1. Background

TiABs are currently just limited to aerospace industry but becoming popular for applications in concrete structures because of their exceptionally outstanding advantages. Compared to conventional reinforcing, the advantages that TiABs offer include but are not limited to higher strength, superior fatigue performance, high strength-to-weight ratio, lighter weight, lower modulus of elasticity, reduction in rebar congestion, smaller inelastic residual deformation, and excellent corrosion resistance [

1]. Similarly, UHPC offers numerous advantages critical for bridge application such as exceptionally higher compressive strength, superior mechanical properties, and excellent durability compared to conventional or high-strength concrete [

2]. However, both UHPC and TiABs have not been widely used to date in structural elements due to the lack of knowledge of their structural behavior and failure mechanism. They can be considered for building a new structure and repairing of existing structures. However, it is important to characterize properly the bond performance of reinforcing, i.e., TiABs embedded in UHPC for the safety of UHPC structures. The cost, nevertheless, plays a huge role in the ability of researchers to carry out experimental studies, and identifying an alternative way to model the behavior of these materials which would be a key challenge.

Machine learning (ML) methods are currently used widely, including applications to concrete structures, e.g., compressive strength of concrete by Chopra et al. [

3], compressive strength of FRP-sheet-confined cylindrical specimens by Naderpour et al. [

4], shear capacity of concrete beams/slabs by Hoang and Ashour et al. [

5,

6]. Researchers (Dahou et al., Golafshani et al., Mousavi et al., Liang, Farouk et al.) have also utilized ML in predicting the bond behavior of reinforcing with concrete [

7,

8,

9,

10,

11]. Despite these advancements, it is still challenging to develop data-driven models for materials such as UHPC and TiABs, where experimental data are scarce. This paper presents the description of collected dataset, utilization, and a framework to develop an explainable, data-driven model (based on ensemble learning) to accurately predict the ultimate bond strength between UHPC and TiABs.

2. Description of Dataset

An experimental dataset from the existing literature was collected to train ML models. A total of 350 experimental tests were collected, which include six input parameters (compressive strength, f’c; yield strength, fy; tensile strength, fu; bar diameter, d; embedment length, ; and concrete cover, c) and one output parameter (ultimate bond strength, τ). The input and output parameters are selected based on the availability of data from the existing literature.

3. Transfer Learning Methods

Transfer learning (TL) is the improvement of a learning ML model in a new task through the transfer of knowledge from a related task that has already been learned. Here, a model developed for a task is reused as the starting point for a model on a second task [

12].

