Model-Free Control for Greenhouse Automation with Hardware-in-the-Loop and Raspberry Pi Implementation †

Abstract

1. Introduction

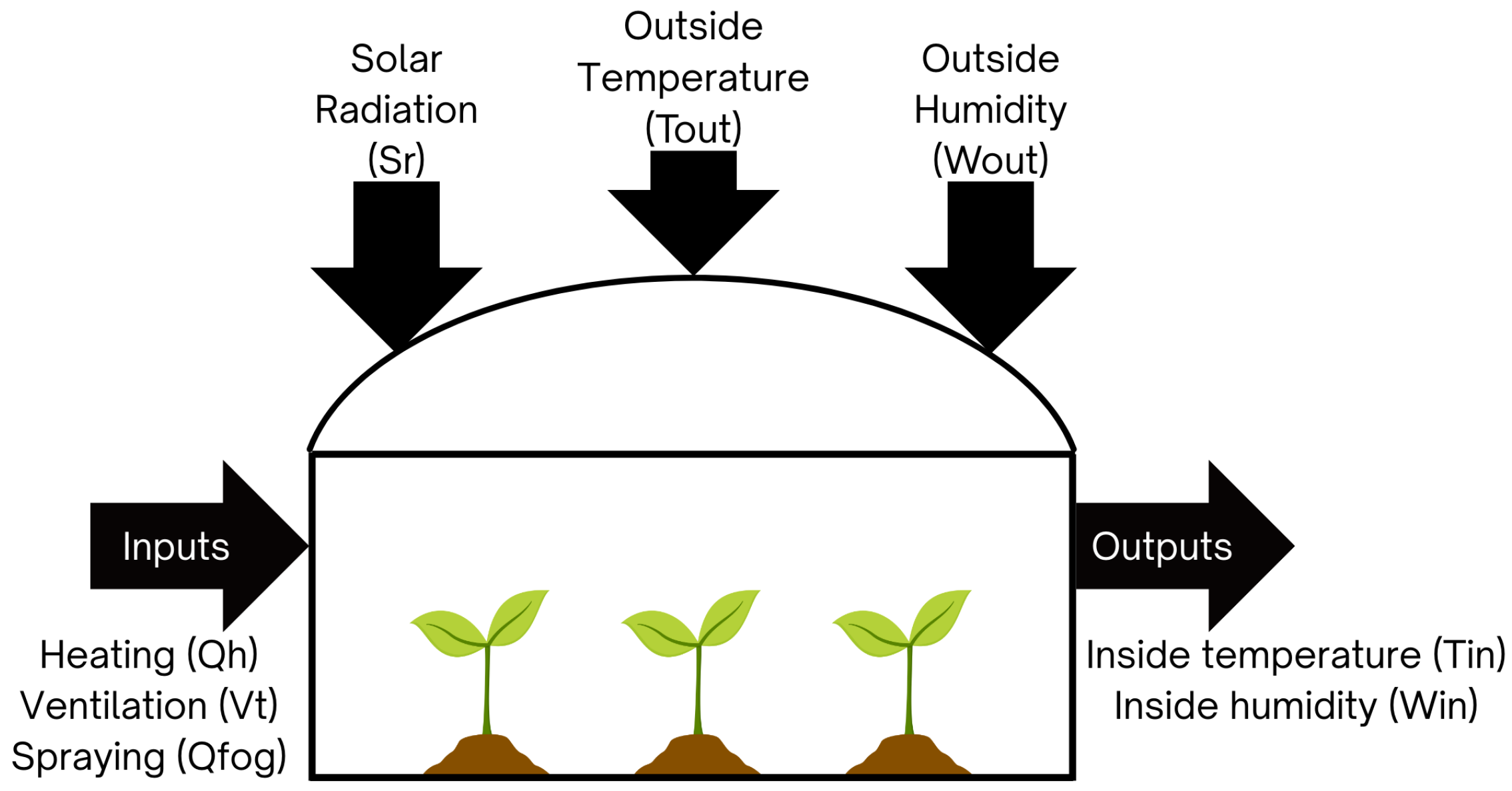

2. Digital Twin for a Greenhouse Climate System

2.1. Differential Equations That Describe the Greenhouse Dynamics

2.2. Steady State Values Around Operation Point

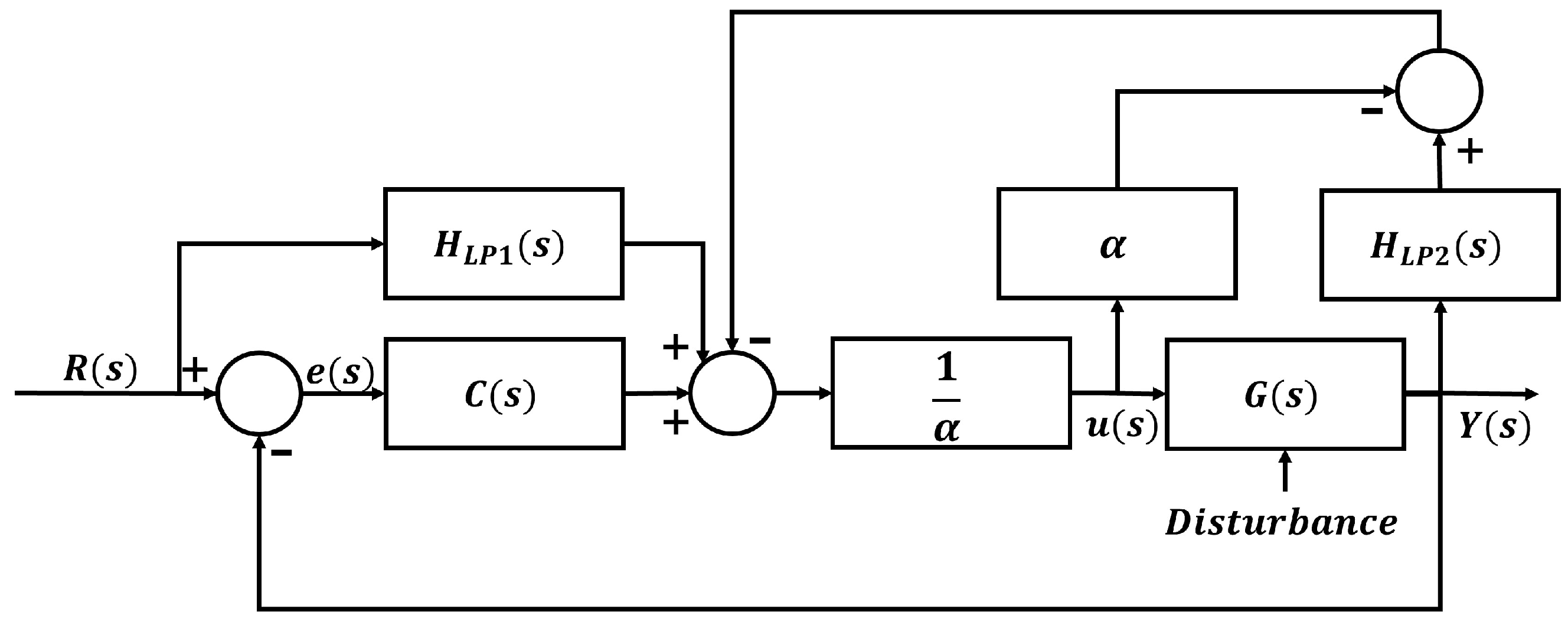

