells—35 pcs.; “Raney” type wells—11 pcs.; drains—53 pcs.; catchments of natural springs—15 pcs. Of these, 165 units are in regular operation mode and 54 units are spare with a total design flow rate of 3946 1/s. The total length of the supply pipelines is 649 km, and the length of the distribution network is 1980 km. There are 111 pumping stations with a total power of 23,250 kW. Pressure reservoirs (119 pcs.) have a total volume of 73,901 m3 and the water withdrawal ones (53 pcs.) have a total volume of 10,417 m3.

All 219 water sources are covered by 105 measuring devices. The measurement of water quantities is carried out at all water sources and the entrance to populated areas. At all water measurement points, water meters and flow meters are installed to measure the volumes of water drawn for the authorized purposes of water intake.

The company uses an automated water supply management system (AWSMS). It is built on a modular principle based on a single-chip microcomputer. The system covers 55 water supply facilities. Using the terminal station (TS) with a large connection board (ST), multiple parameters are monitored through 48 digital and 16 analog inputs. The connection among the measuring devices is by radio air, and a wired network connection is also provided for those in charge.

The system allows the following parameters to be monitored:

- Analog pressure, flow, level, current, electrical energy, etc.

- Digital-level, serviceable electrical supply, rectifier, battery, selected pump, working and emergency status of pumping units (PA), break-in, etc.

Dispatchers have the ability to start and stop the PA on their initiative to limit the work of the PS through the top (without canceling the action of the local automation), as well as emergency start and stop in case of the need for an immediate intervention. The system registers a break-in of the objects with an initiative from a lower level and an audible signal to the staff on duty. The system allows management in autonomous mode without the intervention of dispatchers.

