1. Introduction

According to studies by McKinsey & Company and the Ellen MacArthur Foundation, one of the main reasons for the growing number of end-of-life garments is their reduced durability ([

1]; [

2], p. 3; [

3], p. 36). To extend the product life cycle, sustainability requires a personal bond to the fashion product [

4], high-quality materials, and workmanship; in this environment, digitisation can enable sustainable process design.

1.1. Research Needs

Planetary conditions are changing, creating new challenges for politics, society, and industry. The average global temperature is expected to reach 1.5 °C by the beginning of the next decade; further climate changes will be largely determined by the amount of CO

2 emissions released into the atmosphere [

5]. The global production of textile products, e.g., in agriculture, the textile industry, and distribution, also contributes to the increase in greenhouse gas emissions [

6]. At the same time, the volume of used textiles collected both in Germany [

7] (pp. 2, 12) and across Europe has increased. Currently, 1.7–2.1 million tonnes are collected annually in Europe [

8], but the reuse rates (reuse: 62%, recovery: 20%) and recycling rates (cascade recycling: 12%, fibre-to-fibre recycling: 1%) of these products and recyclables are relatively low ([

3], p. 20; [

7], p. 23; [

9]). The public waste management system also collects textiles in household waste; in Germany, about 2 kg per person is collected per year [

10]. A standardisation project on the requirements and categories for circular textile value chains is underway [

11] and requires innovative developments in the textile and clothing industry.

To make these developments possible, holistic processes that go beyond the sub-processes of production and marketing are needed to integrate the use phase. These sub-processes need to be finely tuned to each other, and they need to be flexible and tailored to different products, specific needs, and different users. The big challenge is to actively involve consumers, i.e., to extend product life cycles in a customer-oriented way, through emotional ties and individual service models.

1.2. Research Object

In the following section, we will illustrate the two sub-processes of product development through integrated mass customisation and the use phase through laundry care service. Using outdoor jackets as an example, we will demonstrate the combination, integration, and synergies of the sub-processes to create a process that is holistic, smart, and sustainable overall. Our research scenario uses radio frequency identification devices (RFIDs) to digitise the service processes. With a personalised customer login, the customer can access all information about the individual product development, as well as possible washing and repair services. This added interactive value creates a personal bond. By comparing conventional life cycles with participatory service offerings, we pursue the following research question: How does the life cycle of a fashion product change in a smart holistic wear-care business model?

2. Mass Customisation (Individualisation) and Laundry Care

In the following section, we will briefly introduce the possibilities of mass customisation in the fashion industry and the use of RFID systems in the laundry service, before then presenting our wear-care model.

2.1. Mass Customisation

Mass customisation (MC) and open innovation (OI) are innovative strategies that involve customers or external experts in product development and enable interactive value creation. While mass customisation aims to produce a single personalised product, open innovation aims to openly develop a new product for a large group of customers [

12]. MC and OI receive little attention from the major players in the garment industry. Customers remain predominantly in the passive role of the recipients [

13]. Some companies are testing mass customisation as a complementary concept to their traditional product development [

14]. On the other hand, open innovation approaches are not yet anchored in mass production in the garment industry. Based on this,