3. Intelligent PI Controller Approach

3.1. iPI Controller Scheme

3.2. Parameter Optimization Using Genetic Algorithm

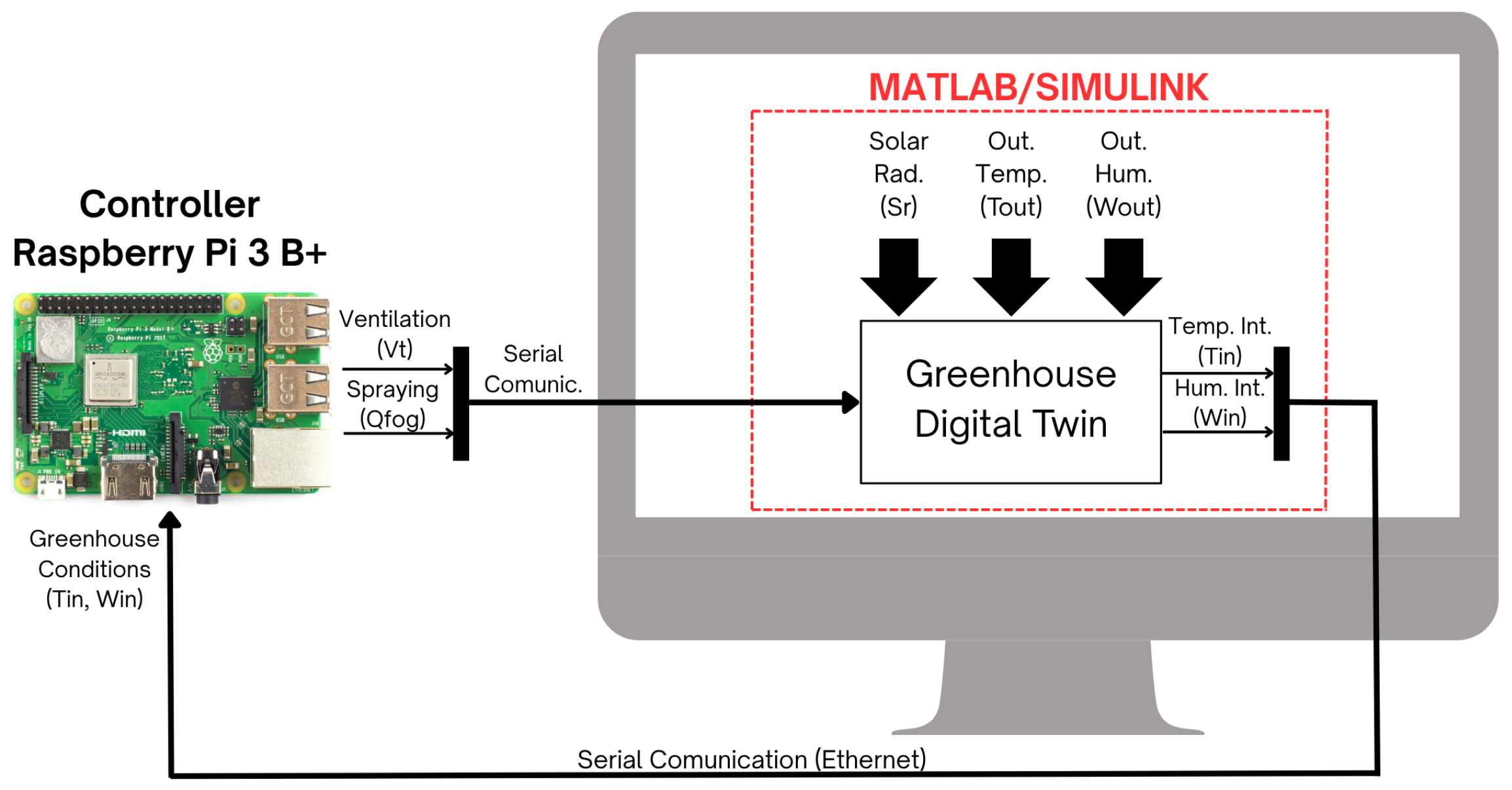

4. Hardware-in-the-Loop Implementation

4.1. Sampling Time for Digital Controller

4.2. Conversion of Designed Controllers from a Continuous System to a Discrete System

5. Results and Discussion

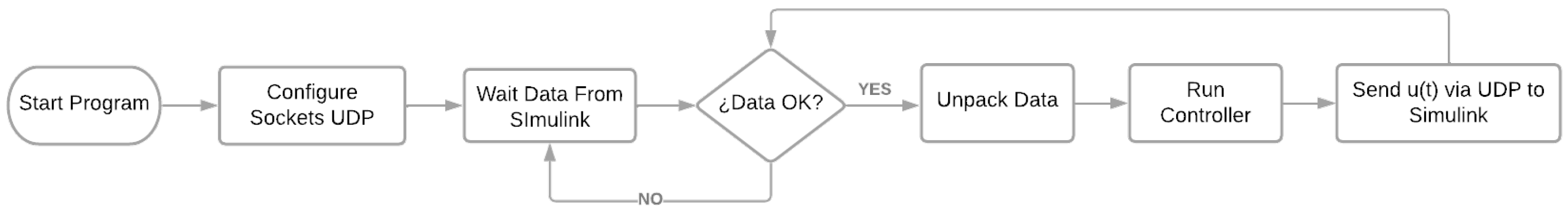

