A Multi-Fidelity Deep Neural Network Approach to Structural Health Monitoring †

Abstract

1. Introduction

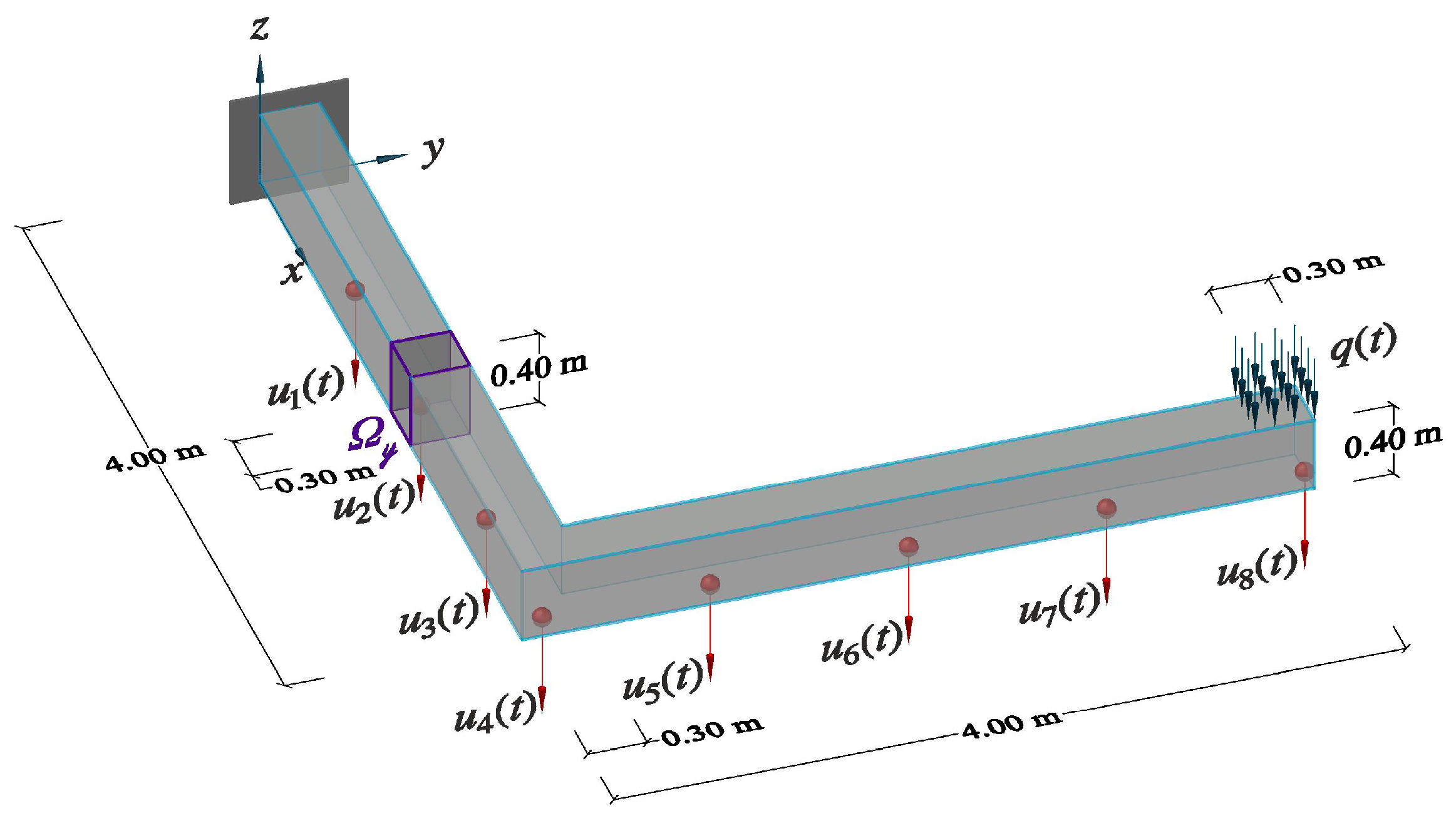

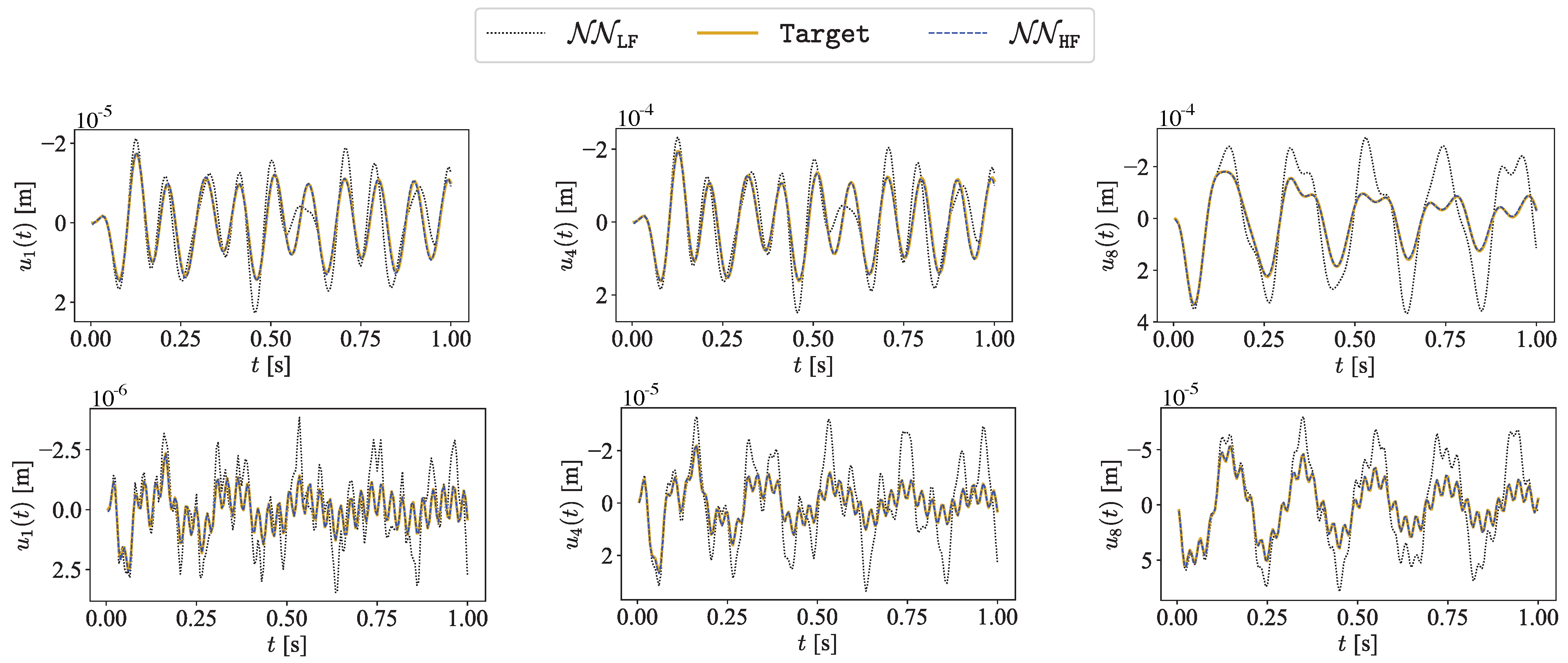

2. MF-DNN Surrogate Modeling

3. Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Farrar, C.; Worden, K. Structural Health Monitoring A Machine Learning Perspective; Wiley: Chichester, UK, 2013. [Google Scholar] [CrossRef]

- Neves, A.C.; Gonzalez, I.; Karoumi, R. Development and Validation of a Data-Based SHM Method for Railway Bridges. In Structural Health Monitoring Based on Data Science Techniques; Springer International Publishing: Cham, Switzerland, 2022; pp. 95–116. [Google Scholar] [CrossRef]

