An Open-Source Web-Based Approach to Industrial Supervision and Data Acquisition in the Context of Industry 4.0 †

Abstract

1. Introduction

2. Methodology

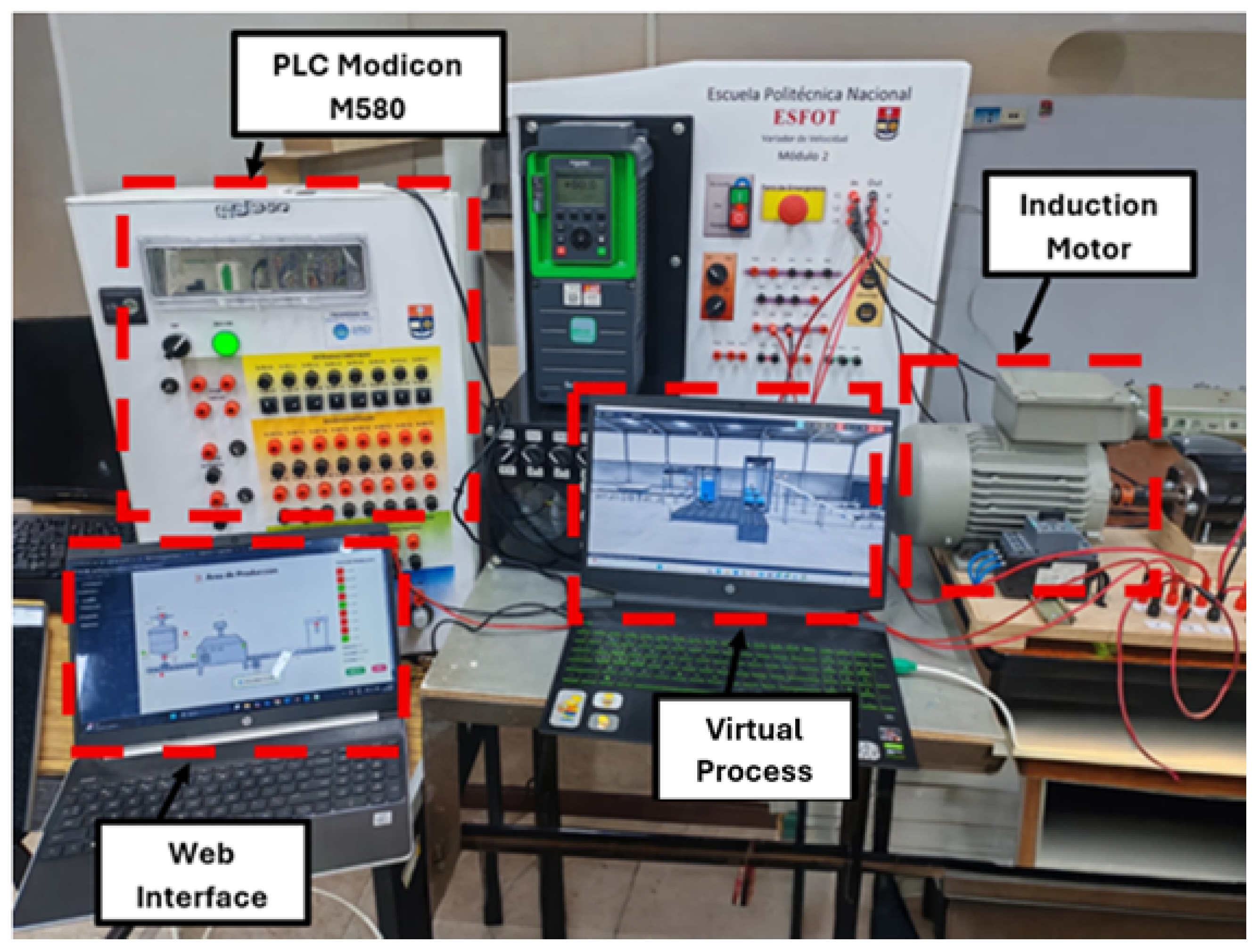

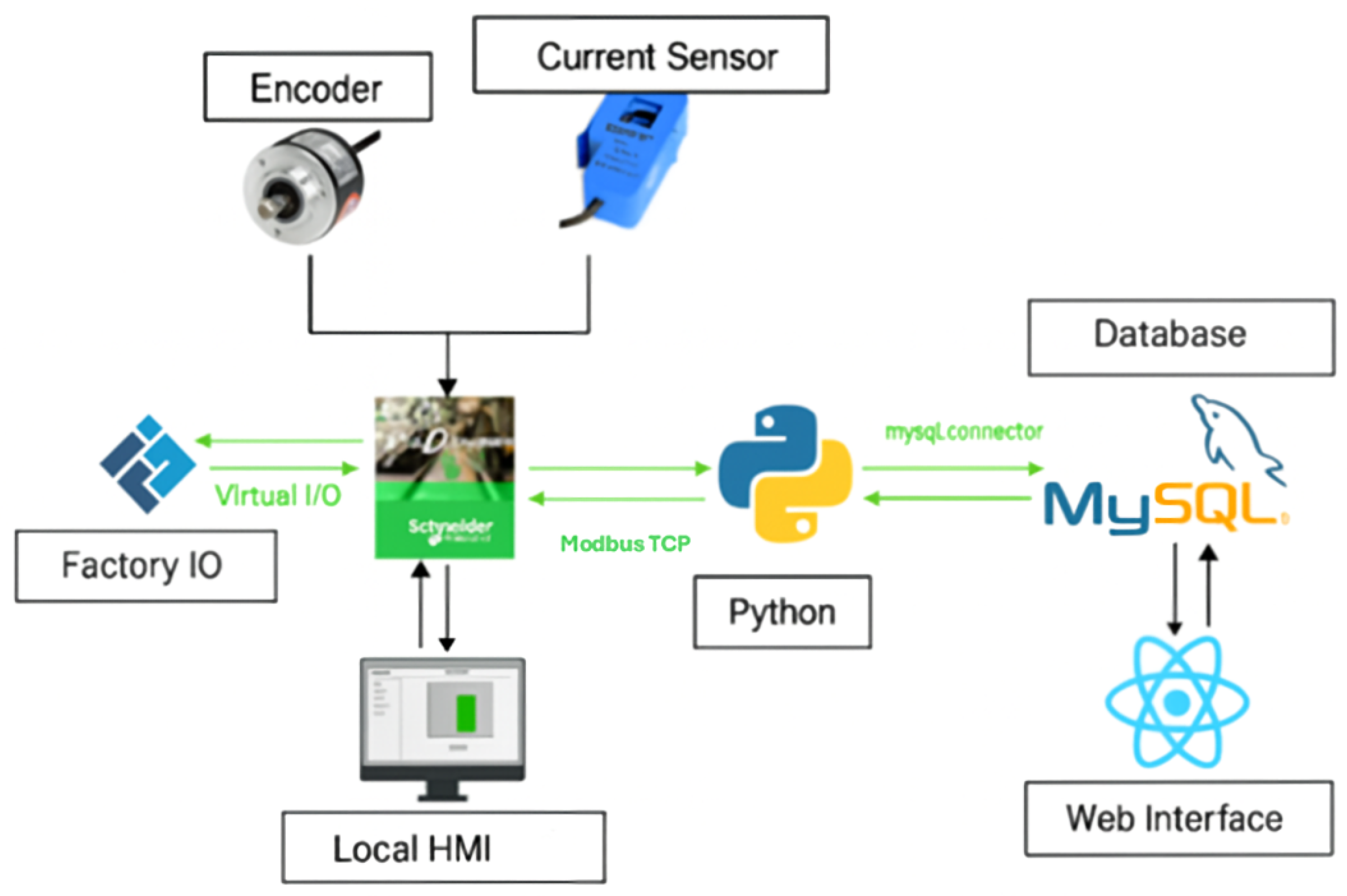

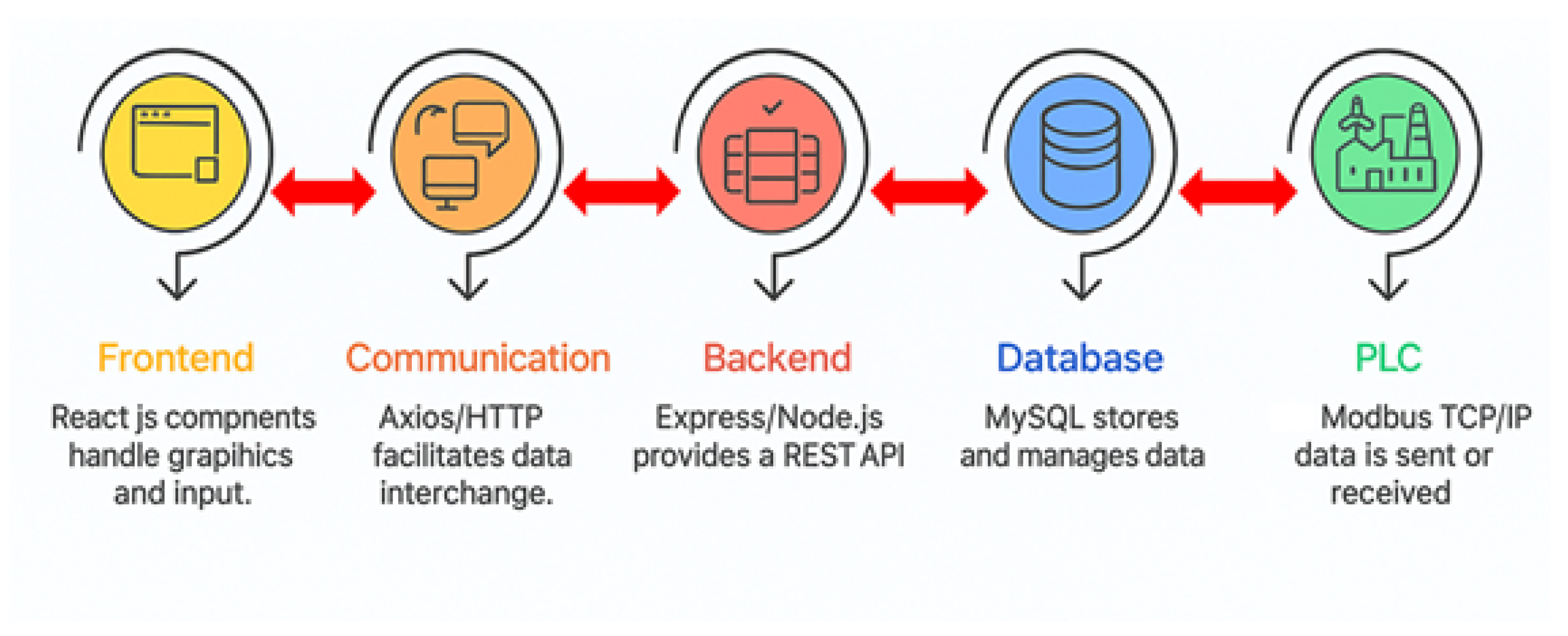

2.1. System Architecture and Overview