5.1. Digital Controller on Python

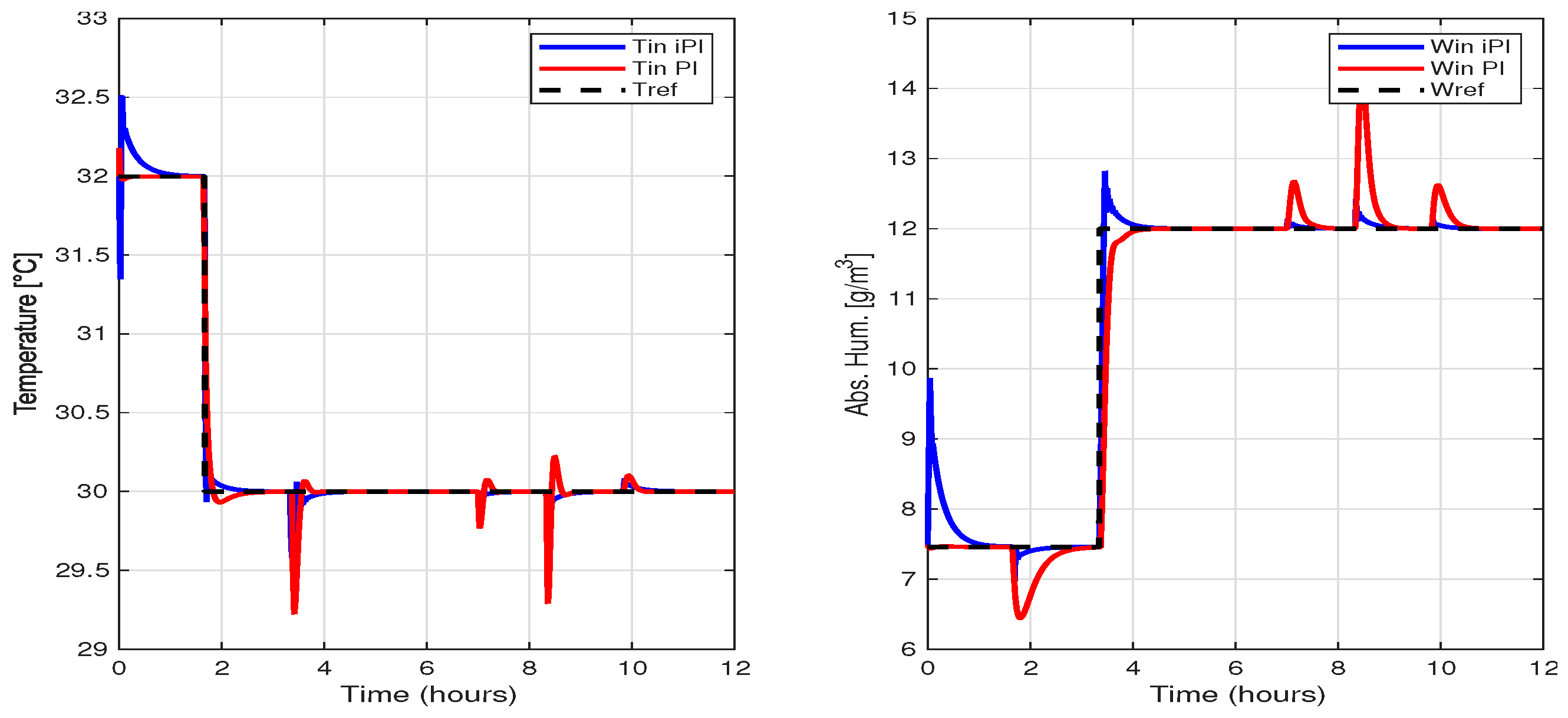

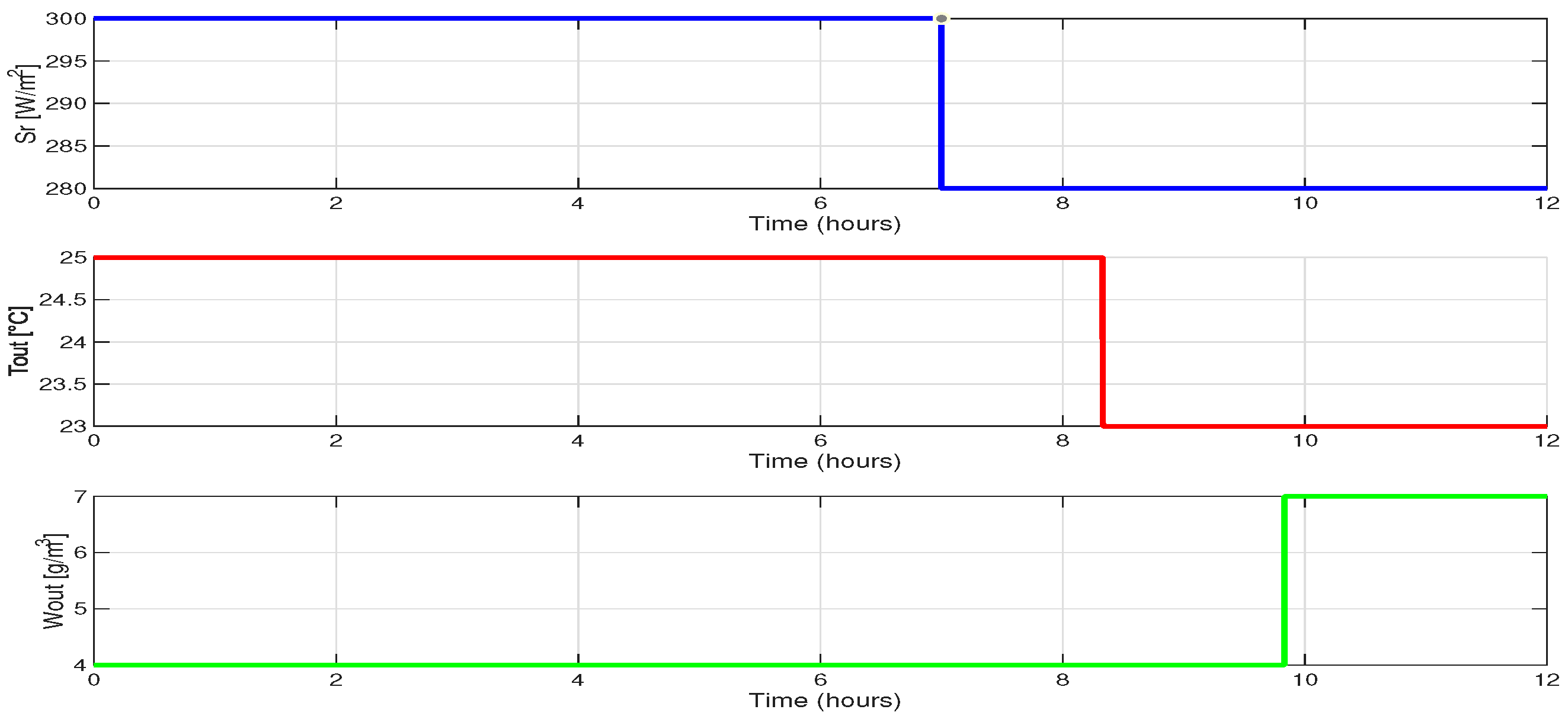

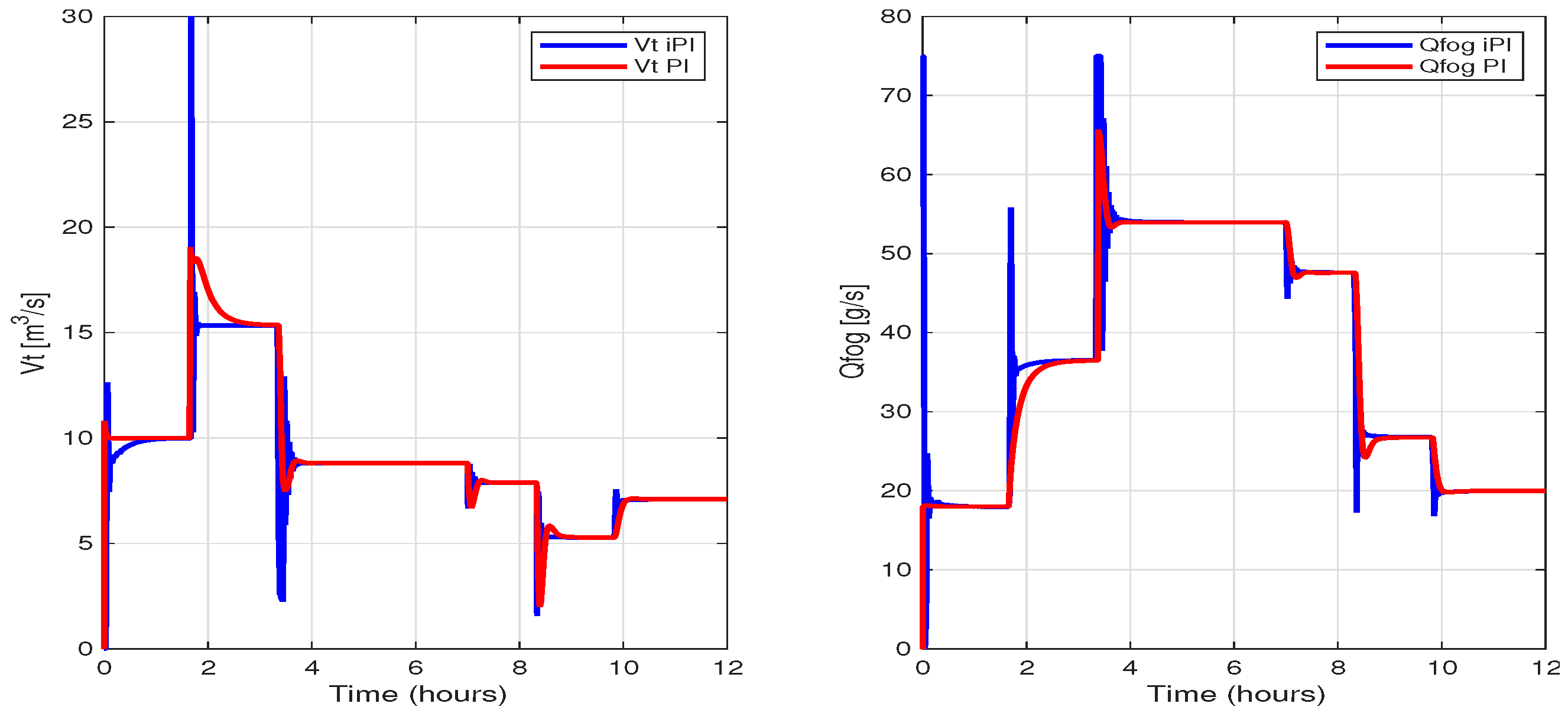

5.2. Reference Tracking and Disturbance

5.3. Analysis of Performance Controller

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cevallos, G.; Herrera, M.; Jaimez, R.; Aboukheir, H.; Camacho, O. A practical hybrid control