- Rosafalco, L.; Torzoni, M.; Manzoni, A.; Mariani, S.; Corigliano, A. A Self-adaptive Hybrid Model/data-Driven Approach to SHM Based on Model Order Reduction and Deep Learning. In Structural Health Monitoring Based on Data Science Techniques; Springer International Publishing: Cham, Switzerland, 2022; pp. 165–184. [Google Scholar] [CrossRef]

- García-Macías, E.; Ubertini, F. Integrated SHM Systems: Damage Detection Through Unsupervised Learning and Data Fusion. In Structural Health Monitoring Based on Data Science Techniques; Springer International Publishing: Cham, Switzerland, 2022; pp. 247–268. [Google Scholar] [CrossRef]

- Torzoni, M.; Manzoni, A.; Mariani, S. Structural health monitoring of civil structures: A diagnostic framework powered by deep metric learning. Comput. Struct. 2022, 271, 106858. [Google Scholar] [CrossRef]

- Worden, K. Structural fault detection using a novelty measure. J. Sound. Vib. 1997, 201, 85–101. [Google Scholar] [CrossRef]

- Rosafalco, L.; Manzoni, A.; Mariani, S.; Corigliano, A. Fully convolutional networks for structural health monitoring through multivariate time series classification. Adv. Model. Simul. Eng. Sci. 2020, 7, 38. [Google Scholar] [CrossRef]

- Entezami, A.; Sarmadi, H.; Behkamal, B.; Mariani, S. Big data analytics and structural health monitoring: A statistical pattern recognition-based approach. Sensors 2020, 20, 2328. [Google Scholar] [CrossRef] [PubMed]

- Kamariotis, A.; Chatzi, E.; Straub, D. Value of information from vibration-based structural health monitoring extracted via Bayesian model updating. Mech. Syst. Signal. Process. 2022, 166, 108465. [Google Scholar] [CrossRef]

- Eftekhar Azam, S.; Mariani, S. Online damage detection in structural systems via dynamic inverse analysis: A recursive Bayesian approach. Eng. Struct. 2018, 159, 28–45. [Google Scholar] [CrossRef]

- Bishop, C.M. Pattern Recognition and Machine Learning (Information Science and Statistics); Springer: New York, NY, USA, 2006. [Google Scholar]

- Avci, O.; Abdeljaber, O.; Kiranyaz, S.; Hussein, M.; Gabbouj, M.; Inman, D. A review of vibration-based damage detection in civil structures: From traditional methods to Machine Learning and Deep Learning applications. Mech. Syst. Signal. Process. 2021, 147, 107077. [Google Scholar] [CrossRef]

- Warner, J.; Zubair, M.; Ranjan, D. Near real time damage diagnosis using surrogate modeling and high performance computing. In Proceedings of the 19th AIAA Non-Deterministic Approaches Conference, Grapevine, TX, USA, 9–13 January 2017; p. 1563. [Google Scholar] [CrossRef]

- Hou, R.; Wang, X.; Xia, Y. Vibration-Based Structural Damage Detection Using Sparse Bayesian Learning Techniques. In Structural Health Monitoring Based on Data Science Techniques; Springer International Publishing: Cham, Switzerland, 2022; pp. 1–25. [Google Scholar] [CrossRef]

- Green, P.L.; Worden, K. Bayesian and Markov chain Monte Carlo methods for identifying nonlinear systems in the presence of uncertainty. Philos. Trans. R. Soc. A 2015, 373, 20140405. [Google Scholar] [CrossRef] [PubMed]

- Mirzazadeh, R.; Eftekhar Azam, S.; Mariani, S. Mechanical characterization of polysilicon MEMS: A hybrid TMCMC/POD-kriging approach. Sensors 2018, 18, 1243. [Google Scholar] [CrossRef] [PubMed]

- Rocchetta, R.; Broggi, M.; Huchet, Q.; Patelli, E. On-line Bayesian model updating for structural health monitoring. Mech. Syst. Signal Process. 2018, 103, 174–195. [Google Scholar] [CrossRef]

