Abstract

Supercritical fluid extraction (SFE) is a non-conventional extraction technique that can be used in the food industry because it can recover both polar and non-polar compounds. This technique is carried out above the critical point of the extraction solvent, allowing for the control and manipulation of different properties, such as diffusivity, viscosity, and density. This is possible due to the fluid’s changes in pressure and temperature that cause variations in selectivity and power. This eco-friendly extraction technique has several advantages, including high selectivity due to changes in pressure and temperature, as well as changes in the solvent’s polarity by adding co-solvents. SFE has already been used in the food industry due to the benefits of this technique and its suitability for both polar and non-polar compound extraction. The goal of this work is to compile the most recent data on SFE applications in the food industry, thereby providing insight into SFE feasibility in a large-scale process.

1. Introducing Supercritical Fluid Extraction (SFE)

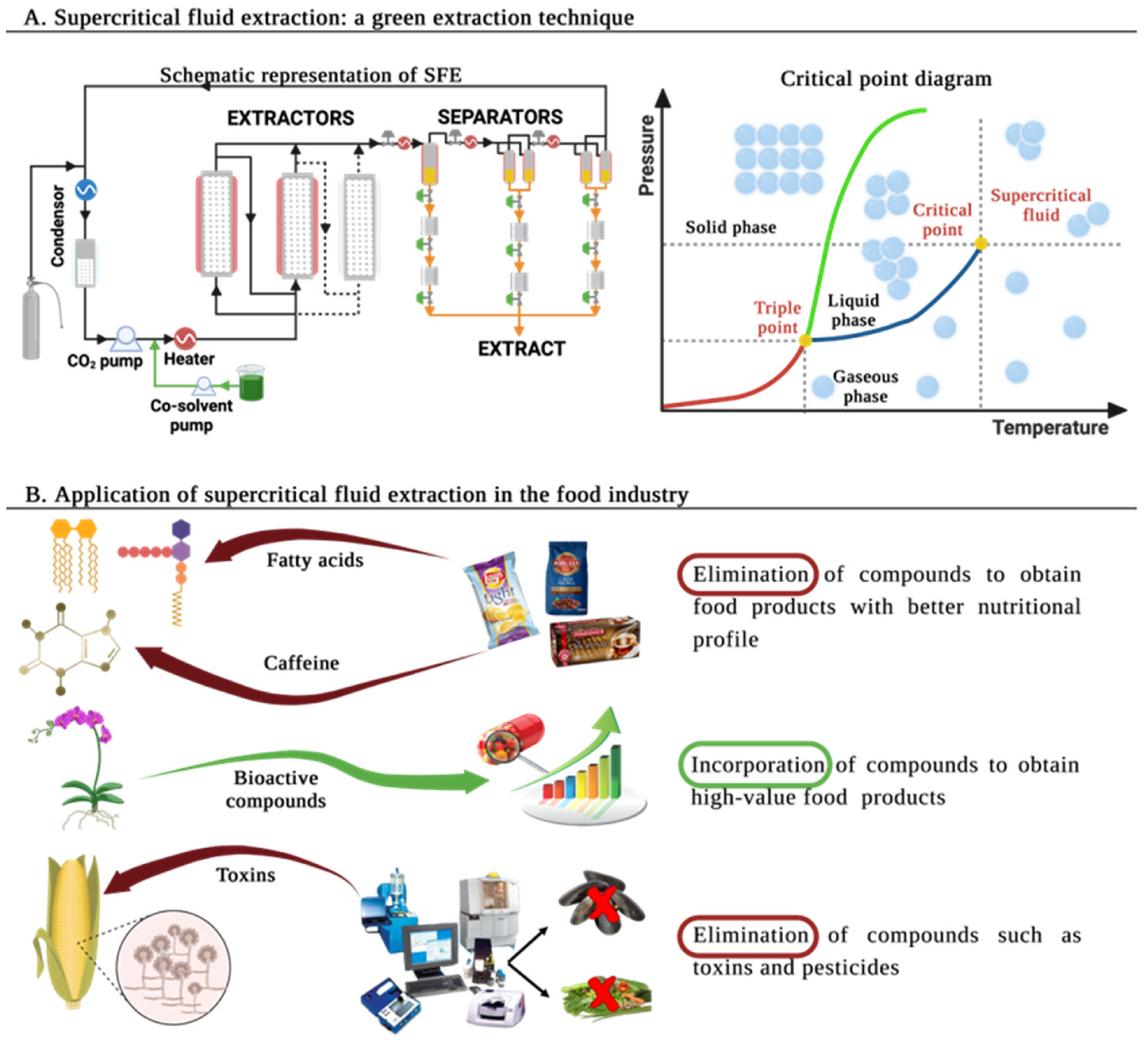

Supercritical fluid extraction (SFE) is a novel technique developed in both laboratories and industries over the past 60 years [1]. This extraction technique occurs in three steps: first, a dissolving/resolving process of the analytes takes place; then, there is a sweeping of the analytes; and finally, the analytes are trapped [2]. A schematic representation of SFE is represented in Figure 1A. SFE extraction optimization plays a key role since the different parameters (e.g., temperature, pressure, time and solvent of extraction, sample size, type, and percentage of cosolvents, etc.) directly affect the extraction yield [3]. For the optimization, two strategies can be performed: phase equilibrium strategies and experimental design statistical optimization, which is the most used. Moreover, it is mandatory to consider both phase equilibrium and mass transfer as limit stages of the process [3].

Figure 1.

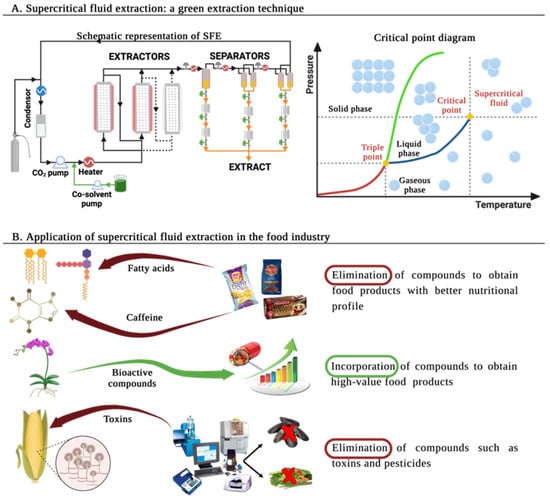

Supercritical fluid extraction (SFE) as a potential extraction technique in the food industry. (A) represents the SFE-CO2 process and the critical point diagram of any substance. (B) shows different uses of SFE in the food industry including.

To extract the target analytes, a solvent above its critical point is used, performing as a supercritical fluid (SCF), as shown in Figure 1A. An SCF is any substance above the temperature and pressure-critical points, having both gas and liquid characteristics [1]. In this way, solvents have liquid-like densities, while viscosity is gas-like, and diffusivity is around two orders of magnitude higher than liquids [1]. SCF can diffuse through solid matrices as gases and dissolve compounds as liquids. When SFE is applied, slight changes in temperature or pressure lead to larger changes in the fluids’ density since the solvent is performing near its critical point [1]. Thus, SFE selectivity depends on the density of the solvent [1].

