Abstract

This paper will give an overview about the development of a material system, which consists of a novel formable magnesium alloy that is provided with an effective corrosion protection coating. The corrosion protection is to be realized in the form of a forming stable powder coating, which can be applied in the coil coating process. To improve the tribological properties, additional additives are added to the powder coating. Within this paper, first results concerning tribological and forming behavior of the new lightweight material system are given. For the benchmark, the results are compared with commercially available AZ31 Mg alloy.

1. Introduction

Magnesium is the lightest metallic construction material and it is suitable for lightweight structural parts. Furthermore, Mg offers nearly unlimited availability and excellent recyclability. However, wrought Mg alloys have virtually the same weight reduction potential, without losing strength, to that offered by high-performance reinforced plastics, which are not recyclable [1,2]. The automotive industry shares up to 58% of the major end-uses of Mg in the EU [3], where non-structural Mg castings are mostly used [4]. Consequently, it is of prime importance to continue developing new solutions to enhance the formability of wrought Mg alloys at a temperature close to room temperature and to improve the corrosion resistance.

Currently, the most economical method of producing an Mg alloy sheet is the two-roll casting (TRC) process, which allows the sheet to be produced continuously [5,6,7]. To improve the forming properties, the TRC process (influencing the grain size) and/or the alloy composition can be varied. For alloy variation, two principal types are investigated: Mg-Zn-RE alloys and the more affordable Mg-Zn-Al-Ca alloy, which does not contain the strategic rare earth (RE) elements [3,8].

Cold formable Mg sheets with multi-functional coatings, with lubrication properties during forming and corrosion protection until their final use, have an enormous and feasible potential to be implemented in mobile assemblies. Furthermore, the utilization of such a lightweight system can reduce the operational costs (no heated tools and extra lubrication) and reduce waste due to elimination of pre-processing steps (e.g., pre-coating removals).

A new selective two-step curing mechanism between uretdione and OH groups using a special catalyst was developed in the past by Gedan-Smolka et al. [9]. Based on these fundamentals, highly flexible, weather-stable low-temperature-curing polyallophanate powder coating systems were developed, which can be completely cured at temperatures between 120 °C and 150 °C. The degree of formability meets all requirements for postforming and deep drawing of aluminum sheets [10], especially for the hardenable alloys [11,12,13]. This opens the possibility of using this new technology on Mg alloys, thus enhancing its corrosion resistance. In addition, functionalized IR-absorber additives and a suitable technology have been developed in the past to enable the curing in seconds instead of minutes as a precondition for high-speed powder coil or blank coating [14]. Recently, an additional latent adhesive function was implemented into the powder formulation that leads to material bonding for multi-material joints, which can be generated by injection molding [15,16,17] or hybrid pultrusion [18,19].

In this paper, an Mg-alloy (Mg-Zn-Y-Zr) is presented which exhibits significantly improved formability at 60 °C compared to commercial alloys. Furthermore, first tribological results of forming stable powder coating formulations with tribo-additives are presented and evaluated.

2. Materials and Methods

2.1. Mg Alloys

Two Mg-Zn-RE alloys were produced via twin-roll casting (TRC). The first composition was a Mg-RE-Y-Zr-Zn alloy, hereafter named Mg-RE1, which was used for the development of the novel powder coating. A lean Mg-Zn-Y-Zr (Mg-RE2) second composition was cast based on the former alloy with the objective of improving its formability. TRC strips of both alloys with 5.2 mm thickness were used for hot rolling experiments to reach a final thickness of 1.5 mm. Before rolling, the strips were homogenized at 450 °C for 16 h. Hot rolling was performed at 400 °C. The rolling schedule consisted of three initial rolling passes with φ = −0.1 and five passes with φ = −0.2:

where φ is true strain, n the number of the pass, and hn the sample thickness after the nth pass. After each rolling step, the sheet was reheated to the rolling temperature and held there for 10 min. After the last rolling pass, the samples were air-cooled and then recrystallized for 10 min at 400 °C. In order to compare the forming capabilities of the more formable Mg-RE2 alloy, commercial Mg AZ31 sheets were used for bending and deep drawing experiments.

