1. Introduction

The evolution of 3D printing in the last couple of decades and its impact on various industrial segments is remarkable [

1]. Nowadays, multiple 3D printing technologies are widely available. Among those, material extrusion (MEX)-based additive manufacturing (AM), also known as fused deposition modeling (FDM) or fused filament fabrication (FFF), is one of the most rapidly growing techniques [

2]. Products fabricated by MEX 3D printing can be applied in a great variety of fields, such as aerospace, automotive, defense, the medical industry, and architecture.

MEX gained popularity owing to its simplicity, low costs of operation and implementation, good efficiency, and high speed, which benefits greatly outweigh its inherent drawbacks [

3]. During the manufacturing process, MEX-based 3D printers use solid thermoplastic filaments that are first melted and extruded through a heated nozzle. Subsequently, the extruded strands, also denoted as beads, are deposited onto a build platform according to the design’s cross-section through the mechanical manipulation of the nozzle in the

x-y plane. Once the bead cools down, it solidifies and integrates with the neighboring beads. After a layer is completed, either the build platform moves vertically (

z-axis) or the nozzle is raised to start the next layer. This process is repeated until the top layer is finished and the product is complete [

4].

Considering the materials suitable for MEX manufacturing, the number of options is greatly limited by processing-related challenges. Thermoplastic polymers available to date include poly(lactic acid) (PLA) [

5], acrylonitrile butadiene styrene (ABS) [

6], glycol-modified poly(ethylene terephthalate) (PETG) [

7], polycarbonate (PC) [

8], and thermoplastic polyurethane (TPU) [

9,

10]. Recently, rising environmental awareness has made biodegradable polymers more attractive to scientific and industrial communities, which has also contributed to PLA becoming the number one choice. PLA has relatively high strength and stiffness compared to commodity plastics, making it an ideal material for rigid parts [

11]. For the MEX 3D printing of ductile objects, however, there is currently little to no environmentally viable option.

Poly(butylene adipate-

co-terephthalate) (PBAT), a biodegradable aliphatic polyester, has been identified as an environmentally friendly material for replacing ductile polymers in various fields, including packaging, agriculture, and the medical industry [

12]. PBAT exhibits properties comparable to those of low-density polyethylene (LDPE) due to its high molecular weight and branched molecular structure [

13]. On the other hand, its application in 3D printing remains quite challenging, partly because of its flexible nature paired with a smooth surface, which makes it prone to buckling and misalignment as it is being fed through the extruder. Furthermore, its intensive shrinkage during cooling can lead to warping and, consequently, delamination from the build platform. In order to address the aforementioned difficulties, recent studies have focused on pairing PBAT with secondary components, including other polymers and various fillers, to enhance its processability in MEX 3D printing. Given the excellent printability of PLA, multiple studies have been devoted to combining PBAT with PLA in order to achieve highly ductile, 3D-printable polymer blends. Most of the literature reports a maximum PBAT content of 40 wt.% in PLA/PBAT filaments designed for MEX 3D printing [

14,

15]. Beyond this level, the printing process becomes increasingly challenging, while the mechanical properties, such as tensile strength and modulus, decrease considerably.

The present study aims to investigate the potential of a PLA/PBAT blend containing 40 wt.% PBAT as a sustainable alternative to TPU for MEX 3D printing purposes, with a particular focus on ductile applications. Considering TPU’s well-known flexibility and toughness, the PLA/PBAT biopolymer blend is assessed for its ability to deliver comparable tensile mechanical properties, such as Young’s modulus, tensile strength, and elongation at break.

2. Materials and Methods

2.1. Materials

The TPU feedstock used in this study was a commercially available 3D Jake’s A95 filament (Niceshops GmbH, Paldau, Austria) with a diameter of 1.75 mm. Meanwhile, the PLA/PBAT filaments were directly fabricated from polymer pellets. PLA, obtained from NatureWorks (Minnetonka, MN, USA) under the trade name Ingeo 3052D, was used as the main component of the blend, and it was blended with PBAT (Ecoflex F blend C1200) purchased from BASF Chemical Company (Ludwigshafen, Germany).

2.2. Filament Fabrication

PLA/PBAT biopolymer blends were prepared using a co-rotating twin-screw extruder Labtech LTE 20–44 (Samut Prakarn, Thailand) with a screw diameter of 20 mm and a length-to-diameter ratio of 44. During the extrusion process, a temperature profile ranging from 155 to 185 °C was maintained in the ten barrel blocks (T1–T10 in

Table 1), while the die temperature was 185 °C. The screw speed was fixed at 30 rpm. The ratio of PLA and PBAT in the prepared blends was 60/40 by weight. After exiting the die, the extruded strands were cooled in a water bath Labtech LW-100 (Samut Prakarn, Thailand) before being granulated by a strand pelletizer Labtech LZ-120/VS (Samut Prakarn, Thailand).

