1. Introduction

Temperature sensors are used for a wide variety of industrial, scientific, medical and domestic purposes, and they differ by design and/or operating principles to better suit their given application. The global market size for these sensors was estimated at USD 6.3 billion in 2020, with a projected annual growth of 4.8% to 2027 [

1]. They are frequently employed in feedback control systems in order to maintain the required temperature of an object irrespective of the temperature changes in the outer environment. For well-insulated objects, the power of the heater/cooler does not need to be very high, as the object can be brought to the required temperature without significant heat losses, albeit slowly. However, the associated time delays might lead to, for example, production losses if the object’s temperature is outside of the acceptable range for a manufacturing process. If the heating/cooling requirements are known and/or can be predicted in advance, the temperature of the object can be managed much more efficiently.

Recent advances in internet technologies, infrastructure and services made it possible to develop automated management systems which provide the level of intelligence that cannot be achieved by using low-cost computing at the edge alone. These services, in addition to already ubiquitous cloud storage, include, i.a., Internet-of-Thigs (IoT), Industrial Internet-of-Things (IIoT), time, weather forecast, mapping and other servers. As a result, it became possible to engineer control systems with features that would be economically unfeasible a few years ago because of their high capital and running costs. This paper presents a detailed account of the development of a prototype industrial control system, featuring a single WiFi-enabled microcontroller unit (MCU), which extensively uses internet services in order to cut off unnecessary energy use and associated costs for a process tank heater. The reported development was initiated by a Sheffield area-based enterprise of a small/medium size that qualified for development support under the auspices of the Digital Innovation for Growth program [

2]. The company provides electrochemical processing services to their customers, which involves the use of heated water tanks. Many processes must be conducted at elevated temperatures to ensure the conformity, consistency and quality of outcome. The appropriate heating of some water tanks requires many hours and should be completed by the start of a working day to avoid any waiting time.

