1. Introduction

One of the main concerns of modern industries is ensuring the safety of their workers while maintaining uninterrupted production processes. For this reason, companies continuously invest financial and technological resources in training personnel to comply with safety procedures and guidelines [

1,

2].

Virtual reality (VR) is defined as an environment that appears realistic and allows user interaction, even though it is artificially generated through computational tools [

1,

3], to digital transformation of industrial environments has significantly reshaped the way safety, efficiency, and risk management are approached across various industries. In complex environments such as brewing facilities, where thermal, electrical, chemical, biological and mechanical processes converge, maintaining safety and operational continuity remains an exhausting challenge [

4,

5,

6]. These industrial spaces are particularly required to maintain hazards keeping on low levels, ranging from any risk exposure, necessitating strict adherence to international safety standards such as ISO 3864 [

7] and ISO 7010 [

8].

Traditional training methods present several disadvantages, such as the need to halt production processes and the exposure of workers to potentially hazardous industrial environments. For this reason, in recent years, and within Industry 4.0, there has been a growing effort to integrate technology on a larger scale into production processes, as described in [

4]. The industries that have made the most progress in adopting virtual reality for this aim are the construction and chemical sectors. However, other industries have shown very limited adoption of such technologies for safety training purposes [

2,

3]. The pursuit of integrating virtual reality technology into industrial safety training, within an industry of great economic importance in Ecuador and for which the reviewed studies provide insufficient information, underpins the development of the present work.

This document presents the integration of these technologies for the development, testing, and validation of a functional, interactive, and user-friendly system aimed at training many personnel in industrial safety protocols. The system is designed to facilitate proper performance within real industrial environments, which have been virtualized for this purpose. Demonstrating virtual reality applications has also gained relevance in industrial personnel training [

1,

9,

10,

11,

12,

13].

