1. Introduction

There are various types of metals and non-metals used in different industries. The various types of metals used are iron, steel, copper, brass, titanium lead, aluminum, and more. Different metals have unique properties and are selected according to their application. However, aluminum is widely used due to its excellent mechanical properties, corrosion resistance, good machinability, and recyclability. It is particularly important in applications such as automotive, aerospace, and structural components. By machining this material, we can achieve the high quality of holes, which increases the product quality, surface roughness (Ra), and material removal rate (MRR). Ra is crucial because it determines both the product’s quality and its esthetic appeal. In traditional machining processes, coolant is used to reduce the heat generated, which increases efficiency and reduces tool wear. However, the cost of coolant has increased, and coolant is harmful to both humans and the environment. To make machining processes sustainable, dry machining has been used more in industry. It is eco-friendly and also cost-saving. We will study the effect of dry machining on the Ra and MRR of Al6061, compared to machining with lubricants. This comparison will help evaluate whether dry machining can achieve similar or better performance in terms of surface quality and productivity. Recently, there has been a rise in nature-inspired optimization techniques, such as swarm optimization, which significantly boosts machining efficiency. These approaches are great for picking the best cutting parameters, which in turn improves Ra and the MRR. In this study, we dive into particle swarm optimization (PSO) to find the ideal machining conditions for the Al6061 alloy.

2. Literature Review

In this study, we consider machining parameters, Ra, MRR, and the tool materials typically used in the dry machining and wet machining of Al6061, with references to previous studies. In machining processes, the choice of parameters like cutting speed, feed rate, depth of cut, tool material, and tool geometry is of prime importance in controlling surface roughness and the material removal rate (MRR), especially when making a comparison between dry and wet machining. Lower cutting speeds ranging from 60 to 120 m/min are used in dry machining conditions where heat generation must be controlled due to the lack of coolants. Conversely, wet machining permits faster cutting speeds, normally as high as 180 m/min or greater, due to successful heat dissipation by coolants. One study concluded that dry machining tends to produce higher surface roughness values (Ra, Rz, Rq) and a lower MRR, whereas wet machining enhances surface finish as well as productivity [

1,

2].

Feed rate is also a determining factor. Feed rates in dry machining are generally in the range of 0.05 to 0.3 mm/rev, and a rise in feed rate tends to produce a rougher surface. Wet machining, however, can better handle larger feed rates (0.1 to 0.3 mm/rev) due to enhanced lubrication and cooling, which preserve surface integrity [

3,

4,

5]. Studies proved that even though higher feed rates could increase the MRR, they could also worsen the surface finish if not well regulated. The depth of cut also affects roughness and productivity in the same manner. Dry machining tends to use smaller cuts (0.5 to 2 mm) to avoid the buildup of heat, while wet machining can use higher cuts (1 to 4 mm) since coolant is available [

3,

4,

5]. In [

6], the authors note that a larger depth of cut in wet machining increases the MRR, but if it is too large, it can have a negative impact on the surface finish. Material selection for the tool has a strong influence on the machining results. Dry machining utilizes heat-resistant materials such as carbide, ceramic, or cermet tools, although these become worn out quicker because of increased friction. Wet machining utilizes materials such as HSS, carbide, or coated carbide with the advantage of lower friction and better life for tools. In [

7,

8], it was established that dry machining resulted in increased tool wear and surface roughness, while the use of coolants in wet machining improved tool life and produced higher surface quality. Finally, the geometry of the tool, such as parameters like rake angle and edge sharpness, plays a significant role, particularly in dry machining where there is greater friction. High rake angle and sharp edge tools reduce heat and increase the surface finish in dry machining. At the same time, geometries optimized for coolant-controlled cutting in wet machining provide greater surface quality and MRR [

7,

8]. Tool wear and geometry influence surface roughness to a greater extent in dry machining, as demonstrated by [

9], whereas wet machining provides more tolerance in terms of cooling and lubrication [

9]. Pavement roughness (IRI) in Laos was predicted using the Adaptive Neuro-Fuzzy Inference System (ANFIS) [

10]. Fourteen years of data was used to create two models for DBST and AC roads. Compared to conventional regression techniques, ANFIS demonstrated superior prediction accuracy, focusing on using Response Surface Methodology (RSM) and particle swarm optimization (PSO) to optimize face milling parameters for AA6061 [

11,

12]. PSO seeks to reduce power consumption, cutting force, and surface roughness. The findings demonstrate that PSO performs more accurately and efficiently than conventional desirability techniques. The authors of [

13,

14,

15,

16,

17,

18] predicted the MRR and SR in the wire-cut EDM of Al7075 with 9% activated carbon by comparing GRNN, SVR, and RVM models. The authors of [

7,

8] reviewed recent developments in cutting tool life modeling and monitoring with an emphasis on increasing manufacturing cost-effectiveness and efficiency. They examined different wear mechanisms as well as conventional and contemporary tool life models [

15,

16]. Future directions for tool performance prediction are highlighted in this study, including adaptive self-learning systems and hybrid modeling approaches. Dry machining generally results in higher Ra values (Ra, Rz, Rq) due to increased friction, heat, and tool wear. Lower CSs (cutting speeds), IPM (feed rates), and DOCs (depths of cuts) are often used to mitigate these issues. Wet machining significantly improves surface finish and tool life due to the cooling and lubrication effects of the coolant. Higher cutting speeds, feed rates, and depths of cut are achievable without compromising surface quality, resulting in a higher MRR.