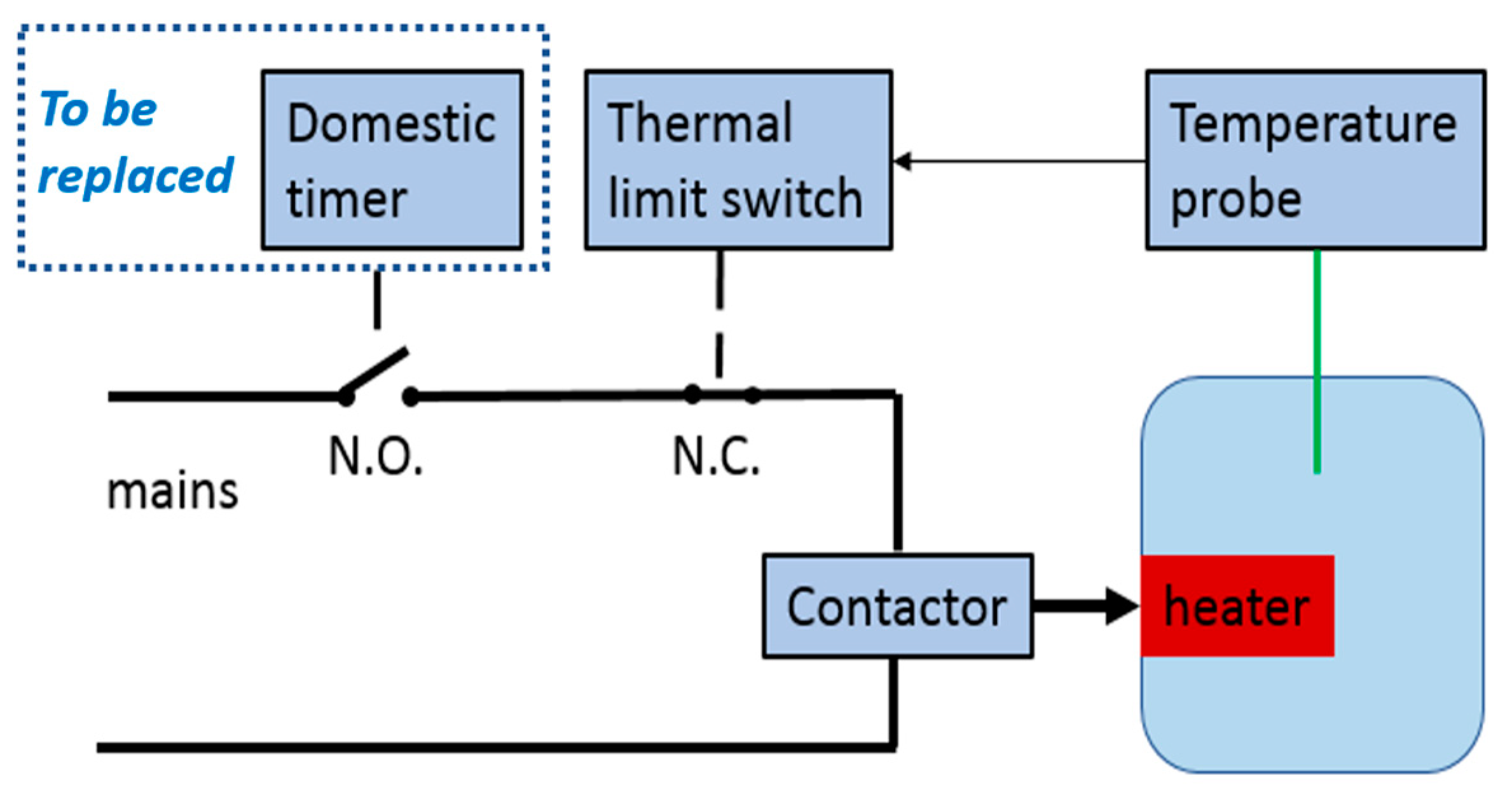

At present, the company uses the setup presented in

Figure 1. A domestic timer is set at the end of a working day to switch on the heater after a guesstimated delay. When the in-tank temperature exceeds that required for the process to be conducted, the next working day, the thermal limit switch switches the heater off. The tank cools down until the temperature crosses the lower threshold of the thermal switch, and the heater starts to operate again.