The metallographic examination was conducted by optical microscopy on the normal direction (ND) and rolling direction (RD) plane. Samples were ground with emery paper to grit 2500, and polished with a water-free oxide polishing suspension (OPS) 0.5 µm. A picric solution was used to reveal the microstructures. Global texture was measured using a Panalytical™ X-ray diffractometer with Cu-Kα radiation. The orientation distribution function (ODF) was calculated using the MTEX toolbox (Open source software 5.3.1, Freiberg, Germany) [20] from six measured pole figures (0001), {10–10}, {10–11}, {10–12}, {10–13} and {11–20}. The results of the samples used for forming tests are presented in terms of the recalculated (0001) pole figure.

Dog-bone tensile samples with gauge length of 24 mm were tested in a universal testing machine Zwick™ 050. Tests up to fracture were performed along the RD and TD at room temperature. All the tensile tests were performed at constant strain rate of 10−3 s−1.

2.2. Powder Coating Development

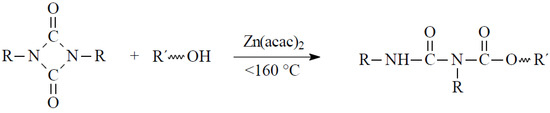

The basis for the integration of an additional internal tribological function into the powder coating was the previously mentioned specific reaction mechanism. In this reaction, OH-functionalized polyesters react with an uretdione hardener in the presence of Zn(acac)2 as catalyst at temperatures ≤ 150 °C to form a selective, highly flexible polyallophanate network (Figure 1).

Figure 1.

Crosslinking mechanism in the basic powder coating system.

Therefore, a powder coating model system was prepared that comprises the following ingredients:

- OH-functionalized polyester (OH-group number 285, Tg = 52 °C)

- uretdione crosslinker (NCO-eq 331, NCO:OH ratio = 2:1)

- Zn(acac)2: 0.5 wt%

- TiO2-pigment: 30 wt%

- degassing agent: 1.0 wt%

- flow agent: 1.5 wt%

Three groups of substances were used as solid lubricants:

- polyolefine wax (PO)

- polytetrafluoroethylene (PTFE) non treated

- PTFE-containing polyolefine wax (PO-PTFE)

- radiation-modified PTFEγ (500 kGy, thermally post-treated)

For the additive contents, with the exception of the last group, contents as recommended in the technical data sheet were used for screening in basic powder coatings. Details are listed in Table 1.

Table 1.

Antifriction powder coating basic formulations/screening of solid lubricants.

For the screening, the powder coatings were prepared in a laboratory scale of 1 kg each by using the usual processing steps pre mixing (Premixer, MTI Mischtechnik International GmbH, Detmold, Germany), melt extrusion (Buss-Cokneader MKS 30-20, Buss AG, Pratteln, Switzerland; max. Tmelt = 110 °C, throughput: 10 kg/h), milling to a fine powder (Hosokwa Alpine AktG, Augsburg, Germany, grinding and sifting plant 100 AFG) and finally, top grain separation by sieving (KTS-V 450/1 GTKM Siebtechnik GmbH, Waibstadt, Germany; d50 = 33 µm). Subsequently, for film characterization, the powders were applied to degreased gradient plates by Corona (film thickness: (60–80) µm) and cured at 150 °C for 15 min. For the forming and tribo-tests, the coatings were applied to Mg RE1 sheets (film thickness: (60–80) µm) with a standard industrial pretreatment for magnesium (Henkel chemistry, Düsseldorf, Germany), and then cured at 150 °C for 15 min.