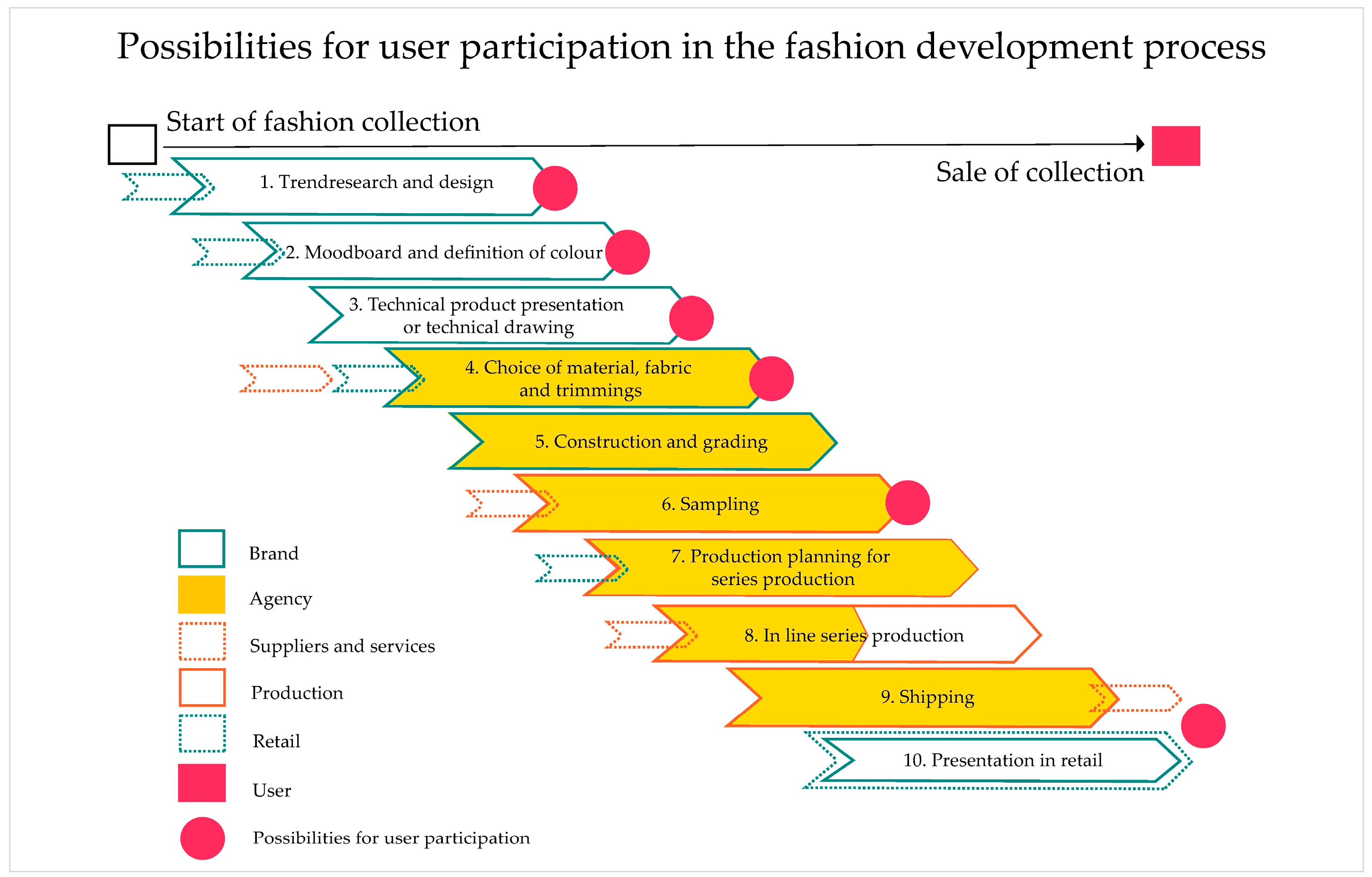

Figure 1 shows the process steps in which user participation is theoretically possible within the fashion development of agency businesses.

In this paper, we focus on mass customisation through size adaptation for outdoor jackets as one possible scenario. The process integrates the user with individual sizes before step five of the product development (“construction and grading”). We chose an outdoor jacket as a complex garment with a high need for laundry care. In addition, the social value and purchasing power of technical outdoor jackets are higher than those of other fashion products.

2.2. Laundry Care—Household and Textile Service

The overall system of the use phase of clothing consists of subsystems in the wear phase and the care phase. The care phase sequence in the consumer’s household and the care phase sequence at the professional level in the textile service (e.g., for workwear) are similar. Preparing: Preparation includes the collection and sorting of dirty laundry, the selection of washing programmes (including the washing temperature), and the selection and dosage of detergents [

15] (p. 12). Washing and Drying: The washing process is automated for consumers, mostly in household washing machines (96% of German households own a washing machine [

16]), and for textile services, in washing machines and special washing systems (e.g., cycle washing systems). Reconditioning: The reconditioning of clothing products includes ironing, for example, but also repair in the event of damage.