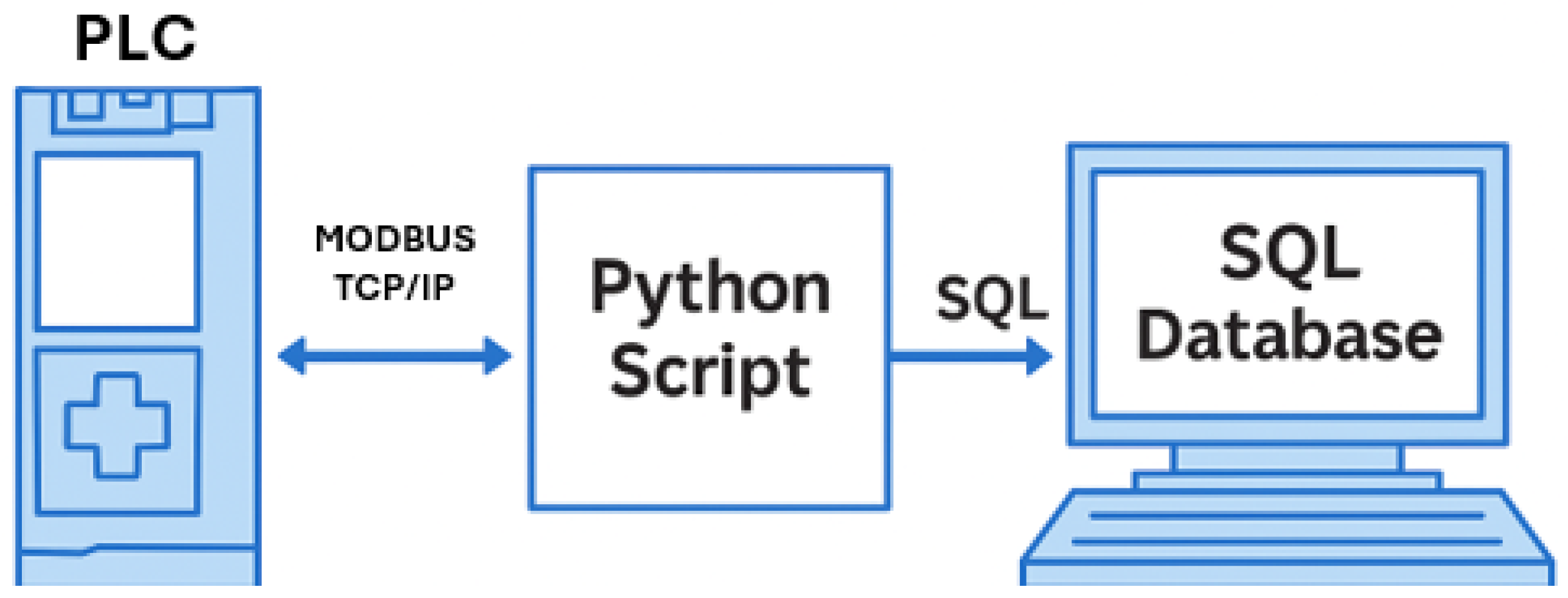

IIoT-Based Communication and Data Flow

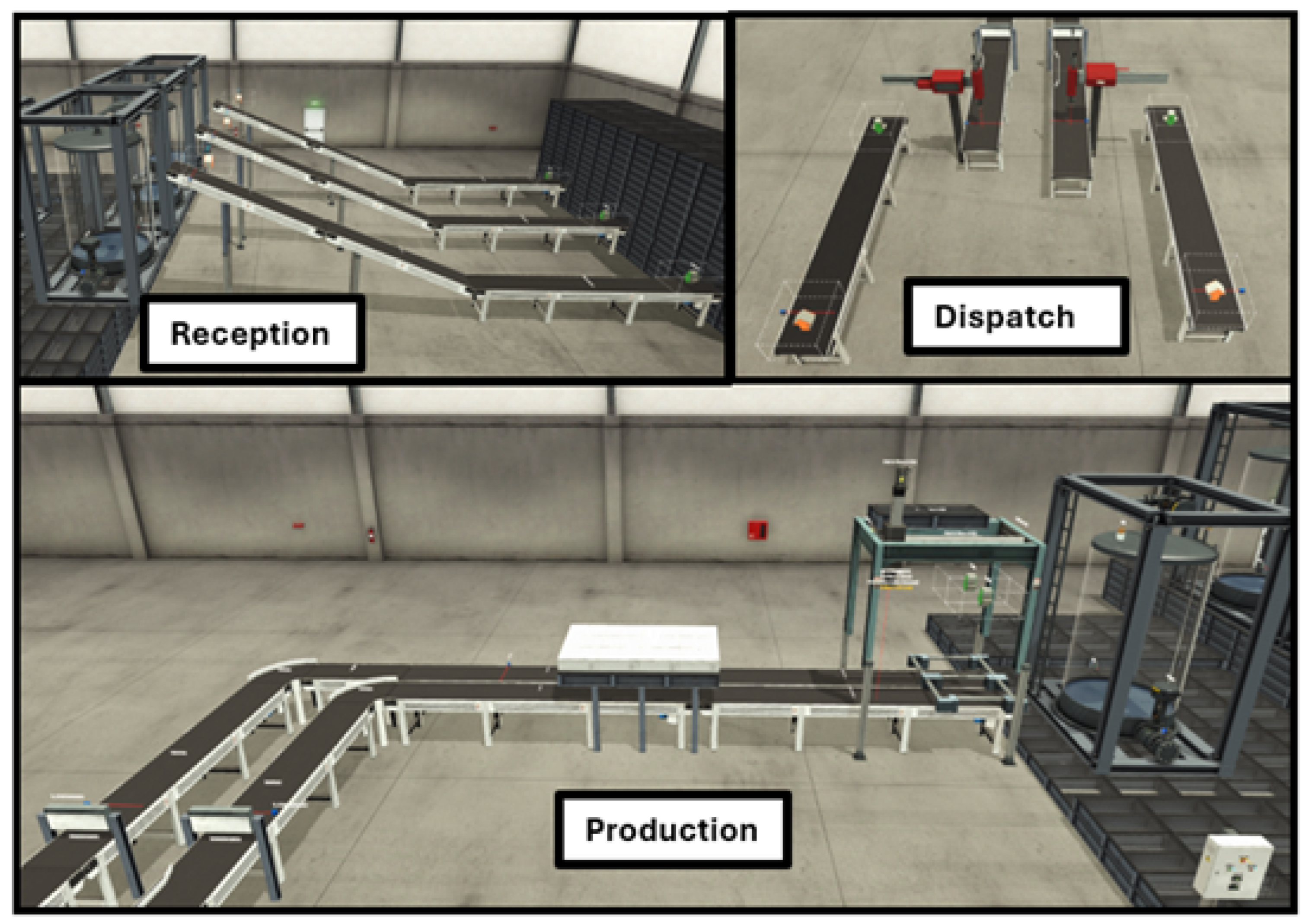

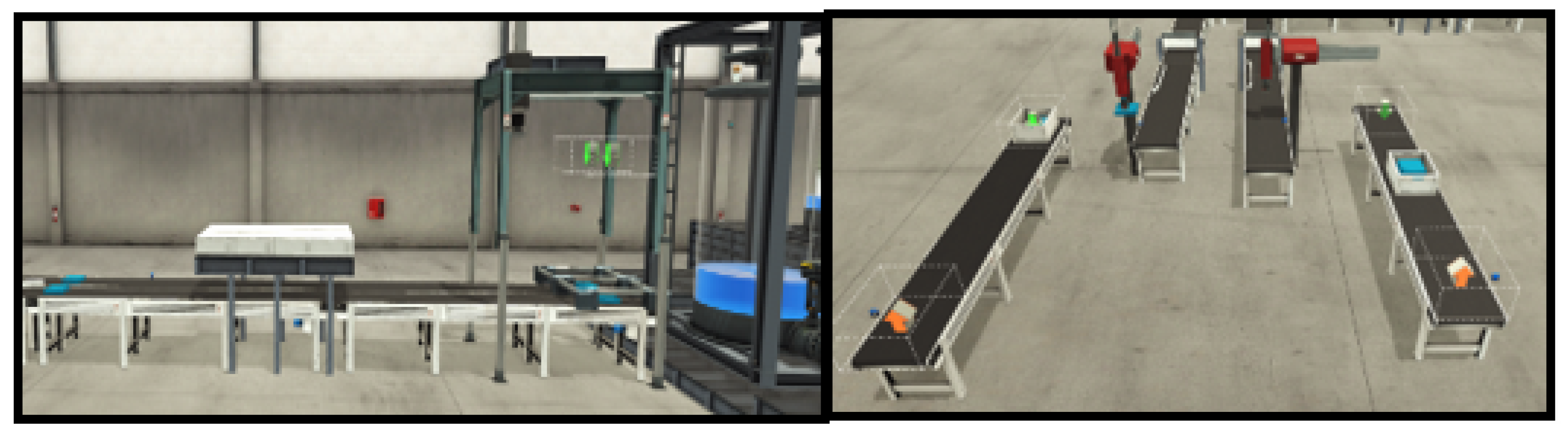

2.2. Process Simulation and Control Integration

- Reception: Conveyors transport raw materials—silica sand, soda ash, and recycled glass—into storage tanks.