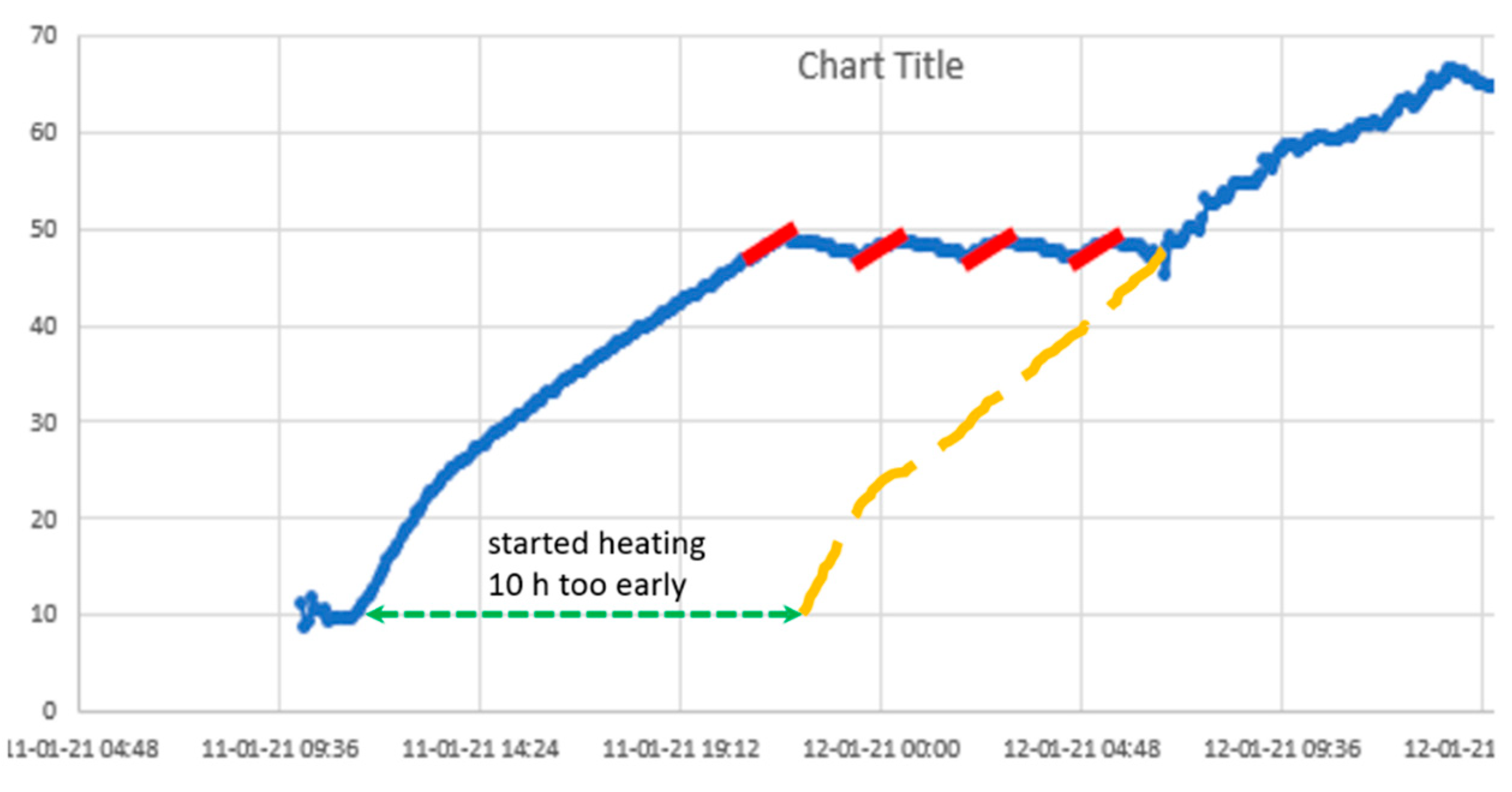

This arrangement generally results in the required temperature by the start of the working day, but because it relies on the guesstimated delay, it can be hit or miss. If the delay is set with a spacious margin that ensures the tank’s readiness, a substantial amount of energy can be wasted (

Figure 2). If the delay is set with the view to minimize energy waste, production delays may be encountered.

This project aims to develop an automatic heater control system that would achieve the required heated tank temperature at the start of a working day without excessive energy consumption by utilizing ambient temperature forecast.

2. Project Requirements and Considerations

As there are approximately ten heated tanks around the company’s premises that must be controlled, the customer requested the development of an independent controller to simplify trial testing and deployment. The controller needed to save the temperature logs in the internet cloud and onto an SD card, and it needed to be able to access internet weather forecasts via the company’s Wi-Fi access point. It also needed to be made from commercially available, off-the-shelf components that do not require the manufacture or assembly of custom electronic boards. Lastly, the controller needed to be encased in a material that was flexible and expandable.

Safety concerns: the heater should be switched off if the temperature exceeds requirements or if the controller loses power.

Security concerns: temperature logs have no notable value to the company or to any actors with malicious intent. For this reason, operating via the company’s password-protected access point is sufficient. The Wi-Fi credentials can be set externally after the first power-up by using a suitable Wi-Fi password manager that is then stored in the controller’s RAM. However, because the company’s premises are secure and the credentials are known to onsite personnel, the option to permanently store the credentials in the flash memory of the controller was instead selected.

3. Selection of the Hardware

Temperature measurements can be conducted by using a variety of sensors; thermocouples and resistance temperature detectors (RTDs) are the most common in industrial environments. The former has an extended temperature range but a lower sensitivity. For this reason, and because the customer had previously installed RTDs on-site, the Pt100 RTD sensor was selected. It requires glue electronics to communicate data to a microcontroller using either analog voltage or a digital interface. The latter option requires more wiring but is considerably more robust and resilient to noise and was thus considered preferable. We selected an Adafruit Pt100 RTD temperature sensor amplifier [

3], which eases the use of the MAX31865 integrated circuit that is dedicated to RTD handling [

4]. Additionally, we used a DS18B20 digital temperature sensor [

5], a cheaper alternative that can be connected to a microcontroller without the use of glue electronics.

The implementation of a Wi-Fi connection to obtain the weather forecast could be carried out by using a microcontroller with a Wi-Fi gateway that is controlled either through the use of AT commands or by acting as a serial to the TCP converter. However, there is also a well-established line of Wi-Fi-enabled systems-on-chip (SoCs) that is manufactured by Espressif and allows for the use of a single component for both the control and Wi-Fi connection. Although the older-generation ESP8266 series is more established and generally cheaper to deploy, the more recent ESP32 series offers significantly enhanced capabilities that are useful for prototyping and low-volume replication [

6].