The textile service has a higher degree of process automation thanks to extended machine parks and in-house identification and information technology, as well as a pick-up and delivery service for the garments. The following scenario discusses the differences between home laundry and textile service for an outdoor jacket in more detail.

2.3. Identification Systems in the Garment Industry

Radio frequency identification device (RFID) technology can be used to assign garments to a specific and unique address within a network [

17]. An RFID system always has two components: the transponder, which is attached to the objects to be identified, and the reader, which is connected to the information system. Data can be stored via an identification number in a stored database (a data-on-network system) or directly on RFID transponders (a data-on-tag system) [

18]. Due to its international production, the garment industry requires logistics that are understood as a holistic, cross-company, and flow-oriented approach to the supply chain [

19]; product lifecycle management systems manage the entire product lifecycle from customer specification to disposal [

20]. RFID technology has general advantages as an identification system. The transponder and the reader can communicate through various materials, such as cardboard boxes and lids. Dirt and moisture do not affect the function of the transponder, which is why washable RFID chips are on the market. The transponders can be overwritten and reused. Fast reading processed with bulk detection allows multiple transponders to be detected simultaneously [

21]. During manufacturing, RFIDs can help to track details for each item. With automated communication between ordering, planning, and production processes, mass customisation can be realised in mass production.

3. The Scenario of a Mass-Customised Outdoor Jacket in a Smart Holistic Wear-Care Business Model

In this paper, we discuss a smart future scenario for the fashion industry that combines personalised product development and service-oriented laundry care through a smart holistic process approach. In our scenario, RFIDs track all individual information about the garment. The user’s individual measurements are translated into the construction and cutting process. The specific solution space of the scenario is the size adjustment. The RFID chip is integrated into the sleeve hem. This gives the laundry service all information about the garment and the user. They can offer specific laundry care, repair, pick-up, and delivery services.

3.1. Solution Space

Mass-customised products reflect individual needs and, at the same time, achieve a price that is close to that of conventional mass-produced products [

22]. This is possible through industrial production in manufacturing with individualised sub-processes. The customer can choose from a limited range of solutions. With mass customisation, fitting the user’s needs is improved. In our scenario, the solution space takes place between steps four and five of product development (see

Figure 1), The customer is measured with a body scanner to produce the right fit for their individual body measurements. The solution space only facilitates fitting without any design aspects. Communication with RFID systems can help to implement mass customisation in the production line.