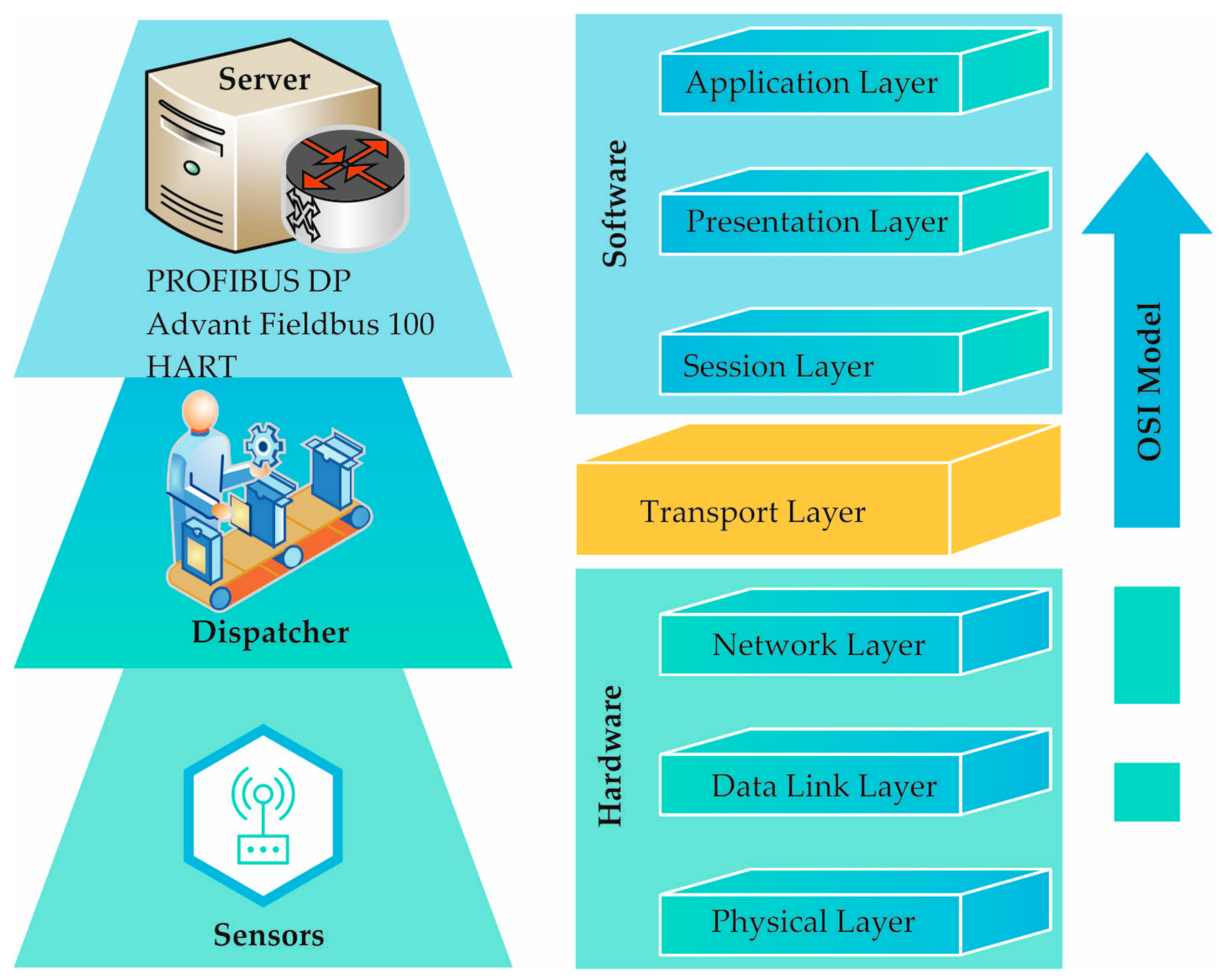

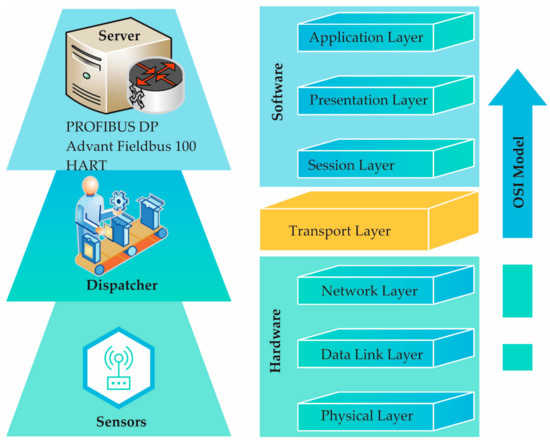

The functionality of the AWSMS can be divided into three levels in collecting and processing data. The first level is based on the installed primary converters in the technological objects. The second level is realized through electronic devices to cover the general measurements and control of various processes. Signals are transmitted via standard communication channels PROFIBUS DP, Advant Fieldbus 100, and HART interface with a high level of security. Logged data are fed to a central server. Most devices have smart features such as remote access to perform service functions such as loading data, downloading archive values, checking clocks, etc. The third level is the central server where the data are collected and processed. Both mechanisms for collecting data are used: polling (cyclic traversal) and exception (transmission of data at the initiative of the end device). The data are stored in a relational SQL database. A daily backup of production data is generated every 30 min.

In the AWSMS built in this way, the actual control and management are carried out by the on-duty dispatchers (manual management and control). They receive data on the PC monitor from the TS by objects and based on the technological assignments manage the processes. To implement an automatic system with intelligent functions, it is necessary to build it according to the requirements of the OSI model (Figure 2). This means digitalization, i.e., replacing dispatchers with a digital device (AI).

Figure 2.

Current communication scheme.

Despite the presence of modern measuring and technical devices, there is a significant share of drinking water losses (Figure 1) due to the outdated and compromised water supply network and the need to modernize the communication system. It can be seen that the automated system requires new functions such as control of internal processes, monitoring the consumption by settlements, performing checks on the accuracy of water meter readings, etc.

