Abstract

This study focuses on the development, characterization, and numerical simulation of novel composite materials based on natural vegetable fibers for applications in civil engineering. Three different bio-based composites were formulated using Alfa plant fibers, wood waste, and an equal mixture of both (50% Alfa, 50% wood), with polyvinyl acetate (PVAc), a non-polluting polymer matrix, as the binder. The performance of these composites is strongly influenced by the fiber morphology, structural characteristics, and the nature of the matrix. Thus, understanding and optimizing these parameters is crucial for tailoring materials to meet specific design requirements. The experimental approach began with the morphological and structural characterization of the raw and treated fibers, followed by the evaluation of the thermal a properties of the resulting composites. Furthermore, thermal conductivity simulations were performed using COMSOL Multiphysics to validate the experimental results and gain deeper insights into heat transfer behavior within the composites. A comparative analysis with conventional synthetic insulation materials revealed that the developed bio-composites offer competitive thermal performance while being more environmentally sustainable. These findings highlight the potential of Alfa and wood waste fibers as effective, eco-friendly alternatives for thermal insulation in building applications.

1. Introduction

The building sector is undergoing a rapid transformation in response to the growing challenges of climate change. In Morocco, this sector accounts for approximately 36% of the country’s total energy consumption and significantly contributes to greenhouse gas emissions. Enhancing thermal insulation in buildings through the use of efficient materials is one of the most effective strategies for reducing energy demand and mitigating environmental impact. While this approach has been widely adopted in developed countries, its application remains limited in other regions due to the high cost of conventional insulation materials and concerns regarding their potential health effects.

Natural fiber-based composites, known for their low carbon footprint, biodegradability, and affordable cost, have emerged as promising alternatives. These bio-based materials appear particularly well-suited to meet the dual challenge of environmental sustainability and energy efficiency. In Morocco and many countries in the Global South, the abundance of natural, renewable resources—such as Alfa grass (Stipa tenacissima), doum palm, date palm fibers, and argan shells—offers a unique opportunity to develop innovative insulation solutions aligned with sustainable development goals [1]. The use of such materials not only helps reduce environmental impact but also contributes to local economic development by creating job opportunities in rural and underdeveloped areas and by improving building quality and comfort.

The incorporation of cellulosic fibers into various composite matrices is not new. The performance of natural fiber composites, or biocomposites, results from the synergistic interaction between the reinforcing fibers and the binding matrix [2]. Today, a wide variety of biocomposites have been developed for applications ranging from automotive to construction. Their increasing use is supported by global shifts toward greener materials and more energy-conscious policies.

This study aims to contribute to this growing field by developing and characterizing new thermal insulation composites based on Alfa plant fibers and wood waste, using a non-toxic polymer matrix. The work includes both experimental characterization and numerical simulations using COMSOL Multiphysics 4.3, with a comparative analysis of the thermal performance of these bio-based materials against conventional synthetic insulators.

2. Materials and Work Method

2.1. Materials

Alfa and sawdust were used as reinforcements for the composites materials involved in this study. Alfa fibers were extracted through alkaline and mechanical treatment of the stems, which are grown in the border of the desert in Oujda region, Morocco and also in the Africa Mediterranean region [3]. As wood fibers, we used sawdust of beech, spruce wood with random as fiber size. These kinds of trees are widespread in the Middle Atlas region of Morocco, particularly around the provinces of Ifrane, Azrou, and Khénifra. A shell layer made of Atlas cedar wood (Cedrus atlantica), known for its aromatic and rot-resistant properties, is also used in some of the samples. The cedar wood is finely processed into veneer sheets or thin planks, offering both structural reinforcement and natural durability. PVAC, is used as matrix. It is also a thermoplastic polymer resin, particularly effective on porous materials such as wood, fibers and paper. PVAC does not require high drying temperatures and can cure at room temperature.