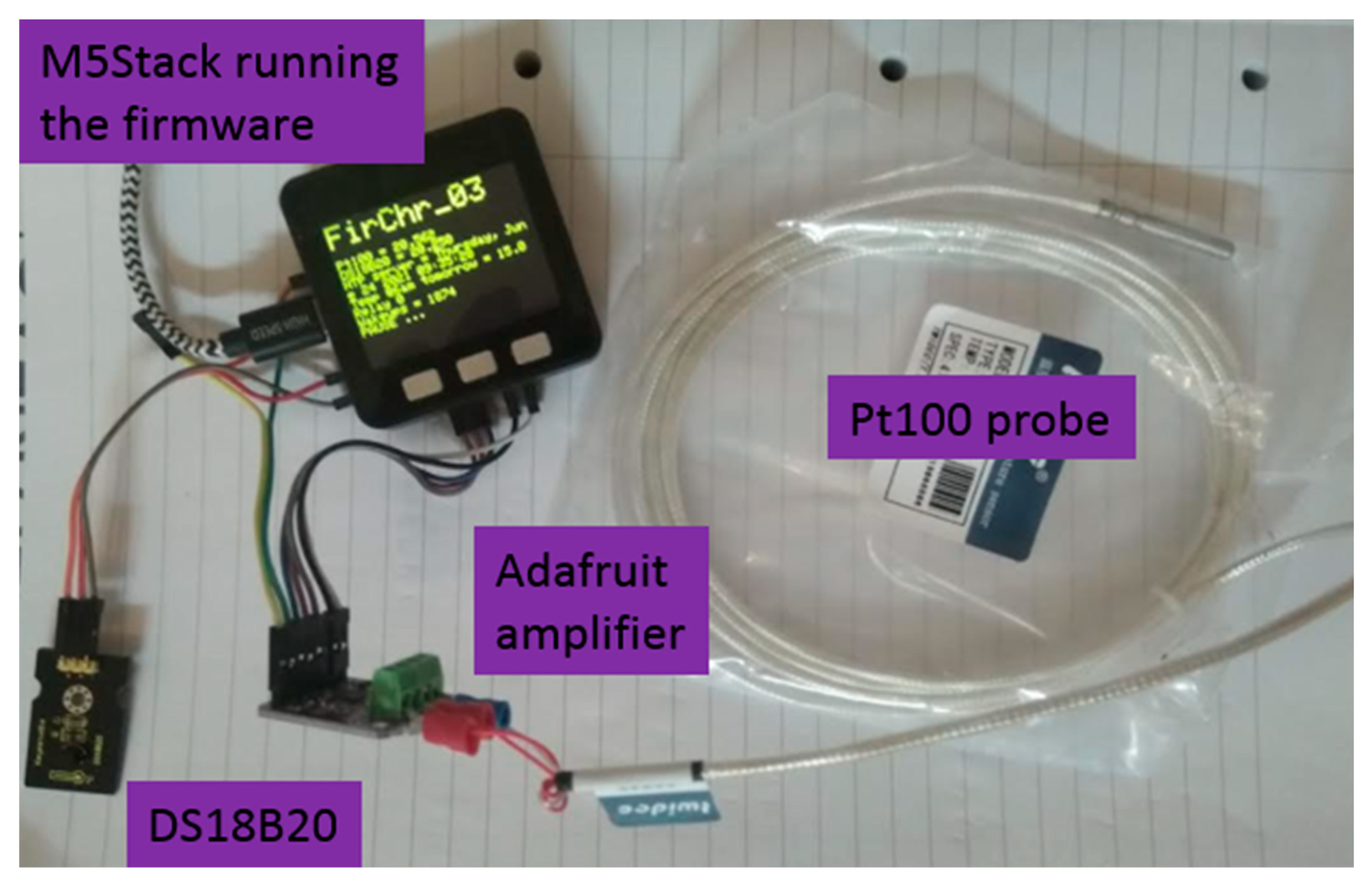

M5Stack Basic Core [

7] was selected because it provides access to a variety of ESP32 pins and allows for easy expansion by combination of the stackable modules. In particular, we connected the output of the Adafruit Pt100 RTD temperature sensor amplifier to the SPI pins of the ESP32 and the data pin of the DS18B20 sensor to an ESP32 GPIO pin. Both sensors were powered by the 3.3 V source available on M5Stack Basic Core.