3. Methodology

In terms of the mechanical properties of Al6061, it is a lightweight yet strong aluminum alloy with a density of 2.7 g/cm3. It has a tensile strength of 310 MPa and yield strength of 276 MPa, making it suitable for structural applications. The alloy exhibits a Brinell hardness of 95 HB, ensuring wear resistance. It has a modulus of elasticity of 68.9 GPa, providing good stiffness and resistance to deformation. With an elongation of 12%, it maintains a balance between strength and ductility. Its thermal conductivity of 167 W/m·K allows for efficient heat dissipation, making it ideal for heat-sensitive applications. The chemical composition of Al6061 includes aluminum (95.8–98.6%), along with magnesium (0.8–1.2%) and silicon (0.4–0.8%), which improve strength and corrosion resistance. Copper (0.15–0.4%) enhances hardness, while chromium (0.04–0.35%) improves wear resistance. Small amounts of iron, zinc, manganese, and titanium refine the grain structure and enhance machinability. The alloy is heat-treatable, allowing for further strengthening through the T6 tempering process. The Taguchi Orthogonal Array (OA) method is a design of experiments (DOE) technique used for improving processes by minimizing the number of experiments while ensuring reliable results. It was developed by Dr. Genichi Taguchi and is widely applied in manufacturing, machining, and engineering optimization. The authors of studied PSO as a population-based metaheuristic technique motivated by the collective social behavior of birds flocking or fish schooling. PSO has found extensive use in solving continuous optimization problems based on its ease, efficiency, and speed. Each particle in PSO is a potential solution in the search space that shifts according to its own best experience and the swarm’s best-known position. There are some limitations of the current research on the use of PSO in the machining of Al 6061. Most studies have been performed on the base alloy, and there are fewer on the composites that act differently during machining. Adaptive, real-time optimization is hardly covered, and these studies are mostly conducted offline. The goal of multi-objective optimization can be reduced to a single metric instead of investigating compromises between other factors such as surface finish, tool wear, and energy consumption. Unorthodox and hybrid processes (such as ultrasonic-assisted, cryogenic, EDM, and laser-assisted processes) are also still underdeveloped as well. Additionally, there are few comparative studies of PSO against other algorithms in fair terms; experimentation tends to have weak and small-scale validation. These gaps include those in composite machining, real-time applications, true multi-objective approaches, unconventional machining, more rigorous benchmarks, and more rigorous experiments. Overall, mathematical formulas based on inertia, cognition, and social factors are used to alliteratively update each particle’s position and velocity. In order to decrease Ra and increase the MRR in the machining of Al6061, PSO is used in this study to optimize CNC turning parameters, such as cutting speed, feed rate, and depth of cut. The algorithm searches for the ideal parameter combination that offers the best balance between quality and productivity. The PSO parameters used in this study were selected based on literature standards and improved through testing to produce reliable results.

