Data Acquisition and Processing Algorithm for Total and Static Pressure Measurement System †

Abstract

1. Introduction

2. Data Acquisition Algorithm

- The Startup of the ADC channel is performed by a trigger from the timer. The data are then saved in the array with the use of direct memory access (DMA).

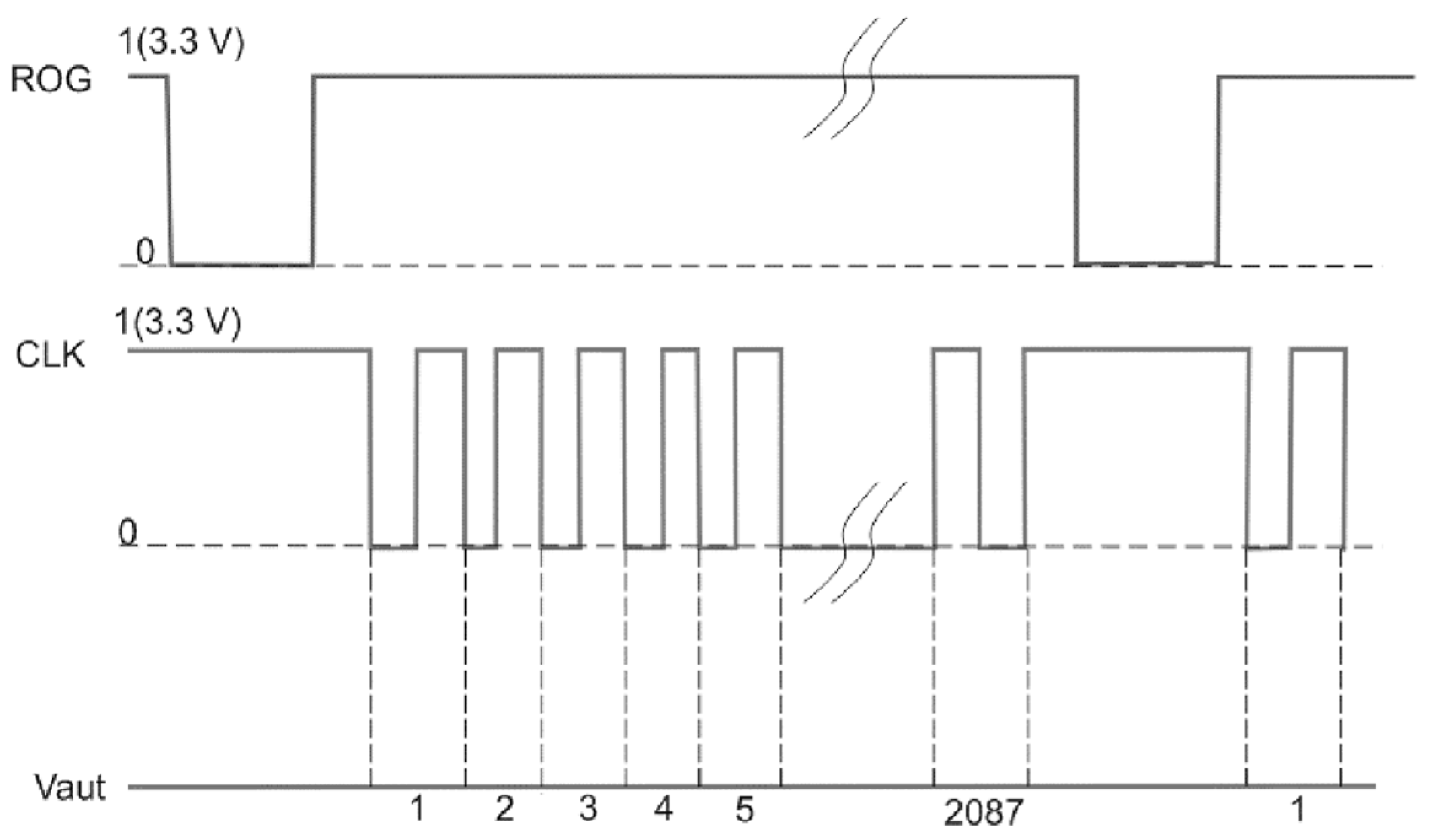

- The CLK signal is inverted by an ADC interrupt handler after each conversion. (This approach to forming CLK pulses allows acquisition of a data array of 4174 values for the PA consisting of 2087 pixels).

- The flag of the completion of polling of the first half of the PD is set in the DMA interrupt handler after half of the data array is filled.