4. Selection of the Development Environment

ESP32 can be programmed using a variety of toolchains, including the Espressif IoT Development Framework ESP32-IDF (C/C++ compiler and linker), the Arduino environment and MicroPython, which has become increasingly popular because its interpreting nature does not require full code re-compilation after every change. The Arduino environment was selected because of the availability of example codes, which covered all the identified needs of this project. This choice was eventually confirmed by the straightforward process of searching for solutions and workarounds when an added code snippet did not integrate well with the developed firmware.

5. Selection of the IoT Service Provider

Currently, the Message Queuing Telemetry Transport (MQTT) protocol seems to be the most used for Internet of Things (IoT) and Industrial Internet of Things (IIoT) applications [

8]. It features a (cloud/LAN) broker that listens constantly for packets from data producers, stores them and then serves data consumers upon their request. This allows both the producers and the consumers to experience disconnection or a loss of power without losing data. A cloud broker eliminates the need for maintaining a local one, which is convenient for a user without a dedicated infrastructure.

Despite the large number of Google search results for IoT service providers, most proved incompatible with the requirements of this project. Some were too expensive, at the yearly cost of EUR 500 or more for commercial applications (Blynk, Thingspeak, Google Cloud, Particle IoT, Oracle IoT, Thinger, Ubidots, Pubnub and IBM Watson, to name a few). Other options did not advertise a transparent pricing structure (e.g., email communication was required for obtaining a quote from my Devices), some top providers would be unlikely to help with development due to the low potential income stream (Microsoft Azure IoT, Amazon IoT Core), some convoluted the process by splitting their operations between two entities (i.e., Dweet for data producers and Freeboard for data consumers) and one quite promising option went out of business (Phant).

In fact, we selected Adafruit IO [

9] from the outset, as it ticked all the right boxes: easy setup, capable free-tier account, USD 10 monthly fee for commercial use, extensive documentation and a support forum. Later, when we encountered difficulties, we searched for alternatives but found none. Throughout our use of Adafruit IO over several months, we did not lose a single datum, observed 100% server uptime, enjoyed their online Graphical User Interface (GUI) editor and easily located relevant documentation, when needed.

6. Firmware Structure and Functionality

The firmware development started by exploring examples and then integrated the selected code snippets from the well-established

Adafruit_MAX31865 (for RTD) and

OneWire/DallasTemperature (for DS18B20) Arduino libraries. The Network Time Protocol (NTP) servers were accessed based on the code snippets from [

10]. For weather forecasting, we used a free service called Datapoint that is provided by the UK’s Meteorological Office (Met Office) to businesses in the UK (it requires registration to obtain an access key and location code) [

11]. In order to prevent the device from hanging, we employed the ESP32 watchdog timer based on the code snippets from [

