Application of Artificial Intelligence in Maintenance as an Important Factor of Corporate Business Strategy †

Abstract

1. Introduction

2. Core Characteristics of Artificial Intelligence

- Supervised learning—the model learns from labeled input–output data [7];

- Semi-supervised learning—combines a small amount of labeled data with a large amount of unlabeled data [8];

- Unsupervised learning—identifies patterns in unlabeled data [9];

- Reinforcement learning—an agent learns by interacting with an environment and receiving rewards or penalties [10].

- Convolutional Neural Networks (CNNs)—used for image and video recognition; notable models include LeNet-5 and AlexNet [11];

- Recurrent Neural Networks (RNNs)—suited for sequential data like time series or natural language, with advanced variants such as LSTM to handle long-term dependencies [12];

- Generative Adversarial Networks (GANs)—consist of a generator and a discriminator that improve through competition, widely used in image synthesis and data augmentation [13].

3. Traditional Approach to Maintenance and Maintenance Costs

- Reactive maintenance—this approach involves addressing equipment failures after they occur. It often leads to unplanned downtime and increased production costs. According to recent studies, approximately 45.7% of machine maintenance is reactive. Facilities in the top 25% of reactive maintenance usage experienced 3.3 times more downtime compared to those in the bottom 25%. Moreover, these organizations reported 16 times more defects, 2.8 times more lost sales due to maintenance-related defects, 2.4 times more lost sales due to maintenance delays, and 4.9 times higher inventory levels caused by maintenance inefficiencies [14].

- Planned (Preventive) maintenance—this strategy involves scheduling regular inspections and repairs based on predefined intervals, either time-based or usage-based. The objective is to extend asset lifespan and prevent failures before they happen. However, without proper monitoring, this approach may result in redundant tasks, inefficient use of resources, and even post-maintenance failures due to over-maintenance [15].

- Predictive maintenance—this strategy uses real-time monitoring technologies, sensors, and data analytics to detect early signs of equipment failure. The aim is to perform maintenance only when it is needed, optimizing costs and minimizing downtime [16].

