1. Introduction

Hydrogen is known as future fuel in perspective of human fuel evolution. For the socio-economic development of modern civilization, sufficient energy resources and proper exertion are very valuable factors. We are living in the age of fossil fuels as a fundamental energy resource, but it is finishing off. Consequently, finding surrogate energy resources are one of the most crucial provocations for the present world [

1,

2]. To sort out this problem, hydrogen has a potential as alternative energy resource and comprised as an important fuel of the future for automotive sector instead of fossil fuels [

3,

4]. Nevertheless, hydrogen-based energy cycles are subsisted with several challenges, such as hydrogen production, purification and storage [

5,

6]. The main stumbling block is of the hydrogen storage. To resolve the energy crisis for future, effective hydrogen storage method is still a main obstacle. Therefore, over the past decade tremendous efforts of hydrogen adsorption have been precariously focused on the materials research [

7,

8,

9].

For hydrogen adsorption metal organic frameworks (MOFs); so called inorganic organic hybrid is an auspicious candidate. Metal organic framework (MOFs) or porous coordination networks are advanced materials which are designed by engaging metal ions and organic linkers [

10,

11]. They are crystalline, extremely porous having large surface area with low density. Such hybrid structure comprises with suitable rigid or flexible tripod ligands expected to create large pore volume and surface area to nurture the capturing of hydrogen. Therefore, a great variety of new porous can be designed and synthesized by MOFs. These materials show excellent features for hydrogen storage and as a catalyst. Frameworks with various pore shape, size, volume and chemistry can be synthesized, depending on the metal cluster and organic linker used, and thus, encourages the specific needs of the adsorption process contemplated [

10].

These days lot of work is being performed on the hydrogen uptake capacities of MOFs. Furukawa and coworkers revealed that MOF-210 has the record BET surface area of 6240 m

2 g

−1. MOF-210 showed 8.6 wt% of hydrogen uptake and estimated total hydrogen uptake of 0.176 kg kg

−1 [

11]. Mostly, if the crystal density is low, the surface area is high. Most of the times due to low density of MOFs low volumetric hydrogen uptake capacities are obtained. So, a compromise is necessary between surface area and crystal density for porous MOFs with high hydrogen uptake capabilities.

In this study, different composites of metal organic framework and graphite oxide are synthesized with different ratios. The composites as well as the parental elements are studied for the hydrogen uptake capacities.

2. Experimental

GO was prepared by Hummer’s modified method. Firstly, 2 g of graphite powder was oxidized in 46 mL of cold concentrated H2SO4 at 0 °C. After that, 6 g of KMO4 was added slowly and temperature was kept less than 20 °C. After this, 40 mL of H2O2 was added to end the oxidation process. The composite was prepared by mixing GO powder to well dissolved MOF precursor. After that the resulting mixture was stirred and sonicated for 30 min. The added GO contains 10, 20 and 30 weight% of the final product.

3. Methods

Crystal structure and phase analysis of the lab prepared samples were characterized by XRD over a range of 5 to 50°. The shapes and morphologies of these materials were verified by analytical scanning electron microscope (JEOL—Tokyo, Japan), model JSM-6490A. The surface area of lab prepared samples was measured at 77 K on a Micromeritics apparatus under vacuum for 3 h at 200 K temperature. Adsorption experiments were performed to investigate the uptake capacity of hydrogen.