3. Prerequisites for Implementation of IoT and Blockchain Technologies

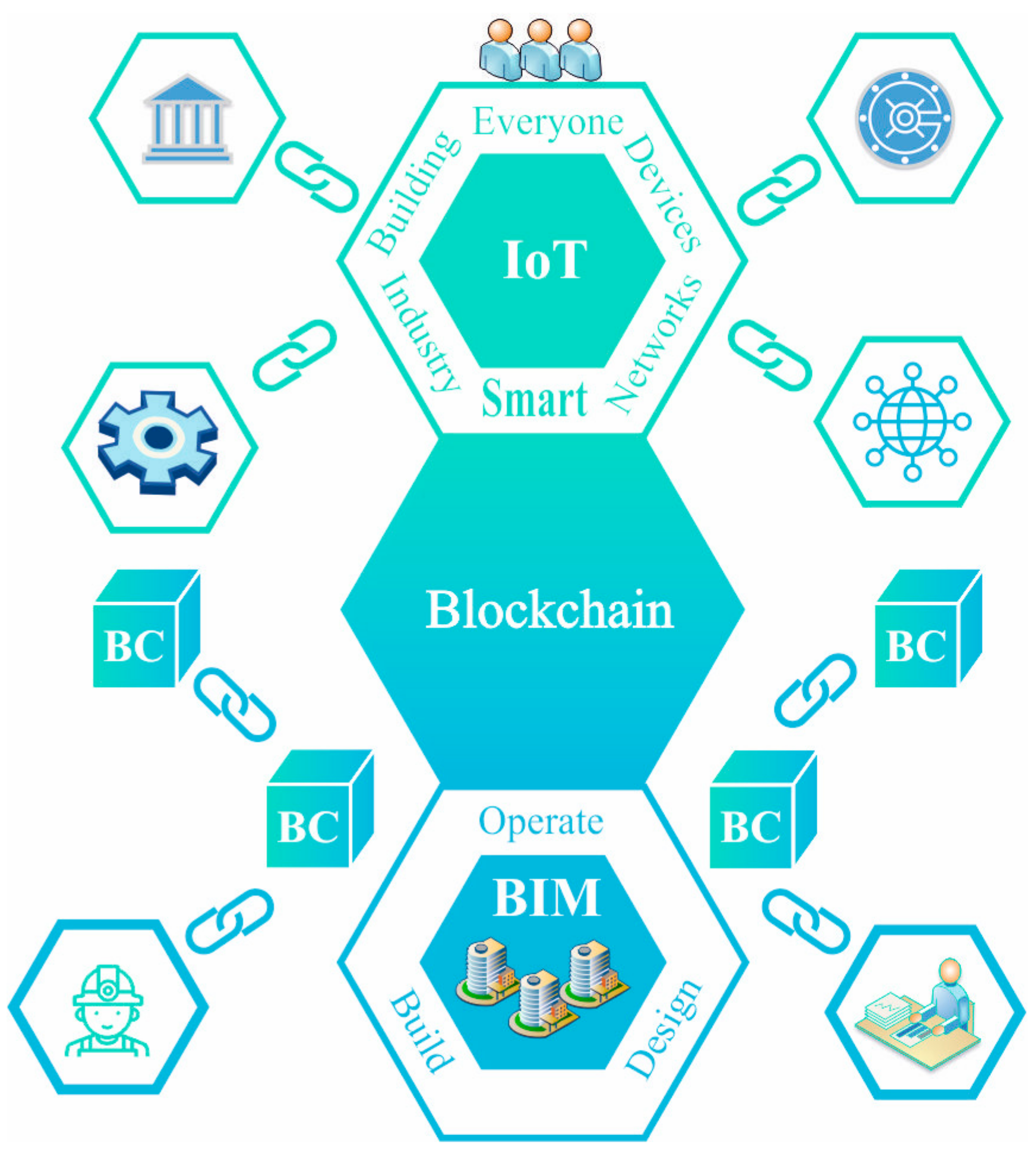

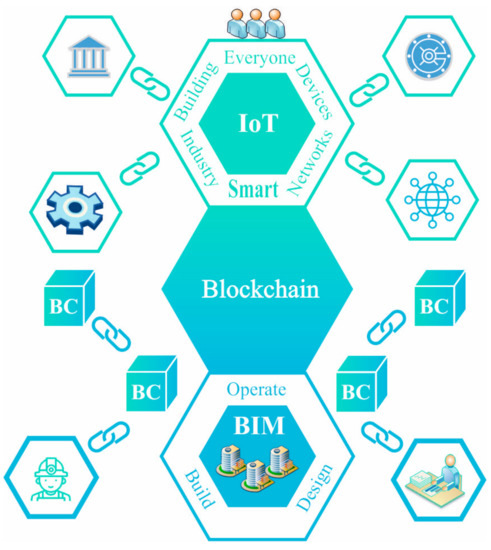

To improve the functionality of the water supply system through IoT and blockchain technologies, it is necessary to carry out additional research to build a smart city [7]. For this purpose, the difficulties and possibilities of implementing the cited technologies must be analyzed so that they are compatible with the currently existing measuring devices and that the digitized information is managed according to the BIM (building information modeling) life cycle—IoT and BIM are interconnected technologies [8] (Figure 3).

Figure 3.

Interaction of BIM, IoT, and blockchain.

In BIM, a mandatory condition for improving the quality and functionality of water supply services is the remote and continuous monitoring of systems and problems, determining the quality of drinking water, optimizing water distribution, and last but not least, achieving trust among the parties involved [8]. The implementation of new technologies serves not only to maintain public infrastructure but also to optimize services in buildings, i.e., construction of modern systems for building automation (BMS) of processes and the transformation of a building from passive to intelligent [8]. These are integrated solutions oriented towards the most efficient management based on the joint work of all available installations.

The introduction of smart technologies helps to transform existing systems into ones that interact, learn, and adapt. They actively contribute to increased energy efficiency and reduction in losses, and hence increase the functionality of the water supply system. In addition, they help operators and users to collect and analyze data to improve their behavior and thereby reduce their costs. With the capabilities of Industry 4.0, efficiency increases in the management of not only production processes. The implementation of intelligent measuring and control devices leads to an increase in energy efficiency and improvement of the management of technological processes, as well as to the quality of life of people [8].

Other basic requirements for water supply infrastructure are continuous monitoring and high speed of data transmission [7,8], licenses and terms of exchange, increased security, reliability, etc. [9]. To ensure the continuity of the power supply, it is appropriate to use a UPS whose charge is maintained by an independent energy source [10], which will guarantee the high reliability and trouble-free operation of the control system. All this positively affects the operating characteristics of water supply systems not only for urban conditions but also for small settlements. With the aim of the correct subsequent processing and analysis of the obtained results, the implementation of a digitized urban pipeline management system is related to the preliminary planning of the quantities and parameters for data collection and transfer in accordance with the requirements of Industry 4.0 and more specifically Big Data [11]. The reason is that, in addition to volume, data are also classified by transmission speed and diversity, which requires first categorizing them and then determining the type of parameters [12].

3.1. Issues and Challenges for Implemented IoT

Dogo’s study [8] determined the capabilities of IoT and BC in stormwater management, water resource quality, increasing trust, and achieving payment speed. Automated management is particularly suitable when building systems for flood risk prevention, dam status monitoring, technical risks, natural disasters, and drought. A suitable solution for scarce water resources, for example, in the countries of North Africa, Central Asia, West Asia, and Latin America [9], is to define water licenses and terms of exchange, or even the issuance of green bonds for distribution, collection of funds, and implementation of the infrastructure to improve the quality of water supply and irrigation systems precisely on the basis of IoT and BC. In [13], a communication model for IoT with real-time traffic priority in terms of channel resource occupation and utilization was proposed.