Differential Scanning Calorimetry (DSC) measurements of the resulting powders were carried out by DSC (TA Instruments Discovery 2500, Eschborn, Germany; (−20–250) °C, heating rate: 10 K/min). Gloss values at 60° were determined using a Multi Gloss 268, Konica Minolta Bremen, Germany (mean values from 5 measurements) and surface roughness Rz (mean values 3 plates with 3 measurements each) using a Hommel W5, Jenoptic industrial Metrology GmbH, Schwenningen, Germany.

3. Results

3.1. Mg Alloys

3.1.1. Microstructural Analysis

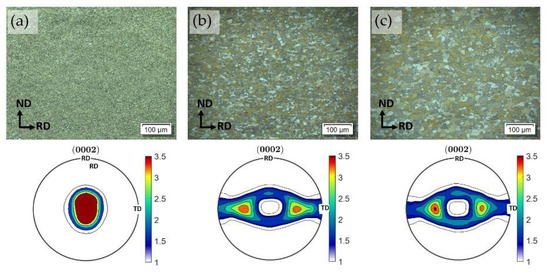

The microstructures and crystallographic textures of the (a) AZ31 alloy, (b) Mg-RE1 alloy and (c) Mg-RE2 alloy are presented in Figure 2. In the case of the AZ31 alloy can be seen a very fine and homogenous grain structure with an average grain size of 6 µm. It is characterized by a strong basal type texture with an intensity of 11 of multiple random distributions (m.r.d.). This texture is known for reducing the forming capabilities of this alloy. With regard to the Mg-RE1, the microstructure is also homogeneous with an average grain size of 8 µm. This material shows the characteristic texture of Mg-RE-containing alloys, where there are two main basal peaks inclined towards a transverse direction (TD). In this sample, several secondary phase particles sitting along grain boundaries were observed, which were detrimental of the forming capability, despite the weak texture of 3 m.r.d. In the case of the Mg-RE2 alloy, the sheet alloy shows a homogeneous grain structure. Yet, it is coarser than the previous materials. The average grain size is 12 µm. It also shows the characteristic TD-split texture with a weak intensity of 3.5 m.r.d.

Figure 2.

Microstructures and textures in terms of the (0001) pole figure of the: (a) AZ31 alloy, (b) Mg-RE1 alloy and (c) Mg-RE2 alloy.

3.1.2. Mechanical Characterization

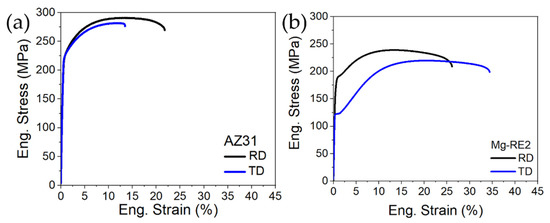

Figure 3 shows the representative stress–strain curves of (a) AZ31 alloy and (b) Mg-RE2 alloy. The AZ31 alloy shows a significantly higher strength and less anisotropy in terms of the difference of the yield stresses measured along RD (218 MPa ± 5 MPa) and TD (225 MPa ± 5 MPa). In addition, the ultimate tensile strength is rather similar to 285 MPa in both directions. In the case of the Mg-RE2 alloy, the material is significantly more ductile than the AZ31 alloy. Elongation higher than 30 % could be reached along TD, while the ductility along RD is always lower. The anisotropic behavior is also visible in the mechanical properties where the yield stress along RD (178 MPa ± 5 MPa) is significantly lower than that of TD (239 MPa ± 3 MPa). This anisotropic behavior is well known and it is related with the characteristic TD-split texture. Despite the anisotropic behavior, the Mg-RE2 alloy shows significantly improved formability than its counterpart AZ31 alloy as shown in the next section.

Figure 3.

Engineering stress–strain curves of (a) AZ31 alloy and (b) Mg-RE2 alloy.