2.2. Work Method

2.2.1. Treatment of the Alfa Fibers

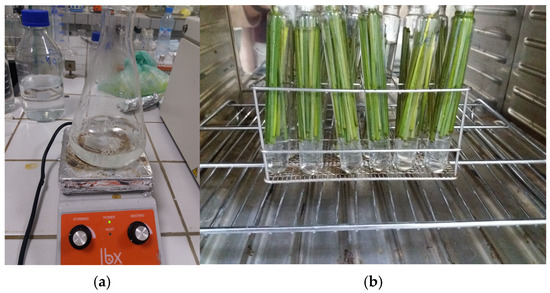

Alfa fibers were extracted through a combination of chemical and mechanical treatments applied to alfa stems, which ranged in length from 0.5 to 0.6 m and had diameters between 0.4 and 1.8 mm [3]. Initially, the stems were rinsed with distilled water (Figure 1a), then soaked in a 10% NaCl solution at 60 °C for 24 h to eliminate surface impurities [4,5]. After this, they were washed again with distilled water and immersed in an 8% NaOH solution at 100 °C for 2 h. Following this alkaline treatment, the stems were thoroughly rinsed before being bleached in a 5% sodium hypochlorite (NaOCl) solution for 2 h at 80 °C to remove any remaining lignin. The final washing step involved distilled water, and the fibers were then dried in a vacuum oven at 60 °C for 48 h (Figure 1).

Figure 1.

(a) NaOH solution preparation; (b) Alfa fibers stems alkaline treatment.

2.2.2. Preparing of the Samples

To prepare the composite materials, the following steps were performed. First, wood and Alfa fibers were accurately weighed using a precision balance, with specific quantities selected to achieve the target thickness (less than 20 mm). Alfa stems were cut to a uniform length of 50 mm to facilitate easy placement into the mold, While sawdust was prepared at a random particle size, prior research has shown that certain particle size ranges can offer superior thermal insulation and sound absorption properties [6].

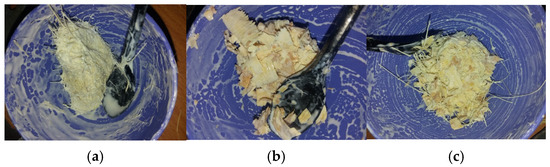

Next, mixtures of fibers and PVAC [7] were prepared in the specified ratios: 80% PVAC and 20% Alfa for the Alfa sample, 60% PVAC and 40% Wood for the Wood sample, and 60% PVAC, 20% Wood, and 20% Alfa for the Alfa-Wood sample. These mixtures (Figure 2a–c) were thoroughly blended and then poured into a plastic mold with a diameter of 50 mm, which was constructed using a plastic tube attached to a silicone base layer. The mixture was manually pressed to ensure uniformity and proper compaction.

Figure 2.

(a) 80% PVAC and 20% Alfa mixture; (b) 60% PVAC and 40% Wood mixture; (c) 60% PVAC, 20% Wood, and 20% Alfa mixture; (d) 80% PVAC and 20% Alfa sample; (e) 60% PVAC and 40% Wood sample; (f) 60% PVAC,20% Wood, and 20% Alfa sample.

After molding, the specimens were left to dry at room temperature (25 °C) for two days to achieve sufficient rigidity for removal from the mold (Figure 2d–f). This process ensured that the final densities of the samples matched the desired values, maintaining consistency and quality across all specimens see Table 1.

Table 1.

Sample composition and density.

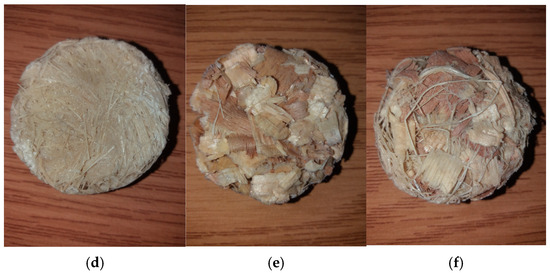

3. Morphological Analysis of Alfa Fibers

Scanning electron microscopy (SEM) hirox (Tokyo, Japan) was employed to analyze the morphology of alfa fibers, comparing untreated and alkali-treated samples. The alkali treatment, likely using sodium hydroxide, induced significant structural changes in the fibers. Untreated fibers exhibited a smooth surface, a characteristic attributed to the presence of non-cellulosic components such as lignin and hemicellulose (Figure 3a). In contrast, treated fibers displayed a rougher surface due to the removal of these non-cellulosic materials (Figure 3b), which plays an important role in enhancing interfacial bonding with polymer matrices in composite applications. This increased surface roughness provides more contact points for adhesion, improving the mechanical properties of the resulting composites. Additionally, a notable decrease in fiber diameter from 1.66 mm in untreated fibers to 0.4 mm in treated samples further confirms the effective removal of lignin and hemicellulose, resulting in a purer cellulose structure [4]. The zoomed views revealed micropores and microfibrils in untreated fibers, which are associated with the presence of hemicellulose and lignin. These microfibrils were largely absent in treated fibers, underscoring the chemical efficacy of the alkali treatment. These morphological changes, including increased surface roughness, reduced fiber diameter, and the absence of microfibrils, collectively contribute to improved tensile strength, stiffness, and overall performance of the fibers in reinforced composites.