- Production: A virtual furnace and mold station process the materials. A physical three-phase induction motor is integrated into the cooling zone, adding realism and enabling hybrid control evaluation.

- Dispatch: Robotic arms handle the packaging and preparation of finished products for delivery.

2.3. Data Acquisition and Storage

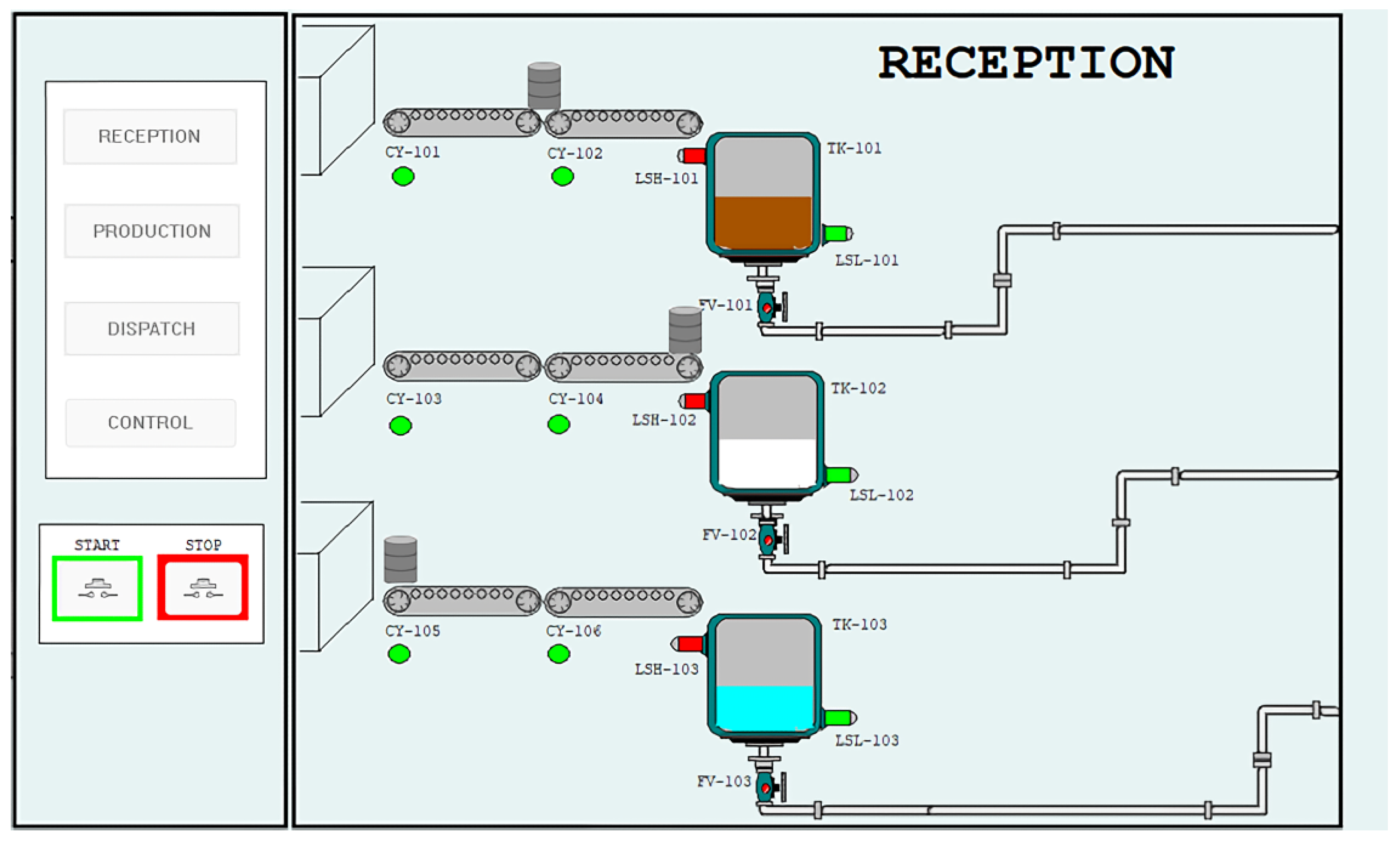

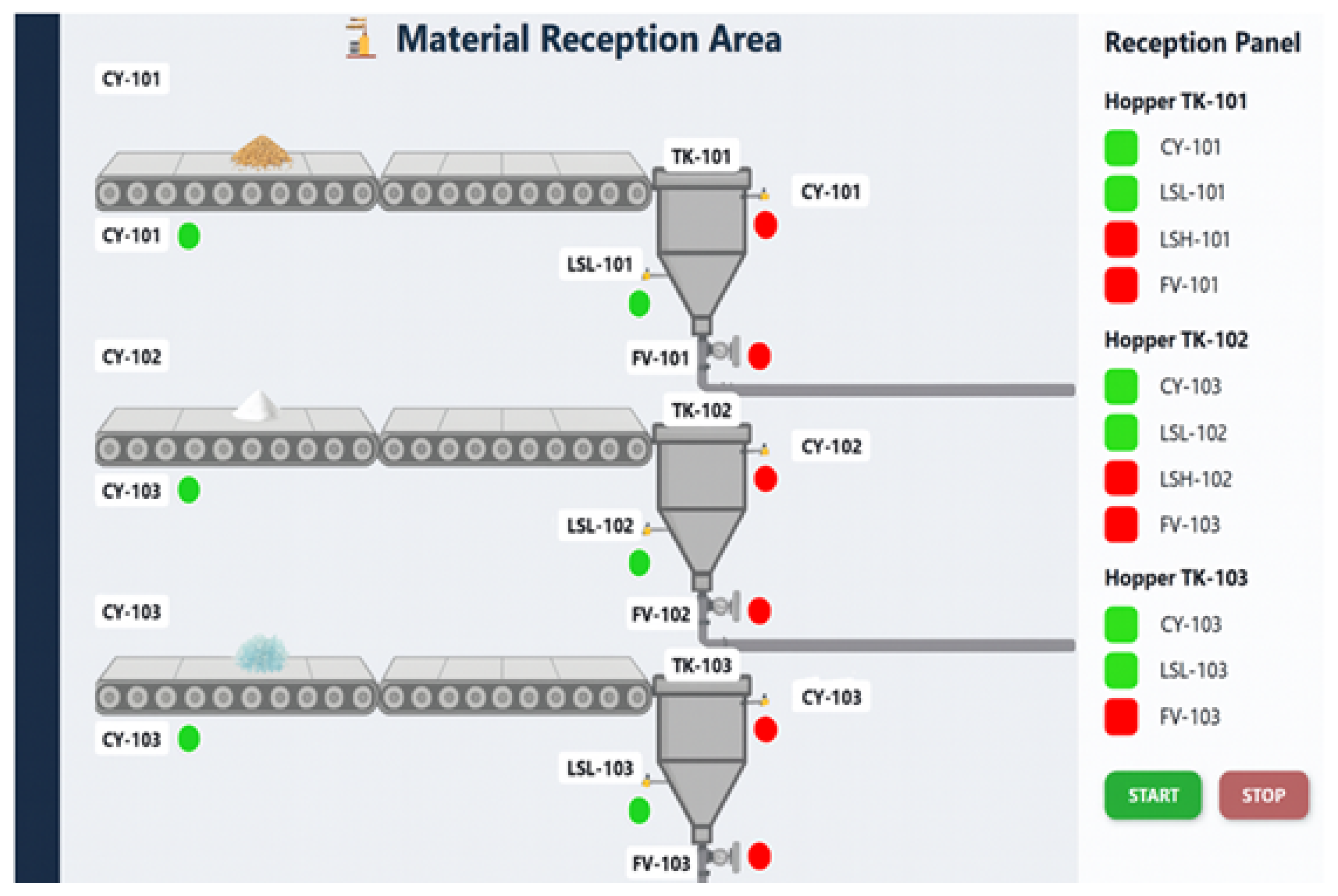

2.4. Human-Machine Interfaces (HMI)

- Local HMI: Developed in Control Expert, it provides direct access to PLC variables with animated views of each process stage and motor operation.

- Remote HMI: Implemented using React and Node.js, it mirrors the local interface and retrieves data from MySQL via REST APIs. Features include status indicators, real-time charts, and historical trends (Figure 6).

2.5. Comparison with Commercial Alternatives

- Ignition (Inductive Automation): A highly flexible commercial platform supporting OPC UA, Modbus TCP, and MQTT. While it offers full web integration and modular extensibility, licensing starts at approximately $1500, which may be restrictive for small deployments.

- AVEVA Citect SCADA: A robust commercial solution with WYSIWYG graphical tools and support for proprietary industrial protocols. It targets large-scale installations and involves significant licensing costs.

- ThingsBoard: A freemium/commercial platform focused on IoT applications, compatible with MQTT, Modbus TCP, and HTTP. It provides a customizable web interface, although the free version is limited to 30 devices.

- Eclipse NeoSCADA: An open-source Java-based project supporting OPC and Modbus protocols. While flexible, it requires advanced configuration and technical expertise for deployment.

- Karabo: A powerful open-source platform developed for scientific infrastructures. It supports AMQP and P2P TCP protocols but is primarily designed for research environments rather than industrial production lines.

