1. Introduction

In recent years, the accelerated advancement of technologies such as the Industrial Internet of Things (IIoT) and the Industry 5.0 paradigm has driven a profound transformation in the industrial sector. This evolution, motivated by both technological developments and the growing demands for efficiency, sustainability and resiliency, has generated the need for implementing control systems capable of responding to constantly changing and expanding industrial environments. Industry 5.0, in particular, represents a model focused on collaboration between humans and intelligent machines, promoting more automated, resilient and human-oriented factories through the use of advanced technologies such as robotics, Internet of Things (IoT), Artificial Intelligence (AI) and Cognitive Cyber-Physical Systems (CCPS).

This approach is also being adopted in the shipbuilding sector, a manufacturing industry intensive in labor, capital and technology, where the automation of complex processes can significantly improve operational efficiency and overall performance [

1]. However, this sector faces persistent challenges, such as space management, resource utilization and the need for promoting sustainable shipbuilding [

2].

Navantia, one of the ten largest shipbuilding companies worldwide, with a trajectory that dates back to 1717, is currently immersed in a process of integral transformation towards a Shipyard 5.0 model. This transition implies facing three key challenges: the vertical integration of production systems, horizontal integration through new generation value creation networks and the complete reengineering of the production chain, affecting the entire life cycle of each ship component.

In this context, the trend towards the construction of larger vessels increases the need to effectively manage a growing volume of smart elements [

3]. To meet sustainability and efficiency objectives, it is essential to guarantee their traceability, localization and continuous monitoring. These tasks can be addressed through the use of CCPSs, which must respond to fundamental challenges such as scalability, maintainability and predictability.

In this article, a set of guidelines for the design of usable interfaces for CCPSs in the context of shipbuilding is proposed. These guidelines are based on consolidated usability principles and have been formalized from their practical application in a real industrial environment. The objective is to improve operational efficiency and reduce the cognitive load of operators, facilitating the precise and effective supervision of industrial processes.

Certain technical details concerning the design and implementation of the CCPS have been intentionally omitted from this work to preserve the potential for future intellectual property protection, as some components may be eligible for patenting. Additionally, this omission ensures compliance with confidentiality agreements and internal policies established by Navantia.

The rest of the article is organized as follows.

Section 2 presents the state of the art on the design of usable interfaces in the context of Industry 5.0.

Section 3 describes the context of manufacturing production and the different plant layouts. In

Section 4, the proposed set of design guidelines is formalized.

Section 5 presents a case study where an interface based on these guidelines is developed and evaluated. Moreover, it details the preliminary results obtained from the evaluation of the proposed system. Finally,

Section 6 discusses the lessons learned and presents the main conclusions of the paper.

2. State of the Art: Designing Usable Interfaces for Industry 5.0 Applications

The sustained advancement in areas such as electronics, communication networks and robotics, as well as the consolidation of technological paradigms like IoT, has led to a profound transformation in contemporary industrial systems. These developments have enabled the design and implementation of intelligent and autonomous systems capable of optimizing operational efficiency, reducing costs and improving productivity in multiple sectors. Thanks to the integration of sensors, real-time connectivity and distributed processing, industries can now automate complex processes and make data-driven decisions, oriented towards specific objectives such as improving energy efficiency [

4].

However, the adoption of the previously mentioned technologies also poses new challenges, particularly regarding interface design and system usability. The increasing quantity and variety of data that must be visualized on control panels has generated a significant increase in informational complexity, which demands design solutions that guarantee effective understanding and action by operators. In this regard, interface designers face the challenge of representing large scale data clearly, intuitively and operationally useful. For instance, recent works have explored how persuasive and dark patterns can affect user interaction in IIoT and Cyber-Physical Systems, highlighting the impact on user experience and navigation efficiency [

5]. Moreover, the development of emotion-aware Metaverse applications for training, such as shipboard fire drill simulators, emphasizes the need for human-centric design that considers emotional responses and cognitive load in immersive environments [

6].

To mitigate the complexity of visualization systems, it is fundamental to understand not only the type of information presented (e.g., textual, numerical, graphical) but also its volume, how the operator interacts with it and the navigation paths that facilitate its access. Various studies have highlighted the direct relationship between interface design and the operator’s cognitive load. For example, it has been shown that panels with analog displays generate a lower cognitive load than their digital equivalents, by offering a faster and more direct reading of key parameters [

7].