The prepared PLA/PBAT blend was formed into filaments of 1.75 mm, suitable for MEX 3D printing using a 3devo Precision 450 maker system (Utrecht, The Netherlands). The barrel blocks, from feeder to die, were set to 170 °C, 190 °C, 185 °C, and 180 °C, and the rotational speed of the screw was 3.5 rpm.

2.3. Three-Dimensional Printing

Dumbbell-shaped specimens corresponding to the type 1BA according to ISO 527-2 [

16] were fabricated using a Craftbot Plus MEX-based 3D printer (Budapest, Hungary). The nozzle toolpath (G-code) was generated using the SuperSlicer software (version 2.5.59.13). The 3D printing process was conducted using a 0.4 mm nozzle. The specimens were prepared with 100% infill density, a nozzle temperature of 220 °C (PLA/PBAT) or 230 °C (TPU), and a build platform temperature of 60 °C. The layer height was 0.2 mm, the infill density was 100%, and one shell layer was applied, with its width being 0.8 mm. The specimens were 3D printed using three different infill raster angles: an infill parallel to the length of the specimen (0°), a grid-like infill alternately at an angle of ±45°, and an infill perpendicular to the length of the specimen (90°).

2.4. Characterization

Tensile tests were carried out on the fabricated specimens in accordance with the ISO 527 standard [

16]. The tests were performed using the universal testing machine Instron 5582 (Norwood, MA, USA) equipped with a 10 kN load cell at a general crosshead speed of 50 mm/min. Note that the initial speed until 0.3% elongation was 1 mm/min to determine Young’s modulus. All tests were carried out at room temperature, and four replicas were tested for each sample type.

The obtained results were statistically evaluated using one-way analysis of variance (ANOVA), and averages were compared using Tukey’s post hoc test with a 95% confidence level (p < 0.05) using the Minitab statistical software version 15 (State College, PA, USA).

3. Results and Discussion

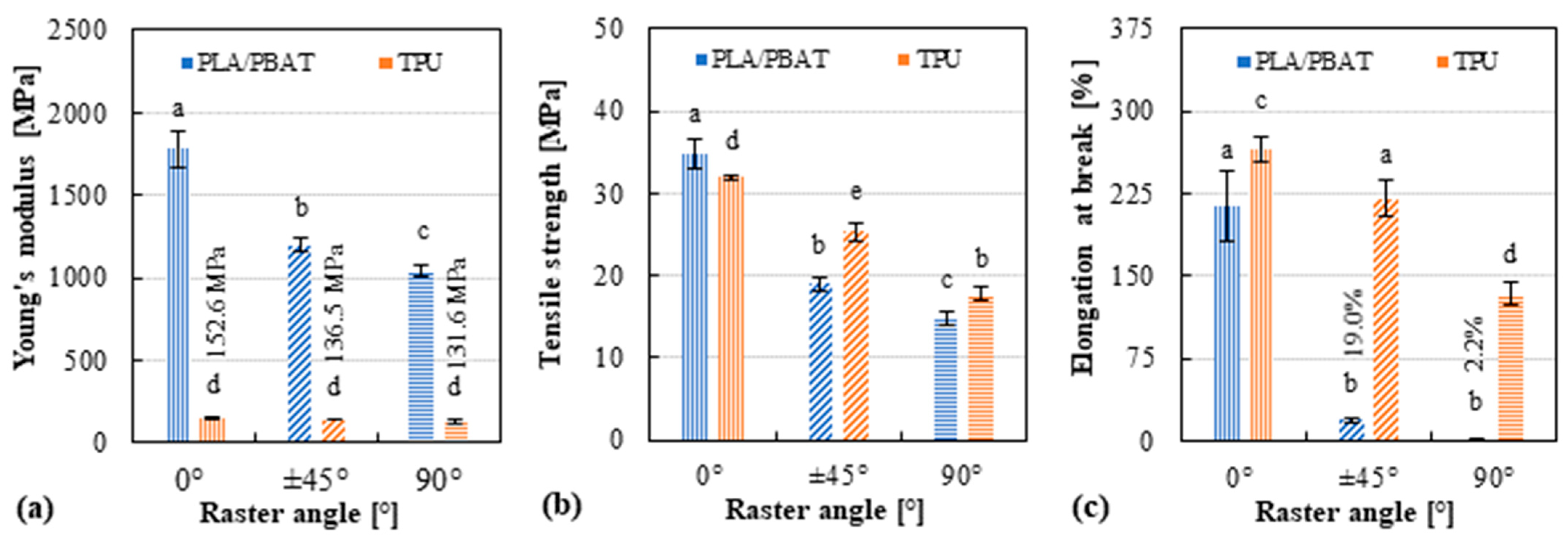

The tensile mechanical parameters, along with representative stress–strain curves, are presented in