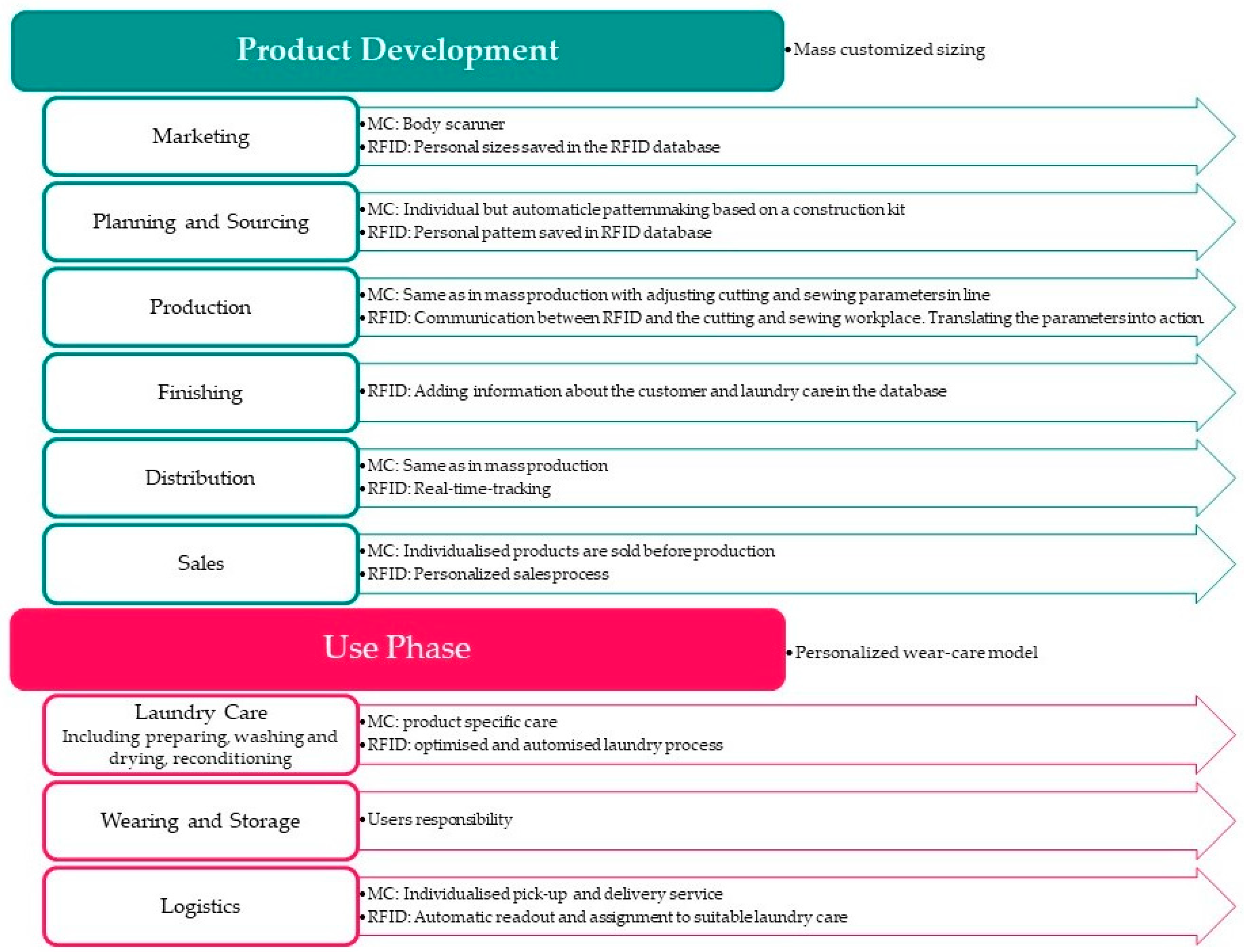

Figure 2 shows the objective of mass customisation (MC) and the role of the RFID system (RFID) in each step of the product development and the use phase. From the moment the mass-customised outdoor jacket is purchased, the consumer’s use phase begins, consisting of wearing, preparing, washing, drying, reconditioning, and storing steps.

Outdoor jackets are complex products; the entire value chain from raw material (natural/chemical), fibre, yarn, textile (e.g., woven/knitted fabrics and membranes), finishing steps (e.g., dyeing, printing, and coating), and components (e.g., zips and buttons) to the finished garment targets specific functions (e.g., breathable and wind- and water-repellent functions) and high wearing comfort (thermo-physiological, ergonomic, and skin sensory factors). These individual steps of product development, as well as the interaction of all components, have an influence on the care requirements during the use phase. At the end of their life cycle, outdoor jackets are currently difficult or impossible to recycle due to interconnected components (e.g., laminates) and material heterogeneity [

23,

24]. This makes it all the more desirable to ensure a long product life cycle, facilitating the preservation of all functions and the greatest possible conservation of resources through proper use (wearing) and product-specific gentle laundry. The solution to this is a product-specific professional care service from the garment manufacturer.

3.2. Service-Oriented Laundry Care

When the jacket is purchased, the customer receives an interactive customer profile. The profile provides information on the entire product development process (including the mass-customised own participation) as well as the extended laundry service for the jacket whereby washing (preparation included), drying, and reconditioning (such as waterproofing or repair) can be booked individually, including a pick-up service and a delivery service. Depending on the season, the system automatically offers the user service options, such as refreshing the waterproofing. Any damage can be marked online by the consumer and repaired at the next service, avoiding premature disposal. As mentioned in

Section 2.2, the differences between the process steps of the care phase in the household and in the textile service will be briefly discussed below and then applied to the customer-friendly and resource-saving laundering of the outdoor jacket in the textile service.