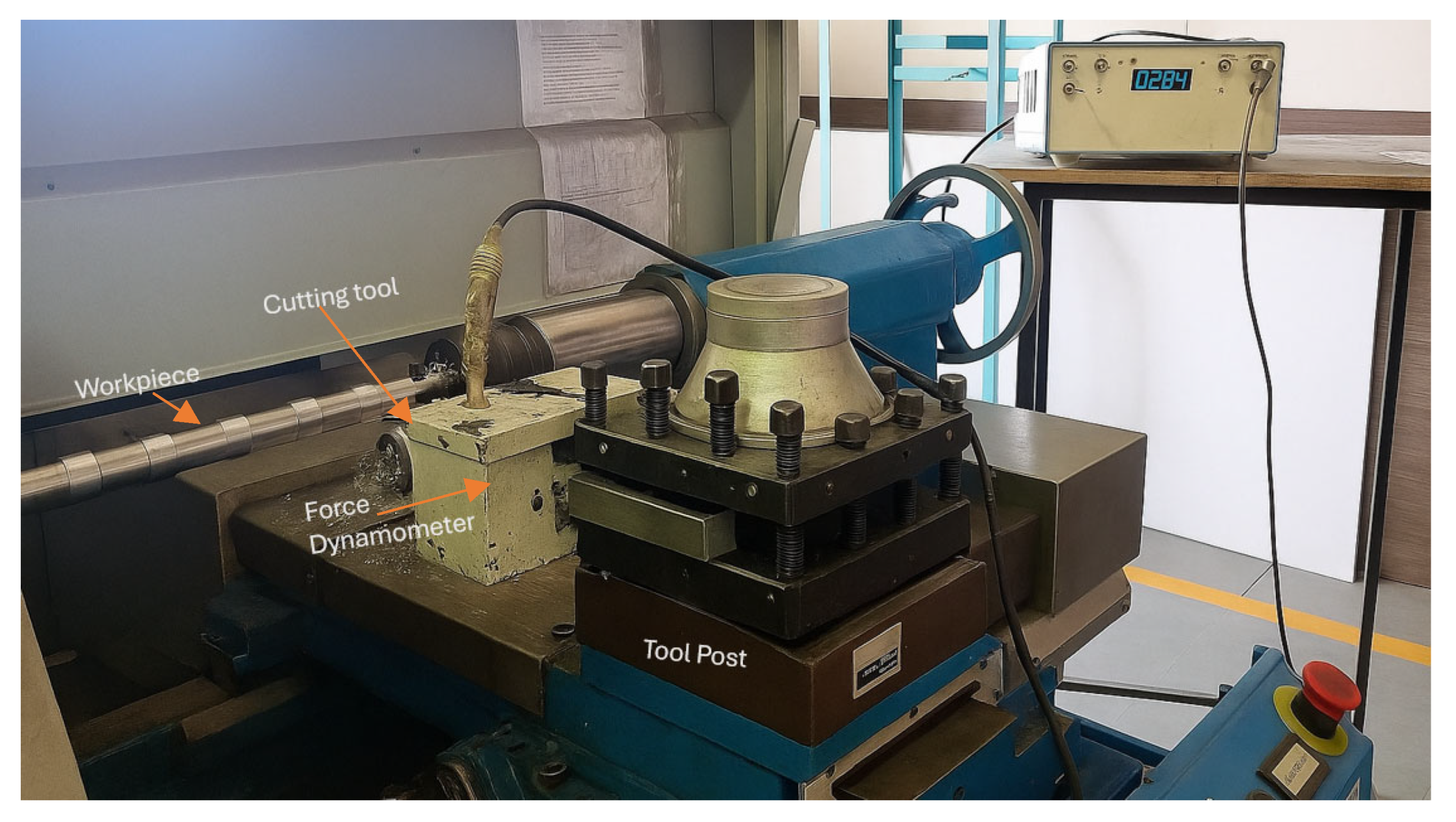

Figure 1 dry machining was performed on a 30 mm diameter and 450 mm long bar, and wet machining was performed on a 30 mm diameter and 240 mm long bar. In each case, 25 readings were taken. The input parameters taken into consideration while machining were spindle speed (RPM) with values of 600, 900, 1200, 1500, and 1800; feed rate with values of 0.25, 0.2, 0.15, 0.1, and 0.05 mm/rev; and depth of cut fixed at 2.5, 2, 1.5, 1, and 0.5 mm.

The output parameters that were quantified included the arithmetic average Ra and MRR. Increasing the RPM (increasing the spindle speed), feed rate (IPM), and depth of cut (DOC) was found to result in an increased MRR. At the same time, however, it caused higher heat generation, faster tool wear, and increased machining instability. It was thus important to balance these parameters to ensure optimum productivity without jeopardizing machining quality.

In wet machining, a coolant composed of a mixture of water and cutting oil was employed. The coolant minimizes cutting temperature and enhances the surface finish. In both dry and wet machining, a digital tool dynamometer was used to record the cutting forces. Three kinds of cutting forces were recorded by the dynamometer: thrust, feed, and radial. These forces showed varying (positive and negative) values with variations in RPM, IPM, and DOC. Chip thickness was found to change with DOC. As the DOC decreased, the chips thinned, and the radial forces decreased.

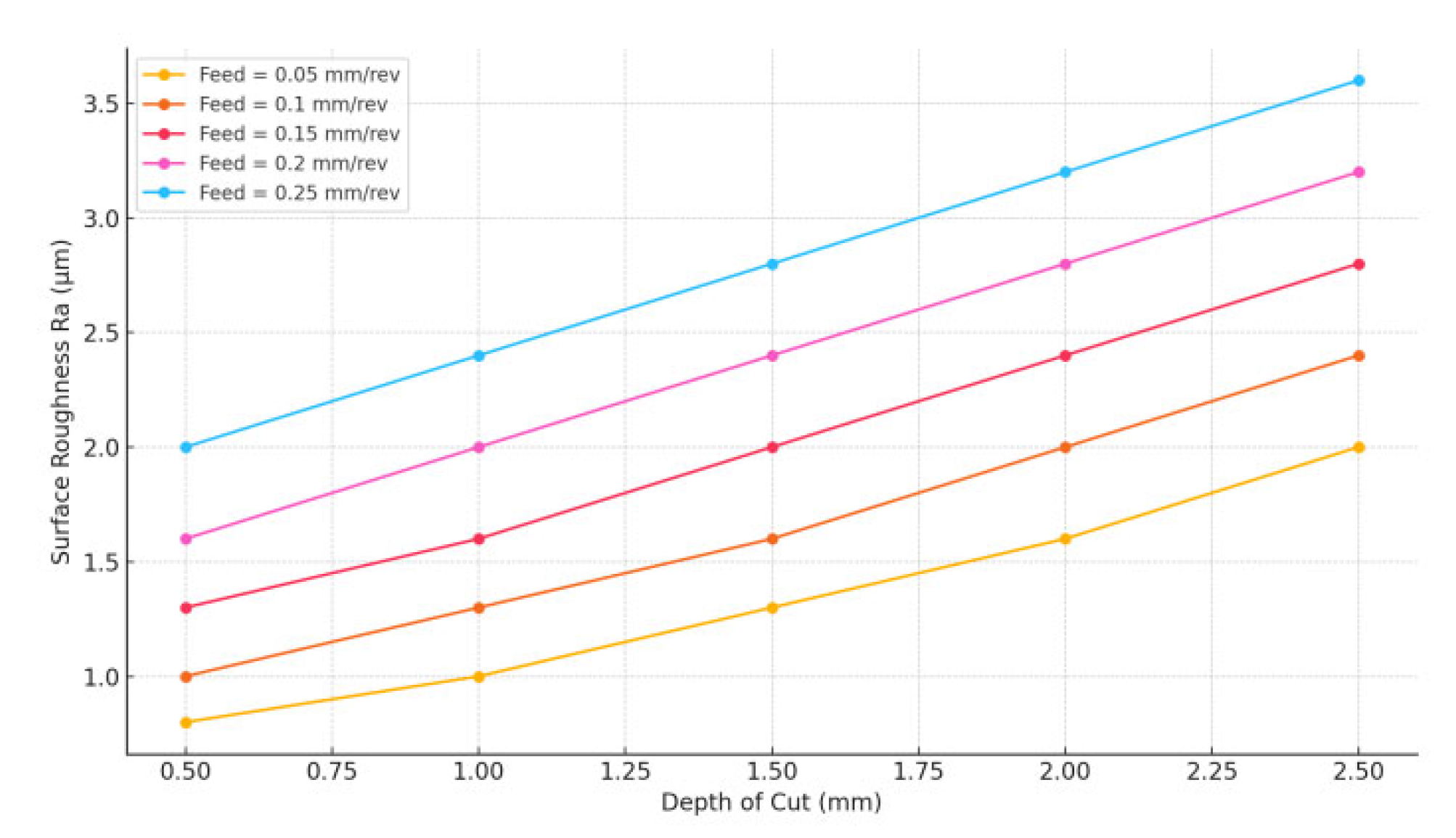

In dry machining, Ra increases the DOC for different feed rates, as shown in

Figure 2. In dry machining at higher IPM, the roughness increases more sharply, and the surface finish tends to worsen as both feed and depth increase.