In his report, Sriyono identified problems for small communities through local indicators such as floods, dry spells, shortages, mature base, water quality, water wastage, managers, and inefficiently controlled use [9]. According to him, the problems can be solved only through the joint application of Industry 4.0 technologies and the use of the advantages of other infrastructure networks—electricity, renewable sources, etc. In this aspect, the management of even urban water pipes is related to measures in SDGs 6, 9, 11, 12, 13, and 17. In this way, there are better quality services for people, higher yields in agricultural production, and more high efficiency of water supply systems [14].

3.2. Issues and Challenges for Implemented Blockchain

Researchers have undertaken various studies not only on the risks to the deployment of BC but also on the maintenance of functionality and security. To begin with, implementation is associated with technological, social, and legal requirements that must be addressed by each country. All these areas will be considered as measures to increase the efficiency of an urban water transmission system.

In addition, social security and the willingness of society not only to accept the technology but also to use it is important. For now, interest in blockchain technology is still focused on cryptocurrency mining despite the rising prices of energy resources. Therefore, according to the OECD, countries should devote more resources to scientific research and development (R&D), carry out system preparation and testing, and create norms to promote the implementation of Industry 4.0 for water management by proving its benefits [14].

3.3. Maintaining the Integrity of the Specifications

Measures to modernize the management and increase the reliability and energy efficiency of the water supply network for cities are related to the following requirements:

- Regulatory measures—regulation and a legal basis are needed to encourage system modernization. Despite the existence of EU regulations on the open, clear, and digital measurement of all technological processes [15], the local WS (water supply) companies do not have the means, desire, and legal basis to introduce the new technologies;

- Technological measures—new measuring devices are needed that can transmit and receive digital data;

- Infrastructure—currently, not only in Ruse but also in other cities, accidents lead to interruption of water supply in a large area. For example, in Sofia, during the modernization of the water supply system, pumps and taps were installed in some places, which allows the isolation of the damaged section in the event of an accident, while the other part of the network continues to work, i.e., to supply water;

- Public–social—need for material goods and products to satisfy the demands of people; need for scientific and evaluative–normative reflection; need for exchange of data, goods, etc. In this way, better access to services, a focus on the effectiveness of social services, as well as their flexibility and efficiency, are guaranteed.

The listed areas lead to two main obstacles to the implementation of Industry 4.0 technologies—financial, technological means, and organizational. Despite the serious barriers, the benefits would be great for both society and companies. For society, these are increasing reliability and reducing accidents, and supplying good quality water. Despite the high financial and organizational costs for enterprises, these are reduced water losses, reduced benefits for subscribers in case of accidents, increased water and energy efficiency, and achievement of trust among communication partners.

3.4. The functionality of WSS Companies and Effects of the Deployment of BC

The WS system is composed of pipelines, pumps for increasing the pressure, and taps for starting and stopping the water. In this simplest scheme, the implementation of a general project needs to be presented initially, and then it can be detailed. Undoubtedly, some of the advantages will be:

- Reduction in water losses;

- Accurately determining the location of accidents and quickly organizing the teams;

- Absence of financial losses regarding the cost of repairs;

- Fast, unmodified, and provable communication with customers, repair companies, users, and government institutions;

- Timely notification of citizens about upcoming repairs, suspensions, payments, obligations, promotions, and others.

3.5. Selection of BC Platform

The DLT distributed ledger is technology for the immutable replication and synchronization of data according to a pre-made smart contract among participants [16]. These participants are networked and all own the same copy of this book. Initially, this technology was described as for making profits, with the most famous platform being Bitcoin [17]. With the development of technology, it becomes possible to implement applications that can serve industrial, health, technological, educational, and other tasks [18]. Given the development not only of public needs but also the growing requirements for transparency and trust among partners, the new EU regulation requires the implementation of digital technology for measuring and tracking the parameters of infrastructure networks such as heat transmission, electricity transmission, water supply, and gas distribution [19]. Therefore, in the present task, it is very appropriate to implement a data-tracking BC.

In the implementation of the BC system, in order to be able to realize the intended positive effects, it is necessary to choose the right platform. There are different solutions: some of them are created for cryptocurrency mining, and others are designed to be suitable for engineering solutions. To select the appropriate one, the participants and functions of the network must first be defined:

- To determine the actors in the scheme;

- To determine the communication channels,

- Access to data;

- Electricity consumption.

Regarding the actors, the parties involved are the WS company, repair and trading companies, customers, state and banking institutions, state supervision, health ministry, and others.

The main communication channels in a water supply system are water quantity, financial resources, repair works, electricity consumption, decontamination, wages, and training. It is possible that in the process of operation or with a change in the legal basis, other needs may appear.

Since the requirement is to achieve reliability and low energy consumption, it is suggested that the system is private, i.e., all participants know each other. Systems where the participants do not know each other are public. They are characterized by lower data transmission speed and high energy consumption. Not all clients on the network indeed know each other, but some platforms such as Hyperledger Fabric [20] can receive data with read-only rights.

Various platforms such as MultiChain, Waltonchain, Cardano, and others have been examined [21,22,23]. The network feature thus made provides an opportunity to choose and deploy Hyperledger Fabric. The advantages of this platform are that all participants know and trust each other, resulting in relatively fast data transmission with low energy consumption. It is possible to implement a smart contract according to the requirements of individual participants.