3.1.3. Forming Tests

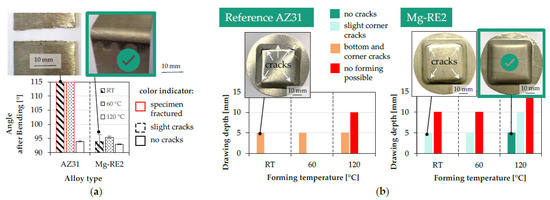

For evaluation of the principal formability of the presented alloy Mg-RE2 (sheet thickness: 1.5 mm), 90°-bending test and deep drawing trials were performed at different temperatures. As benchmark, the results were compared with the commercially available alloy AZ31 (sheet thickness: 1.0 mm).

The results of the bending test (Figure 4a) show a significant improvement of the formability of the Mg-RE2 alloy at room temperature (RT) compared to the complete fractured AZ31 reference. Only slight micro-cracks parallel to the rolling direction occurred in the stretched outer fiber of the Mg-RE2 alloy, which is reflected in the wide scatter of the measured values for the bending angle. At a forming temperature of 60 °C, no surface defects are visible anymore.

Figure 4.

Forming tests in laboratory scale: (a) Results of bending tests for tool with bending radius of 2 mm, rolling direction parallel to bending line, three repetitions for each configuration; (b) Results of lubricated deep drawing tests at different temperatures; drawing gap: 2.0 mm, punch and die radii: 5 mm, lubrication: Zeller+Gmelin Multidraw KTL-N16, three repetitions for each configuration.

At the more complex deep drawing process (Figure 4b) a defect-free part could only be produced with the Mg-RE2 alloy at a forming temperature of 120 °C with a drawing depth of 5 mm. For AZ31, this was not possible with the examined parameters. The cold formable potential of the Mg-RE2 alloy can be seen at room temperature where only slight cracks in the corner area of the cup occur. In contrast, additional bottom cracks are visible at the AZ31 reference.

3.2. Powder Coatings

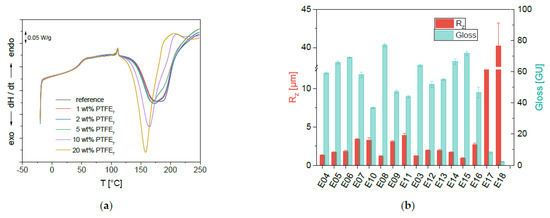

To implement an additional tribological function into the highly flexible protective powder coating film, a screening of various solid lubricants was carried out. Polyolefine waxes, PO-PTFE and micronized plain PTFE are mixed physically with the other formulation components via melt extrusion. In contrast, in the case of PTFEγ, a chemical bonding of the lubricant to the polymer matrix is intended that can cause a drastically improved wear resistance and lower influences on the mechanical and appearance film properties. All powder coating formulations were prepared by using the same extrusion process parameters as for the reference system. Therefore, there are large differences in melt viscosity and the conditions were not optimal for the breaking down behavior and distribution so far and have to be optimized in future. However, DSC-measurements (Figure 5a) showed comparable Tg values for all formulations, which can be taken as an indication of a good homogenization each. In addition, no effect on the onset temperature of the crosslinking reaction or on the maximum peak temperature was observed for formulations with low lubricant content. In contrast, an acceleration of the crosslinking reaction was observed with high amounts (>10 wt%) of the functionalized PTFEγ. This is surprising in so far as a deactivation of the catalyst for the crosslinking reaction was actually to be expected due to the functional carboxylic groups contained.

Figure 5.

(a) Comparison of the reactivity of basic powder coatings in the presence of radiation modified PTFEγ depending on the lubricant amount by DSC; (b) Gloss values at 60° angle and roughness depth Rz of cured powder coating films at 150 °C for 15 min.

With regard to the mechanical film properties, the impact values (according to American Society for Testing and Materials (ASTM) 2794 [21]) for the physically mixed additives are already lowered at proportions < 1 wt% compared to the reference (>160 inlb). In the formulations with the functionalized PTFEγ, this is observed only at 5 wt.% and above. The reason for this behavior is considered to be the chemical bonding of the additive into the polymer matrix.