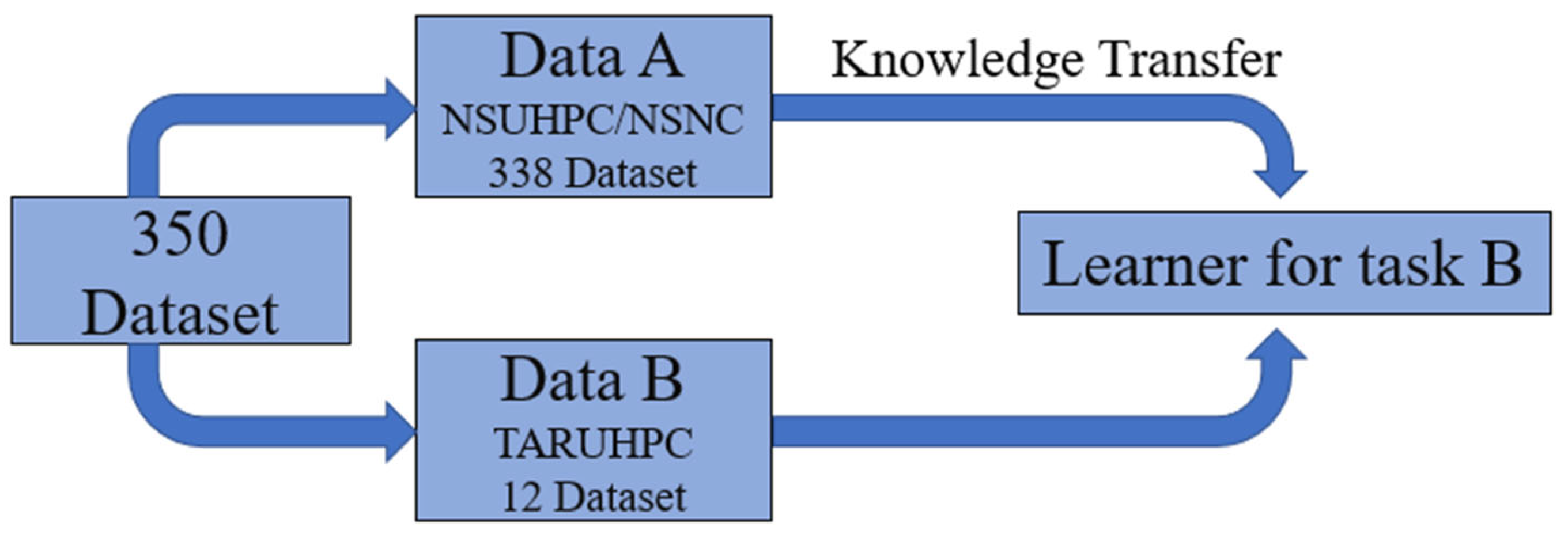

Figure 1 explains the transfer learning with the dataset used in the study. The entire dataset is first split into two different sets. The first set of data includes all the collected data for normal steel–normal concrete specimens and/or normal steel–UHPC specimens. The second set of data includes all the collected data for titanium-alloy-reinforced ultra-high-performance concrete (TARUHPC). Boundary condition in identifying the TARUHPC specimen is with the yield strength of TiABs (

fy: 130 ksi) and compressive strength of UHPC (

f’c: 18 ksi). Both A and B datasets are trained separately and then the knowledge is transferred for a new task. Two major TL methods were selected for this study: (a) Domain-Weighted Support Vector Transfer Regression (DW-SVTR) and (b) Two-stage TrAdaBoost.R2.

3.1. Domain-Weighted Support Vector Transfer Regression (DW-SVTR)

Domain-weighted support vector transfer regression (DW-SVTR) is a novel regression-based transfer learning (TL) model which is a variant of least squares support vector machines for regression (LS-SVMR), coupling LS-SVMR with two weight functions [

13]. Both weight functions have different effects. The first weight is obtained using kernel mean matching (KMM) to balance the source and target domains which offers more weight to source domain points that are relevant to target domain points. The second weight is a function of residuals to further reduce the negative interference of irrelevant source domain points corresponding to outliers for the target domain training sample. In short, the model first applies KMM to balance the source and target domains, then performs data augmentation to increase the number of training examples, and finally trains a weighted LS-SVMR model using the augmented training set. It then uses the trained model to predict the target values of the test set. The predicted target values are returned as the output.

3.2. Two-Stage TrAdaBoost.R2

Two-stage TrAdaBoost.R2 is a transfer learning (TL) model for regression problems modified by Paroe and Stone [

14] from the existing boosting-based classification TL model TrAdaBoost [

15]. For the prediction of bond strength, the model is obtained by implementing the Two-stage TrAdaBoost.R2 algorithm to train a decision tree regressor on a source domain and adapting it to a target domain. Best hyperparameters for transfer learning are then obtained. The model is then trained on the source domain data and a set of adapted models for each transfer learning step is produced. Finally, the adapted model is used to predict the target domain data to produce the predicted target value using the adapted model.

