1. Introduction

Supply Chain X.0 represents the evolution of supply chain management (SCM) across six distinct phases from rudimentary manual processes (0.0) [

1] to mechanized operations (1.0), automated systems (2.0), IT-supported networks (3.0) [

2], digitally integrated systems (4.0) [

3], and human–robot collaborative frameworks (5.0) [

4,

5]. This systematic review examines the impacts of these stages on operational efficiency, resilience, and ecological sustainability. Using the PRISMA protocol, it addresses the research question: How has the transition from Supply Chain 0.0 to 5.0 influenced performance and sustainability outcomes? By analyzing this progression, this study seeks to provide actionable insights for practitioners and identify critical areas for future research (

Figure 1).

The concept of Supply Chain X.0 has evolved through distinct stages, each marked by technological advancements and shifting priorities in SCM. Ref. [

1] provide a foundational understanding of SCM’s origins, describing Supply Chain 0.0 as a pre-1990s era dominated by manual processes with limited coordination between supply chain partners. Efficiency gains were minimal, and sustainability was not a priority, as firms focused on basic operational survival. The transition to Supply Chain 1.0 in the 1990s introduced mechanization, such as forklifts and conveyor systems, which improved output by an estimated 12–18% [

1]. However, these early advancements had negligible environmental benefits, as the focus remained on productivity rather than sustainability.

By the 2000s, Supply Chain 2.0 emerged with the adoption of automation technologies like automated storage and retrieval systems (AS/RS). Ref. [

2] notes that such systems increased operational speed by 18–22%, enabling faster order fulfillment and inventory turnover. Despite these gains, sustainability impacts remained negligible, as environmental considerations were still secondary to cost and efficiency. The 2010s marked the rise of Supply Chain 3.0, characterized by IT systems, such as enterprise resource planning (ERP) software. Ref. [

2] highlights that ERP systems reduced operational costs by 15–20% through improved demand forecasting and inventory management, though sustainability impacts were minimal due to a lack of focus on green practices.

The advent of Supply Chain 4.0 in the mid-2010s brought digital integration through technologies like the Internet of Things (IoT) and artificial intelligence (AI). Ref. [

3] emphasize that 4.0 reduced lead times by 20–28% and emissions by 12–18%, as IoT-enabled real-time tracking optimized logistics and reduced waste. Finally, Supply Chain 5.0, emerging in the 2020s, focuses on human–robot collaboration and AI-driven resilience. Ref. [

4] report that 5.0 enhances resilience by 25–35% through adaptive systems that respond to disruptions, while also reducing waste by 15% through circular economy practices [

5]. This progression underscores the increasing integration of technology and sustainability in SCM, setting the stage for this review’s analysis of performance and sustainability outcomes across Supply Chain X.0 stages.

2. Materials and Methods

To meet the requirements of a systematic literature review (SLR), the Protocol and Reporting Result with Search, Appraisal, Synthesis, and Analysis (PSALSAR) framework was followed [

6]. The preferred reporting items for systematic review and meta-analyses (PRISMA) statement is integrated within the PSALSAR framework. The six steps that were followed are described in the following sections. The PRISMA methodology requirements specified by the PRISMA 2020 statement that were integrated are title, rationale, objectives, eligibility criteria, information sources, search strategy, selection process, data items, discussion, support, competing interests, and availability of data [

6]. The PRISMA framework shaped the selection process and VosViewer version 1.6.20 was used to analyze keyword trends across the literature.

2.1. Protocol

The research protocol was applied with the goal of ensuring transparency and reproducibility [

6]. The application of this framework is shown in

Table 1.

2.2. Search Method

A comprehensive literature search was conducted through Scopus database. Terms such as “Supply Chain 0.0”, “Supply Chain 1.0”, “Supply Chain 2.0”, “Supply Chain 3.0”, “Supply Chain 4.0”, “Supply Chain 5.0”, “evolution”, “performance”, and “sustainability” were paired with Boolean operators (e.g., “Supply Chain 4.0 AND sustainability”). The included studies were peer reviewed, covering 1998–2025, in English, and focused on implementation outcomes. Non-empirical works or those unrelated to SCM were omitted. Different combinations of search strings were tried to assess the most relevant results. For the different strings tried, Scopus metrics show that publications related to SC were insignificant between 1998 and 2019.