3.1. X-ray Diffraction Analysis (XRD)

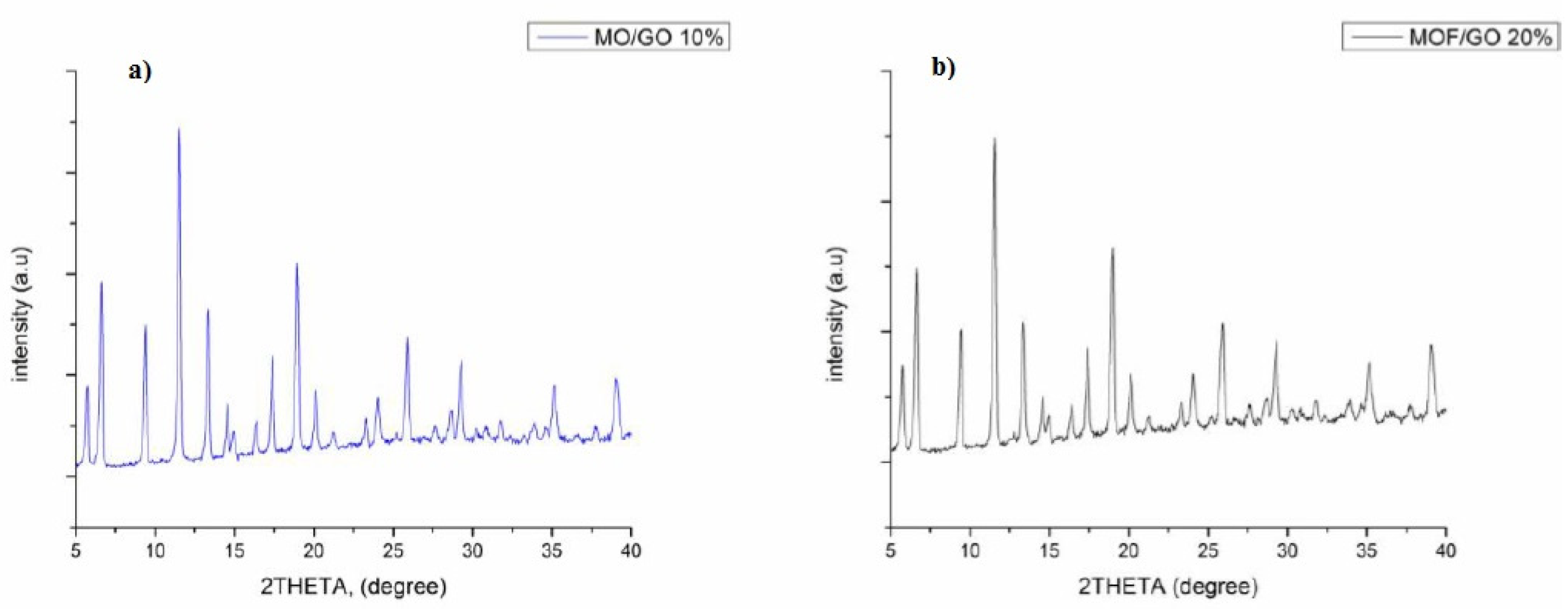

The X-ray diffraction patterns of the prepared composites are elaborated in

Figure 1. The MOF/GO composite exhibited well-defined MOF present in the prepared composites. Hence, it can be presumed that GO did not obstruct the formation of linkage among Cu dimers and organic linkers. Another interesting fact is that the broad GO peak did not appeared in the composites pattern. The reason can be dispersion of GO during the synthesis of MOF/GO composites.