In the wet machining graph, lines (solid) are consistently lower than dry machining lines (dashed), as shown in

Figure 3. This indicates better surface finish under wet conditions due to reduced depth of cut. The graph shows a general comparison between dry machining and wet machining.

The minimum resultant force in dry machining (13.58 N) was achieved at 600 RPM, 0.05 mm/rev feed, and a 0.5 mm depth of cut due to the alignment of minimal mechanical and thermal loads. The minimum spindle speed limits heat generation, whereas the minimum feed rate and low depth of cut reduce the tool’s engagement with the material, thus leading to cutting resistance. These conditions produce finer chips and minimize interface friction. Even in the absence of a coolant, the conservative parameters ensure tool stability and minimize wear, as shown in

Table 1. This equilibrium results in very small cutting forces. PSO efficiently determined this set as optimal by assessing trade-offs between force, tool life, and machining stability.

The optimal reading for wet machining with the lowest resultant force of 11.57 N was obtained at 600 RPM, 0.05 mm/rev feed, and a 0.5 mm depth of cut based on several factors. Low spindle speed minimizes the generation of heat, and a low depth of cut with slight feed maintains lower material engagement and cutting resistance. The coolant is an important element that reduces friction and efficiently distributes the available heat generated, leading to easier cutting and improved evacuation of chips. These conditions produce even, thin chips and prevent tool overload, as shown in

Table 2. In conclusion, the PSO algorithm effectively selected this set of parameters as optimal by analyzing the influence of the machining parameters and coolant on reducing force while ensuring machining stability.