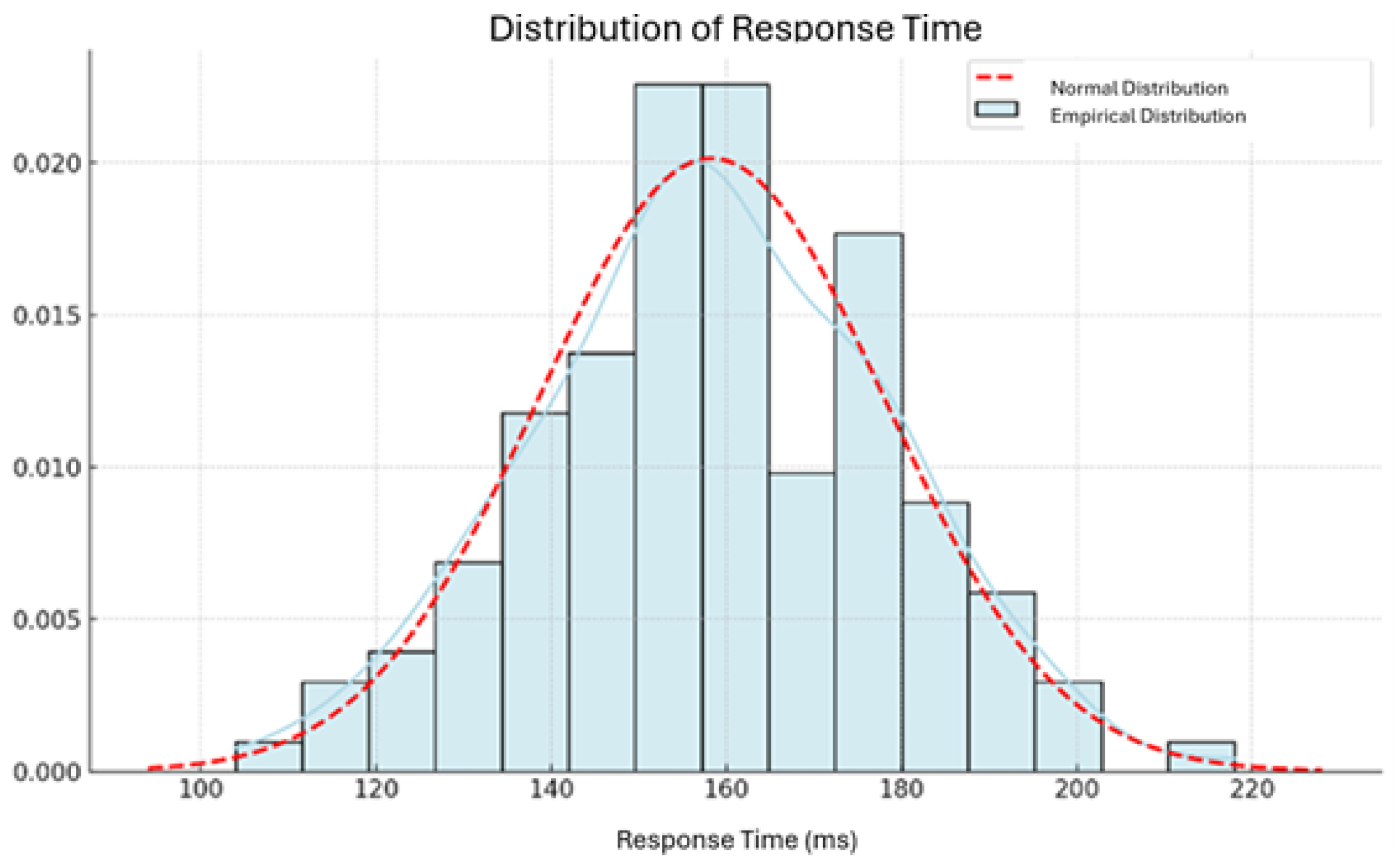

- Proposed solution: This work introduces a modular, open-source architecture combining Python, React, and MySQL. It enables synchronized local and remote supervision using Modbus TCP/IP but is adaptable to any industrial communication protocol. It achieves sub-200 ms latencies and is particularly suited for academic, prototyping, and SME scenarios without the need for commercial licenses.

3. Results and Discussion

3.1. System Integration and Real-Time Operation

3.2. Performance Evaluation and Synchronization Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tomar, B.; Kumar, N.; Sreejeth, M. Real Time Automation and Ratio Control Using PLC & SCADA in Industry 4.0. Comput. Syst. Sci. Eng. 2023, 45, 1495–1516. [Google Scholar] [CrossRef]

- Karabegović, I.; Karabegović, E.; Mahmić, M.; Husak, E. Implementation of Industry 4.0 and Industrial Robots in the Manufacturing Processes. In International Conference “New Technologies, Development and Application II”; Karabegović, I., Ed.; Springer: Cham, Switzerland, 2020; pp. 3–14. [Google Scholar]

- Wai, E.; Lee, C.K.M. Seamless Industry 4.0 Integration: A Multilayered Cyber-Security Framework for Resilient SCADA Deployments in CPPS. Appl. Sci. 2023, 13, 12008. [Google Scholar] [CrossRef]

- Méndez, R.A. Critical success factors for implementing Industry 4.0 in Latin American manufacturing pymes. In Proceedings of the Leadership in Education and Innovation in Engineering in the Framework of Global Transformations: Integration and Alliances for Integral Development, Buenos Aires, Argentina, July 19–21 2023. Conference Paper #841. [Google Scholar]

- Chacón-Ramírez, E.A.; Cardillo-Albarrán, J.J.; Uribe-Hernández, J. Industry 4.0 in Latin America: A roadmap for its implementation. Rev. Ingenio 2020, 17, 28–35. [Google Scholar] [CrossRef]

- Kumar, V.; Jondhale, Y.; Phasale, Y.; Tambe, V.; Sodnar, K. Remote Monitoring and Controlling Electrical Devices for Industrial Application. Int. J. Res. Appl. Sci. Eng. Technol. (IJRASET) 2023, 11, 3666–3672. [Google Scholar] [CrossRef]