CO2 is the main solvent applied in SFE since it is non-toxic, non-explosive, and chemically inert and has low viscosity, surface tension, and high diffusivity. Moreover, the extract is easy to obtain and remove, and its critical point does not negatively affect the biological components [4,5]. The critical temperature and pressure of CO2 are moderate (31 °C and 7.38 MPa, respectively), so the operational conditions can avoid the labile compounds’ degradation [5]. Even though CO2 is ideal for the bioactive compounds’ recovery [6], pure CO2 is not suitable for the polar compounds’ extraction, so adding a cosolvent is necessary to improve the solubility of the target analyte in the solvent [4]. When a cosolvent is used, it is important to consider how the critical temperature and pressure of the solvent are changed in the extraction system, causing changes in the density of CO2 and polarity of the mixed solvent, resulting in better efficiency of the extraction process [4].

SFE is considered a green extraction technique since this process needs a lower extraction time and lower quantities of non-toxic organic solvents compared with conventional extraction techniques such as solvent extraction [2]. Moreover, by applying SFE, no solvent residues are found in the extract, and the selectivity achieved is higher than in other extraction techniques [2,3]. However, the main disadvantage of SFE is the expensive equipment compared to conventional extraction techniques [5]. In this work, the potential use of SFE in the food industry is discussed based on the current available data, considering not only the recovery yields obtained and the wide compound application but the scaling-up process suitability.

2. Supercritical Fluid Extraction (SFE) in the Food Industry

Although SFE has been studied and applied in the past few decades in other industries, the food sector has shown interest in this extraction technique since 2016 [1]. Despite the increasing interest of the food sector in SFE, there is a notable delay between research and industrial applications since there is a need to prove this technology’s efficiency, validate the process, including the products in the novel foods regulations, as well as confirm the nutritional profile, toxicity, allergenic potential, and presence of the contaminants in the products obtained [1].