4. Strategic Maintenance Supported by Artificial Intelligence

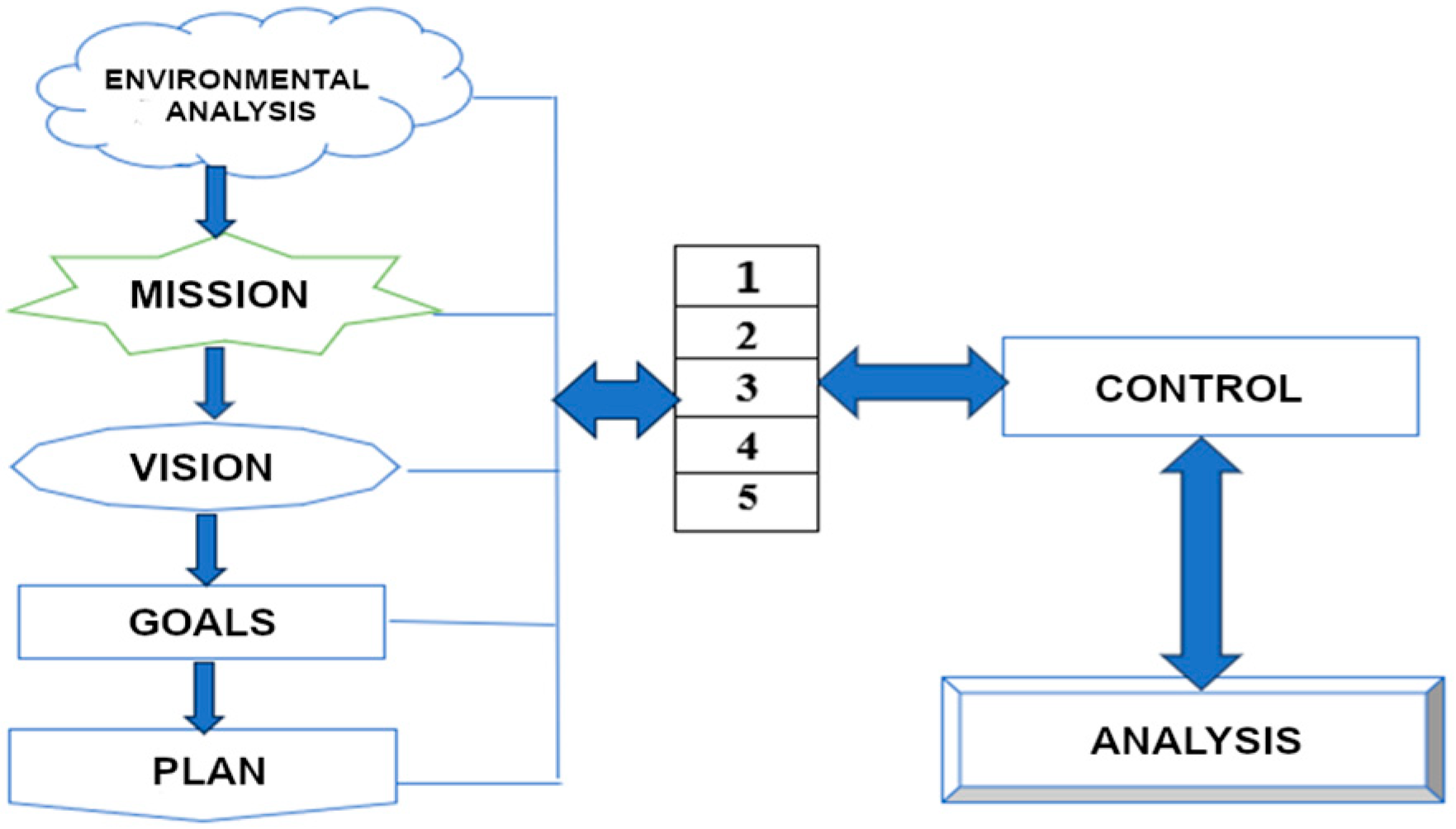

4.1. Corporate Business Strategy

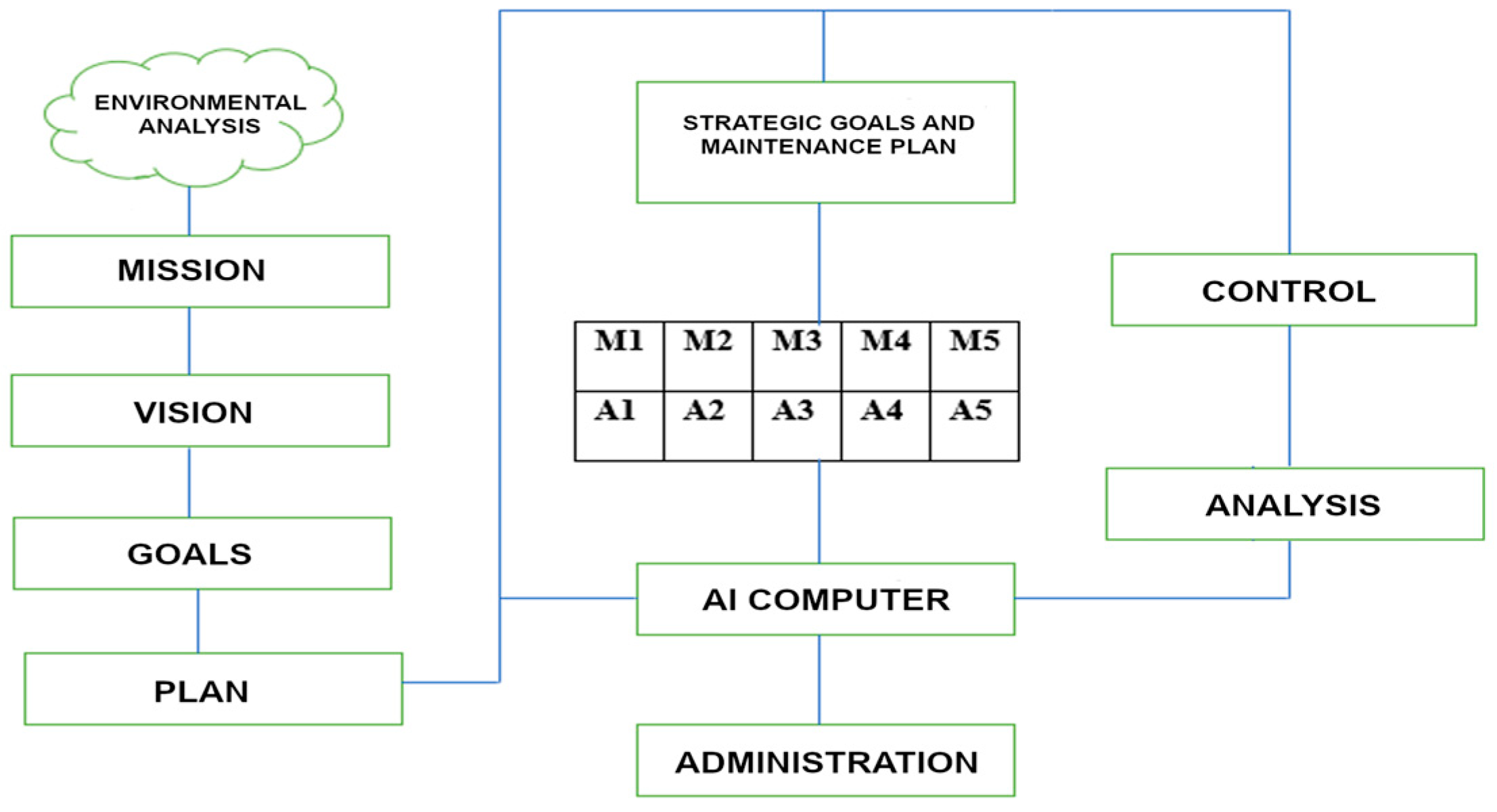

4.2. The Role of Artificial Intelligence in Strategic Maintenance

- Identify maintenance problem points for all business units of the corporation and specifically for each unit.

- Review current maintenance practices in all units and their impact on production efficiency.

- Pay special attention to types of downtime according to the intensity of impact on the production system.

- Precisely determine costs by units and time periods.

- Identify essential factors in order to set a maintenance strategy based on the application of artificial intelligence in combination.

4.3. Artificial Intelligence Tools in Implementing a Maintenance Strategy

- IoT Sensors—sensors provide real-time data, including vibration, sound, and thermal readings. These data are essential for predictive maintenance applications.

- Metilja (with Fluke infrared thermometers)—enables manufacturers to obtain temperature readings from a safe distance, helping to prevent unexpected failures or accidents.

- Teledyne FLIR—offers thermal sensors designed for enhancing safety and maintenance in electrical substations.

- C3 AI—utilizes generative AI and natural language processing (NLP) to detect equipment risks. It provides summary insights to help reduce maintenance costs, downtime, and improve operational productivity and asset uptime.

- Ferro Labs—offers contextual machine learning services aimed at optimizing industrial processes by reducing energy usage, costs, waste, and raw material consumption.

- MachineMetrics—allows users to develop, monitor, and manage custom algorithms for predictive analytics. It also integrates with CMMSs (Computerized Maintenance Management Systems) to provide critical machine performance data.

- Hitachi Lumada—a collaborative platform that supports optimization of production and maintenance planning across organizational teams.

- Aurora by Stottler Henke—identifies key scheduling decision points and performs sensitivity analyses to determine the optimal timing and allocation of resources. It helps maintain a stable schedule while incorporating new data inputs.

5. Discussion

- Increased equipment uptime, improved operational efficiency, and better asset utilization;

- Enhanced worker safety through reduced risk of failures and unexpected breakdowns;

- Flexibility of AI models to adapt to various equipment types, enabling tailored maintenance solutions;

- Improved decision-making through human–AI collaboration, where AI provides data-driven insights to support human expertise;

- Integration with advanced robotics and autonomous systems, which further boosts maintenance automation;

- Effective processing and analysis of large industrial data sets, leading to more accurate failure predictions and actionable insights.