3.2. Scanning Electron Microscopy Analysis

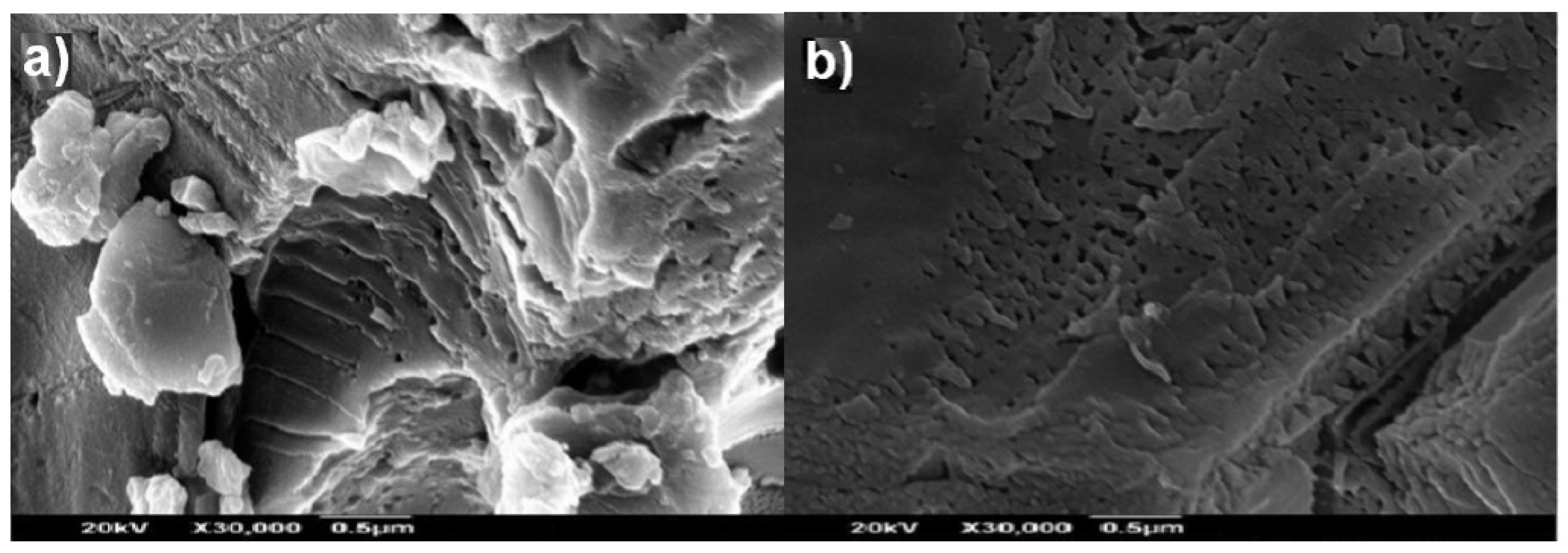

The SEM image of prepared samples are shown in

Figure 2. The composite with 10% of GO/MOF showed the presence of graphene layers with submerged MOF. In case of 20% of GO/MOF composite, more graphene layers are observed showing a legible lattice image within GO layers. It is a known fact that electron beams can be a reason of the collapse of HKUST-1, and, hence, it prevents any visualization of its lattice structure. GO deformed graphene layers in MOF/GO composite assisted MOF in retaining its crystallinity by dissipation of electrostatic charges.

3.3. Brunauer–Emmett–Teller (BET) Surface Area Analysis

BET surface area of the MOF as well as the composites are given in

Table 1. The results suggest that surface area of MOF/GO composites with lowest GO contents is higher than the parental MOF, however as the GO content increases the surface area decreases. This is due to the increasing amount of GO which causes deformation in the structures of the material.

3.4. Hydrogen Storage Experiments

Adsorption experiments are performed to investigate the uptake capacity of hydrogen. An accurately weighed quantity of sample (5–6 ± 0.02 mg) was packed in a pre-weighed quartz tube used as sample holding device. The hydrogen gas was passed continuously for 20 min at the flow rate of 5 mL/min. After that the samples tube was reweighed precisely and quantity of hydrogen gas adsorbed was calculated by difference in weight method. The results of prepared samples are shown in

Table 2. These results depict that the hydrogen uptake first increases when the amount of GO content increases up to 20%, and then decreases. This is because of the increase in GO content that causes disturbance in the structures of the material. Another elucidation is that as the GO amount increases in the sample, number of functional groups on GO transcends the number of available sites on MOF which react with each other. At this point some amount of the GO behaves like as if there was no other compound present in composites except solvents. Therefore, when the sample was dried the GO layers reassembled together in irregular way resulting agglomeration which decreases the porosity as well as the surface area.