The high cognitive load observed in supervision and control tasks is closely linked to the inherent limitations of human working memory for managing large volumes of complex information. To address this, methodologies like the NASA-Task Load Index (NASA-TLX) have been developed to quantify mental workload across various dimensions, including mental, physical and temporal demands, performance, effort and frustration [

8]. Given the challenges in managing complex data, strategic grouping of data and the incorporation of self-explanatory diagrams, instead of raw data, have proven to be effective strategies for reducing the user’s mental load. Research indicates that busy displays, when highlighting priority readings and indicating relative importance, can decrease overall task load, particularly perceived mental and temporal demand [

9]. This approach contrasts with simply reducing the number of alarms, emphasizing the importance of providing necessary information in an easily digestible format.

In [

10,

11] multiple usability problems associated with information overload are identified when concentrating large volumes of data on a single interface. This situation can limit the operator’s ability to interpret and manage information efficiently. Both studies emphasize the need for a usability-centered design as a fundamental element for operators to detect and adequately respond to system anomalies before they lead to critical failures or emergency situations.

As demonstrated in [

12], improving usability not only increases operational effectiveness, but also positively impacts the overall economic performance of the plant. The author estimates that an optimized interface design can generate annual savings of up to CAD 1,090,000, by facilitating early fault detection, increasing response capability and reducing the incidence of human errors.

Collectively, the analyzed literature reveals that, while the incorporation of intelligent technologies offers enormous benefits to industry, their potential can only be fully leveraged if accompanied by interface solutions that prioritize clarity, accessibility and the user’s ability to interpret and act upon information. These elements are especially critical in complex industrial contexts, such as a shipyard, where processes are highly interdependent and the margin of error must be minimized as much as possible. A comparative summary of the analyzed literature and the identified knowledge gaps is provided in

Table 1.

3. Classification of Manufacturing Plant Layouts

In the industrial field, the organization of production facilities responds to multiple factors, such as the nature of the product, the production volume and the repeatability of processing cycles. The central objective of any layout scheme is to maximize operational efficiency, while guaranteeing a safe working environment for the operator. Over time, four fundamental models of plant layout have been consolidated: fixed position, process, cellular and product [

13].

The fixed position layout is characterized by products that remain static at a specific location, while the necessary resources, including personnel, machinery, tools and materials, are moved to its immediate vicinity. This type of configuration is adopted when the product is bulky, highly complex and difficult to move, as is the case in shipbuilding. The mobility of resources around the product facilitates its manufacturing, although it implies more demanding logistical planning.

In the process layout, work areas are organized according to the functional affinity of the machines. For example, in a shipyard, welding machines are usually grouped in an area dedicated to structural fabrication, while another area will house machinery for cutting and shaping steel plates. In this model, parts follow variable processing routes depending on the sequence of operations required, which allows for flexibility but can generate certain complexity to manage workflows.

The cellular layout emerges as an intermediate alternative when the parts to be manufactured, although distinct, present functional or geometric similarities that allow them to be grouped into homogeneous families. In these cases, machines are configured so they can process these families without significant changes in setup, which improves efficiency and reduces downtime. Compared to the process model, the cellular layout improves efficiency and simplifies management, though with less flexibility to product variations.

On the other hand, the product layout organizes workstations in a linear sequence that follows the production flow. Each station executes a specific operation on a part, which is moved station by station, generally via automated conveyor belts. This configuration is adopted in contexts of high series production, where process standardization allows for maximizing efficiency and minimizing cycle times.

While these four typologies represent the most widely used models in the industry, in practice they are often combined and adapted to the particular characteristics of each manufacturing process. Thus, they can coexist within the same plant or be reconfigured to respond to specific performance and productivity objectives.

Each type of layout also poses particular needs regarding data presentation and the supervision of the state of production processes. For example, in the case of shipbuilding, the manufacturing of a vessel is composed of multiple stages in which different components are first assembled into blocks and subsequently, these blocks are integrated into the final structure of the vessel. In companies like Navantia this production process unfolds in three main scenarios: the component manufacturing workshop, block outfitting and the vessel itself, where the final assembly is executed. The diversity and sequentiality of these environments require highly adaptable control and visualization systems, capable of responding to the operational complexity inherent in each phase of the process.