Preparing: Preparation involves several interdependent sub-steps. For example, the choice of wash programmes and detergents should be based on the textile and care labels on the garments, and the detergent dosage in turn should be based on the dosage recommendation [

25] and the detergent packaging. This in turn depends on the local water hardness, the load size, and the degree of soiling in the garments. In the household, these complex co-ordinations do not take place automatically [

15] (p. 13), but are the responsibility of the consumer. The service for the jacket in the scenario is booked by the consumer and sent to the nearest cooperating textile service. A courier picks up the jacket; it is read out in the system using RFIDs and assigned to a suitable wash load and treatment at the textile service. A control station checks for foreign objects in pockets, as well as additional soiling and damage; if necessary, stains are gently and specifically pre-treated. The wash programme, including the temperature, wash duration, load size, and resulting mechanical action, are directly matched to the outdoor jacket to ensure gentle cleaning of the functional materials. The specific composition and dosage of the detergent, and, if required, the waterproofing agent, are adapted and fed to the different cleaning phases.

Washing and Drying: The correct interplay of factors listed in the preparation process step is essential for the optimum conservation of resources and laundry items, but in Germany, for example, the cotton wash programme is usually underloaded, while the easy-care and delicate wash programmes are usually overloaded [

26,

27]. Fibre shedding and the release or formation of microplastics of textile origin from washing and drying processes have received extensive political and scientific interest in recent years [

28,

29,

30]. In the textile service, wastewater from washing machines can be filtered in the company’s water treatment plants, recirculated, and used for heat recovery. In this scenario, the wastewater is treated internally and the waste heat is used in the gentle drying process (e.g., tunnel finisher).

Reconditioning: In Germany [

2] (p. 4) and internationally [

31], wear and tear are common reasons for discarding and disposing of clothing. Various product-specific reprocessing and repair processes can be applied downstream in the textile service. In this scenario, the jacket is individually repaired and returned to the customer ready to be worn.

Additional Service—Wearing and Storage: The wearing and storing sub-processes are the responsibility of the user in both home laundry and textile services. When worn, the jacket, the wearer’s body, and the prevailing climate influence each other. To make the best use of the mass-customised jacket and its functions in the wearing system (the base layer, insulation layer, and weather protection layer), individual wearing and storage tips are stored in the customer’s profile to complete the service for the entire use phase.

4. Results and Discussion

Sewing workplaces in mass production have no RFID reading systems yet. If we want to work with mass-customised fashion in our current fashion supply chain with working production lines, we need to technically expand the sewing workstations with RFID readers and displays for the operator. This investment is environmentally and economically useful because we only produce products that users have already bought. Within the individual measurements, a personal bond is formed in relation to the outdoor jacket, and, with the right laundry care, the product life cycle is extended, serving to sustain fashion needs. The implementation and combination of sub-processes listed can help improve the circulation of textiles in the use phase, prevent waste generation, and conserve resources. This way, manufacturing companies can also contribute to the longevity of garments during their use phase. At the same time, expanding business models leads to new collaborations with companies at other stages of the process. However, interfaces still need to be created or scaled to develop sub-processes into processes that are tailor-made and flexible overall, in line with demand. This is where the development of a product passport comes in as a tool, for example. In conclusion, the smart holistic wear-care business model can help to extend the service of mass-customised products, creating economic, social, and environmental benefits.

5. Conclusions

The laundry service process has already been established at the large consumer level. The textile service combines specific laundry care, repair, pick-up, and delivery services. Compared to home laundering, this model saves resources (such as energy, water, and chemicals) and cares for each fashion item. The digital application scenario integrates these subprocesses into private use. The adaptation of established models of mass customisation and laundry care in a smart holistic wear-care business model results in environmentally friendly processes in the product development and use phase. Material durability, awareness, and emotional longevity through strong user integration determine the new sustainable product life cycle.