2. Materials and Methods

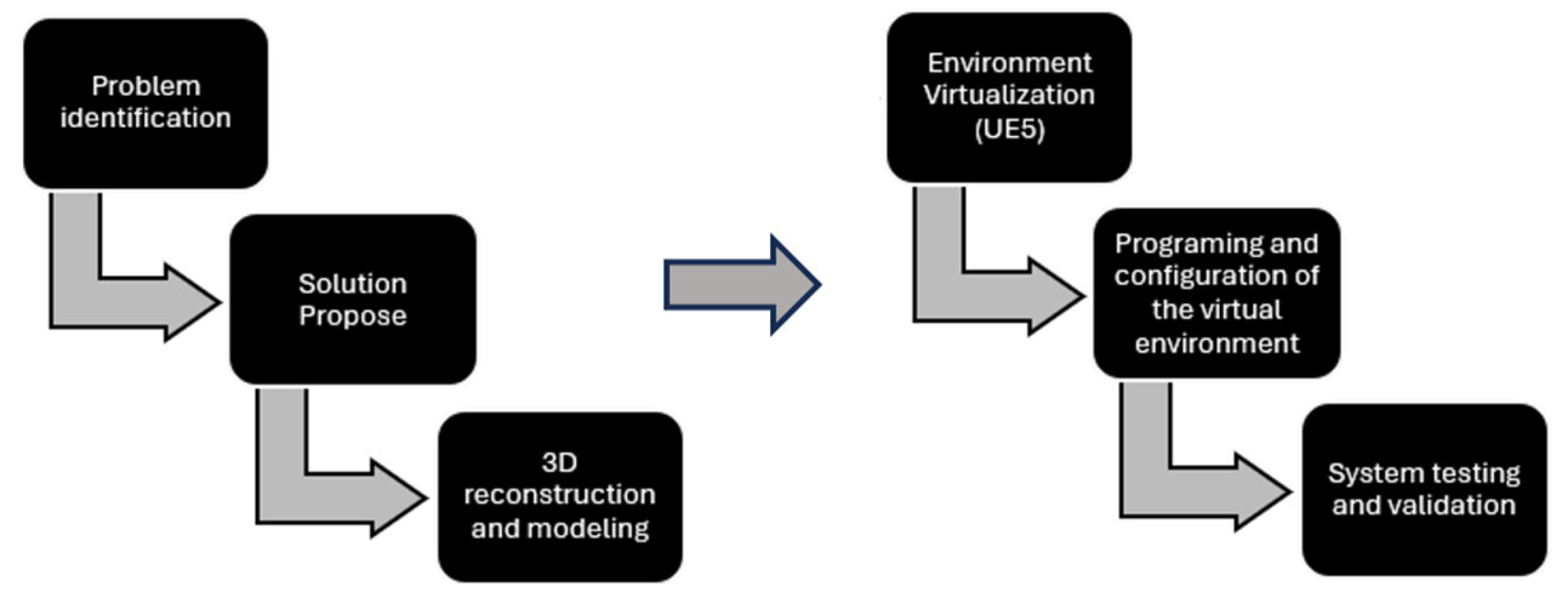

This paper outlines the methodological process undertaken—from problem analysis to final product validation—structured into a series of sequential phases, as illustrated in

Figure 1.

2.1. Participants

The study involved a total of 13 participants, with ages ranging from 27 to 40 years. All participants were professionals working in this facility, where safety and continuous training are essential. Given that they are constantly seeking opportunities for professional development, the adoption of new technological tools is of particular interest to them. Virtual reality offered a safe environment in which they could acquire new knowledge and practice procedures without being exposed to real risks, aligning with the emphasis on industrial safety standards.

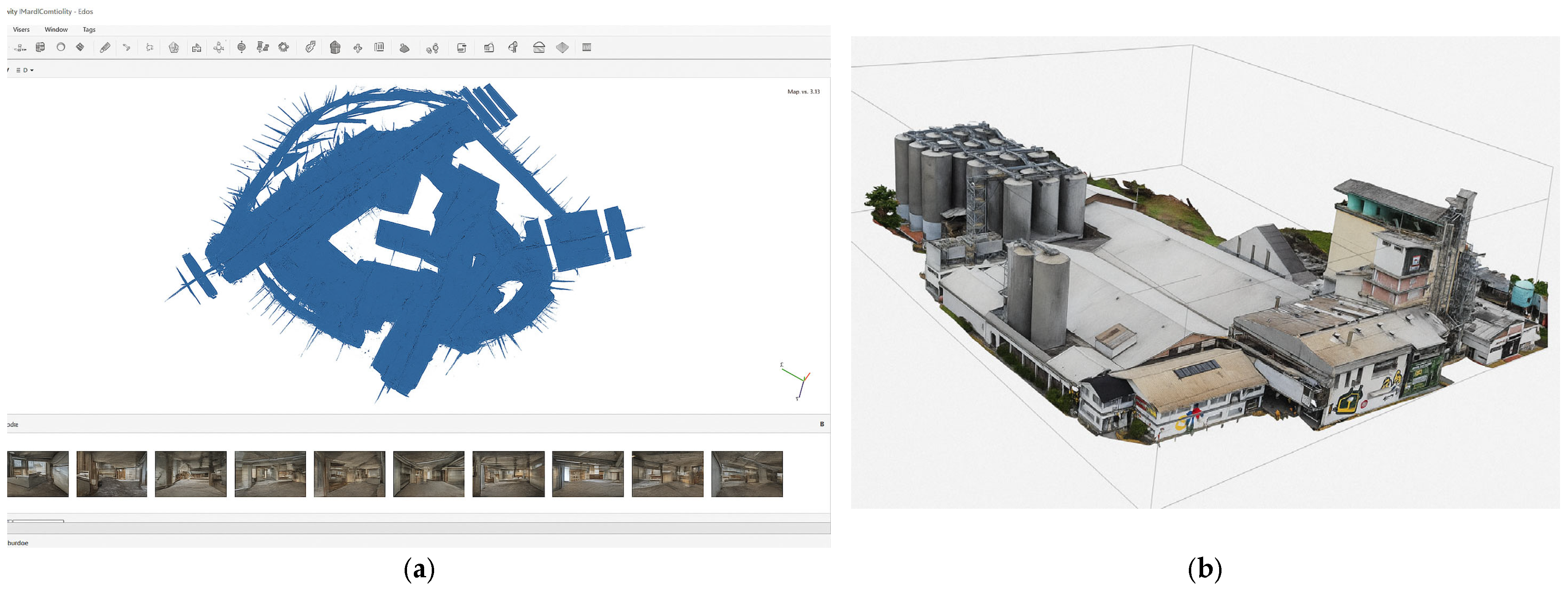

2.2. Three-Dimensional Reconstruction and Modeling

Aerial photogrammetry was conducted using a DJI Mini 2 drone and Agisoft Metashape 2.1.1 software, which enabled the processing of aerial images to generate a 3D reconstruction of the environment as looking in

Figure 2. Manual 3D modeling was performed based on technical schematics and direct on-site observations to achieve accurate interior reconstruction and detailed geometric definition. Autodesk Inventor and Blender were used for detailed modeling and mesh optimization [

14,

15,

16].