- The flag of the PA polling completion is set in the DMA interrupt handler and the reset signal (ROG) is formed after the whole data array is filled.

- Tracking the status of the polling of the first half of the PA. If the corresponding flag is set, data are copied to the other memory region and then processed.

- If the averaging is not performed the results are transmitted via the USART interface.

- Tracking the status of the polling of the whole PA. If the corresponding flag is set, the data are copied to the other memory region and then processed.

- If the averaging is not performed the results are transmitted via the USART interface.

- The results are averaged and then transmitted via USART.

3. Data Processing Algorithm

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fraden, J. Handbook of Modern Sensors; Springer: New York, NY, USA, 2003. [Google Scholar]

- Auersvald, J.; Draxler, K.; Sipo, M. A Low-cost Aerometric Sensor system for Sport Aviation. J. Electr. Eng. 2019, 4, 295–302. [Google Scholar] [CrossRef]

- Auersvald, J.; Draxler, K. Aerometric System for General Aviation. In Proceedings of the International Conference on Military Technologies (ICMT), Brno, Czech Republic, 19 May–21 May 2015; pp. 1–6. [Google Scholar]

- Almazov, V.V.; Makarov, N.N.; Sorokin, M.Y. Evaluation of Performance of Aerometric Systems. Izv. Samara Sci. Cent. Russ. Acad. Sci. 2017, 1, 385–390. [Google Scholar]

- Philippe, J.; De Paolis, M.V.; Arenas-Buendia, C.; Henry, D.; Coustou, A.; Rumeau, A.; Aubert, H.; Pons, P. Passive and Chipless Packaged Transducer for Wireless Pressure Measurement. In Sensors and Actuators A: Physical; Elsevier: Amsterdam, The Netherlands, 2018; pp. 753–762. [Google Scholar]

- Soldatkin, V.V.; Soldatkin, V.M.; Derevyankin, V.P. Models of Signals, Characteristics, and Errors of the Axisymmetric Multifunction Air Pressure Sensor for Aircraft Aerometric Systems. Russ. Aeronaut 2021, 64, 105–110. [Google Scholar] [CrossRef]

- Jena, S.; Gupta, A. Embedded Sensors for Health Monitoring of an Aircraft. In Sensors for Automotive and Aerospace Applications. Energy, Environment, and Sustainability; Bhattacharya, S., Agarwal, A., Prakash, O., Singh, S., Eds.; Springer: Berlin/Heidelberg, Germany, 2019. [Google Scholar]

- Leitzke, J.P.; Della Mea, A.; Faller, L.M.; Mühlbacher-Karrer, S.; Zangl, H. Wireless Differential Pressure Measurement for Aircraft. Measurement 2018, 122, 459–465. [Google Scholar] [CrossRef]

- Kwon, H.; Park, Y.; Shin, C.; Kim, J.H.; Kim, C.G. In-Flight Strain Monitoring of Aircraft Tail Boom Structure Using a Fiber Bragg Grating Sensor Based Health and Usage Monitoring System. Int. J. Aeronaut. Space Sci. 2021, 22, 567–577. [Google Scholar] [CrossRef]

- Antonets, I.V.; Gorshkov, G.M.; Borisov, R.A. Datchik Aerometricheskikh Davleniy (Aerometric Pressure Sensor). RU Patent 2653596, G01L7/00, 11 May 2018. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Krotov, A.; Tarasov, S.; Lunev, A.; Borisov, R.; Kushevarova, D. Data Acquisition and Processing Algorithm for Total and Static Pressure Measurement System. Eng. Proc. 2022, 27, 23. https://doi.org/10.3390/ecsa-9-13332

Krotov A, Tarasov S, Lunev A, Borisov R, Kushevarova D. Data Acquisition and Processing Algorithm for Total and Static Pressure Measurement System. Engineering Proceedings. 2022; 27(1):23. https://doi.org/10.3390/ecsa-9-13332

Chicago/Turabian StyleKrotov, Alexander, Sergey Tarasov, Andrey Lunev, Ruslan Borisov, and Darya Kushevarova. 2022. "Data Acquisition and Processing Algorithm for Total and Static Pressure Measurement System" Engineering Proceedings 27, no. 1: 23. https://doi.org/10.3390/ecsa-9-13332

APA StyleKrotov, A., Tarasov, S., Lunev, A., Borisov, R., & Kushevarova, D. (2022). Data Acquisition and Processing Algorithm for Total and Static Pressure Measurement System. Engineering Proceedings, 27(1), 23. https://doi.org/10.3390/ecsa-9-13332