Author Contributions

Conceptualization, L.W. and L.T.; methodology, L.W. and L.T.; formal analysis, L.W. and L.T.; resources, L.W. and L.T.; writing—original draft preparation, L.W. and L.T.; writing—review and editing, L.W. and L.T.; visualization, L.W. and L.T.; All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- McKinsey & Company. The State of Fashion 2023; McKinsey & Company: New York, NY, USA, 2022; p. 76. [Google Scholar]

- Brodde, K.; Groth, H.; Wahnbaeck, C. Wegwerfware Kleidung—Repräsentative Greenpeace Umfrage zu Kaufverhalten, Tragedauer und der Entsorgung von Mode; Greenpeace e.V.: Hamburg, Germany, 2015. [Google Scholar]

- Ellen MacArthur Foundation. A New Textiles Economy—Redesigning Fashion’s Future; Ellen MacArthur Foundation: The Isle of Wight, UK, 2017. [Google Scholar]

- Kleinhückelkotten, S.; Neitzke, P.; Schmidt, N. Slow Fashion: Gestalterische, Technische und Ökonomische Innovationen für Massenmarkttaugliche Nachhaltige Angebote im Bedarfsfeld ‘Bekleidung’; Research Networks InNaBe: Hannover, Germany, 2019; pp. 2, 30. [Google Scholar]

- Federal Environment Agency (UBA). IPCC-Bericht. 2021. Available online: https://www.umweltbundesamt.de/themen/ipcc-bericht-klimawandel-verlaeuft-schneller (accessed on 13 April 2023).

- Manshoven, S.; Christis, M.; Vercalsteren, A.; Arnold, M.; Nicolau, M.; Lafond, E.; Mortensen, L.F.; Coscieme, L. ETC/WMGE Report 2019/6: Textiles and the Environment in a Circular Economy; European Topic Centre on Waste and Materials in a Green Economy: Flanders, Belgium, 2019; p. 22. [Google Scholar]

- Federal Association of Secondary Raw Materials and Disposal (bvse). Bvse Alttextilstudie 2020: Bedarf, Konsum und Wiederverwendung von Bekleidung und Textilien in Deutschland. Available online: https://www.bvse.de/dateien2020/1-Bilder/03-Themen_Ereignisse/06-Textil/2020/studie2020/bvse%20Alttextilstudie%202020.pdf (accessed on 13 April 2023).

- Köhler, A.; Watson, D.; Trzepacz, S.; Löw, C.; Liu, R.; Danneck, J.; Konstantas, A.; Donatello, S.; Faraca, G. EUR 30734 EN: Circular Economy Perspectives in the EU Textile Sector; Publications Office of the European Union: Luxembourg, 2021; p. 8. [Google Scholar] [CrossRef]

- Maire, E. Circular Economy Action Plan—For a cleaner and more competitive Europe. In Proceedings of the Aachen-Dresden-Denkendorf International Textile Conference, Stuttgart, Germany, 9–10 November 2021. [Google Scholar]

- Federal Statistical Office (Destatis). Aufkommen an Haushaltsabfällen: Deutschland, Jahre, Abfallarten. 2021. Available online: https://www-genesis.destatis.de/genesis/online?sequenz=tabelleErgebnis&selectionname=32121-0001&zeitscheiben=2#abreadcrumb (accessed on 13 April 2023).

- German Institute for Standardization (DIN). Annual Report 2021; DIN Standards Committee Textile and Textile Machinery (Textile Standard); German Institute for Standardization: Berlin, Germany, 2021; p. 33. [Google Scholar]

- Fuchs, M.; Tihon, L. Grenzenlose Produktentwicklung—Mit Partizipation zu innovativen Bekleidungskonzepten. In Grenzen in Zeiten Technologischer und Sozialer Disruption. Beiträge und Position 2019; Molthagen-Schnöring, S., Ed.; Berliner Wissenschafts-Verlag: Berlin, Germany, 2019; Volume 9, p. 141. [Google Scholar]

- Tihon, L. Participatory product development for innovative smart garments. In Proceedings of the Aachen-Dresden-Denkendorf International Textile Conference, Aachen, Germany, 2 December 2022. [Google Scholar]

- Fuchs, M. Mass Customization und Open Innovation—Anwendung und Bedeutung in Unternehmen der deutschen Bekleidungswirtschaft; OPUS: Berlin, Germany, 2014. [Google Scholar]

- Ellmer, K. Wäsche-Cluster in Konsumentenhaushalten; Mensch und Buch: Berlin, Germany, 2016. [Google Scholar]