4. Results and Discussion

4.1. Dry Machining

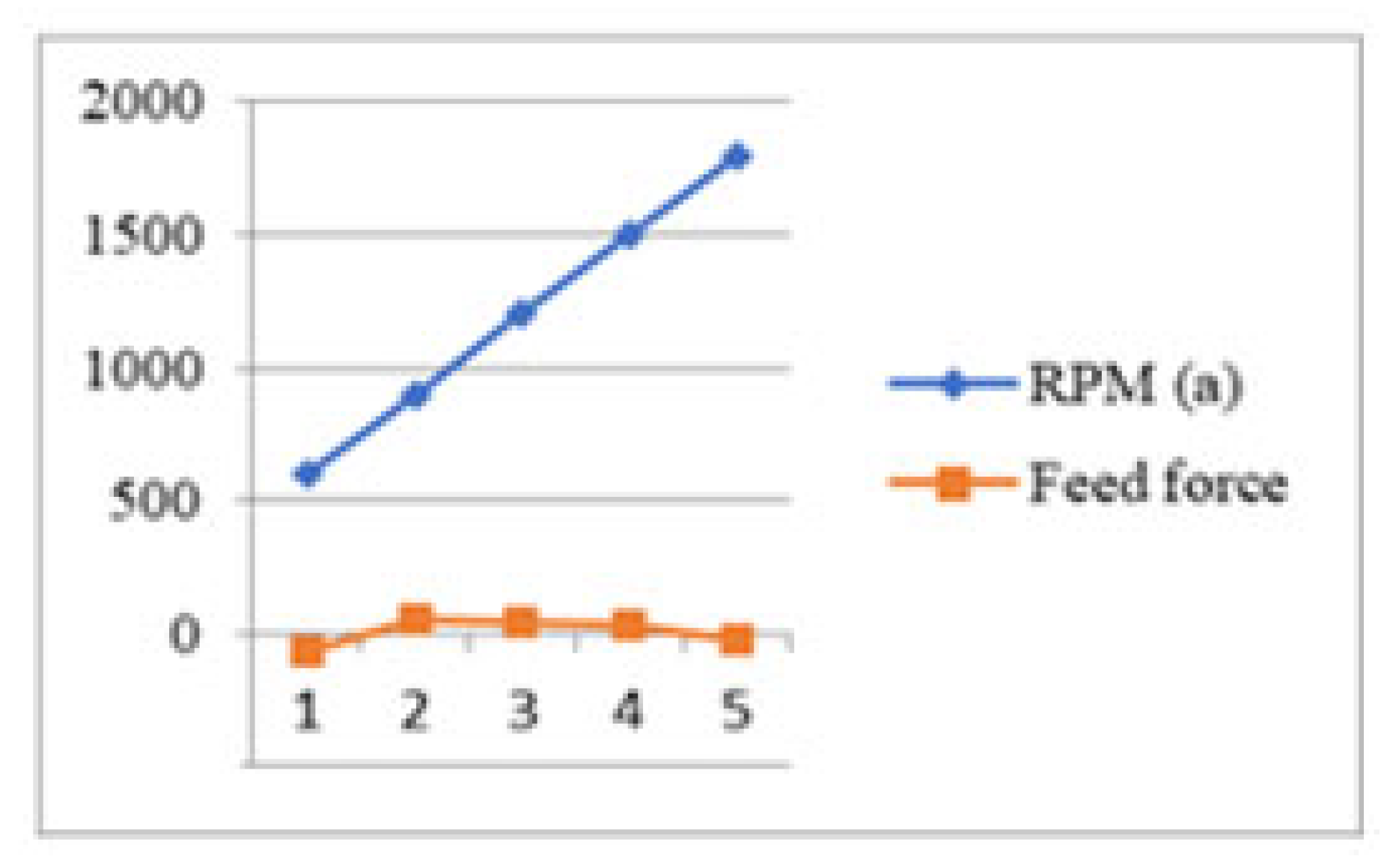

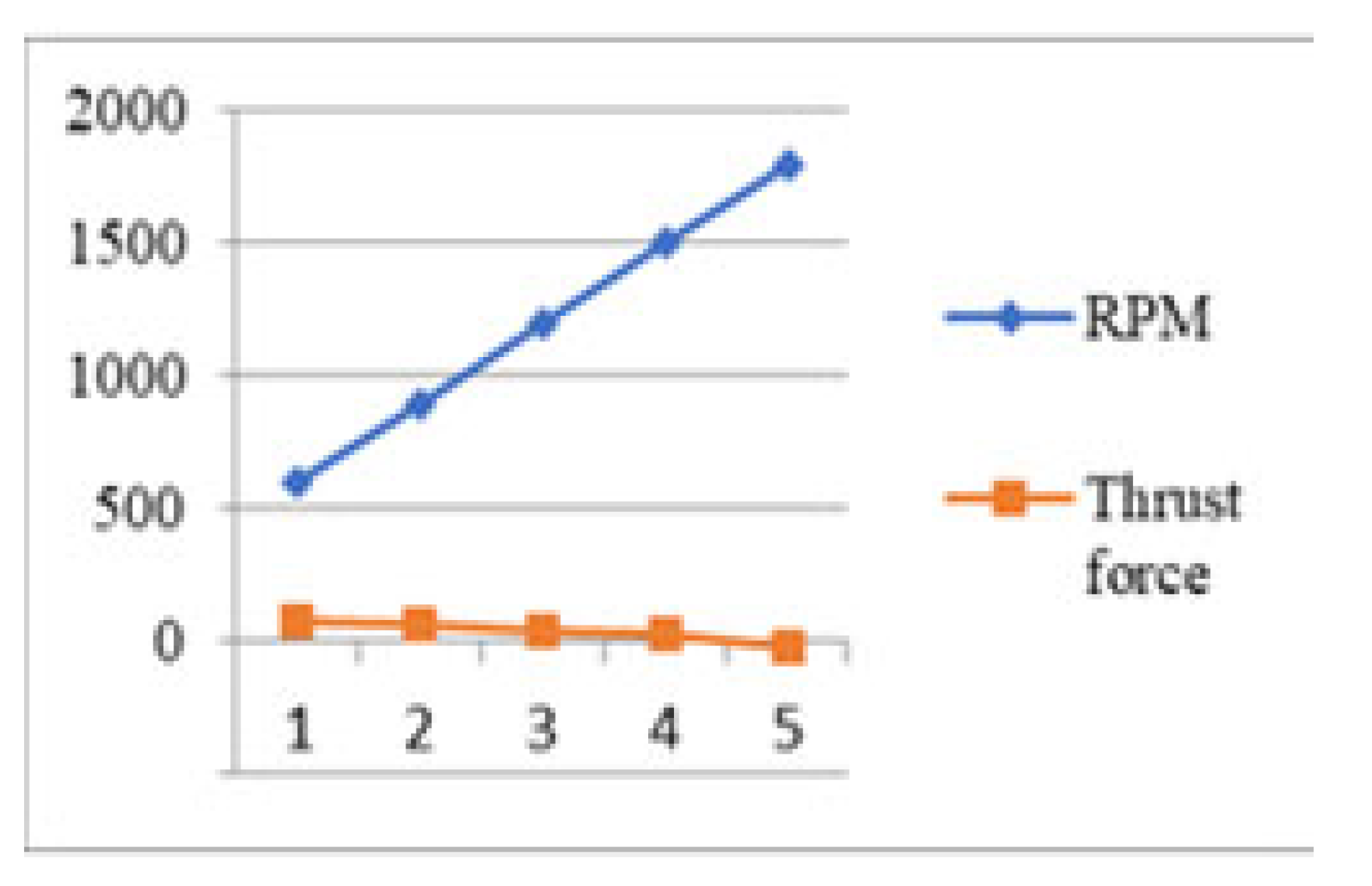

The above graph (

Figure 4) shows the thrust force as a function of spindle speed (RPM) for each of the five experiments. The blue line shows the steady incremental increase in spindle speed between 600 RPM and 1800 RPM max, as was performed for each of the five trials. The thrust force is shown as a decreasing orange curve from a small positive value to about −100 at the end of the final trial. This implies that spindle speed and thrust force are inversely related, i.e., a lower thrust force is experienced when higher spindle speeds are used in machining.

The above graph (

Figure 5) shows the RPM and feed force in the five trials. So, in this case, the spindle speed starts at around 600 RPM and goes to about 1800 RPM in the first five trials, as denoted by the blue graph. In contrast, the feed force (orange) is very different. The RPM (in blue) is nearly stationary (with small positive and negative fluctuations around the center value near zero) with respect to the orange curve. This indicates that in all trials, feed force does not change much even though spindle speed increases a lot, suggesting that the overall feed force is insensitive to spindle speed within the experimental framework.