The presence of multi-channels gives an advantage over platforms such as Bitcoin, Ethereum, and other popular ones. This means that in a network, different actors can access different types of data. Naturally, if there is a need to hide certain types of data from some of the actors, private collections can be created. Only confidential data are exchanged in them, which are shared with other nodes as gossip. For example, the repair company may have two sources of supply for spare parts and pipes. Depending on the speed and quality of the delivery, the same repair company may set different prices, which remain as data only between the two companies.

4. Implementation of Blockchain

4.1. Transaction Communication

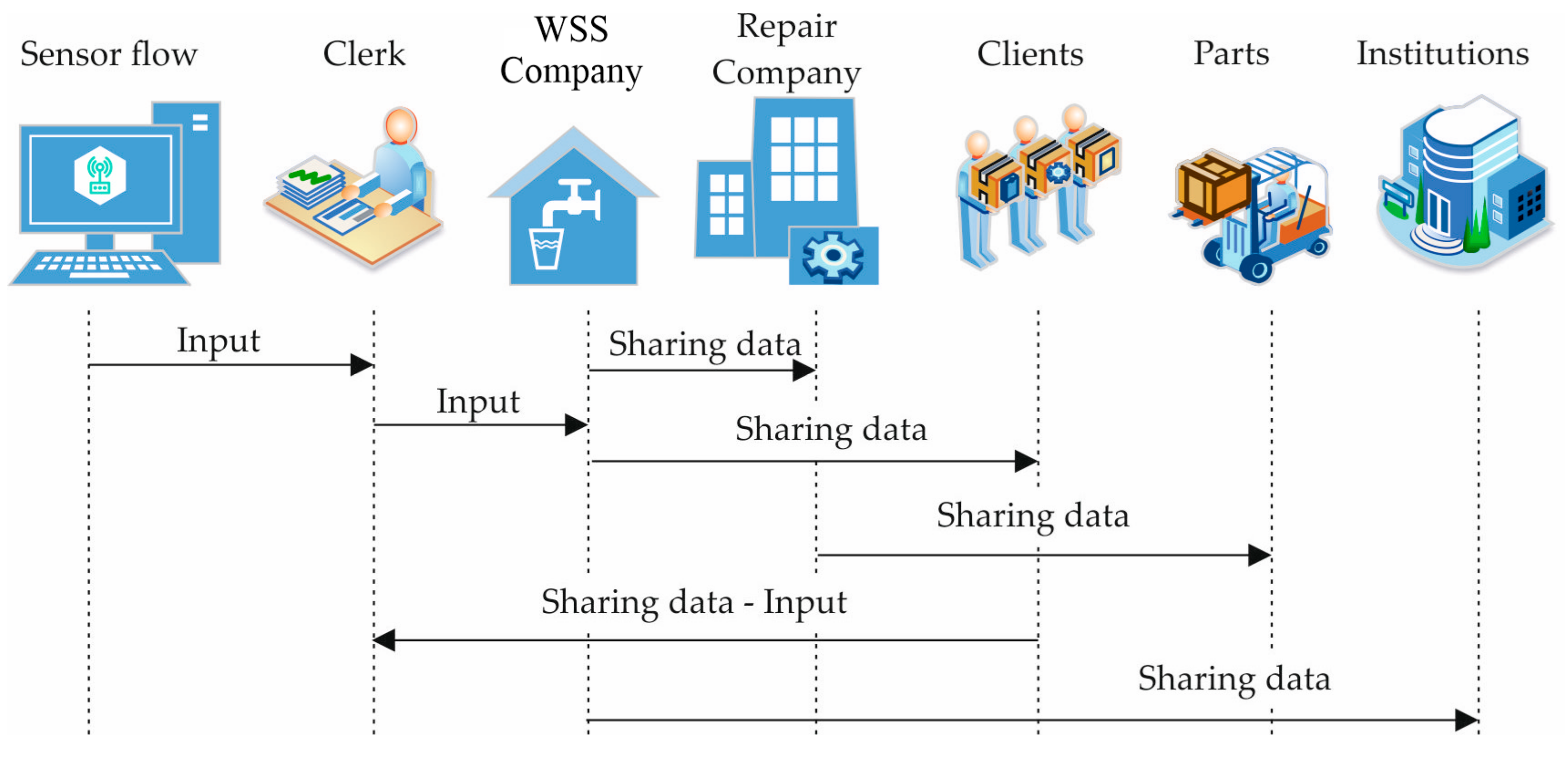

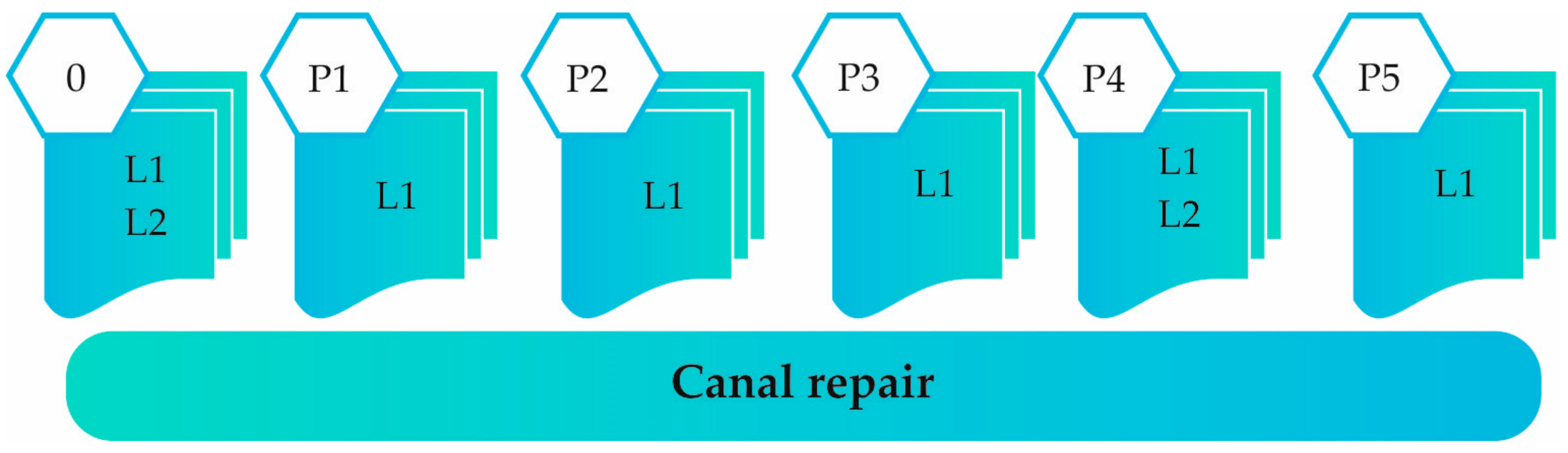

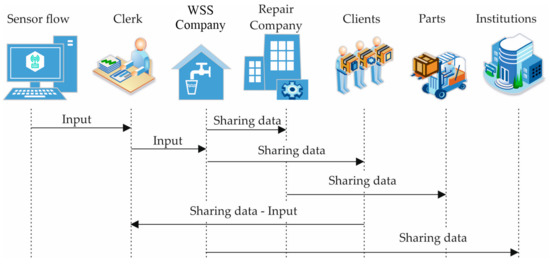

The action and data transmission scheme in Hyperledger Fabric will be presented through a crash (accident) communication channel (Figure 4).

Figure 4.

Transaction communication.

The communication scheme in Figure 4 presents the data-sharing flows in the event of an emergency. The accident can be registered by a sensor or by a client. They transmit data about the location of the accident to an employee. This employee enters the event into the company’s system and all nodes that are responsible verify this event—in this case, it is an employee and a sensor or customer that stops signaling the event. An emergency signal is sent by the company to a repair company or a team. It responds that it has received event data and sends a transaction to its suppliers or other teams. They also return a reply that they have received the transaction and within a certain time place the corresponding part order. One may be available in stock but may also be specific. In addition to the repair node, the WSS company sends transactions to all customers in the area where there is an accident and the deadline for its elimination. At the same time, depending on the type of accident (e.g., leak), a signal is sent to the responsible state institution (Ministry of Environment and Water) for testing the cleanliness of the soil in the presence of a construction site to the local electricity supply company for the presence of increased danger to construction companies.