- Federal Statistical Office (Destatis). Laufende Wirtschaftsrechnungen—Ausstattung privater Haushalte mit Ausgewählten Gebrauchsgütern; Subject-matter series 15 Series 2; Federal Statistical Office (Destatis): Wiesbaden, Germany, 2021; p. 12. [Google Scholar]

- Engemann, C.; Sprenger, F. (Eds.) Internet der Dinge. Über Smarte Objekte, Intelligente Umgebungen und die Technische Durchdringung der Welt, 1st ed.; Transcript: Bielefeld, Germany, 2015; p. 16. [Google Scholar]

- Tamm, G.; Tribowski, C. RFID; Springer: Heidelberg, Germany, 2010; pp. 13, 22. [Google Scholar]

- Lehmacher, W. The Global Supply Chain. How Technology and Circular Thinking Transform our Future, 1st ed.; Springer: Cham, Germany, 2017; p. 72. [Google Scholar]

- Ehrlenspiel, K.; Meerkamm, H. Integrierte Produktentwicklung. Denkabläufe, Methodeneinsatz, Zusammenarbeit, 5th ed.; Hanser: München, Germany, 2013; p. 315. [Google Scholar]

- Pretzel, J. GS1 Standards—EPC; GS1 Germany GmbH: Köln, Germany, 2017. [Google Scholar]

- Piller, F. Interaktive Wertschöpfung Kompakt. Open Innovation, Individualisierung und Neue Formen der Arbeitsteilung; Springer: Wiesbaden, Germany, 2017; p. 85. [Google Scholar]

- Lechleitner, A.; Schwabl, D.; Schubert, T.; Bauer, M.; Lehner, M. Chemisches Recycling von gemischten Kunststoffabfällen als ergänzender Recyclingpfad zur Erhöhung der Recyclingquote. Osterr. Wasser Abfallwirtsch. 2020, 72, 47–60. [Google Scholar] [CrossRef]

- Plociennik, M. Ökologisch nachhaltige Regenjacken—Gestaltungspotenziale im Produktentwicklungsprozess. Ein Beitrag zur Berufsbildung für Nachhaltige Entwicklung; wbv Publikation: Bielefeld, Germany, 2022; pp. 24, 31–32. [Google Scholar]

- European Parliament and Council of the European Union. Verordnung (EG) Nr. 648/2004 des Europäischen Parlaments und des Rates über Detergenzien. 2004. Available online: https://eur-lex.europa.eu/legal-content/DE/ALL/?uri=celex%3A32004R0648 (accessed on 13 April 2023).

- Berkholz, P.; Brückner, A.; Kruschwitz, A.; Stamminger, R. Verbraucherverhalten und Verhaltensabhängige Einsparpotentiale Beim Betrieb von Waschmaschinen; Shaker: Aachen, Germany, 2017; pp. 27–28. [Google Scholar]

- Kruschwitz, A.; Karle, A.; Schmitz, A.; Stamminger, R. Consumer laundry practices in Germany. Int. J. Consum. Stud. 2014, 38, 265–277. [Google Scholar] [CrossRef]

- Heller, C.; Altmann, K.; Braun, U.; Kerndorff, A.; Bannick, C.G.; Fuchs, M.; Thamsen, P.U. Garment ageing in a laundry care process under household-like conditions. Appl. Res. 2023, e202200086. [Google Scholar] [CrossRef]

- Tiffin, L.; Hazlehurst, A.; Sumner, M.; Taylor, M. Reliable quantification of microplastic release from the domestic laundry of textile fabrics. J. Text. Inst. 2021, 113, 558–566. [Google Scholar] [CrossRef]

- Bertling, J.; Bannick, C.G.; Brinkmann, L.; Barkmann, L.; Braun, U.; Knoblauch, D.; Kraas, C.; Mederake, L.; Nosić, F.; Philipp, B.; et al. Kunststoff in der Umwelt—Ein Kompendium, 1st ed.; Fraunhofer UMSICHT: Oberhausen, Germany, 2021; pp. 23–24. [Google Scholar] [CrossRef]

- Laitala, K. Consumers’ clothing disposal behavior—A synthesis of research results. Int. J. Consum. Stud. 2014, 38, 444–457. [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).