With regard to film appearance (Figure 5b), even very small amounts of additive (e.g., E13) in the physically mixed formulations lead to a significant reduction in gloss compared with the reference film E08. In the presence of the functionalized PTFEγ, this effect is only clearly pronounced from 5 wt%. However, it must be recognized that the differences determined in the surface roughness influence the gloss level measurements, so that a complete comparability is not achieved. In the physical mixtures, a significant increase in surface roughness was observed, especially with the pure waxes (E09, E11) and the unmodified PTFE additives (E07, E10), as well as with the chemically coupled systems at very high PTFEγ contents (E17, E18).

In order to determine realistic values, which reflect the tribological system between the blank holder and the sheet during deep drawing, flat strip drawing tests (Figure 6a) without additional lubrication were carried out for each powder coating formulation shown in Table 1. In this test, the coated sheet metal strip is fixed on a sledge and pulled under a polished drawing tool to which the normal force FN is applied. By determining the resulting frictional force FR, the coefficient of friction is calculated from the ratio of FR and FN.

Figure 6.

Flat strip drawing test for determination of the coefficient of friction: (a) test principal; (b) results without lubrication.

As substrate material, the alloy Mg-RE1 was chosen, as this was the first alloy produced. In this case, the preliminary results are valid, as the drawing tool is not in contact with the substrate during the test, and the type of Mg alloy has no effect on the tribological properties, assuming that delamination of the powder coating does not occur. The results in Figure 6b show that the coefficient of friction can be reduced significantly by powder coatings supplemented with tribo-additives. The best results were obtained by the powder coating E11 (µ = 0.09) which was additivated with polyethylene wax. There, the coefficient of friction could be reduced up to 70% compared to the pure powder coating E08 (µ = 0.30). The combination of the additives PTFE and polyolefine performed marginally worse (µ = 0.10–0.13), followed by the coating variants in which different PTFE grades were used as the sole additive (µ = 0.12–0.16). After tests without lubricant, no delamination occurred. Only a slight smoothing of the coating in the edge area of the contact zone with the drawing tool could be detected macroscopically.

4. Discussion

As shown above, there is good potential for using Mg-Zn-RE alloys to manufacture structural components at a relatively low temperature, as the formability is significantly higher than the AZ31 alloy. Nevertheless, more adjustments to the chemical composition and thermomechanical treatment have to be carried out in order to lower the forming temperature even further. This will have two main advantages, which are the use of cold forming tools and the concomitant prevention of damaging the coating during forming operations due to increased temperature. With regard to the development of the lightweight system, the results shown above indicate that there is no delamination of the powder coating from the Mg-RE1 substrate. More recent results, not yet shown, indicate that there is no visible difference between the powder coating adhesion on different Mg alloy substrates.

With regard to the powder coating development, screening of various solid lubricants has shown that all additives used, regardless of the type and proportion in the powder coating formulation and independently of the type of integration into the polymer matrix (physical mixing versus chemical coupling), enable a significant reduction in the coefficient of friction. In addition, all additives, with the exception of high levels of PTFEγ (>10 wt%), have no influence on the reactivity of the powder material so that the curing conditions can be maintained in all cases. In addition to the lowering of the coefficient of friction, the additivated coating films exhibit a reduction in film flexibility even at low additive contents, and the gloss level drops drastically in some cases. This is particularly evident with the physical mixtures, while with chemically coupled PTFEγ this effect is only observed at very high lubricant contents. Thus, the powder coating films with chemically coupled PTFE do not show the lowest coefficient of friction, but instead a balanced film performance, which differs only slightly from the reference sample and an advantage for the subsequent forming into components can be supposed.

At this moment of the project, experiments on the forming capabilities of the lightweight system are under progress. Yet, preliminary experiments have shown the positive results of stretch forming tests as the powder coating significantly lowers the friction of the Mg substrate with the forming tool, thus enhancing the forming limit of the novel lightweight system.