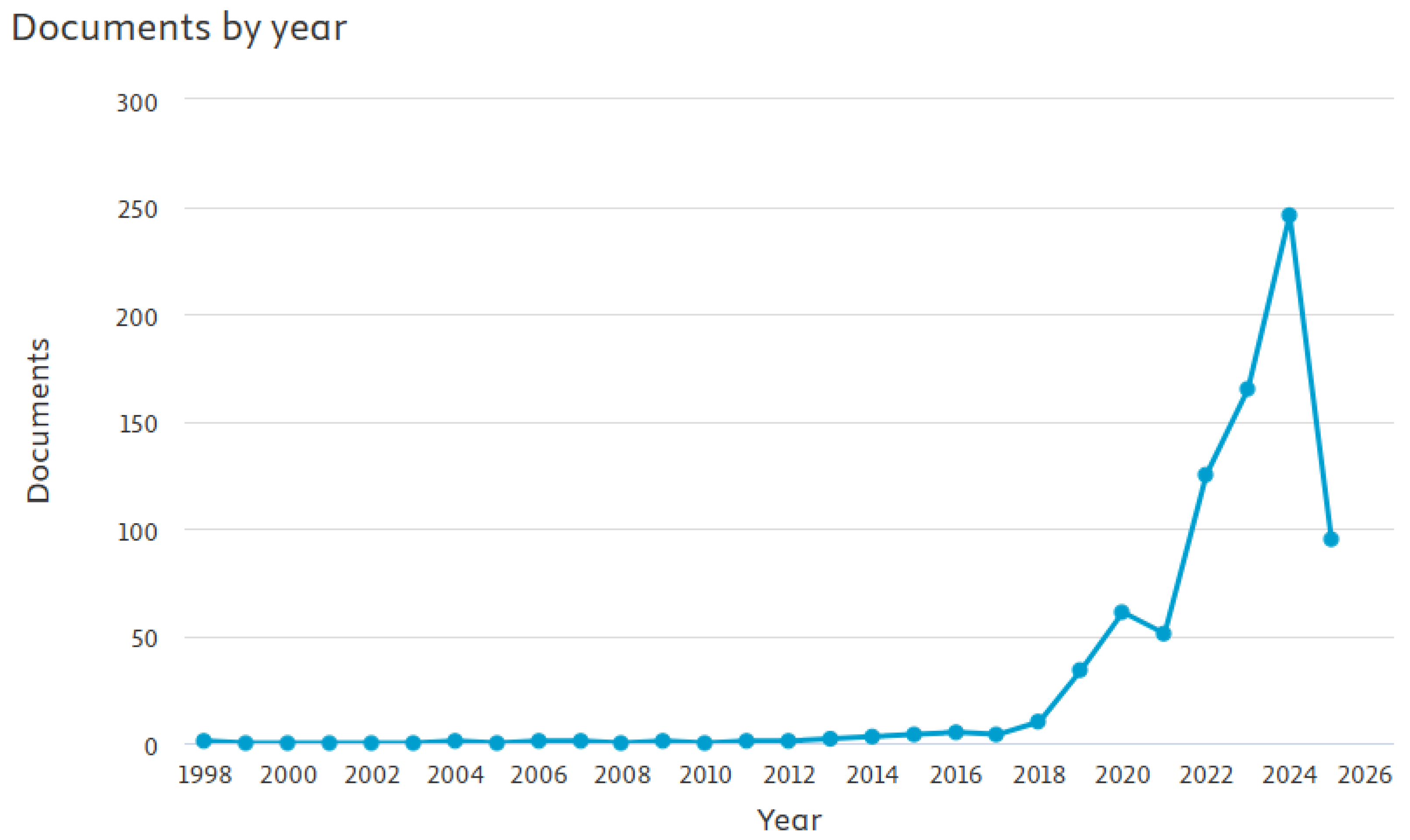

Figure 2 visualizes the records used in the next section.