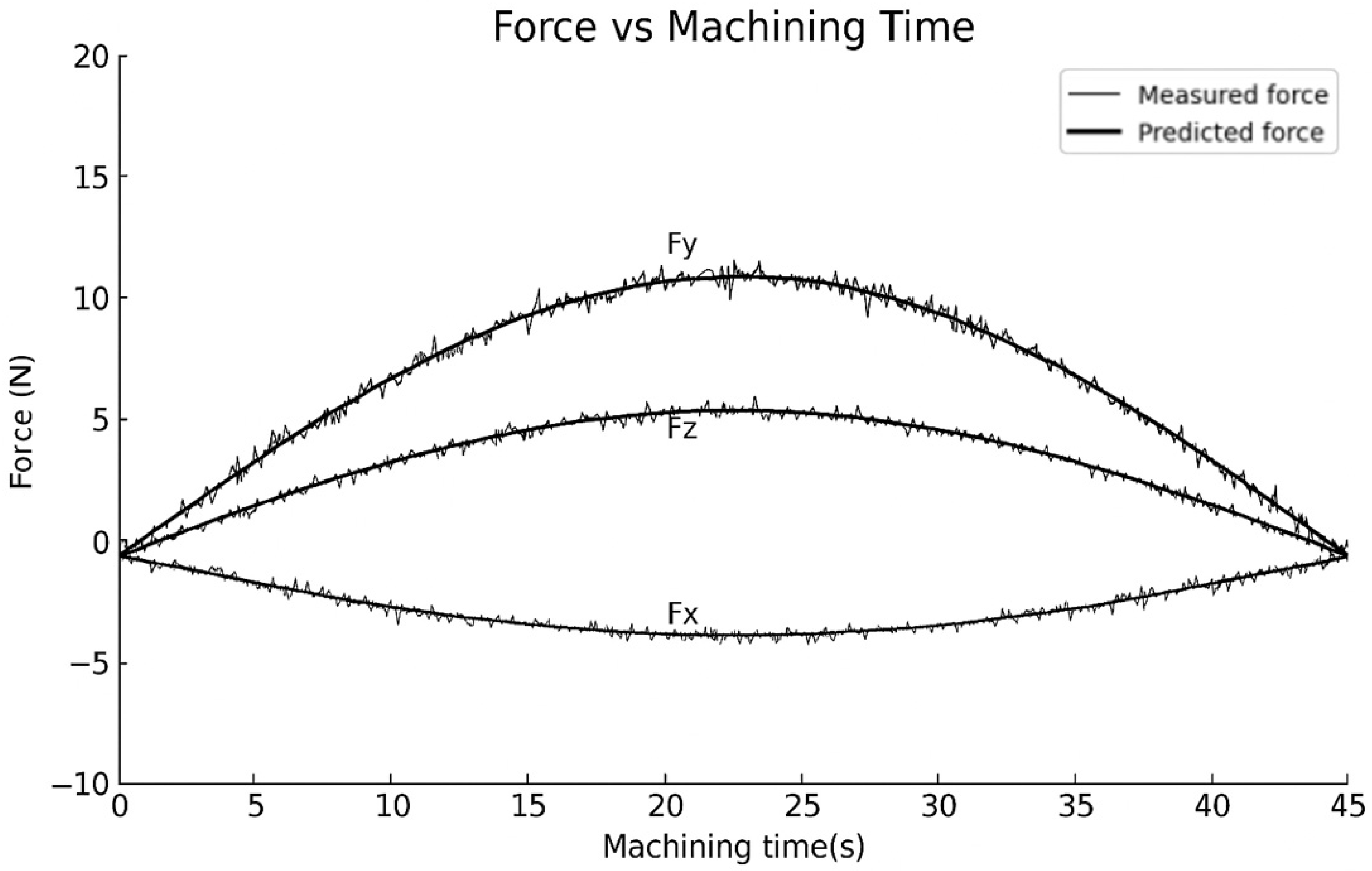

Figure 6 illustrates force components (Fx, Fy, Fz) against machining time (seconds). The forces increase first, reach a peak at 20–25 s, and symmetrically decrease afterward, creating a parabolic pattern. Three force components are graphed: Fy (highest peak ~16 N), Fz (middle ~9 N), and Fx (negative, ~–5 N). Both experiment and calculated forces are graphed, with a tight overlap, which reflects a good model fit. The machining operation takes approximately 45 s, and all forces come close to returning to zero at the end.