approach for a greenhouse microclimate: A hardware-in-the-loop implementation. Agriculture 2022, 12, 1916. [Google Scholar] [CrossRef]

- Albright, L.D.; Arvanitis, K.; Drysdale, A. Environmental control for plants on earth and in space. IEEE Control. Syst. Mag. 2001, 21, 28–47. [Google Scholar]

- Faramarzpour, H.; Ghaderi, M.; Reddick, C.; Sorin, M.; Grégoire, M. Specification of a greenhouse in cold climate condition, mathematical model and optimization. J. Build. Phys. 2025, 48, 579–608. [Google Scholar] [CrossRef]

- Kimball, B. Simulation of the energy balance of a greenhouse. Agric. Meteorol. 1973, 11, 243–260. [Google Scholar] [CrossRef]

- Subin, M.C.; Singh, A.; Kalaichelvi, V.; Karthikeyan, R.; Periasamy, C. Design and robustness analysis of intelligent controllers for commercial greenhouse. Mech. Sci. 2020, 11, 299–316. [Google Scholar] [CrossRef]

- Fliess, M.; Join, C. Model-free control. Int. J. Control. 2013, 86, 2228–2252. [Google Scholar] [CrossRef]

- Precup, R.E.; Radac, M.B.; Roman, R.C.; Petriu, E.M. Model-free sliding mode control of nonlinear systems: Algorithms and experiments. Inf. Sci. 2017, 381, 176–192. [Google Scholar] [CrossRef]