Figure 1 and

Figure 2. As demonstrated in

Figure 1a, the Young’s modulus of both TPU and PLA/PBAT decreased with increasing infill raster angle. The high modulus observed for samples 3D-printed with a 0° raster orientation can be ascribed to the alignment of deposited beads with the direction of the tensile load, allowing them to directly carry the load and thereby maximize the stiffness. Meanwhile, by increasing the raster angle (to ±45° or 90°), more load is transferred through the inherently weaker inter-bead bonds. Note that PLA/PBAT blends have an order of magnitude higher modulus (average of 1342 MPa) compared to TPU (average of 140 MPa). This considerable difference in stiffness indicates that the two materials are expected to behave quite differently under small deformations, with TPU being much softer. The higher modulus of the PLA/PBAT blends occurs due to the presence of PLA, which is considerably more rigid than either TPU or PBAT. Without PLA, however, PBAT alone would be difficult to process by MEX 3D printing, as it was pointed out in the Introduction section. It is also worth mentioning that, according to the statistical analysis, PLA/PBAT suffered a substantial reduction in Young’s modulus (from 1783 MPa to 1046 MPa) with increasing raster angle, while TPU was less sensitive to raster orientation, dropping only from 153 MPa to 132 MPa.

Considering the tensile strength (

Figure 1b), the examined materials performed more similarly. At 0° raster angle, PLA/PBAT and TPU exhibited strengths of 34.8 MPa and 31.9 MPa, respectively, showing a relative difference of less than 10%. Increasing the raster angle, however, led to a decrease in tensile strength for both materials due to the growing contribution of the weak inter-bead bonds, which is consistent with the available literature [

17]. As more of the load is transferred through the interfaces, stress concentration and shear deformation occur, rather than uniform axial stretching, which promotes the formation of cracks and ultimately results in premature failure. Accordingly, at a 90° raster angle, the tensile strength of PLA/PBAT dropped to 14.7 MPa, while that of TPU decreased to 17.8 MPa. The greater loss in strength observed for the biopolymer blend suggests that it is more sensitive to raster misalignment due to lower inter-bead bonding quality.

The elongation at break values are presented in

Figure 1c. Based on the results, at a 0° raster angle, there is barely any difference between PLA/PBAT and TPU, with the former exhibiting an elongation of 214% and the latter exhibiting an elongation of 265%, demonstrating that both materials are highly ductile. There is, however, a major difference between them when the raster angle is increased. While TPU retained most of its deformability (exhibiting an elongation at break of 221% at ±45° and 134% at 90°), PLA/PBAT experienced an abrupt drop by falling below 20% even at ±45° and decreasing to just 2% at 90°. Evidently, when the load orientation differs from the raster angle, and the role of interphases becomes more dominant, TPU can redistribute stress by stretching, effectively bridging weak inter-bead regions rather than fracturing immediately. On the other hand, the PLA/PBAT blend has a more limited elasticity and stress redistribution capacity, leading to crack initiation and rapid propagation at inter-bead boundaries. These results are in good agreement with the Young’s modulus and tensile strength results, further supporting the conclusion that TPU’s intrinsic elasticity and stronger interfacial bonding greatly outperform those of PLA/PBAT.