The potential use of this novel extraction technique is represented in Figure 1B. In this way, researchers have shown the potential application of this eco-friendly extraction technique in the food industry to obtain different compounds (e.g., bioactive compounds, fatty acids, pigments, etc.). Regarding flavonoid extraction from leaves, Song et al. applied SFE-CO2 to Ziziphus jujuba Mill. under optimal conditions (52.52 °C, 27.12 MPa, 113.42 min, and 0.41 mL/min of co-solvent flow), and the flavonoid content was 29.052 mg, with the main compounds being both kaempferol and quercetin glycosides [6]. Another study, by Frohlich et al., used SFE for antioxidant compounds and eugenol extraction in clove leaves. The optimal operation conditions were 300 bar 60 °C, obtaining 1.94% of extraction yield [7]. Fatty acids of the pulp and nu oils from Terminalia catappa fruits were obtained in another study by applying SFE. After an extraction run at 300 bar 60 °C, 7.4 and 61.5% of pulp and nut extraction yields were achieved. The extract was mainly formed of unsaturated fatty acids, of which omega-3 and -6 were predominant, showing suitable physicochemical properties [8]. SFE has also been applied in edible flowers. Volatile oils from Surangi flowers were extracted with SFE-CO2 and steam explosion. The optimal extractions conditions for SFE-CO2 were 35.03 °C, 179 min, 142 bar, and 3 mL/min of flow rate, achieving 4.75% of overall recovery yield [9].

Although SFE seems to be a potential technique to extract different compounds that can be incorporated into several food products, improving their nutritional profile, this technique can be applied to eliminate substances, e.g., oil, to reduce the fat content. Michael E. Wagner et al. extracted the oil in chips, applying SFE-CO2 at different operational conditions that ranged between 27.6 and 41.4 MPa, 35 and 80 °C, and 0.5 and 5 g CO2/min. Up to 100% of extraction was achieved when the highest temperature and pressure were performed [10]. The decaffeination process of coffee beans using SFE-CO2 was studied by Lolanda De Marco et al., showing the suitability of the process since it can be performed in a single step [11]. Moreover, SFE can be applied to recover compounds or metabolites that can negatively affect the quality or/and food product safety. Hina Shanakhat et al. studied the application of SFE for macrocyclic lactone mycotoxin recovery in maize flour. The results showed how using methanol as a solvent extract allowed for 100% of these mycotoxins to be recovered [12].

Considering the current interest from the scientific community in the study of SFE for the compound recovery for food industry applications, showing positive results in a laboratory-scale performance, it is necessary to continue the research considering the scaling-up process to prove the efficiency and the economic feasibility of SFE for the food industry.

3. Conclusions

SFE is a green technique that has recently become an interest in the food sector since it is characterized by its high selectivity, low solvent requirement, low extraction time, and wide range of compounds that can be extracted. In this way, several studies have established the optimal extraction conditions to release bioactive compounds, fatty acids, pigments, and other substances in different matrices, e.g., leaves, fruits, or edible flowers, showing high recovery yields. These high-value compounds can be incorporated into different food products, improving their nutritional profile. However, there are a lack of data regarding the efficiency of this technology on an industrial scale applied in these high-value products. Nowadays, SFE is used in the food industry to eliminate compounds such as caffeine for decaffeinated coffee production or fatty content in low fat. Moreover, SFE has been suggested to eliminate non-desirable substances that can be found to hurt human health, e.g., toxins. Considering the current available data, it is necessary to provide information on the efficiency of this technology on a large scale, as well as its economic feasibility, to determine its application in the food industry.

Supplementary Materials

The following supporting material can be downloaded at: https://www.mdpi.com/article/10.3390/ECP2023-14674/s1.

Author Contributions

Conceptualization, A.P.-V., P.B. and M.C.; methodology, A.P.-V., P.B., P.D. and S.S.-M.; software, A.P.-V. and P.B.; validation, M.F.-C., P.O., H.C. and L.C.; formal analysis, M.C. and M.A.P.; investigation, A.P.-V. and P.B.; resources, J.S.-G. and M.A.P.; writing—original draft preparation, A.P.-V., P.B., P.D. and S.S.-M.; writing—review and editing, M.C., H.C., M.F.-C., P.O. and L.C.; visualization, M.C., M.A.P. and L.C.; supervision, J.S.-G., M.A.P. and L.C.; project administration, M.A.P. and L.C.; funding acquisition, J.S.-G. and M.A.P. All authors have read and agreed to the published version of the manuscript.