4. Results

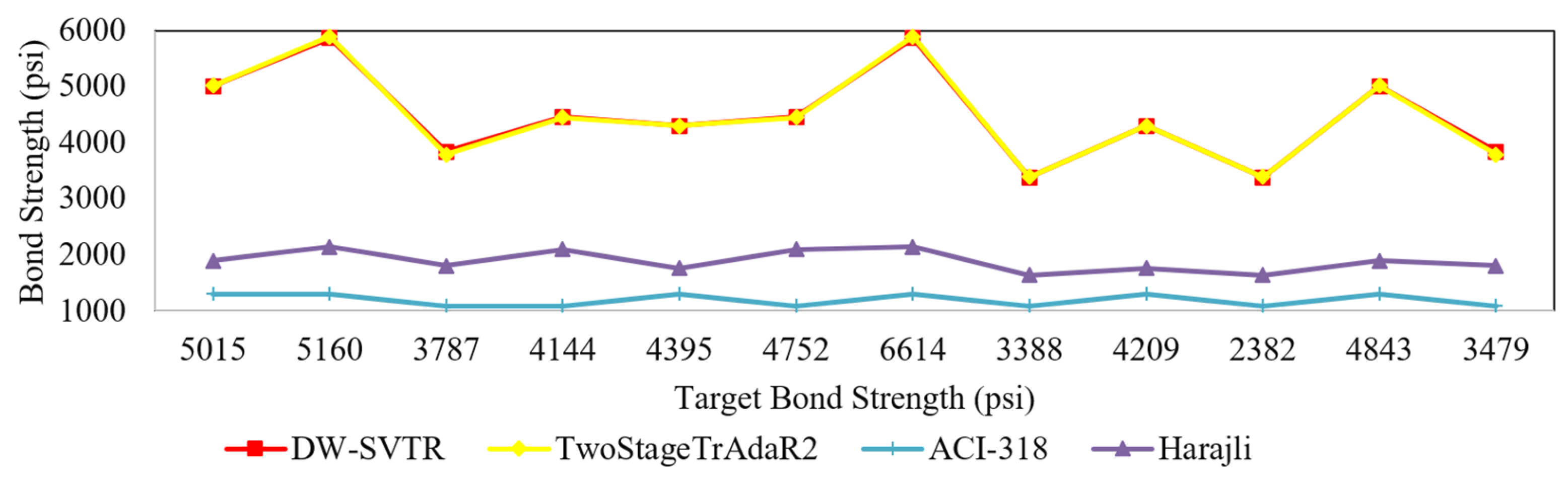

The dataset was used to train and test the TL model in the target domain, i.e., TARUHPC specimens. The predicted bond strength from both DW-SVTR and TwoStage TrAdaBoost.R2 was then compared against the target bond strength that was obtained from the experimental results (

Figure 2). The figure also presents the predicted output obtained from the empirical equations from ACI 318-19 (Equation (1)) [

16] and Harajli (Equation (2)) [

17]. It is evident from the plot that the empirical equations from ACI 318-19 and Harajli cannot accurately predict the bond strength of TARUHPC. However, the TL models can predict the bond strength more accurately for TARUHPC.

DW-SVTR, TwoStageTrAdaR2, ACI-318 and Harajli obtained an R2 score (coefficient of determination) of 0.807, 0.809, −9.35 and −5.52, respectively. The R2 score simply measures the amount of variance in the predictions explained by the dataset. Similarly, the MARD score (mean absolute relative deviation) was 0.0471, 0.0497, 0.722 and 0.570, respectively. MARD is interpreted as the average percentage error of the model in predicting the target variable.

5. Discussion

Titanium alloy bars (TiABs) and ultra-high-performance concrete (UHPC) are considered to be novel materials for civil infrastructures, e.g., bridges. The advantages associated with these materials are the main cause for them to be considered in sustainable infrastructure. TiABs is currently being studied by various researchers as a replacement of traditional steel reinforcing for concrete structures (beam and columns) and being utilized by various DOTs (Departments of Transportation) in the United States. UHPC as well are being studied and utilized as a replacement of traditional normal concrete for bridges, buildings and more. However, the combination of these two novel materials is yet to be studied. This research aimed to successfully predict the ultimate bond strength of TiABs with UHPC, which is an important factor in safety of concrete structures, e.g., structural load-bearing capacity, stiffness, or crack control. This research utilized two major TL techniques, DW-SVTR and TwoStageTrAdaR2, which very closely predicted the bond strength of TiABs with UHPC. On the other hand, empirical equations (ACI-318 and Harajli) need to be modified to successfully predict the bond strength of TiABs with UHPC. The research at Idaho State University is ongoing to accurately define the bond–slip relationship between TiABs and UHPC.

Author Contributions

Conceptualization, M.M. and J.C.; methodology, L.B., M.A. and M.M.; software, L.B., M.A. and A.B.; validation, M.A., L.B., A.B., M.M. and J.C.; formal analysis, M.A., L.B. and A.B.; investigation, M.A., L.B. and A.B.; resources, M.M. and J.C.; data curation, M.A., A.B. and L.B.; writing—original draft preparation, M.A. and A.B.; writing—review and editing, M.A., A.B., J.C., L.B. and M.M.; visualization, M.A., L.B. and A.B.; supervision, M.M., J.C. and L.B.; project administration, M.M. and J.C.; funding acquisition, M.M. and J.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Idaho State University Center for Advanced Energy Studies Seed Grant.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data are available upon request to the corresponding author.

Acknowledgments

This work was supported by State of Idaho, appropriated/funded for the Center for Advanced Energy Studies (CAES).