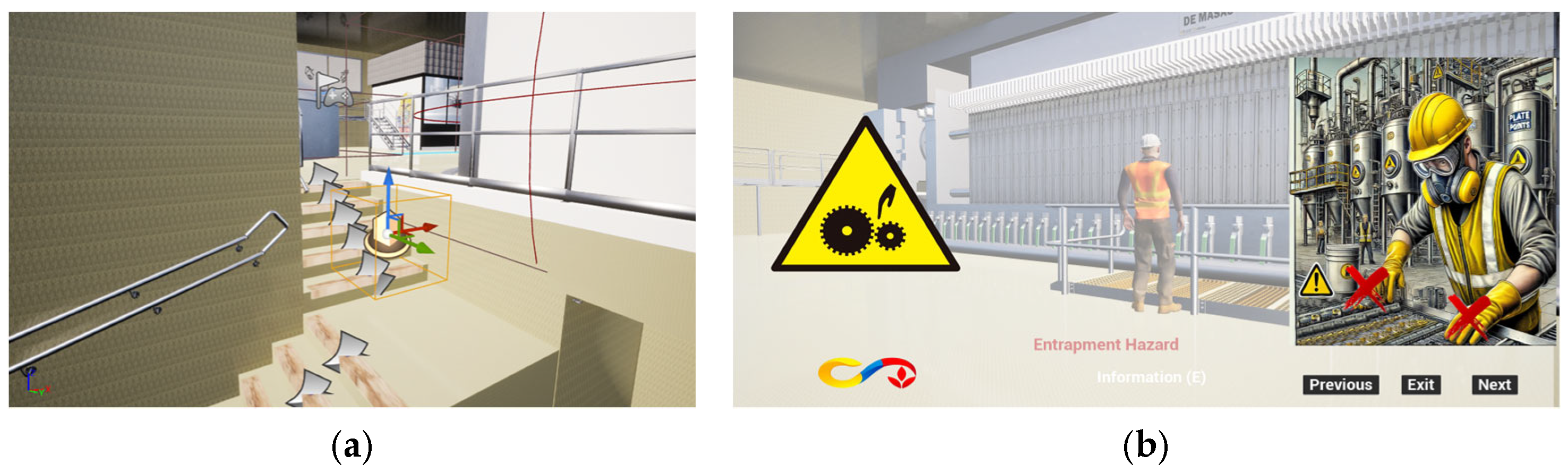

2.3. Environment Virtualization in UE5

Once the 3D industrial equipment and components were assembled in Autodesk Inventor and required reconstructions were completed, Unreal Engine 5 (UE5) was selected as the development environment due to its key features: real-time rendering engine, robust scripting based on Blueprints, and cross-platform compatibility. To enhance visual realism, 3D assets were refined with Blender [

16], and physically based materials were made in blueprint coding. The virtual environment featured an interactive avatar, equipped with industrial personal protective equipment (PPE), which allowed users to explore the facility. As shown in

Figure 3, the avatar was programmed to walk through corridors, ascend stairs, and interact with hazardous areas, simulating realistic movement within the industrial facility [

17,

18,

19,

20].

Interactive events were programmed to activate when the user walks into the predefined hazardous area. Each of these areas included a trigger box that launched pop-up windows containing detailed information about the specific hazard, its standardized safety pictogram, and an instructional illustration. The interaction system was adapted to the user’s pace, supporting both guided sessions led by a trainer and autonomous exploration modes [

21].