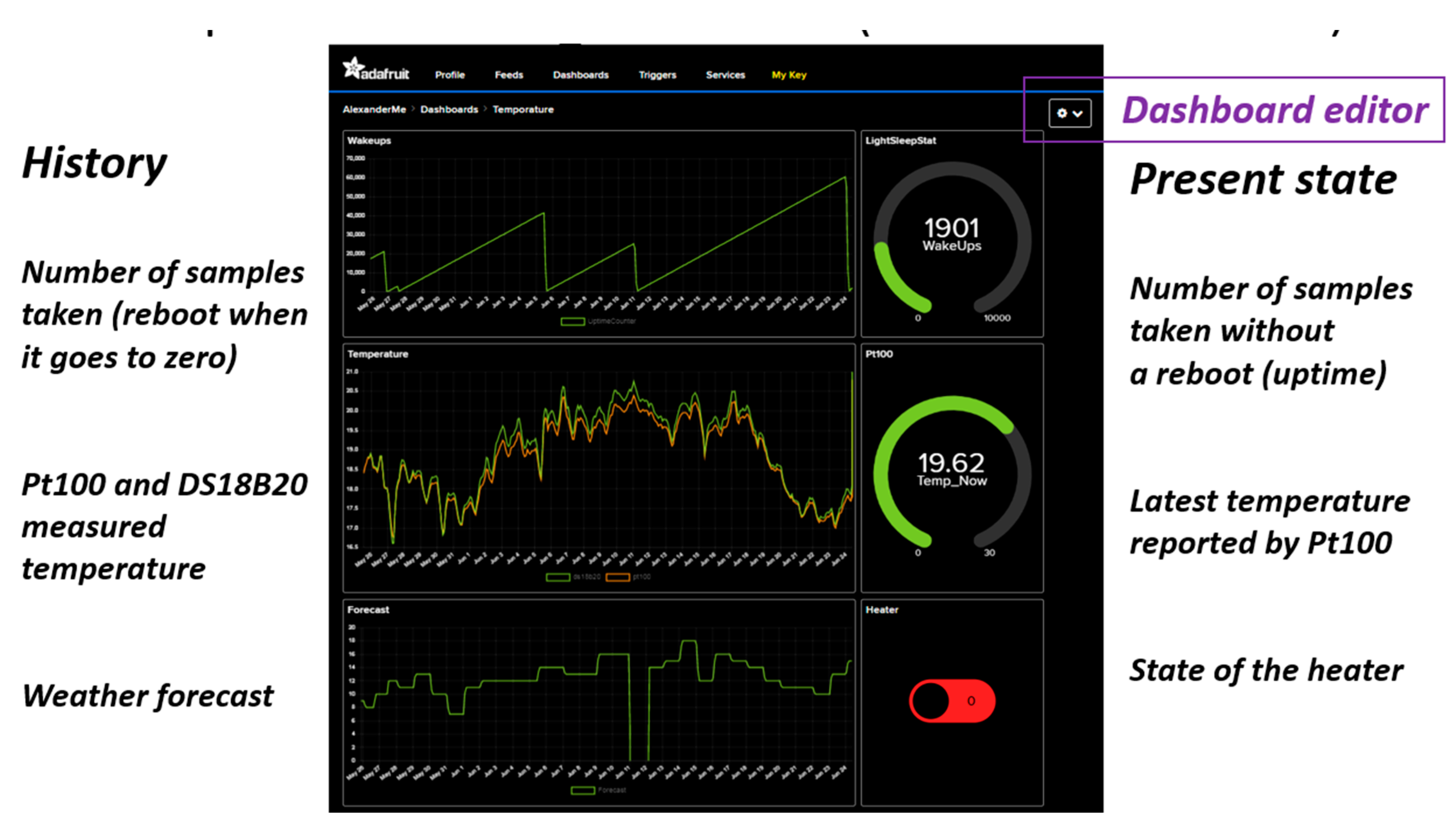

12]. The Adafruit IO code was integrated at the final stage, after familiarization with the provided examples. After the relatively straightforward process of getting the code to work, the user interface (a.k.a. the dashboard) was easily developed through use of Adafruit’s online dashboard editor (

Figure 3).

As using the Adafruit IO Arduino API resulted in some complications, the Adafruit IO REST API (via POST and GET HTTP requests) were employed instead. The developed code was shared on the Adafruit IO support forum [

13].

The device, when operating at full throttle, consumes around 0.11 A of current. During the light sleep, M5Stack consumes less than 0.01 A, which results in a reduction of power consumption by over ten times, as the sampling temperature and reporting results take less than 5 s.

The loop Arduino function, therefore, takes temperature samples from the two temperature sensors, sends the readings to the cloud, displays them on the local M5Stack color LCD display, checks the position of the manual switch on the dashboard, determines if it is necessary to update the RTC and weather forecast, clears the watchdog timer and then enters the light sleep mode.

The time to switch the heater on is calculated by considering the heat losses through the surface and the walls of the tank, the rated heater power and the difference between the tank’s required and forecasted ambient temperatures.

The prototyped device is presented in

Figure 4.

7. Summary and Conclusions

We detailed the development of a prototype intelligent control system, including considerations for the relevant hardware, the development environment, the internet services used (NTP, weather forecast, cloud MQTT servers) and the results of the development.

In particular, the system made use of the following technologies and services:

NTP servers for obtaining accurate time references;

Adafruit IO’s MQTT servers, acting as a broker between the data producer (the ESP32 MCU) and the data consumer (the end user);

Adafruit IO’s dashboard and layout editor for designing the graphical user interface for the end user;

UK Met Office’s Datapoint for obtaining the location- and time-specific weather forecast;

Adafruit’s Arduino application programming interface calls were replaced with HTTP’s more robust GET and PUT commands.

The required hardware includes only parts that are available off-the shelf.

The prototype allows the water tanks to achieve and maintain the required temperatures, excess energy consumption is curtailed and absolutely no guesstimation is involved.