4. Guidelines for Usable Interfaces for Industry 5.0 CCPSs

In IIoT environments, proper interface design is crucial. It not only allows operators to effectively identify and intervene in anomalies before they escalate into emergency situations but also optimizes overall system supervision from both the operator’s and supervisor’s perspectives. Within the framework of Industry 5.0, where the integration of smart technologies and human-machine interaction are fundamental, usable interfaces are an essential requirement.

Interfaces must be capable of representing data, processes and, in particular, Key Performance Indicators (KPIs) in a clear and accessible manner that is tailored to the specific operational context. The effective visualization and contextualization of KPIs are essential for enabling comprehensive monitoring of production status, as they provide a quantifiable basis for evaluating system performance and identifying deviations from expected outcomes. Furthermore, well-designed interfaces that prioritize the accurate and timely display of KPIs significantly enhance the ability to detect anomalies at an early stage, thereby supporting proactive maintenance strategies and promoting evidence-based decision-making at all organizational levels.

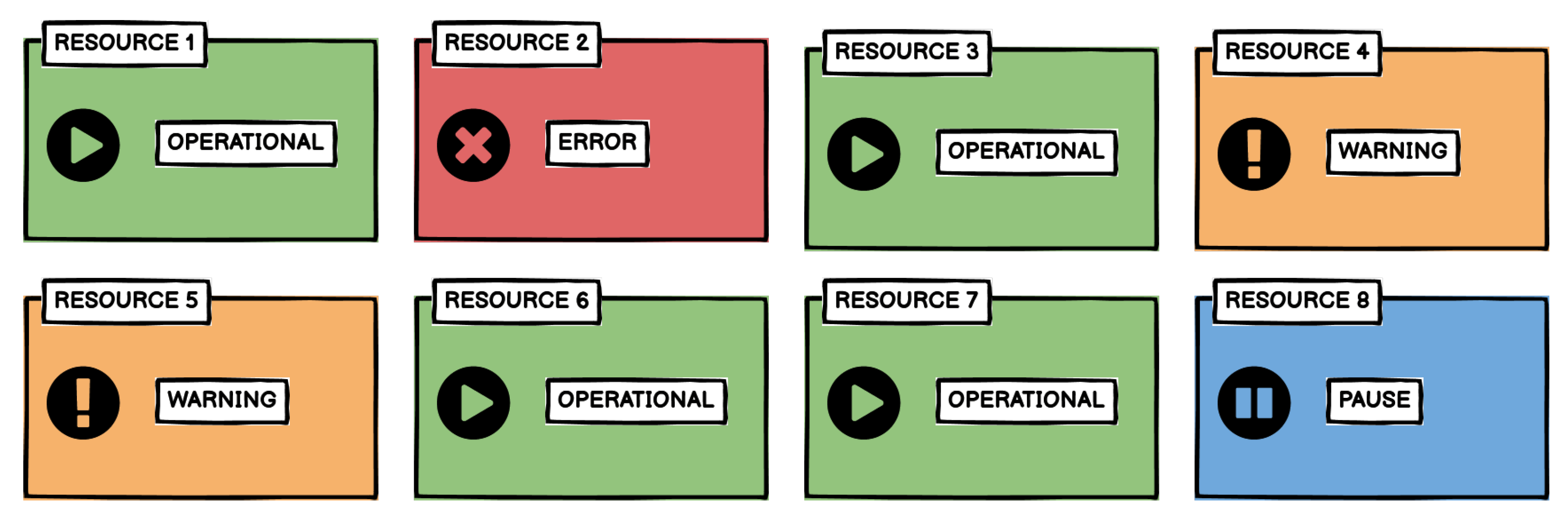

From the analysis of solutions currently applied in the industry, four design guidelines oriented to common visual management activities have been identified and formalized: resource status visualization (