5. Conclusions

The present work has shown a holistic approach on the design of a lightweight system consisting of a formable Mg alloy coated with a novel powder coating. The use of an Mg-Zn-Y-Zr increases significantly the deep drawability at significantly lower temperatures than the conventional AZ31 alloy. Yet, further adjustments in the chemical composition and thermomechanical treatment have to be performed to reduce the forming temperature further. With regard to the powder coating development, good hints reducing the friction coefficient have been measured without delamination of the coating from the substrate.

Author Contributions

Conceptualization, P.S.; Mg-alloy development, J.V.-H. and D.L.; powder coating development, M.G.-S. and M.T.; sheet pretreatments, L.K.; tribological evaluation and forming tests, P.S. and S.V.; writing—review and editing, P.S., M.G.-S., J.V.-H. and L.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research is supported by the Federal Ministry for Economic Affairs and Climate Action (BMWK) on the basis of a decision by the German Bundestag. This article is based on the project “Cold formable Magnesium alloy combined with forming stable anti corrosion powder coating” coordinated by the German Federation of Industrial Research Associations (AiF) via European Research Association for Sheet Metal Working (EFB) under Grant No. 289 EBG.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors are grateful for the donation of materials by Clariant, Deurex AG, Lubrizol and Allnex. The technical support of G. Cano and S. Woo at Hereon is gratefully acknowledged.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- Luo, A.A.; Sachdev, A.K. Applications of Magnesium Alloys in Automotive Engineering. In Advances in Wrought Magnesium Alloys: Fundamentals of Processing, Properties and Applications; Woodhead Publishing Ltd.: Sawston, UK, 2012; pp. 393–426. [Google Scholar]

- Bandivadekar, A.; Bodek, K.; Cheah, L.; Evans, C.; Groode, T.; Heywood, J.; Kasseris, E.; Kromer, M.; Weiss, M. On the road in 2035: Reducing transportations petroleum consumption and GHG emissions laboratory for energy and environment. Available online: https://energy.mit.edu/publication/on-the-road-in-2035/ (accessed on 24 October 2022).

- Study on the Review of the List of Critical Raw Materials. Available online: https://op.europa.eu/de/publication-detail/-/publication/08fdab5f-9766-11e7-b92d-01aa75ed71a1/language-en (accessed on 4 July 2022).

- Romanowski, C. Magnesium Alloy Sheet for Transportation Applications. Magnesium Technology 2019; The Minerals, Metals & Materials Series; Springer International Publishing: Cham, Switzerland, 2019; pp. 3–12. [Google Scholar]

- Kurz, G.; Wendt, J.; Bohlen, J.; Letzig, D. Microstructure Evolution of Different Magnesium Alloys During Twin Roll Casting. In Magnesium Technology; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2015; Volume 2015, pp. 465–470. [Google Scholar]

- Victoria-Hernández, J.; Kurz, G.; Bohlen, J.; Yi, S.; Letzig, D. Influence of Twin-Roll Casting Speed on Microstructural Homogenity, Center line Segregation, and Surface quality of Three Different Mg Alloys. JOM 2021, 72, 1460–1470. [Google Scholar] [CrossRef]

- Klaumuenzer, D.; Victoria-Hernández, J.; Yi, S.; Letzig, D.; Kim, J.; Seo, M.H.; Ahn, K. Magnesium Process and Alloy Applications in the Automotive Industry. In Magnesium Technology Symposium; Springer International Publishing: Berlin, Germany, 2019; ISSN 23671181. [Google Scholar]

- Ha, C.; Bohlen, J.; Zhou, X.; Brokmeier, H.G.; Kainer, K.U.; Schell, N.; Yi, S. Texture Development and Dislocation Activities in Mg-Nd and Mg-Ca Alloy Sheets. Mater. Charact. 2021, 175, 111044. [Google Scholar] [CrossRef]