- Meeds, E.; Welling, M. GPS-ABC: Gaussian process surrogate approximate Bayesian computation. arXiv 2014, arXiv:1401.2838. [Google Scholar]

- García-Macías, E.; Ierimonti, L.; Venanzi, I.; Ubertini, F. An innovative methodology for online surrogate-based model updating of historic buildings using monitoring data. Int. J. Archit. Herit. 2021, 15, 92–112. [Google Scholar] [CrossRef]

- Meng, X.; Babaee, H.; Karniadakis, G.E. Multi-fidelity Bayesian Neural Networks: Algorithms and Applications. J. Comput. Phys. 2021, 438, 110361. [Google Scholar] [CrossRef]

- Guo, M.; Manzoni, A.; Amendt, M.; Conti, P.; Hesthaven, J. Multi-fidelity regression using artificial neural networks: Efficient approximation of parameter-dependent output quantities. Comput. Methods Appl. Mech. Eng. 2022, 389, 114378. [Google Scholar] [CrossRef]

- Rosafalco, L.; Manzoni, A.; Mariani, S.; Corigliano, A. Combined Model Order Reduction Techniques and Artificial Neural Network for Data Assimilation and Damage Detection in Structures. In Computational Sciences and Artificial Intelligence in Industry: New Digital Technologies for Solving Future Societal and Economical Challenges; Springer International Publishing: Cham, Switzerland, 2022; pp. 247–259. [Google Scholar] [CrossRef]

- Rosafalco, L.; Torzoni, M.; Manzoni, A.; Mariani, S.; Corigliano, A. Online structural health monitoring by model order reduction and deep learning algorithms. Comput. Struct. 2021, 255, 106604. [Google Scholar] [CrossRef]

- Torzoni, M.; Rosafalco, L.; Manzoni, A.; Mariani, S.; Corigliano, A. SHM under varying environmental conditions: An approach based on model order reduction and deep learning. Comput. Struct. 2022, 266, 106790. [Google Scholar] [CrossRef]

- He, K.; Zhang, X.; Ren, S.; Sun, J. Deep residual learning for image recognition. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Las Vegas, NV, USA, 27–30 June 2016; pp. 770–778. [Google Scholar] [CrossRef]

- He, K.; Zhang, X.; Ren, S.; Sun, J. Delving Deep into Rectifiers: Surpassing Human-Level Performance on ImageNet Classification. In Proceedings of the IEEE International Conference on Computer Vision (ICCV), Santiago, Chile, 7–13 December 2015; pp. 1026–1034. [Google Scholar] [CrossRef]

- Goodfellow, I.; Bengio, Y.; Courville, A. Deep Learning; MIT Press: Cambridge, MA, USA; London, UK, 2016. [Google Scholar]

- Hochreiter, S.; Schmidhuber, J. Long short-term memory. Neural Comput. 1997, 9, 1735–1780. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Torzoni, M.; Manzoni, A.; Mariani, S. A Multi-Fidelity Deep Neural Network Approach to Structural Health Monitoring. Eng. Proc. 2022, 27, 60. https://doi.org/10.3390/ecsa-9-13344

Torzoni M, Manzoni A, Mariani S. A Multi-Fidelity Deep Neural Network Approach to Structural Health Monitoring. Engineering Proceedings. 2022; 27(1):60. https://doi.org/10.3390/ecsa-9-13344

Chicago/Turabian StyleTorzoni, Matteo, Andrea Manzoni, and Stefano Mariani. 2022. "A Multi-Fidelity Deep Neural Network Approach to Structural Health Monitoring" Engineering Proceedings 27, no. 1: 60. https://doi.org/10.3390/ecsa-9-13344

APA StyleTorzoni, M., Manzoni, A., & Mariani, S. (2022). A Multi-Fidelity Deep Neural Network Approach to Structural Health Monitoring. Engineering Proceedings, 27(1), 60. https://doi.org/10.3390/ecsa-9-13344