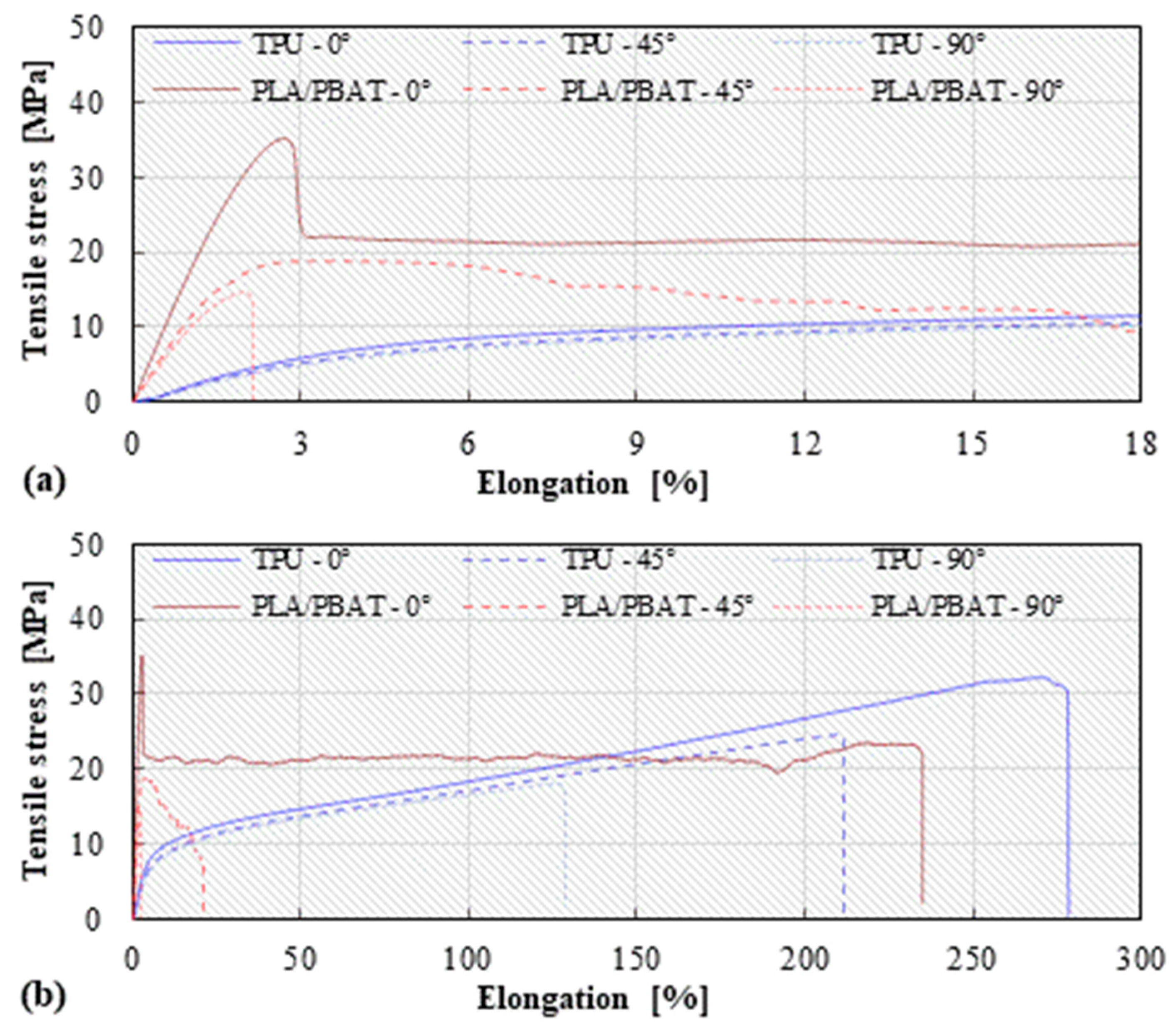

As illustrated in

Figure 2, the investigated PLA/PBAT and TPU samples exhibited distinctly different stress–strain responses during the tensile tests. TPU samples displayed a gradual increase in stress as a function of elongation, characterized by a steep initial slope followed by continuous hardening until the point of sudden failure. This kind of behavior is typical of rubber-like, flexible materials that store elastic energy quite efficiently. On the other hand, the PLA/PBAT blend exhibited a well-defined yield point, followed by strain softening and a nearly constant stress level until fracture. This behavior indicates considerable plastic deformation, suggesting that while PLA/PBAT is also ductile, its deformation mechanism differs markedly from that of TPU.

4. Conclusions

In this study, a biopolymer blend of poly(lactic acid) and poly(butylene adipate-co-terephthalate) in a 60/40 weight ratio was evaluated as a sustainable alternative to thermoplastic polyurethane for material extrusion-based additive manufacturing. The tensile mechanical properties of 3D-printed specimens with varying raster orientations (0°, ±45°, and 90°) were compared. While both materials exhibited similar tensile strengths across the tested infill orientations, the PLA/PBAT blend demonstrated considerably higher stiffness, with Young’s modulus values roughly an order of magnitude greater than those of TPU. However, TPU maintained its deformability more effectively as the raster angle increased, with elongation at break remaining above 130%. In contrast, PLA/PBAT showed a sharp decline, dropping to as low as 2% at 90°. Overall, it can be concluded that, despite some major differences between the investigated materials, PLA/PBAT offers a viable balance between tensile mechanical performance and environmental friendliness for use in ductile 3D-printed parts. While PLA/PBAT provides advantages in renewability and biodegradability compared to the petrol-based TPU, its lower flexibility, reduced durability and reliance on industrial composting represent trade-offs against TPU’s superior elasticity, longer lifespan and lower replacement frequency.