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Acharya, M.; Khadka, R.; Mashal, M. Preliminary Bond Testing and Splicing of Titanium Alloy Bars. Transp. Res. Rec. J. Transp. Res. Board 2022, 2676, 410–427. [Google Scholar] [CrossRef]

- Khadka, R.; Acharya, M.; LaBrier, D.; Mashal, M. Visualization of Macroscopic Structure of Concrete Based on X-ray Computed Tomography using Immersive Environments. In HCII 2022; Springer: Cham, Switzerland, 2022. [Google Scholar] [CrossRef]

- Chopra, P.; Sharma, R.K.; Kumar, M. Prediction of Compressive Strength of Concrete Using Artificial Neural Network and Genetic Programming. Adv. Mater. Sci. Eng. 2016, 2016, 7648467. [Google Scholar] [CrossRef]

- Naderpour, H.; Nagai, K.; Fakharian, P.; Haji, M. Innovative models for prediction of compressive strength of FRP-confined circular reinforced concrete columns using soft computing methods. Compos. Struct. 2019, 215, 69–84. [Google Scholar] [CrossRef]

- Hoang, N.-D. Estimating punching shear capacity of steel fibre reinforced concrete slabs using sequential piecewise multiple linear regression and artificial neural network. Measurement 2019, 137, 58–70. [Google Scholar] [CrossRef]

- Ashour, A.; Alvarez, L.; Toropov, V. Empirical modelling of shear strength of RC deep beams by genetic programming. Comput. Struct. 2003, 81, 331–338. [Google Scholar] [CrossRef]

- Dahou, Z.; Sbartaï, Z.M.; Castel, A.; Ghomari, F. Artificial neural network model for steel–concrete bond prediction. Eng. Struct. 2009, 31, 1724–1733. [Google Scholar] [CrossRef]

- Golafshani, E.M.; Rahai, A.; Sebt, M.H.; Akbarpour, H. Prediction of bond strength of spliced steel bars in concrete using artificial neural network and fuzzy logic. Constr. Build. Mater. 2012, 36, 411–418. [Google Scholar] [CrossRef]

- Mousavi, S.M.; Peyma, A.B.; Moodi, Y. Predicting the Ultimate and Relative Bond Strength of Corroded Bars and Surrounding Concrete by Considering the Effect of Transverse Rebar Using Machine Learning. Iran. J. Sci. Technol. Trans. Civ. Eng. 2022, 47, 193–219. [Google Scholar] [CrossRef]

- Liang, R.; Huang, Y.; Xu, Z. Experimental and Analytical Investigation of Bond Behavior of Deformed Steel Bar and Ultra-High Performance Concrete. Buildings 2022, 12, 460. [Google Scholar] [CrossRef]

- Farouk, A.I.B.; Zhu, J.; Ding, J.; Haruna, S. Prediction and uncertainty quantification of ultimate bond strength between UHPC and reinforcing steel bar using a hybrid machine learning approach. Constr. Build. Mater. 2022, 345, 128360. [Google Scholar] [CrossRef]

- Brownlee, J. A Gentle Introduction to Transfer Learning for Deep Learning. In Deep Learning for Computer Version; Machine Learning Mastery. Available online: https://machinelearningmastery.com/category/deep-learning-for-computer-vision/ (accessed on 15 November 2022).

- Luo, H.; Paal, S.G. Reducing the effect of sample bias for small data sets with double-weighted support vector transfer regression. Comput. Civ. Infrastruct. Eng. 2020, 36, 248–263. [Google Scholar] [CrossRef]

- Pardoe, D.; Stone, P. Boosting for regression transfer. In Proceedings of the 27th International Conference on Machine Learning; Fürnkranz, J., Joachims, T., Eds.; Omni Press: Madison, WI, USA, 2010. [Google Scholar]

- Dai, W.; Yang, Q.; Xue, G.; Yu, Y. Boosting for transfer learning. In Proceedings of the 24th International Conference on Machine Learning. Ghahramani, A., Ed.; Omni Press: New York, NY, USA, 2007. [Google Scholar]

- ACI 318-19; Building Code Requirements for Structural Concrete: (ACI 318-19); and Commentary (ACI 318R-19). American Concrete Institute: Farmington Hills, MI, USA, 2019.

- Harajli, M.H. Development/splice strength of reinforcing bars embedded in plain and fiber reinforced concrete. ACI Struct. J. 1994, 91, 511–520. [Google Scholar]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).