4. Conclusions

MOF/GO composites were synthesized with different ratios. New composites as well as the parental elements were characterized by SEM, XRD, FTIR, TGA and BET. The properties of MOF-199 in MOF/GO composites were assertive while the porosity was higher as compared to the parent elements. It is considered that the interaction of MOF-199 with functional groups of GO (epoxy, hydroxylic, carboxylic and sulfonic groups) assists the formation of new pores. The increase in the porosity was observed up to 20% of GO. As the higher contents of GO were present after 20%, functional groups on the deformed graphene layer surpassed the number of available sites on MOF which reacted with each other. Hence, GO deformed graphene layers formed agglomerates which deceased the porosity. The enhanced porosity of the composites was responsible for better uptake of hydrogen as compared to the parental elements.

Author Contributions

Conceptualization, A.M. and A.A. (Ali Ahmad); methodology, A.M.; software, A.S.; validation, A.M., A.A. (Ali Ahmad) and M.T.S.; formal analysis, A.M.; investigation, A.M.; resources, G.A.; data curation, A.S.; writing—original draft preparation, A.M.; writing—review and editing, A.A. (Ali Ahmad); visualization, A.A. (Asad Ali); supervision, A.A. (Ali Ahmad); project administration, A.A. (Ali Ahmad); funding acquisition, G.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Moriarty, P. Hydrogen’s role in an uncertain energy future. Int. J. Hydrogen Energy 2009, 34, 31–39. [Google Scholar] [CrossRef]

- Jain, I.P. Hydrogen the fuel for 21st century. Int. J. Hydrogen Energy 2009, 34, 7368–7378. [Google Scholar] [CrossRef]

- Corbo, P.; Migliardini, F.; Veneri, O. Dynamic behaviour of hydrogen fuel cells for automotive application. Renew. Energy 2009, 34, 1955–1961. [Google Scholar] [CrossRef]

- Ho, T.; Karri, V. Hydrogen powered car: Two-stage modelling system. Int. J. Hydrogen Energy 2011, 36, 10065–10079. [Google Scholar] [CrossRef]

- Felderhoff, M.; Weidenthaler, C.; von Helmolt, R.; Eberle, U. Hydrogen storage: The remaining scientific and technological challenges. Phys. Chem. Chem. Phys. 2007, 9, 2643. [Google Scholar] [CrossRef] [PubMed]

- Mori, D.; Hirose, K. Recent challenges of hydrogen storage technologies for fuel cell vehicles. Int. J. Hydrogen Energy 2009, 34, 4569–4574. [Google Scholar] [CrossRef]

- Saha, D.; Deng, S. Hydrogen Adsorption on Ordered Mesoporous Carbons Doped with Pd, Pt, Ni, and Ru. Langmuir 2009, 25, 12550–12560. [Google Scholar] [CrossRef] [PubMed]

- Gao, X.; Liu, J.; Ye, S.; Song, D.; Zhang, Y. Hydrogen adsorption of metal nickel and hydrogen storage alloy electrodes. J. Alloys Compd. 1997, 253–254, 515–519. [Google Scholar] [CrossRef]

- Saha, D.; Deng, S. Synthesis, characterization and hydrogen adsorption in mixed crystals of MOF-5 and MOF-177. Int. J. Hydrogen Energy 2009, 34, 2670–2678. [Google Scholar] [CrossRef]

- Rowsell, J.L.; Millward, A.R.; Park, K.S.; Yaghi, O.M. Hydrogen Sorption in Functionalized Metal—Organic Frameworks. J. Am. Chem. Soc. 2004, 126, 5666–5667. [Google Scholar] [CrossRef] [PubMed]

- Sun, D.; Ma, S.; Ke, Y.; Collins, D.J.; Zhou, H.-C. An Interweaving MOF with High Hydrogen Uptake. J. Am. Chem. Soc. 2006, 128, 3896–3897. [Google Scholar] [CrossRef] [PubMed]

| Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).