Figure 3.

Scanning electron microscopy (SEM) of (a) untreated and (b) treated Alfa fibers.

4. Thermal Characterization

4.1. Experimental Setup

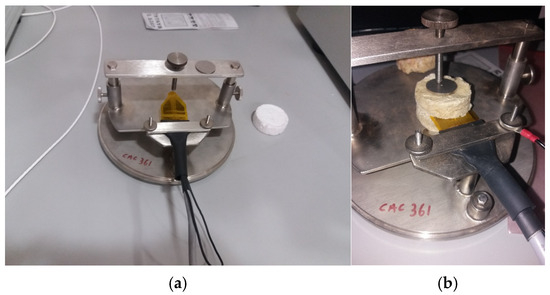

The procedure for measuring thermal conductivity using the HOT DISC (Hot Disk, Göteborg, Sweden) device is a highly precise and systematic process designed to ensure accurate and reliable results. The first step involves preparing the sample specimen, which is carefully placed in a holder or sandwiched between two identical pieces of the material under investigation. This arrangement ensures uniform heat distribution and minimizes any potential thermal gradients that could affect the measurement. The HOT DISC is then positioned between the two samples. This probe serves a dual function: it acts as both a heat source and a temperature sensor, enabling simultaneous heat generation and temperature monitoring [8].

The procedure for measuring thermal conductivity using the HOT DISC device involves a precise and systematic approach. First, the sample specimen (as shown in Figure 4) is prepared by placing it in a holder or between two identical pieces of the material to ensure uniform heat distribution. The HOT DISC probe, which acts as both a heat source and a temperature sensor, is then positioned between the two samples. A constant electrical power is applied to the probe, generating a controlled heat flux that propagates through the specimens. As the heat flows, the temperature variation across the samples is measured in real-time by the probe. This data is recorded and analyzed to determine the material’s thermal conductivity, thermal diffusivity, and heat capacity. The setup ensures accurate and repeatable measurements by minimizing heat loss to the surroundings and maintaining consistent contact between the probe and the samples.

Figure 4.

(a) HOT DISC device; (b) Experimental Setup.

4.2. The Thermal Properties

The thermal properties of the tested materials—100% Alfa, 100% wood, and a mixture—are summarized in Table 2. The thermal conductivity values are 0.09743 W/m·K for 100% Alfa, 0.08645 W/m·K for 100% wood, and 0.1253 W/m·K for the mixture. The mixture exhibits the highest thermal conductivity, while 100% wood shows the lowest. In terms of thermal diffusivity, the mixture also leads with 0.2091 mm2/s, followed by 100% wood (0.1812 mm2/s) and 100% Alfa (0.04999 mm2/s). Specific heat values are highest for 100% Alfa (1.949 MJ/m2·K), with the mixture (0.5996 MJ/m2·K) and 100% wood (0.4770 MJ/m2·K) showing lower values. Density measurements indicate that 100% Alfa is the densest material (85.67 g/cm3), followed by the mixture (72.99 g/cm3) and 100% wood (62.92 g/cm3). These results highlight that the Alfa-based biocomposite offers better thermal stability, as it reaches high temperatures more slowly compared to wood. This suggests potential suitability for applications requiring prolonged heat resistance, while wood may be more appropriate for scenarios needing rapid thermal response [9].

Table 2.

Thermal properties for Alfa, wood and mixture.

5. Thermal Modeling of the Composite Materials

An unsteady state heat conduction problem is chosen to model the thermal behavior of a composite material composed of Alfa and wood. With the consideration of transient conditions, the governing equation describing the heat conduction through the material is expressed as:

where is the density, is the specific heat capacity, k is the thermal conductivity, and T is the temperature.