- Vega, S.; Iza, J.; Cruz, W.; Gude, J.J.; Camacho, O. A Comparative Experimental Evaluation of iPI and iPI-Fuzzy Controllers for a Thermal Process with a Long Dead Time. In Proceedings of the 15th International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH 2025), Bilbao, Spain, 11–13 June 2025; pp. 209–216. [Google Scholar]

- Lafont, F.; Pessel, N.; Balmat, J.F.; Fliess, M. On the model-free control of an experimental greenhouse. Comput. Electron. Agric. 2015, 110, 139–149. [Google Scholar] [CrossRef]

- Seol, J.; Park, Y.; Pak, J.; Jo, Y.; Lee, G.; Kim, Y.; Ju, C.; Hong, A.; Son, H.I. Human-Centered Robotic System for Agricultural Applications: Design, Development, and Field Evaluation. Agriculture 2024, 14, 1985. [Google Scholar] [CrossRef]

- Cevallos, G.; Pinzón, J.; Camacho, O. A Microclimate Greenhouse Multivariable Control: A Guide to use Hardware in the Loop Simulation. In Proceedings of the 2022 IEEE International Conference on Automation/XXV Congress of the Chilean Association of Automatic Control (ICA-ACCA), Curico, Chile, 24–28 October 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 1–6. [Google Scholar]

- Lakshmi, A.J.; Dasari, R.; Chilukuri, M.; Tirumani, Y.; PramodKumar, A. IoT Based Smart Greenhouse Using Raspberry Pi. In Proceedings of the 2023 International Conference on Computer, Electronics & Electrical Engineering & their Applications (IC2E3), Garhwal, India, 8–9 June 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 1–6. [Google Scholar]

- Pasgianos, G.; Arvanitis, K.; Polycarpou, P.; Sigrimis, N. A nonlinear feedback technique for greenhouse environmental control. Comput. Electron. Agric. 2003, 40, 153–177. [Google Scholar] [CrossRef]

- Giraldo, S.A.C.; Flesch, R.C.; Normey-Rico, J.E. Multivariable greenhouse control using the filtered smith predictor. J. Control. Autom. Electr. Syst. 2016, 27, 349–358. [Google Scholar] [CrossRef]

- Hu, H.; Xu, L.; Wei, R.; Zhu, B. Multi-objective control optimization for greenhouse environment using evolutionary algorithms. Sensors 2011, 11, 5792–5807. [Google Scholar] [CrossRef] [PubMed]

- Rubio-Díaz-Cordovés, Á.; Gil-Nobajas, J.J. Fundamentos de Control Automático de Sistemas Continuos y Muestreados; Universidad de Navarra, Escuela Superior de Ingenieros: San Sebastián, España, 2009; ISBN 978-84-613-4618-9. Available online: https://www.euskariana.euskadi.eus/euskadibib/eu/bib/1157906.do (accessed on 2 August 2025).

| Performance Indie | iPI | PI |

|---|---|---|

| ISE | 1.492 | 1.557 |

| ISE | 2.501 | 2.49 |

| ISCO | 5.812 | 9.766 |

| ISCO | 3.55 | 1.234 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Montalvo, A.; Vega, S.; Chavez, D.; Camacho, O. Model-Free Control for Greenhouse Automation with Hardware-in-the-Loop and Raspberry Pi Implementation. Eng. Proc. 2025, 115, 15. https://doi.org/10.3390/engproc2025115015

Montalvo A, Vega S, Chavez D, Camacho O. Model-Free Control for Greenhouse Automation with Hardware-in-the-Loop and Raspberry Pi Implementation. Engineering Proceedings. 2025; 115(1):15. https://doi.org/10.3390/engproc2025115015

Chicago/Turabian StyleMontalvo, Alexis, Sebastian Vega, Danilo Chavez, and Oscar Camacho. 2025. "Model-Free Control for Greenhouse Automation with Hardware-in-the-Loop and Raspberry Pi Implementation" Engineering Proceedings 115, no. 1: 15. https://doi.org/10.3390/engproc2025115015

APA StyleMontalvo, A., Vega, S., Chavez, D., & Camacho, O. (2025). Model-Free Control for Greenhouse Automation with Hardware-in-the-Loop and Raspberry Pi Implementation. Engineering Proceedings, 115(1), 15. https://doi.org/10.3390/engproc2025115015