In addition, the employee can start the initialization process themself in the absence of an electrical signal from any sensor for a certain and preselected period. This means that it may not work. In such a case, the repair team is also notified to check the technical condition of the sensor.

In order to achieve consistency in the described actions, all infrastructure organizations (construction, electricity companies, etc.) must be clients of the respective blockchain in advance and send signals in the presence of an action from their side. Thus, the WSS company will know whether or not to send a signal in the event of an emergency and to which of them.

A problem with this communication is how to motivate customers to send data about a registered accident. These can be bonus points that are deducted from the account or tokens. Remuneration of companies and institutions is simpler because for them the communication is two-way, and they also benefit economically from such notification.

4.2. Channel of Communication

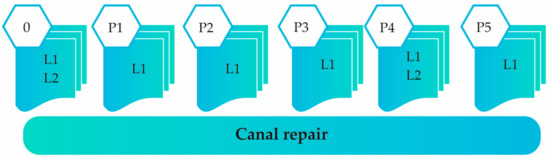

After the actors in the scheme and the data transmission flow are defined, it is necessary to build the channel.

The channel scheme is visualized in Figure 5. The actors are named P1—WSS company, P2—customer, P3—sensor, P4—repair company, and P5—institution. All of them have identity certificates and are recognizable by the system, i.e., can transmit data. This is rendered with CC1. The employee who verifies the data is like an orderer node. All of them have recognized the smart contract under whose rules they work. They also have a copy of the L1 book in which they record data as they are received. It can be seen, however, that node P4 has two books. It also operates under two smart contracts. This is not shown in the figure, but this node is included in another channel. This is the participating repair company that orders parts from other companies, has subcontractors, checks inventory, or contacts financial institutions. This activity is described in another channel and the clients of the WSS company and the Ministry of Environment and Water are not interested in this activity. They at the same time cannot access the Ledger 2 data because they have not recognized the Ledger 2 smart contract.