Table 2 and

Figure 1), KPI representation (

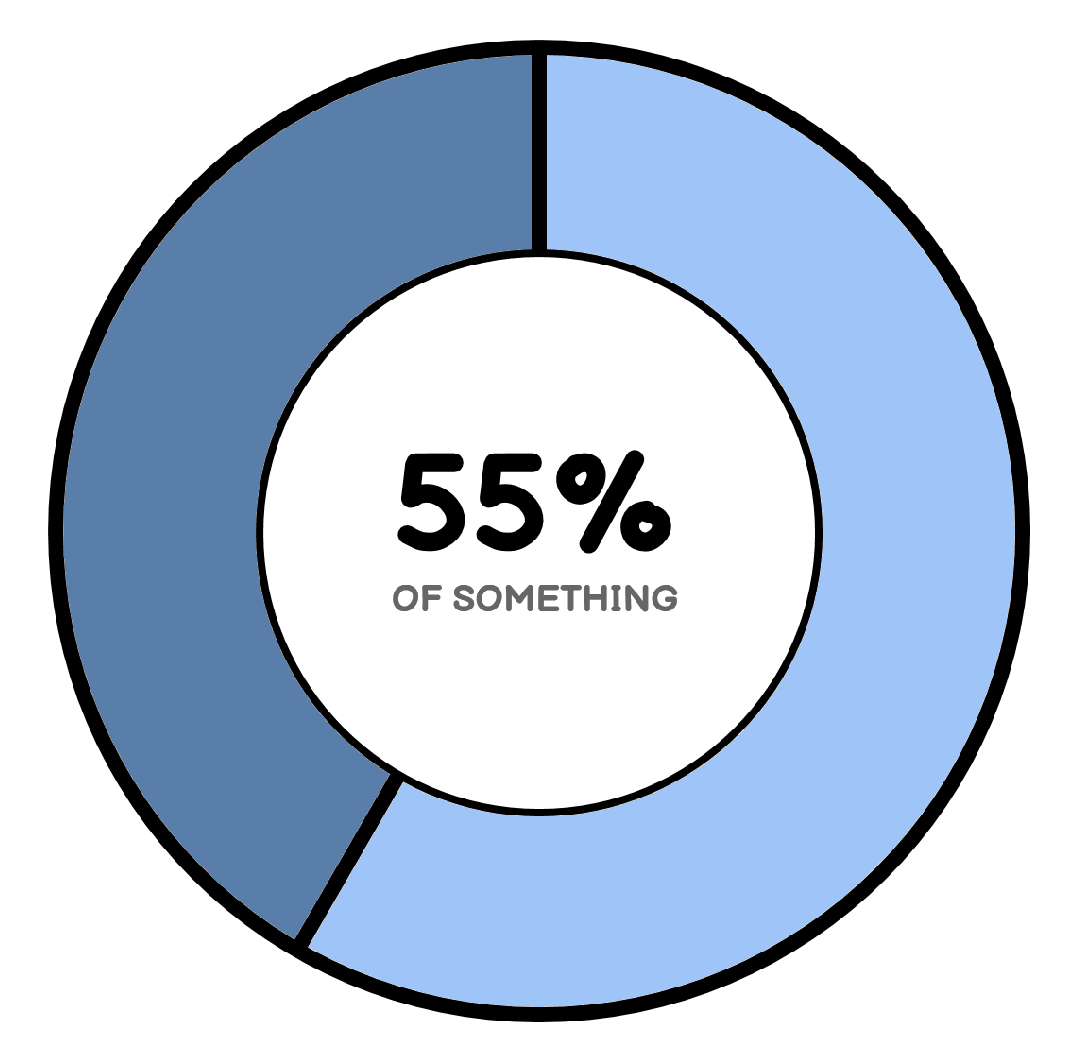

Table 3 and

Figure 2), temporal representation of states (

Table 4 and

Figure 3) and temporal evolution of KPIs (

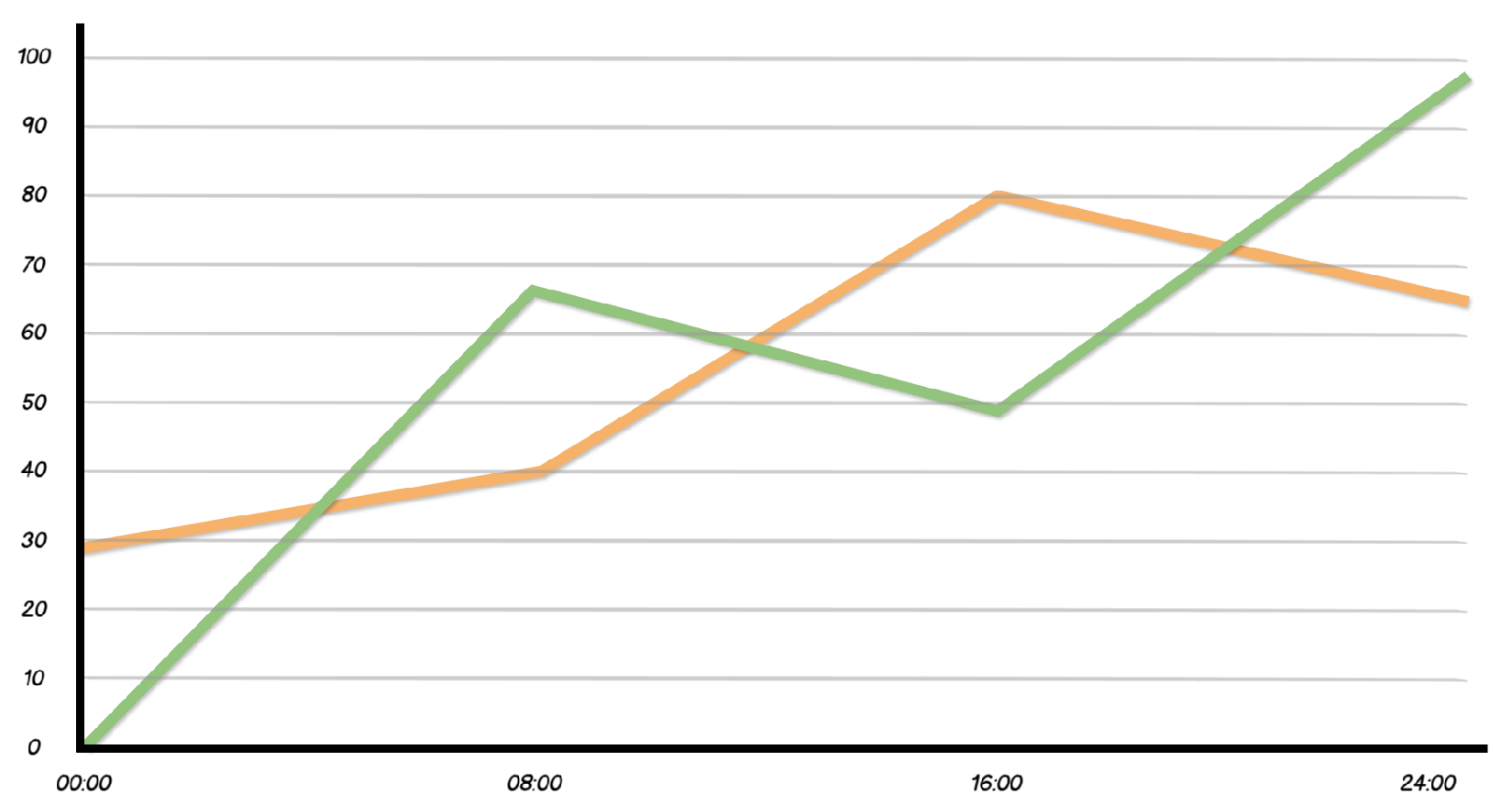

Table 5 and

Figure 4). Each guideline is described following a standardized structure that includes: title, problem (description of the usability problem to be addressed), context (operational situation where the guideline is applicable), solution (design recommendation that solves the stated problem) and example (visual representation of the proposed design).

5. Case Study

In large-scale industrial environments such as shipyards, traditional operational procedures often rely on paper-based documentation for work order execution, including details about component transportation and the smart vehicles involved. In addition, large dimensions of such environments and the high mobility of the smart elements make precise localization and traceability complex and inefficient. This need intensifies with the current trend in the naval industry towards the construction of larger vessels, which significantly increases the volume of resources and the complexity of managing numerous smart IIoT devices [

3]. Enhancing the identification, traceability and precise localization of smart elements is therefore crucial for boosting productivity and safety in resource transportation.

To address these challenges, we propose a CCPS specifically designed for the shipyard operational space, aligning with essential functional guidelines. As depicted in

Figure 5, the system integrates physical components (e.g., smart elements, sensors) with computational and networking capabilities to enable real-time data collection, analysis and intelligent decision-making, optimizing shipyard operations. The primary objective is to facilitate the identification and localization of smart elements, such as the trailers and trucks shown in

Figure 6, which transport critical ship components like pipes or steel plates between workshops, dry docks or slipways.