- Gedan-Smolka, M.; Lehmann, F.; Lehmann, D. New Catalysts for the Low Temperature Curing of Uretdione Powder Coatings. In Proceedings of the 28th International Waterborne, High Solids, & Powder Coatings Symposium, New Orleans, LA, USA, 29 January 2001. [Google Scholar]

- Gedan-Smolka, M.; Edelmann, J.; Töpfer, A.; Lehman, F.; Komber, H. Wetterstabile Niedertemperatur-Pulver-Beschichtungs- Systeme für Tiefziehfähige Aluminiumfeinbleche. Available online: http://docplayer.org/31450552-Wetterstabile-niedertemperatur-pulverbeschichtungssysteme-aluminiumfeinbleche.html (accessed on 11 November 2022).

- Dresden, I.P.F.; Lehmann, D.; Gedan-Smolka, M. Beschichtete Umgeformte Aluminiumbauteile und Verfahren zu ihrer Herstellung. DE 102 11 512 B4, 31 May 2007. [Google Scholar]

- Gedan-Smolka, M.; Lehmann, D.; Lehmann, F. Catalysis in uretdione powder coatings enables innovative processing lines. Polymer 2003, 44, 58–59. [Google Scholar]

- Gedan-Smolka, M.; Demmler, M.; Edelmann, M.; Töpfer, A. Shapable weather-resistant low temperature thermosetting uretdi- one powder coating prototypes. Pitture E Vernici–Eur. Coat. 2006, 82, 19–28. [Google Scholar]

- Strohbeck, U.; Cudazzo, M.; Vogelsang, H.; Gedan-Smolka, M.; Tuschla, M.; Demmler, M. Innovative technology for highly productive powder coating of coils and blanks. In Proceedings of the European Coatings Congress Proceedings, Nuremberg, Germany, 28–30 March 2011; p. 8. [Google Scholar]

- Gedan-Smolka, M.; Kühnert, I.; Scholz, P.; Fischer, M.; Berger, J.; Tuschla, M.; Landgrebe, D.; Lehmann, D. Powder coating films with latent adhesive function for metal-plastic hybrids. In Proceedings of the Euradh 2016, Glasgow, UK, 21–23 September 2016; pp. 228–231. [Google Scholar]

- Kühnert, I.; Gedan-Smolka, M.; Fischer, M. Prefinished metal polymer hybrid parts. Technol. Lightweight Struct. 2017, 1, 89–97. [Google Scholar] [CrossRef]

- Puentes-Parodi, A.; Kühnert, I.; Leuteritz, A.; Gehde, M.; Gedan-Smolka, M. Effect of a thermal treatment on thermoplastic polyurethane- metal hybrids. J. Compos. Mater. 2018, 52, 3669–3680. [Google Scholar] [CrossRef]

- Schubert, K.; Gedan-Smolka, M.; Marschner, A.; Rietzschel, T.; Uhlig, K.; Löpitz, D.; Wagner, D.; Knobloch, M. Basic material and technology investigations for material bonded hybrids by continuous hybrid profile fabrication. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1140, 012030. [Google Scholar] [CrossRef]

- Wagner, D.; Löpitz, D.; Knobloch, M.; Gedan-Smolka, M.; Schubert, K. Profile structures for economical hybrid lightweight design. Technol. Lightweight Structures. 2021, 5, 87–95. [Google Scholar] [CrossRef]

- Hielscher, R.; Schaeben, H. A Novel Pole Figure Inversion Method: Specification of the MTEX Algorithm. J. Appl. Crystallogr. 2008, 41, 1024–1037. [Google Scholar] [CrossRef]

- ASTM D 2794:1993; Standard Test Method for Resistance of Organic Coatings to the Effects of Rapid Deformation. ASTM International (ASTM): West Conshohocken, PA, USA, 2004.

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).