Figure 5.

Scheme of communication channel of repair.

The only one who has access is the employee to be able to determine the duration of the repair in the event of the need to order parts. Node P4 then contacts its own suppliers, but the verification employee records the data and is informed about the delivery process of the part needed for the repair.

Thus, with the multi-channel functionality of Hyperledger Fabric, versatile communication is enabled.

The Hyperledger Fabric platform makes it possible to build a network with all the described functionalities for free. The accuracy of work is directly proportional to the accuracy and precision of the measuring devices used [24].

4.3. Securing the System

The construction of the system must be tied not only to the possibility of subsequent analysis through Big Data but also to the achievement of security. Weak security is caused by a lack of interoperability, system-wide visibility, and a security deployment project. This leads to data loss, data blurring in the cloud, and the inability to perform real analysis, causing cyber threats and data seizure, and causing technical damage to the system, and sometimes even being an opportunity for a terrorist act [25]. Functionality issues can be classified as:

- Device heterogeneity;

- The presence of fragmentation;

- The availability of various operational technologies that do not match the exact requirements;

- The operation of old devices that cannot be protected.

Therefore, to secure the system already at the IoT design stage, devices must be selected that meet the following requirements:

- The compatibility with the system;

- To ensure the quality of service (QoS)—used hardware, noise, and interference in the communication environment, number of devices affecting transactions, delay, throughput, and packet loss ratio [26];

- To envisage a system of security and protection against cyber threats.

5. Conclusions

This article analyzed the possibilities for increasing the efficiency and functionality of the water supply system for the city of Ruse. Based on circular economy measures, it has been proven that with the means of Industry 4.0, the efficiency of the process can be improved in the supply of drinking water of high quality. This is in accordance with the paradigm of sustainable development and European norms not only for increasing the well-being and quality of life of the population but also with the appropriate use of resources.

The current state of the public utility water supply network has been studied and a number of weaknesses in the regulatory, technical, infrastructural, and social readiness have been identified. On their basis, measures were proposed to improve the processes by implementing an automated management system with integrated IoT and blockchain technologies. It was proposed to change the currently existing model of the IoT system by digitizing the dispatcher. To ensure a high level of cyber security when implementing multi-channel and secure data sharing, and trust among individual participants, the Hyperledger Fabric platform was chosen. A communication model has been developed for sharing data in the event of an accident among a company, citizens, repair companies, banks, power transmission companies, and local and state governing bodies. The proposed technical measures and solutions to improve the functionality of water supply systems through automation via IoT and blockchain technologies can also be used in other companies performing a similar subject of activity. It is necessary to verify the proposed measures after their implementation in a real environment, not only for accident reporting but also for water decontamination. In this way, their expediency and efficiency will be shown, as well as the need to develop additional technical solutions that meet the requirements of the circular economy model and the expectations of Industry 5.0.

Author Contributions

Conceptualization, T.H., I.S. and B.E.; methodology, T.H., I.S. and B.E.; formal analysis, T.H. and B.E.; investigation, I.S. and B.E.; resources, T.H. and I.S.; writing—original draft preparation, T.H. and I.S.; writing—review and editing, T.H., I.S. and B.E.; visualization, I.S.; project administration, I.S. and B.E.; funding acquisition, B.E. All authors have read and agreed to the published version of the manuscript.

Funding

This article was funded by the University of Ruse Research Fund under project 2023–FEEA-02 “Creating and exploring models for ensuring energy-efficient consumption of electronic systems and appliances”.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Acknowledgments

The authors would like to give special thanks to the anonymous reviewers, whose valuable comments and suggestions significantly improved the quality of the paper.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Organisation for Economic Co-Operation and Development, OECD Annual Report. 2009. Available online: https://www.oecd.org/newsroom/43125523.pdf (accessed on 2 March 2023).

- Mensah, J. Sustainable development: Meaning, history, principles, pillars, and implications for human action: Literature review. Cogent Soc. Sci. 2019, 5, 1653531. [Google Scholar] [CrossRef]

- Dantas, T.; De-Souza, E.; Destro, I.; Hammes, G.; Rodriguez, C.; Soares, S. How the combination of Circular Economy and Industry 4.0 can contribute towards achieving the Sustainable Development Goals. Sustain. Prod. Consum. 2020, 26, 213–227. [Google Scholar] [CrossRef]

- Dolega, W. Development of electric power network infrastructure in aspect of electric energy supply security—Case study Poland. E3S Web Conf. 2019, 84, 02002. [Google Scholar] [CrossRef]

- Mihaylov, G.; Hristova, T. Increasing the Efficiency of Irrigation Systems in the Republic of Bulgaria Through New Electrical Systems and Blockchain. In Proceedings of the 2022 International Conference on Communications, Information, Electronic and Energy Systems, CIEES, Veliko Tarnovo, Bulgaria, 24–26 November 2022. [Google Scholar] [CrossRef]

- Dong, J.; Asif, Z.; Shi, Y.; Zhu, Y.; Chen, Z. Climate Change Impacts on Coastal and Offshore Petroleum Infrastructure and the Associated Oil Spill Risk: A Review. J. Mar. Sci. Eng. 2022, 10, 849. [Google Scholar] [CrossRef]