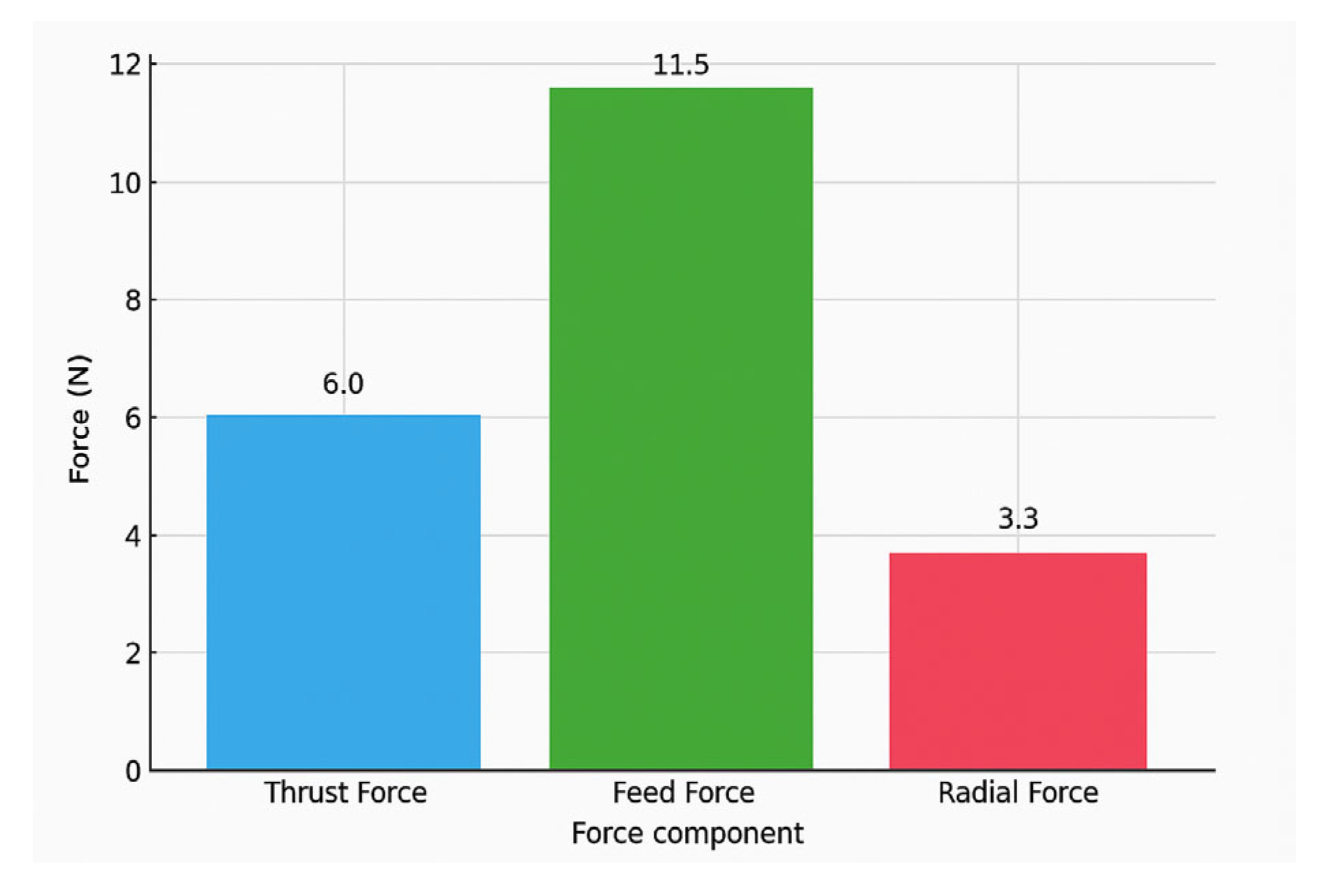

Figure 7 displays the various force components in the machining process. The

Y-axis indicates the force in Newtons, while the

X-axis shows the type of force: thrust, feed, or radial. The feed force is the highest at 11.5 N, followed by the thrust force at 6.0 N. The radial force is the lowest at 3.3 N. This comparison helps in assessing tool performance and improving machining parameters.

4.2. Wet Machining

Figure 8 presents the variation in RPM and thrust force under five different test conditions. The blue diamond line is for RPM, which rises continuously from about 600 to 1800. The red line with squares represents thrust force, which reduces slowly over the same conditions. Though RPM remains in a linear ascending trend, thrust force demonstrates a minor declining trend. This implies that with an increase in RPM, the thrust force reduces, indicating an inverse proportion.

Figure 9 compares RPM and feed force under five test conditions. The blue diamond line indicates that RPM rises linearly from roughly 600 up to 1800. The square orange line represents the feed force, which increases first, reaches its peak at point 3, and decreases afterwards. RPM and feed force show opposite trends after point 3, which may reflect the effect of RPM on reducing feed force. Generally, as RPM increases, feed force increases slightly at first, then decreases, indicating a nonlinear relationship.

Figure 10 shows the change in RPM and radial force in five test conditions. The blue diamond line shows a linear, constant rise in RPM from approximately 600 to 1800. The orange line with squares is representative of radial force, varying a little but staying close to zero. Unlike RPM, radial force shows no clear increasing or decreasing trend, indicating stability. In general, as the RPM rises considerably, the radial force is almost constant with little variation.

Figure 11 illustrates the dynamic behavior of cutting forces (Fx, Fy, Fz) versus machining time, with a comparison between calculated and measured values. Fy (the maximum force) rises slightly until about 15 s and then slowly returns, reaching a peak close to 12 N. Fz is almost unchanged at 5 N with little variation during machining. Fx, the minimum force, varies slightly around −5 N, being relatively stable over time. The narrow overlap of measured and calculated force lines reflects high prediction precision by the model.