It is important to clarify that the system was not implemented through head-mounted VR devices, but rather in a desktop computer. The virtual environment was experienced on a conventional computer screen, with navigation and interaction controlled via keyboard and mouse inputs with an Avatar, wich is visualized in

Figure 3. This approach maintained accessibility for all participants, reduced hardware requirements, and avoided possible discomfort related to VR headsets, while still providing a realistic and interactive industrial training environment. The environment was configured so that interaction with “trigger boxes” enables context-specific engagement with the associated hazard or resource shown as

Figure 4, interaction prompts only appear when the user approaches an interactive object.

2.4. Programing and Configuration of the Virtual Environment

The environment allows the user to navigate freely from the starting point, located in the Industrial Safety office of the virtualized industrial facility, to points of interest within the cooking/fermentation area. The system is designed to operate in both individual and group modes. A third-person camera helps maintain the user’s spatial awareness, reinforcing the connection between virtual signage and the user’s physical position within the environment. Red “X” marks on the user’s hands indicate zones or actions of potential hazard, enhancing visual feedback on risk exposure. In addition to hazards, safety elements such as fire extinguishers, evacuation routes, and emergency cabinets were integrated. The character is restricted from entering prohibited areas, reinforcing training in industrial traffic regulations.

3. Results

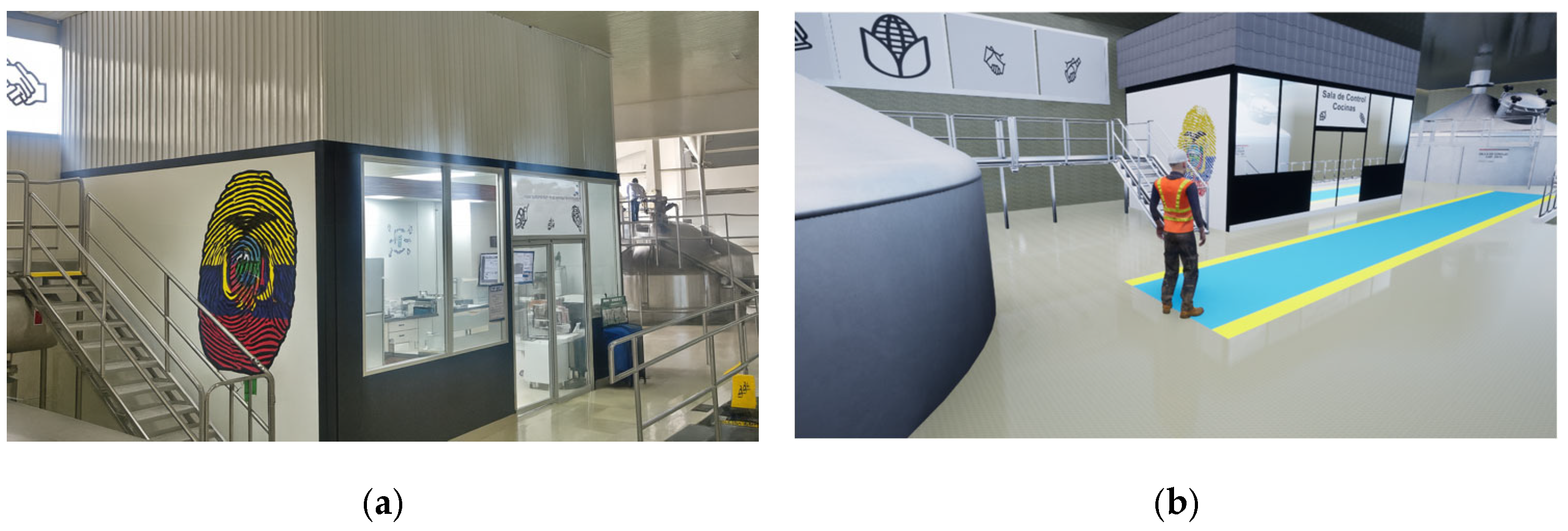

The result is an optimized software application compatible with Windows 10 or latest versions. It constitutes a 3D learning environment currently used for training personnel, contractors, and external staff entering the industrial production facility. This system allows users to explore the industrial environment and become familiar with it while dynamically interacting with the hazards areas and resources specific to each area. As illustrated in

Figure 5 and

Figure 6, a comparative visualization between the real industrial environment and the virtual reality environment is presented.

