Characterization and Performance Analysis of Non-Metallic Oxide Nano-Fluids in Compound Parabolic Trough Solar Collectors †

Abstract

:1. Introduction

2. Materials and Methods

2.1. Selection of Nanoparticles

2.2. Preparation of Nanofluids

2.3. Experimental Setup and Measurement Procedure

3. Results and Discussion

3.1. UV-Vis Spectroscopy

3.2. Thermal Conductivity Measurement (W/m·K)

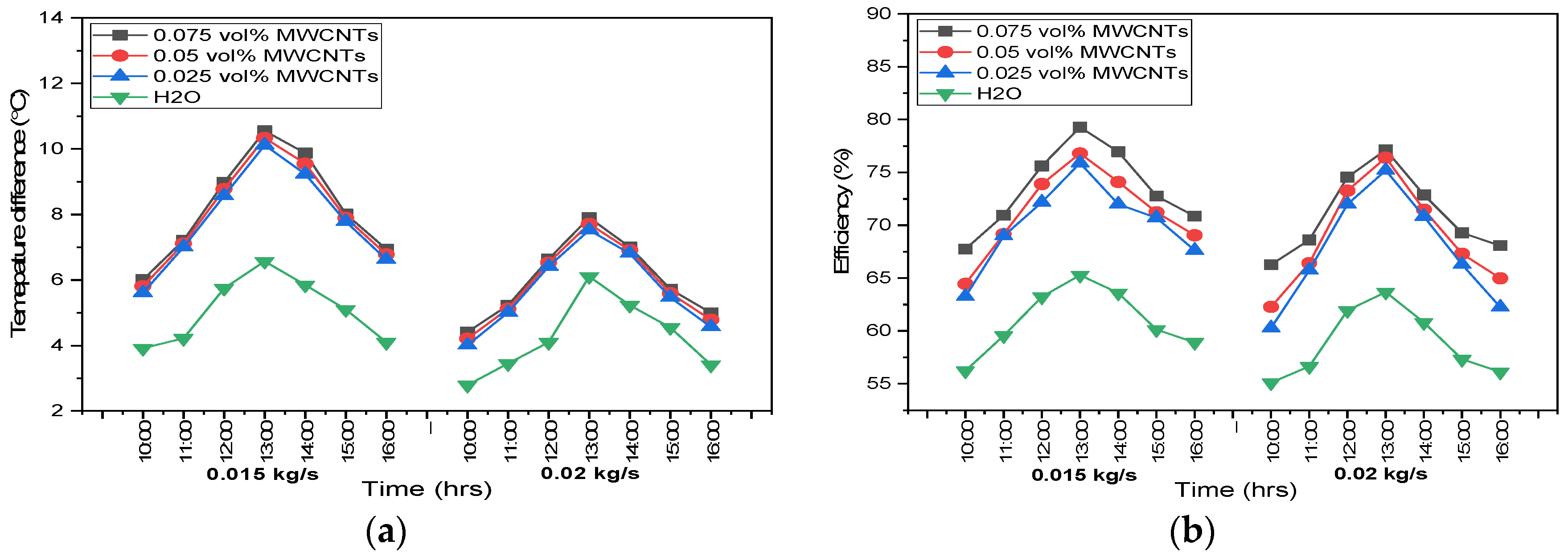

3.3. Variation in Temperature Difference and Thermal Efficiency

4. Conclusions

Acknowledgments

References

- Said, Z.; Saidur, R.; Sabiha, M.A.; Rahim, N.A.; Anisur, M.R. Thermophysical properties of Single Wall Carbon Nanotubes and its effect on exergy efficiency of a flat plate solar collector. Sol. Energy 2015, 115, 757–769. [Google Scholar] [CrossRef]

- Eltaweel, M.; Abdel-Rehim, A.A. Energy and exergy analysis of a thermosiphon and forced-circulation flat-plate solar collector using MWCNT/Water nanofluid. Case Stud. Therm. Eng. 2019, 14, 100416. [Google Scholar] [CrossRef]

- Eltaweel, M.; Abdel-Rehim, A.A.; Attia, A.A.A. Energetic and exergetic analysis of a heat pipe evacuated tube solar collector using MWCNT/water nanofluid. Case Stud. Therm. Eng. 2020, 22, 100743. [Google Scholar] [CrossRef]

- Kumar, L.H.; Kazi, S.N.; Masjuki, H.H.; Zubir, M.N.M.; Jahan, A.; Bhinitha, C. Energy, exergy and economic analysis of liquid flat-plate solar collector using green covalent functionalized graphene nanoplatelets. Appl. Therm. Eng. 2021, 192, 116916. [Google Scholar] [CrossRef]

- Sabiha, M.A.; Saidur, R.; Hassani, S.; Said, Z.; Mekhilef, S. Energy performance of an evacuated tube solar collector using single walled carbon nanotubes nanofluids. Energy Convers. Manag. 2015, 105, 1377–1388. [Google Scholar] [CrossRef]

- Verma, S.K.; Tiwari, A.K.; Chauhan, D.S. Experimental evaluation of flat plate solar collector using nanofluids. Energy Convers. Manag. 2017, 134, 103–115. [Google Scholar] [CrossRef]

- Singh, T.; Almanassra, I.W.; Olabi, A.G.; Al-Ansari, T.; McKay, G.; Atieh, M.A. Performance investigation of multiwall carbon nanotubes based water/oil nanofluids for high pressure and high temperature solar thermal technologies for sustainable energy systems. Energy Convers. Manag. 2020, 225, 113453. [Google Scholar] [CrossRef]

- Mwesigye, A.; Yılmaz, İ.H.; Meyer, J.P. Numerical analysis of the thermal and thermodynamic performance of a parabolic trough solar collector using SWCNTs-Therminol® VP-1 nanofluid. Renew. Energy 2018, 119, 844–862. [Google Scholar] [CrossRef] [Green Version]

- Mahbubul, I.M.; Khan, M.M.A.; Ibrahim, N.I.; Ali, H.M.; Al-Sulaiman, F.A.; Saidur, R. Carbon nanotube nanofluid in enhancing the efficiency of evacuated tube solar collector. Renew. Energy 2018, 121, 36–44. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kaleem, M.; Ali, M.; Riaz, H.; Akhter, J. Characterization and Performance Analysis of Non-Metallic Oxide Nano-Fluids in Compound Parabolic Trough Solar Collectors. Eng. Proc. 2021, 12, 88. https://doi.org/10.3390/engproc2021012088

Kaleem M, Ali M, Riaz H, Akhter J. Characterization and Performance Analysis of Non-Metallic Oxide Nano-Fluids in Compound Parabolic Trough Solar Collectors. Engineering Proceedings. 2021; 12(1):88. https://doi.org/10.3390/engproc2021012088

Chicago/Turabian StyleKaleem, Muhammad, Muzaffar Ali, Hamza Riaz, and Javed Akhter. 2021. "Characterization and Performance Analysis of Non-Metallic Oxide Nano-Fluids in Compound Parabolic Trough Solar Collectors" Engineering Proceedings 12, no. 1: 88. https://doi.org/10.3390/engproc2021012088

APA StyleKaleem, M., Ali, M., Riaz, H., & Akhter, J. (2021). Characterization and Performance Analysis of Non-Metallic Oxide Nano-Fluids in Compound Parabolic Trough Solar Collectors. Engineering Proceedings, 12(1), 88. https://doi.org/10.3390/engproc2021012088