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| AI | Multidisciplinary Digital Publishing Institute |

| IR | Infrared |

| GAN | Generative Adversarial Networks |

| RNN | Recurrent Neural Network |

| CNN | Convolutional Neural Networks |

| IoT | Internet of Things |

| CMMS | Computerized Maintenance Management System |

References

- Weck, O.L.; Roos, D.; Magee, C.L. Engineering Systems: Meeting Human Needs in a Complex Technological World. Available online: https://ieeexplore.ieee.org/book/6267533 (accessed on 11 November 2024).

- Tomić, Z. Teorija i Praksa Odnosa s Javnošću; Synopsis: Zagreb, Croatia, 2016; p. 329. [Google Scholar]

- Leksikografski Zavod Miroslav Krleža, Zagreb. Available online: https://www.enciklopedija.hr/clanak/umjetna-inteligencija (accessed on 11 October 2024).

- Russell, S.T.; Norvig, P. Artificial Intelligence: A Modern Approach, 3rd ed.; AIMA; Pearson: London, UK, 2009. [Google Scholar]

- Prister, V. Umjetna inteligencija. Medija Cult. Public Relat. 2019, 10, 67–72. [Google Scholar]

- GeeksForGreeks. Difference Between Machine Learning and Deep Learning. Available online: https://www.geeksforgeeks.org/artificial-intelligence/difference-between-machine-learning-and-deep-learning/ (accessed on 13 October 2024).

- Haykin, S. Neural Networks: A Comprehensive Foundation, 2nd ed.; Prentice Hall PTR: Hoboken, NJ, USA, 1998. [Google Scholar]

- SAS. Machine learning: What It Is Why It Matters. Available online: https://www.sas.com/en_us/insights/analytics/machine-learning.html (accessed on 17 October 2024).

- Bantan, R.A.; Ali, A.; Naeem, S.; Jamal, F.; Elgarhy, M.; Chesneau, C. Discrimination of sunflower seeds using multispectral and texture dataset in combination with region selection and supervised classification methods. Chaos: Interdiscip. J. Nonlinear Sci. 2020, 30, 113142. [Google Scholar] [CrossRef] [PubMed]

- Sutton, R.S.; Barto, A.G. Reinforcement Learning: An Introduction, 2nd ed.; MIT Press: Cambridge, MA, USA, 2019. [Google Scholar]

- Sultana, F.; Sufian, A.; Dutta, P. Advancements in image classification using convolutional neural network. In Proceedings of the 2018 Fourth International Conference on Research in Computational Intelligence and Communication Networks (ICRCICN), Kolkata, India, 22–23 November 2018. [Google Scholar]

- Hochreiter, S.; Bengio, Y.; Frasconi, P.; Schmidhuber, J.; Elvezia, C. Gradient flow in recurrent nets: The difficulty of learning long-term dependencies. In A Field Guide to Dynamical Recurrent Neural Networks; Kolen, J.F., Kremer, S.C., Eds.; IEEE Press: Piscataway, NJ, USA, 2001. [Google Scholar]

- Jordan, M.I. On Discriminative vs. Generative Classifiers: A Comparison of Logistic Regression and Naïve Bayes; NIPS MIT Press: Cambridge, MA, USA, 2002. [Google Scholar]

- Rodrigues, T. Planned, Reactive, Predictive: What’s the Right Maintenance Mix? 2023. Available online: https://www.industryweek.com/operations/maintenance/article/21271953/planned-reactive-predictive-whats-the-right-maintenance-mix (accessed on 22 November 2024).

- Goncavles, T. Available online: https://fiixsoftware.com/blog/evaluating-maintenance-strategies-select-model-asset-management/ (accessed on 15 December 2024).

- ISO 13374-4:2010; Praćenje Stanja i Dijagnostika Strojnih Sustava Obrada Podataka, Komunikacija i Prezentacija. ISO: Geneva, Switzerland, 2010. Available online: https://repozitorij.hzn.hr/norm/HRN+ISO+13374-1%3A2010 (accessed on 15 December 2024).