- Borissova, D.; Danev, V.; Garvanov, M.; Yoshinov, R.; Garvanov, I. Advances in Systems Engineering; Borzemski, L., Selvaraj, H., Świątek, J., Eds.; Lecture Notes in Networks and Systems, 364; Springer: Cham, Switzerland, 2012. [Google Scholar] [CrossRef]

- Dogo, E.M.; Salami, A.F.; Nwulu, N.I.; Aigbavboa, C.O. Artificial Intelligence in IoT; Al-Turjman, F., Ed.; Transactions on Computational Science and Computational Intelligence; Springer: Cham, Switzerland, 2019. [Google Scholar] [CrossRef]

- Sriyono, E. Digitizing water management: Toward the innovative use of blockchain technologies to address sustainability. Cogent Eng. 2020, 7, 1769366. [Google Scholar] [CrossRef]

- Simeonov, K.; Mihailov, N.; Valov, N.; Gabrovska-Evstatieva, K. Analysis of a PV Installation with a Battery Storage and BMS at a Residential Building. In Proceedings of the 2022 8th International Conference on Energy Efficiency and Agricultural Engineering, EE&AE, Ruse, Bulgaria, 30 June–2 July 2022. [Google Scholar] [CrossRef]

- Dimitrov, A.; Ivanova, N.; Nesheva, R.; Yanev, N. Annual of University of Mining and Geology St. Iivan Rilski. Sofia 2021, 64, 151–154. [Google Scholar]

- Ivanova, E.; Iliev, T.; Stoyanov, I. Modelling and Simulation of Big Data Networks. In Proceedings of the 2020 7th International Conference on Energy Efficiency and Agricultural Engineering, EE&AE, Ruse, Bulgaria, 11–13 June 2020. [Google Scholar] [CrossRef]

- Al-Dulaimi, A.M.K.; Al-Dulaimi, M.K.H. Construction and Analysis of Dynamic Distribution for Resource Blocks of Real-Time and Data Elastic Traffic in IMS/LTE networks. In Proceedings of the 2021 International Congress of Advanced Technology and Engineering (ICOTEN), Taiz, Yemen, 4–5 July 2021; pp. 1–7. [Google Scholar] [CrossRef]

- Water, Growth and Finance. Policy-Perspectives. OECD. 2016. Available online: www.oecd.org/water (accessed on 2 April 2023).

- ISO/IEC 20924:2018; Information Technology—Internet of Things (IoT)—Vocabulary. ISO: Geneva, Switzerland, 2018.

- Nakamoto, S. Bitcoin: A Peer-to-Peer Electronic Cash System. Available online: https://bitcoin.org/bitcoin.pdf (accessed on 3 February 2023).

- Crosby, M.; Nachiappan, P.; Pattanayak, S.; Verma, V. Kalyanaraman, BlockChain Technology Beyond Bitcoin. UC Berkeley: Sutardja Center for Entrepreneurship & Technology Technical Report. 2015. Available online: https://scet.berkeley.edu/wp-content/uploads/BlockchainPaper.pdf (accessed on 2 March 2023).

- Valchanov, H.; Aleksieva, V. Novel Blockchain–Based Models for Healthcare and Life Science Solution. In Proceedings of the 2022 International Conference on Communications, Information, Electronic and Energy Systems, CIEES, Veliko Tarnovo, Bulgaria, 24–26 November 2022. [Google Scholar] [CrossRef]

- EU: Commission Recommendation of 9 March 2012 on Preparations for the Roll-Out of Smart Metering Systems. EC. 2012. Available online: https://op.europa.eu/en/publication-detail/-/publication/a5daa8c6-8f11-4e5e-9634-3f224af571a6/language-en (accessed on 28 February 2023).

- Krstić, M.S.; Krstić, L.J. Hyperledger frameworks with a special focus on Hyperledger Fabric. Vojn. Glas. 2020, 68, 639–663. [Google Scholar] [CrossRef]

- Zlyme, r/Cardano. 2018. Available online: www.reddit.com/r/cardano/comments/9dknwg/cardano_and_privacy/ (accessed on 30 March 2023).

- Ecosystem, A.B. Medium. 2020. Available online: https://alastria-es.medium.com/comparison-of-dlt-platforms-be84950d339d (accessed on 24 March 2023).

- Greenspan, G. MultiChain Private Blockchain—White Paper, Multichain. 2018. Available online: https://www.multichain.com/download/MultiChain-White-Paper.pdf (accessed on 20 February 2023).

- Using the Fabric Test Network. Available online: https://hyperledger-fabric.readthedocs.io/en/latest/test_network.html (accessed on 3 February 2023).

- Jekov, B.; Dimitrov, W.; Panayotova, G.S.; Kovatcheva, E. Intelligent protection of Internet of things systems. In Proceedings of the 2022 International Conference on Electrical, Computer, Communications and Mechatronics Engineering, ICECCME, Maldives, Maldives, 16–18 November 2022. [Google Scholar] [CrossRef]

- Haka, A.; Dinev, D.; Aleksieva, V.; Valchanov, H. Comparative analysis of ZigBee, 6LoWPAN and BLE technologies for the Internet of Things. AIP Conf. Proc. 2022, 2570, 020007. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).