An instructor guides the training at the user’s pace, emphasizing the most relevant topics, maintaining user engagement, and maximizing immersive training as looking in

Figure 5. To validate the system, tests were conducted with plant operators, including newly hired personnel. The evaluation focused on visual realism which visualized in

Figure 6, information clarity, technical performance, and instructional applicability. These parameters were assessed using quantitative surveys with questions targeting each of the evaluated aspects, as shown in

Table 1 for the external environment and

Table 2 for the internal environment. For the quantitative questions, respondents were asked to rate each statement on a scale where 5 meant ‘Strongly agree’, 4 ‘Agree’, 3 ‘Neutral’, 2 ‘Disagree’, and 1 ‘Strongly disagree’. Additionally, the survey included close questions with ‘Yes’ or ‘No’. Finally, an open-ended question was included at the end of each survey to gather insights into future improvements, with responses analyzed in the Discussion section.

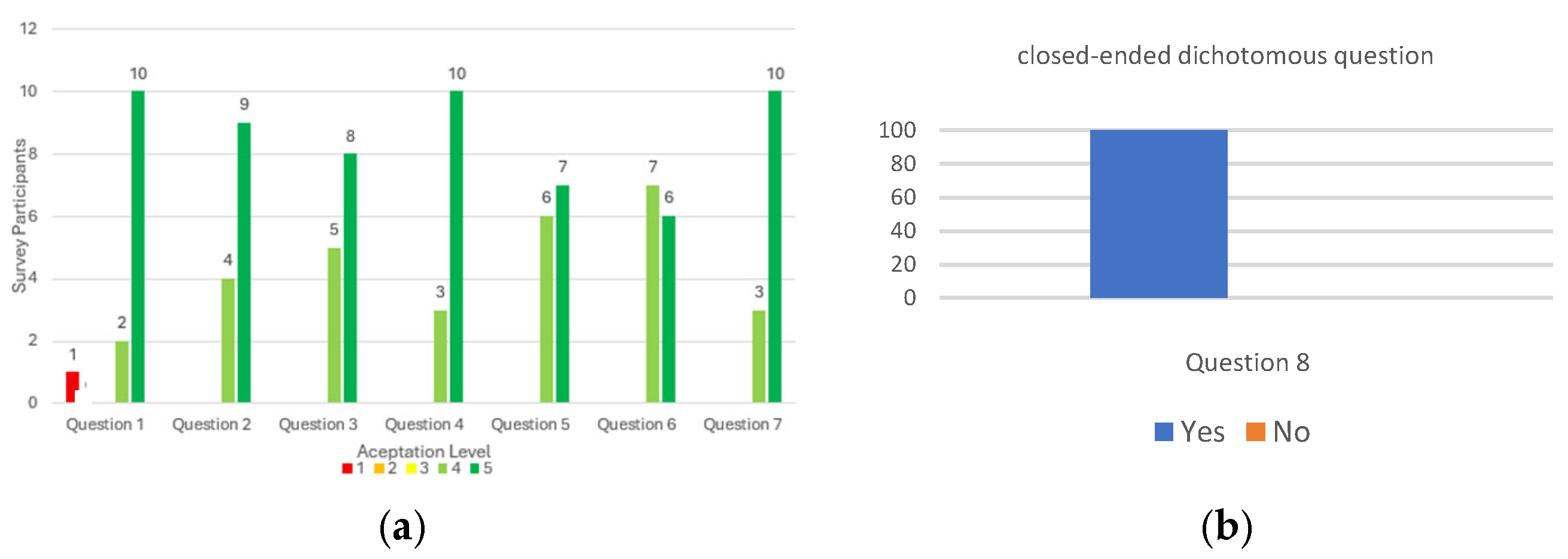

The surveys yielded the following results in

Figure 7, the implications of which are analyzed in the Discussion section.

4. Discussion

Industrial safety training is essential for preventing accidents and protecting personnel in workplace environments. However, traditional methods often based on theoretical presentations or repetitive in-person instructions tend to be ineffective, as they are typically monotonous, disengaging, and hinder the understanding and retention of information. In this context, the present work proposes a solution aligned with the principles of Industry 4.0 through the development of an interactive virtual learning environment that digitalizes and modernizes the industrial safety training process. This tool not only enables the safe simulation of risk scenarios but also enhances the learning experience by increasing user attention, engagement, and information retention [

4,

5].