- Adamović, Ž.; Manojlović, N.; Marinković, S. Ciljevi, struktura i troškovi funkcije održavanja strojeva u industriji Srbije i u svijetu. In Proceedings of the 38 Međunarodna Konferencija Održavatelja Srbije i 1 Konferencija Napredne Tehnologije u Funkciji Razvoja Privrede, Vrnjačka Banja, Srbija, 1–3 June 2022. [Google Scholar]

- Poslovna Strategija—Što je To, Definicija i Koncept. Available online: https://hr.economy-pedia.com/11039450-business-strategy (accessed on 21 November 2024).

- Misija i Vizija Poduzeća—Zašto su Važne i Primjer iz Prakse. Available online: https://mentorica.biz/aktualno/vizija-i-misija-64/ (accessed on 28 November 2024).

- Ali, A.; Abdelhadi, A. Condition-Based Monitoring and Maintenance: State of the Art and Applications. Appl. Sci. 2022, 12, 688. [Google Scholar] [CrossRef]

- Ucar, A.; Karakose, M.; Kırımça, N. Artificial Intelligence for Predictive Maintenance Applications. Appl. Sci. 2024, 14, 898. [Google Scholar] [CrossRef]

- Aziro Marketing. Available online: https://www.aziro.com/blog/top-predictive-analytics-tools-in-2024/ (accessed on 29 November 2024).

- 23. AI for Predictive Maintenance in Industrial Systems. Available online: https://www.researchgate.net/publication/375722960_AI_for_Predictive_Maintenance_in_Industrial_Systems (accessed on 2 December 2024).

- Serradilla, O.; Zugasti, E.; Ramirez de Okariz, J.; Rodriguez, J.; Zurutuza, U. Methodology for data-driven predictive maintenance models design, development and implementation on manufacturing guided by domain knowledge. Int. J. Comput. Integr. Manuf. 2022, 35, 1310–1334. [Google Scholar] [CrossRef]

| KPI/Topic | Traditional Maintenance | AI-Supported Strategies (CBM/PdM/PsM) |

|---|---|---|

| Unplanned Downtime | More frequent in reactive; preventive reduces but does not eliminate. | Significantly reduced, since interventions are timed before failure [20,21]. |

| MTBF/Reliability | Often lower MTBF due to cascading failures. | Higher MTBF through timely interventions and better condition monitoring [20]. |

| Maintenance Cost | Variable and often high (emergency repairs, overtime, larger inventories). | Lower in the long run: targeted tasks, fewer emergencies, optimized spare parts, and workforce [21]. |

| Workforce Skills | Focus on mechanical skills and procedures. | Additionally: data engineering, analytics, model interpretation (MLOps), domain expertise [21]. |

| Risks | Risk of “out-of-the-blue” failures and domino effects. | Risks of data quality, false alarms, model generalization, integration with ERP/CMMS [21]. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2026 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Lackovic, Z.; Stavlic, K.; Dokic, K. Application of Artificial Intelligence in Maintenance as an Important Factor of Corporate Business Strategy. Eng. Proc. 2026, 125, 12. https://doi.org/10.3390/engproc2026125012

Lackovic Z, Stavlic K, Dokic K. Application of Artificial Intelligence in Maintenance as an Important Factor of Corporate Business Strategy. Engineering Proceedings. 2026; 125(1):12. https://doi.org/10.3390/engproc2026125012

Chicago/Turabian StyleLackovic, Zlatko, Katarina Stavlic, and Kristian Dokic. 2026. "Application of Artificial Intelligence in Maintenance as an Important Factor of Corporate Business Strategy" Engineering Proceedings 125, no. 1: 12. https://doi.org/10.3390/engproc2026125012

APA StyleLackovic, Z., Stavlic, K., & Dokic, K. (2026). Application of Artificial Intelligence in Maintenance as an Important Factor of Corporate Business Strategy. Engineering Proceedings, 125(1), 12. https://doi.org/10.3390/engproc2026125012