The CCPS provides precise, real-time location information for each smart element within the shipyard. This is achieved through an interactive map that covers both outdoor and indoor areas, like workshops, and visualizes the route each smart element takes when executing a work order, as it can be seen in

Figure 7a. Icons on the map represent the type of smart element, while colors indicate its operational status, enabling quick visual interpretation, as shown in

Figure 7b. Smart elements can be in one of four defined states, as detailed in

Table 6. This interactive map directly applies the resource status visualization guideline, effectively displaying the status of numerous smart elements without saturating the interface, and using clusters to manage the visualization of a high number of dispersed elements.

The implementation of this CCPS eliminates dependence on traditional paper-based documentation, offering a more efficient alternative through dynamic real-time data. It seamlessly integrates with the IIoT ecosystem, providing relevant notifications, such as automatic alerts when a smart element enters or leaves a workshop. Furthermore, the system supports quality control after each logistical process, using sensor data from deployed smart IIoT devices to verify correct work order execution. This functionality allows for the early identification of anomalies or operational deficiencies, such as resource shortages or inefficient utilization of smart elements.

Monitoring is carried out through a series of KPIs, calculated from collected sensor data. These indicators assess both the status and operational efficiency of smart elements and are visualized directly within the system interface. Among the available KPIs are:

Time per installation, which you can see in

Figure 8a.

Distance traveled, as illustrated in

Figure 8b.

Number of displacements, including both total and partial movements, detailed in

Figure 8c.

The presentation of these KPIs adheres to the KPI representation guideline, employing specific visualizations to present consolidated information hierarchically with clear color schemes.

The CCPS performs the calculation and visualization of KPIs at five-day intervals, coinciding with the work week. This temporal representation allows for the timely identification of trends and detection of anomalies. Thanks to this information, operators can analyze the performance of smart elements and make informed decisions to optimize operations. For example, if the execution time of a work order is longer than estimated, its causes can be investigated and corrective measures applied. The system’s ability to display the evolution of states, such as the progress and status of different displacements, including their times, states and durations, aligns with the temporal representation of states guideline.

Likewise, the system helps identify usage patterns of smart elements, which is vital for reducing operational costs. Detecting excessive travel or a high number of partial displacements allows for efficient resource redistribution. The analysis of smart element idle time also provides insights into under utilization or poor management. The visualization of the evolution of key KPIs, such as distance traveled and the number of displacements, over the five-day work week directly applies the temporal representation of KPIs guideline, enabling comprehensive trend observation and period comparisons.

For instance, between 2 June and 6 June 2025, an analysis of the movements at the shipyard was conducted to evaluate the operational efficiency of the smart elements managed by the internal logistics department of Navantia’s shipyard in Ferrol. The dataset, composed of 24 transport events, provided a representative snapshot of routine operations under real working conditions. The KPIs derived from this period are presented in

Figure 8, which summarizes the temporal evolution of the measured key logistics metrics. To assess the efficiency of the transport system, the average time per displacement was calculated using data from 24 transport events, totaling 103 min. This resulted in an average of approximately 5 min per trip. According to Navantia’s internal benchmarks, the maximum acceptable duration for any single trip is 13 min. Trips exceeding this limit are considered delays and negatively affect logistical performance. In this case, the average time is well below the threshold, indicating strong system performance.

This preliminary example illustrates the type of performance metrics that can be defined and visualized, made possible by the data richness and precision offered by the developed CCPS. Future work will focus on identifying and formulating additional relevant metrics, as well as conducting a comprehensive evaluation of system performance and usability.

6. Conclusions

In environments where informational complexity and cognitive load constitute significant obstacles to efficiency and operational precision, the guidelines developed in this paper (covering resource status visualization, KPI representation, temporal representation of states and temporal evolution of KPIs) have proven highly effective. By presenting key data in a clear, hierarchical and accessible format, the system enables faster, more accurate decision-making, leading to measurable gains in performance and reliability.

The integration of intuitive visualizations, IIoT sensors and KPI analytics positions this CCPS as a key tool for modernizing logistics in large-scale shipyards. This proposal not only optimizes operational performance but also demonstrates high potential for application in other industrial sectors in the process of adopting the Industry 5.0 principles. This CCPS establishes a solid foundation for future quantitative research by systematically generating reliable digital data. Building on this foundation, future work will focus on expanding and validating the proposed guidelines in new scenarios involving dynamic resource allocation.