- T, A. Industrial Monitoring System. Int. J. Adv. Res. Sci. Commun. Technol. (IJARSCT) 2024, 4, 372–376. [Google Scholar] [CrossRef]

- Karemore, P.; Jagtap, P.P. A Review of IoT Based Smart Industrial System for Controlling and Monitoring. In Proceedings of the 2020 Fourth International Conference on Computing Methodologies and Communication (ICCMC), Erode, India, 11–13 March 2020; pp. 67–69. [Google Scholar] [CrossRef]

- Li, Q.; Yang, Y.; Jiang, P. Remote Monitoring and Maintenance for Equipment and Production Lines on Industrial Internet: A Literature Review. Machines 2023, 11, 12. [Google Scholar] [CrossRef]

- Gupta, B.K.; Rastogi, V. Integration of technology to access the manufacturing plant via remote access system—A part of Industry 4.0. Mater. Today: Proc. 2022, 56, 3497–3505. [Google Scholar] [CrossRef]

- Aghenta, L.O.; Iqbal, M.T. Low-Cost, Open Source IoT-Based SCADA System Design Using Thinger.IO and ESP32 Thing. Electronics 2019, 8, 822. [Google Scholar] [CrossRef]

- Aghenta, L.O.; Iqbal, M.T. Design and implementation of a low-cost, open source IoT-based SCADA system using ESP32 with OLED, ThingsBoard and MQTT protocol. AIMS Electron. Electr. Eng. 2020, 4, 57–86. [Google Scholar] [CrossRef]

- Augello, A.; Gallo, P.; Sanseverino, E.R.; Sciumè, G.; Tornatore, M. A Coexistence Analysis of Blockchain, SCADA Systems, and OpenADR for Energy Services Provision. IEEE Access 2022, 10, 99088–99101. [Google Scholar] [CrossRef]

- Akhtar, T.; Gupta, B.B. Analysing smart power grid against different cyber attacks on SCADA system. Int. J. Inf. Comput. Secur. 2021, 16, 195–205. [Google Scholar] [CrossRef]

- Tartici, I.; Kilic, Z.M.; Bartolo, P. A Systematic Literature Review: Industry 4.0 Based Monitoring and Control Systems in Additive Manufacturing. Machines 2023, 11, 712. [Google Scholar] [CrossRef]

- Ansari, K.B.M.U. An Analysis and Study on SCADA. Int. J. Adv. Res. Electr. Electron. Instrum. Eng. (IJAREEIE) 2020, 9, 871–874. [Google Scholar]

- Chen, X.; Zhou, Y. Open-Source Collaboration and Technological Innovation in the Industrial Software Industry: A Multi-Case Study. Systems 2025, 13, 433. [Google Scholar] [CrossRef]

- Campos, J.; Sharma, P.; Albano, M.; Ferreira, L.L.; Larrañaga, M. An Open Source Framework Approach to Support Condition Monitoring and Maintenance. Appl. Sci. 2020, 10, 6360. [Google Scholar] [CrossRef]

- Minchala, L.I.; Peralta, J.; Mata-Quevedo, P.; Rojas, J. An Approach to Industrial Automation Based on Low-Cost Embedded Platforms and Open Software. Appl. Sci. 2020, 10, 4696. [Google Scholar] [CrossRef]

- Phansalkar, A. Open-Source Software Challenges and Opportunities. Data Manag. Anal. Innov. 2020, 1, 33–42. [Google Scholar]

- Martikkala, A.; David, J.; Lobov, A.; Lanz, M.; Ituarte, I.F. Trends for Low-Cost and Open-Source IoT Solutions Development for Industry 4.0. Procedia Manuf. 2021, 55, 298–305. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Villamar, R.; Proaño, P.; Cuenca Sánchez, A.; Tipan, J.; Pillajo, R.; Quito Carrión, A. An Open-Source Web-Based Approach to Industrial Supervision and Data Acquisition in the Context of Industry 4.0. Eng. Proc. 2025, 115, 23. https://doi.org/10.3390/engproc2025115023

Villamar R, Proaño P, Cuenca Sánchez A, Tipan J, Pillajo R, Quito Carrión A. An Open-Source Web-Based Approach to Industrial Supervision and Data Acquisition in the Context of Industry 4.0. Engineering Proceedings. 2025; 115(1):23. https://doi.org/10.3390/engproc2025115023

Chicago/Turabian StyleVillamar, Rodney, Pablo Proaño, Alan Cuenca Sánchez, James Tipan, Ronald Pillajo, and Angélica Quito Carrión. 2025. "An Open-Source Web-Based Approach to Industrial Supervision and Data Acquisition in the Context of Industry 4.0" Engineering Proceedings 115, no. 1: 23. https://doi.org/10.3390/engproc2025115023

APA StyleVillamar, R., Proaño, P., Cuenca Sánchez, A., Tipan, J., Pillajo, R., & Quito Carrión, A. (2025). An Open-Source Web-Based Approach to Industrial Supervision and Data Acquisition in the Context of Industry 4.0. Engineering Proceedings, 115(1), 23. https://doi.org/10.3390/engproc2025115023