The system developed stands out from previous proposals [

1,

2,

3,

4,

5,

6] as it is a virtual environment based on a real industrial setting and designed for application within that same context, specifically in a nationally recognized brewery production plant. It enables the training of both new personnel and experienced operators. The realistic and interactive system complements training through expert guidance, allowing users to engage with the actual risks present in the industrial environment at their own pace. This significantly enhances concentration, information retention, and other key aspects of the learning process. As a result, personnel trained using this new system who had previously undergone traditional training methods evaluated the experience positively and strongly recommended its implementation, as evidenced by the results obtained. The developed system can also be defined as a low-cost, high-benefit solution, since its integration requires only elements and resources commonly available in any industry, namely a computer with basic processing capabilities and limited resources, without the need to acquire additional equipment such as virtual reality glasses or other devices that would increase the implementation cost. Thus, the presented work constitutes a solution applicable to any industry without requiring significant investment.

To validate the effectiveness of the virtual environment, a structured questionnaire (

Table 1) was administered to the personnel who underwent training using the developed system. The aggregated results illustrated in

Figure 7, reveal a consistently positive perception across key evaluation criteria such as visual realism, user interaction, system usability, and overall applicability for safety training. Notably, more than 90% of participants responded with “Agree” or “Strongly Agree” to all assessed items, indicating a high level of acceptance and alignment with the intended learning objectives. These outcomes suggest that the virtual environment not only meets the functional and pedagogical requirements defined at the outset but also holds significant potential for integration into real-world industrial safety programs.

5. Conclusions

The selection of the different software tools used in this project such as Agisoft Metashape, Unreal Engine 5, Blender, and 3D design software was based on an analysis of the specific needs for realism, levels of interaction, level of detail, and their suitability for real-world application in industrial safety training within an actual beer production plant.

The implementation of this system proved to be an innovative tool for industrial safety training, as it provides immersive experience that significantly enhances the understanding and retention of key concepts. The use of virtual reality technology for safety training represents a step forward in modernizing the learning process within the framework of Industry 4.0.

The work carried out, as can be seen from the results, represents a solution that integrates virtual reality technology to optimize personnel training by incorporating industrial safety within the framework of Industry 4.0, in a production process where previous studies, as described in [

1,

2], had not ventured. However, the results demonstrate the applicability of the proposal and show levels of acceptance similar to those reported in earlier studies.

This virtual learning environment represents a digital tool that directly addresses the challenges of Industry 4.0: smart training, process digitalization, continuous improvement, and a preventive safety culture. It functions as a partial digital twin that replicates operational reality and enables the simulation of actions without affecting the physical process. It contributes to the automation of training and reduces the need for physical presence in hazardous areas

Another key indicator to validate the applicability of the virtual environment was the level of acceptance by the personnel who tested it. This aspect was evaluated through question 8 (

Table 2), which directly asked participants whether they would recommend the use of the virtual environment for industrial safety training processes. In this question, 100% of the respondents who interacted with the system expressed their approval and recommended its implementation in future training sessions. This unanimous acceptance reinforces the technical functionality and instructional application of the tool and also demonstrates its perceived usefulness and positive impact from the end user’s perspective. The favorable response highlights the system’s potential to be adopted as an alternative method to traditional industrial safety training approaches.

6. Recommendations

Based on the responses obtained from the open-ended questions in the survey, a large percentage of respondents consider it important to increase the level of user immersion within the virtual environment. Therefore, as future work, it is proposed to leverage technological advancements to create a virtual reality environment that enhances user immersion with the support of devices such as virtual reality headsets and haptic feedback peripherals.

Author Contributions

This work presents the design and implementation of a virtual reality environment for safety training in key stages of the brewing industrial process. For the development, the contribution was as follows: Conceptualization, K.M.Q. and N.M.; Investigation and Methodology: K.M.Q. and N.M.; Software and validation: N.M. and K.M.Q.; Writing—original draft preparation, N.M., K.M.Q. and M.F.T.; Writing—review and editing: N.M., K.M.Q. and M.F.T.; visualization, N.M.; Supervision: M.F.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Díaz-Díaz, B.; de la Torre Díez, J.B.; García-Sánchez, R. Enriching Industrial Training Experience in Virtual Reality with Adaptive Feedback. In Proceedings of the 2024 CHI Conference on Human Factors in Computing Systems, Honolulu, HI, USA, 11–16 May 2024; pp. 1–12. [Google Scholar] [CrossRef]