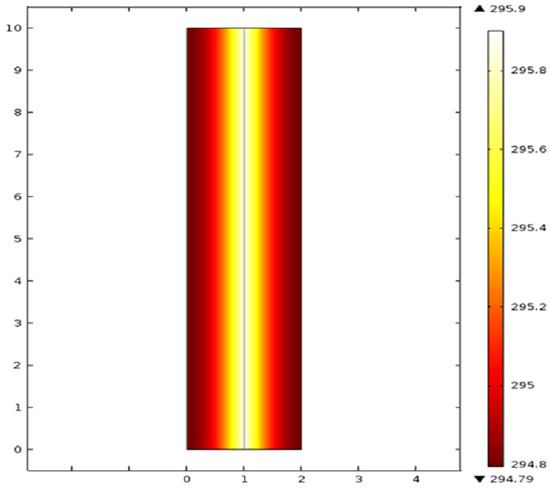

Figure 5 illustrates the transient temperature distribution within a cylindrical domain, simulated using COMSOL Multiphysics. The study employs the time-dependent heat conduction equation, numerically solved through the finite element method (FEM). The computational domain is discretized into a limited number of finite elements, allowing for the temperature at each node to be computed as a function of time. The resulting temperature field shows a symmetric heat diffusion pattern, with the highest temperatures (around 295.9 K) concentrated along the central axis of the cylinder, gradually decreasing toward the outer edges, where the lowest temperature reaches approximately 294.8 K. This gradient highlights the effect of internal heat generation or an imposed boundary condition leading to a temperature peak at the core [10,11].

Figure 5.

Temperature Contour Distribution Within the Sample.

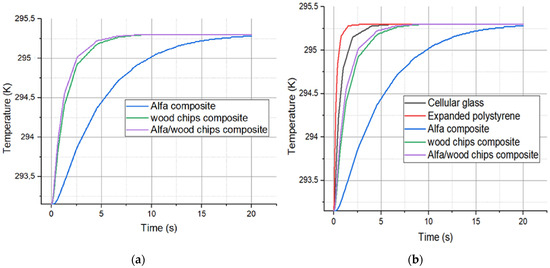

Figure 6a,b provides a comprehensive summary of the thermal response of the tested materials, highlighting their distinct thermal behaviors. The figure illustrates key thermal properties such as thermal conductivity, diffusivity, and heat capacity, enabling a direct comparison of their performance. The Alfa/Wood composite mixture exhibits the highest thermal conductivity at 0.125 W/m·K, indicating relatively faster heat transfer compared to its individual components. The 100% Alfa composite shows a thermal conductivity of approximately 0.097 W/m·K, while the 100% Wood composite has the lowest value at 0.086 W/m·K, suggesting better insulation performance [12]. This indicates that pure wood offers the slowest thermal response, making it potentially more effective for insulation, whereas the mixture transfers heat more readily, suitable for applications requiring quicker thermal regulation.

Figure 6.

(a) Simulation of the Dynamic Thermal Response of Alfa and Wood Materials; (b) Comparison of Simulated Dynamic Thermal Responses Across Materials.

In comparison to conventional insulation materials, cellular glass typically has a thermal conductivity ranging from 0.04 to 0.06 W/m·K, which is slightly higher than expanded polystyrene (EPS), whose values lie between 0.032 and 0.038 W/m·K. Although cellular glass generally has a lower embodied energy (~16.6 MJ/kg) than EPS (~109.2 MJ/kg), its cost is significantly higher, around €28.28 per m2 compared to EPS’s €9.62 per m2. From a sustainability perspective, Alfa-based composites offer notable environmental benefits due to their biodegradability and renewable origins, presenting a lower environmental impact throughout their life cycle compared to petrochemical-based materials such as EPS.

6. Conclusions

This study focused on the thermal characterization of treated alfa wood-based composites, including pure alfa, wood, and alfa/wood mixture composites, and compared their performance with cellular glass and expanded polystyrene. The alfa fibers were treated through alkali treatment to enhance their flexibility, and the composites were fabricated for thermal analysis. The results demonstrated that the treated alfa composites exhibit a thermal conductivity range of 0.045–0.065 W/m·K, which is higher than cellular glass (0.040 W/m·K) but lower than expanded polystyrene (0.035 W/m·K). The alfa/wood mixture composites showed intermediate thermal conductivity values, averaging 0.055 W/m·K, reflecting the influence of their hybrid composition.

In terms of thermal diffusivity, the alfa-based composites displayed values in the range of 0.15–0.25 mm2/s, indicating their ability to moderate heat transfer effectively. These properties position the composites as promising candidates for thermal insulation applications, particularly in contexts where sustainability and cost-effectiveness are prioritized. The COMSOL Multiphysics simulations further validated the experimental results, accurately replicating the thermal behavior of the materials and confirming the reliability of the characterization process.