Funding

The research leading to these results was supported by MICINN supporting the Ramón y Cajal grant for M.A. Prieto (RYC-2017-22891), and the Juan de la Cierva Incorporación for Hui Cao (IJC2020-046055-I); by Xunta de Galicia for supporting the program EXCELENCIA-ED431F 2020/12, the post-doctoral grants of M. Fraga-Corral (ED481B-2019/096), and L. Cassani (ED481B-2021/152), and the pre-doctoral grant of M. Carpena (ED481A 2021/313). The authors are grateful to Ibero-American Program on Science and Technology (CYTED—AQUA-CIBUS, P317RT0003), to the Bio Based Industries Joint Undertaking (JU) under grant agreement No 888003 UP4HEALTH Project (H2020-BBI-JTI-2019) that supports the work of P. Otero.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Braga, M.E.M.; Gaspar, M.C.; de Sousa, H.C. Supercritical Fluid Technology for Agrifood Materials Processing. Curr. Opin. Food Sci. 2023, 50, 100983. [Google Scholar] [CrossRef]

- Ray, A.; Dubey, K.K.; Marathe, S.J.; Singhal, R. Supercritical Fluid Extraction of Bioactives from Fruit Waste and Its Therapeutic Potential. Food Biosci. 2023, 52, 102418. [Google Scholar] [CrossRef]

- Herrero, M.; Mendiola, J.A.; Cifuentes, A.; Ibáñez, E. Supercritical Fluid Extraction: Recent Advances and Applications. J. Chromatogr. A 2010, 1217, 2495–2511. [Google Scholar] [CrossRef] [PubMed]

- Gong, T.; Liu, S.; Wang, H.; Zhang, M. Supercritical CO2 Fluid Extraction, Physicochemical Properties, Antioxidant Activities and Hypoglycemic Activity of Polysaccharides Derived from Fallen Ginkgo Leaves. Food Biosci. 2021, 42, 101153. [Google Scholar] [CrossRef]

- López-Hortas, L.; Rodríguez, P.; Díaz-Reinoso, B.; Gaspar, M.C.; de Sousa, H.C.; Braga, M.E.M.; Domínguez, H. Supercritical Fluid Extraction as a Suitable Technology to Recover Bioactive Compounds from Flowers. J. Supercrit. Fluids 2022, 188, 105652. [Google Scholar] [CrossRef]

- Song, L.; Liu, P.; Yan, Y.; Huang, Y.; Bai, B.; Hou, X.; Zhang, L. Supercritical CO2 Fluid Extraction of Flavonoid Compounds from Xinjiang Jujube (Ziziphus Jujuba Mill.) Leaves and Associated Biological Activities and Flavonoid Compositions. Ind. Crops Prod. 2019, 139, 111508. [Google Scholar] [CrossRef]

- Frohlich, P.C.; Santos, K.A.; Ascari, J.; Santos Refati, J.R.D.; Palú, F.; Cardozo-Filho, L.; da Silva, E.A. Antioxidant Compounds and Eugenol Quantification of Clove (Syzygium Aromaticum) Leaves Extracts Obtained by Pressurized Liquid Extraction and Supercritical Fluid Extraction. J. Supercrit. Fluids 2023, 196, 105865. [Google Scholar] [CrossRef]

- Santos, O.V.; Lorenzo, N.D.; Souza, A.L.G.; Costa, C.E.F.; Conceição, L.R.V.; Lannes, S.C.S.; Teixeira-Costa, B.E. CO2 Supercritical Fluid Extraction of Pulp and Nut Oils from Terminalia Catappa Fruits: Thermogravimetric Behavior, Spectroscopic and Fatty Acid Profiles. Food Res. Int. 2021, 139, 109814. [Google Scholar] [CrossRef] [PubMed]

- Pise, V.H.; Thorat, B.N. Supercritical Fluid Extraction of Dried Surangi Flowers (Mammea Suriga). Ind. Crops Prod. 2022, 186, 115268. [Google Scholar] [CrossRef]

- Wagner, M.E.; French, J.; Rizvi, S.S.H. Supercritical Fluid Extraction of Oil from Potato Chips: Two Scale Comparison and Mathematical Modeling. J. Food Eng. 2013, 118, 100–107. [Google Scholar] [CrossRef]

- De Marco, I.; Riemma, S.; Iannone, R. Life Cycle Assessment of Supercritical CO2 Extraction of Caffeine from Coffee Beans. J. Supercrit. Fluids 2018, 133, 393–400. [Google Scholar] [CrossRef]

- Shanakhat, H.; Sorrentino, A.; Raiola, A.; Romano, A.; Masi, P.; Cavella, S. Current Methods for Mycotoxins Analysis and Innovative Strategies for Their Reduction in Cereals: An Overview. J. Sci. Food Agric. 2018, 98, 4003–4013. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).