- Grassini, S.; Laumann, K. Evaluating the use of virtual reality in work safety: A literature review. In Proceedings of the 30th European Safety and Reliability Conference and the 15th Probabilistic Safety Assessment and Management Conference, Venice, Italy, 1–5 November 2020; Springer: Berlin/Heidelberg, Germany, 2020; Volume 1. [Google Scholar]

- Naranjo, J.E.; Sanchez, D.G.; Robalino-Lopez, A.; Robalino-Lopez, P.; Alarcon-Ortiz, A.; Garcia, M.V. A scoping review on virtual reality-based industrial training. Appl. Sci. 2020, 10, 8224. [Google Scholar] [CrossRef]

- Cisneros, M. Emulación del Funcionamiento de la Máquina Envasadora Vertical de la Empresa Terrafertil Ecuador Mediante una Interfaz Interactiva para la Capacitación de Personal de la Empresa. Bachelor’s Thesis, Escuela Politécnica Nacional, Quito, Ecuador, 2022. [Google Scholar]

- Avveduto, G.; Tanca, C.; Lorenzini, C.; Tecchia, F.; Carrozzino, M.; Bergamasco, M. Safety training using virtual reality: A comparative approach. In Augmented Reality, Virtual Reality, and Computer Graphics; Lecture Notes in Computer Science (including subseries Lecture Notes in Artificial Intelligence and Lecture Notes in Bioinformatics); Springer: New York, NY, USA, 2017; Volume 10324, pp. 148–163. [Google Scholar] [CrossRef]

- Goldammer, T. Brewing Process. Available online: https://n9.cl/xdi33 (accessed on 1 November 2024).

- ISO 3864-1:2011; Graphical Symbols—Safety Colours and Safety Signs—Part 1: Design Principles for Safety Signs and Safety Markings. ISO: Geneva, Switzerland, 2011.

- ISO 7010:2019; Graphical Symbols—Safety Colours and Safety Signs—Registered Safety Signs. ISO: Geneva, Switzerland, 2019.

- National Association of Safety Professionals. Types of Hazards; NASP: Wilmington, NC, USA, 2018. [Google Scholar]

- eLearning Industry. The Future of eLearning: Leveraging 3D Visualization and Configuration. Available online: https://elearningindustry.com/the-future-of-elearning-leveraging-3d-visualization-and-configuration (accessed on 1 November 2024).

- Bamforth, C. Wort boiling. In Brewing New Technologies; Woodhead Publishing Limited: Cambridge, UK, 2006; pp. 221–224. [Google Scholar]

- Occupational Safety and Health Administration (OSHA). Regulations (Standards—29 CFR). Available online: https://n9.cl/erilay (accessed on 1 November 2024).

- National Fire Protection Association. NFPA 704; NFPA: Quincy, MA, USA, 2022. [Google Scholar]

- Autodesk. Autodesk Inventor: 3D Modeling Software for Designers and Engineers. Available online: https://n9.cl/o62u2 (accessed on 1 November 2024).

- Blender Foundation. Blender Developer. Available online: https://n9.cl/qdu67 (accessed on 1 November 2024).

- Lumion. Industry-Leading 3D Rendering Software|Lumion. Available online: https://n9.cl/29plq (accessed on 1 November 2024).

- Epic Games. Unreal Engine—Learning Library. Available online: https://n9.cl/um4le (accessed on 1 November 2024).

- Kukreja, A.; Cox, C.M.J.; Gopsill, J.; Snider, C. A comparative study of VR CAD modelling tools for design. Proc. Des. Soc. 2024, 4, 2639–2648. [Google Scholar] [CrossRef]

- Vhive. Simulation Environments. Available online: https://n9.cl/gvdvue (accessed on 1 November 2024).

- Riesener, M. Development of a VR-Based Digital Factory Planning Platform Using Unreal Engine. Digit. Eng. J. 2024, 10, 105–117. [Google Scholar] [CrossRef]

- Epic Games. Quixel|3D World-Building Made Easy. Available online: https://n9.cl/6qi1x (accessed on 1 November 2024).

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).