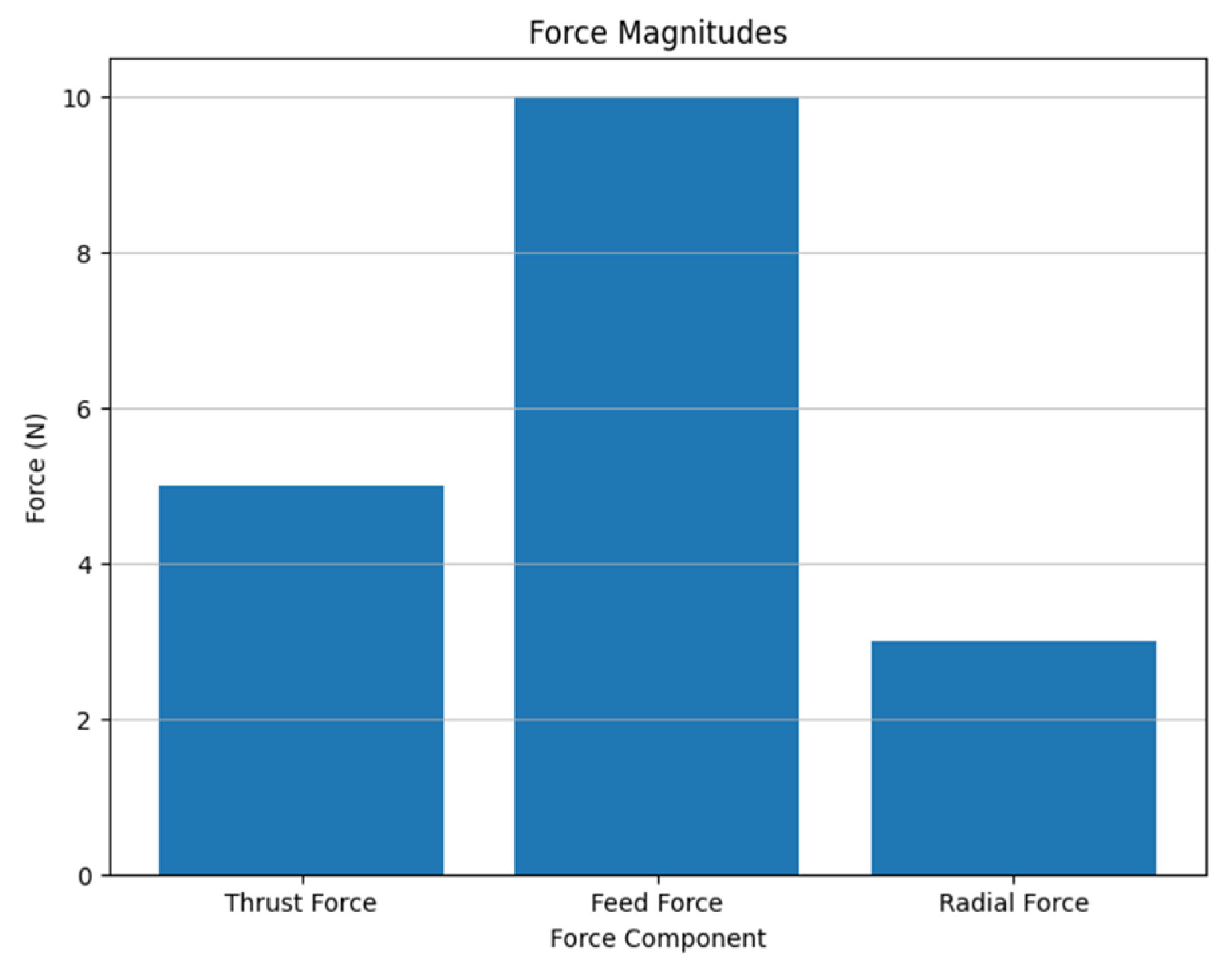

Figure 12 shows the magnitudes of three machining force components: thrust, feed, and radial forces. Feed force is the largest, with a value of 10 N. Thrust force has a medium value of approximately 5 N, whereas radial force is the smallest with a value of approximately 3 N. It is very clear from the graph that feed force overwhelms the distribution of forces in machining.

The total resultant force (RF) may be determined from the following formula:

This adds all three force terms into one magnitude.

Dry Machining: Ra rises with the DOC and IPM. At a 0.05 mm/rev feed rate, Ra rises by ~200% when the DOC increases from 0.5 mm to 2.5 mm. This effect is more pronounced at higher IPM. Wet Machining: The same trend is seen but with lower Ra values. At 0.05 mm/rev, Ra rises by ~67%, and at 0.25 mm/rev, it increases by ~30% for the same depth range. Comparison: Wet machining always yields improved surface finish, with a 22–25% decrease in Ra over dry machining under the same conditions.

The experimental findings based on turning show that spindle speed plays a major role in cutting forces. The thrust force and the feed force both diminish with a rise in RPM since the faster movement of the workpiece better enhances efficiency, and there are fewer changes in chip thickness in each revolution, which consequently reduces the force in the cutting and feed route. Radial force is low and varies around zero, which indicates good tool stability and the minimum lateral deflection. Regarding the machining time, forces are greater when the tool enters the workpiece, are at the highest during the mid-cut, and are symmetrically smaller as the operation of the tool reaches the end, in simple terms, forming a parabola pattern. The components of force, feed force, thrust force, and the lowest radial force show that the majority of the cutting power is used in moving the tool into the material, and this also implies that the lateral instabilities are at lower levels, which is a positive indication for dimensional accuracy and surface finish. Based on cutting force distribution with spindle speed, thrust force (Fz) depicts a downward trend with a rise in RPM due to effective chip ejection and minimal spindle contact between the tool and workpiece as a result of adding lubrication. Feed force (Fy) goes up a bit in the mid-RPM range and then levels off or decreases, indicating that feeding force is more smoothly assisted through lubrication. Radial force (Fx) is the lowest with little change, which is evidence that it has great radial stability and few vibrations. This behavior is further confirmed by examining cutting forces versus machining time when there is agreement in the predicted and measured forces. The force is the highest with feed force (~1012 N), intermediate with thrust force (6–7 N), and the smallest with radial force (−5 to −4 N) and shows uniform cutting performance with the minimum deflection of tools. Bar chart data support this trend: feed force (~10 N) is much higher than thrust (~5 N), then radial (~3 N), and this is to be expected when turning, as the chip flow directly opposes feed force. On the whole, wet machining involves cool and lubricating features, which lower the temperature on the tool–chip interface and lead to friction and the possible occurrence of a built-up edge (BUE), particularly in aluminum alloys such as Al6061. The fact that the thrust force decreased as the spindle speed was increased demonstrates the enhanced cutting performance, whereas the generated force profiles remained at the same level, which confirms that the tool wear was minimized. The overriding feed force justifies the necessity to adjust the tool geometry and feed rate to yet again increase the cutting efficiency when turning wet surfaces.