The findings highlight the potential of treated alfa wood-based composites as sustainable alternatives to traditional insulation materials like cellular glass and expanded polystyrene. Their enhanced thermal properties, coupled with their eco-friendly nature, make them suitable for use in energy-efficient construction and thermal management systems. Future research could explore the optimization of the composite fabrication process, the effects of varying fiber-to-matrix ratios, and the long-term durability of these materials under environmental stressors. This study contributes to the growing body of knowledge in sustainable material science and provides a foundation for further innovation in thermal insulation technologies.

Author Contributions

Conceptualization, Y.C. and O.E.; methodology, M.B. and H.E.Q.; software, O.E.; validation, M.B. and H.E.Q.; formal analysis, S.C.; investigation, Y.C. and R.S.; resources, M.B.; data curation, Y.C.; writing—original draft preparation, Y.C.; writing—review and editing, Y.C., O.E., Y.A. and S.C.; visualization, Y.A.; supervision, M.B. and H.E.Q.; project administration, R.S.; funding acquisition, O.E. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

The data presented in this study are available upon request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Gurunathan, T.; Mohanty, S.; Nayak, S.K. A review of the recent developments in biocomposites based on natural fibres and their application perspectives. Compos. Part A-Appl. Sci. Manuf. 2015, 77, 1–25. [Google Scholar] [CrossRef]

- Kaseem, M.; Hamad, K.; Deri, F.; Ko, Y.G. Material properties of polyethylene/wood composites: A review of recent works. Polym. Sci. Ser. A 2015, 57, 689–703. [Google Scholar] [CrossRef]

- El-Abbassi, F.E.; Assarar, M.; Ayad, R.; Bourmaud, A.; Baley, C. A review on alfa fibre (Stipatenacissima L.): From the plant architecture to the reinforcement of polymer composites. Compos. Part A Appl. Sci. Manuf. 2020, 128, 105677. [Google Scholar] [CrossRef]

- Dallel, M.; Lallam, A.; Renner, M. Processing and characterization of a new ring-spun yarn based on alfa fibre (Stipa Tenacissima L.). In Proceedings of the Fiber Society 2012 Spring Conference, St. Gallen, Switzerland, 23–25 May 2012. [Google Scholar]

- Cherradi, Y.; Rosca, I.C.; Cerbu, C.; Kebir, H.; Guendouz, A.; Benyoucef, M. Acoustic properties for composite materials based on alfa and wood fibres. Appl. Acoust. 2021, 174, 107759. [Google Scholar] [CrossRef]

- Tiuc, A.E.; Borlea, S.I.; Nemes, O.; Vermesan, H.; Vasile, O.; Popa, F.; Pintoi, R. New Composite Materials Made from Rigid/Flexible Polyurethane Foams with Fir Sawdust: Acoustic and Thermal Behavior. Polymers 2022, 14, 3643. [Google Scholar] [CrossRef] [PubMed]

- Jiang, H.; Kamdem, D.P. Development of poly(vinyl chloride)/wood composites. A literature review. J. Vinyl Addit. Technol. 2004, 10, 59–69. [Google Scholar] [CrossRef]

- Yi, H. Rapid thermal conductivity measurement with a hot disk sensor: Part 1. Theoretical considerations. Thermochim. Acta 2005, 436, 122–129. [Google Scholar] [CrossRef]

- Ferrandez-Villena, M.; Ferrandez-Garcia, A.; Garcia-Ortuño, T.; Ferrandez-Garcia, M.T. Acoustic and Thermal Properties of Particleboards Made from Mulberry Wood (Morus alba L.) Pruning Residues. Agronomy 2022, 12, 1803. [Google Scholar] [CrossRef]

- Vay, O.; De Borst, K.; Hansmann, C.; Teischinger, A.; Müller, U. Thermal conductivity of wood at angles to the principal anatomical directions. Wood Sci. Technol. 2015, 49, 577–589. [Google Scholar] [CrossRef]

- Loeb, A.L. Thermal Conductivity: VIII, A Theory of Thermal Conductivity of Porous Materials. J. Am. Ceram. Soc. 1954, 37, 96–99. [Google Scholar] [CrossRef]

- Cherradi, Y.; Cerbu, C.; Rosca, I.C.; Seman, A.; El Qarnia, H.; Dimokrati, A.; Benyoucef, M. Acoustic, Mechanical, and Thermal Characterization of Polyvinyl Acetate (PVA)-Based Wood Composites Reinforced with Beech and Oak Wood Fibres. Polymers 2025, 17, 142. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).