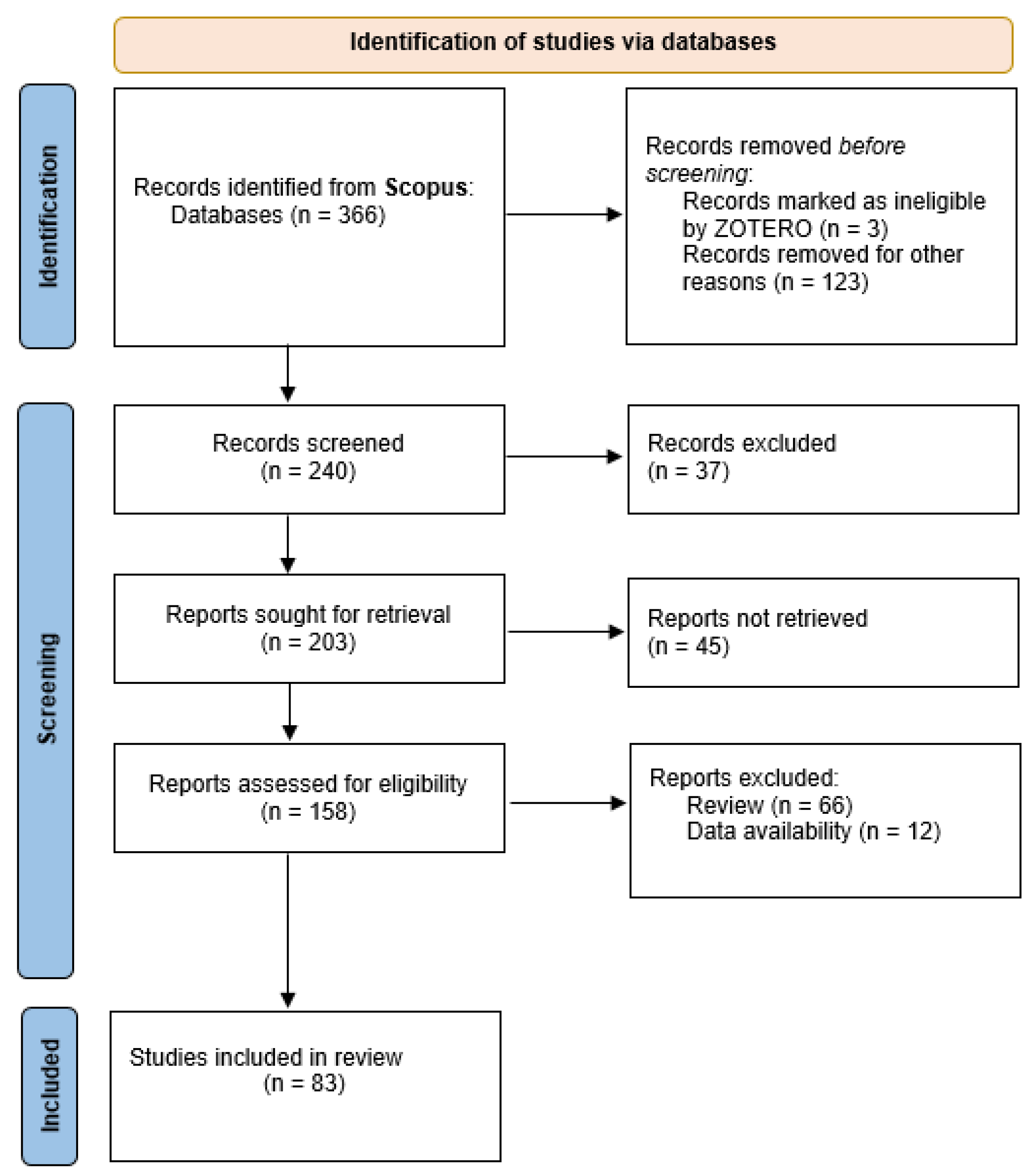

2.3. Selection Process

The PRISMA protocol was used to ensure a rigorous and transparent review process. The methodology included four phases: identification, screening, eligibility, and inclusion. More details are provided in

Figure 3.

To ensure that relevant articles were not omitted in the selected database, another search was also conducted using the ResearchRabbit Application. The three identified articles were included in the final step of the selection process. The analysis of the connection of the papers is shown in

Figure 4.

3. Results

This section exposes the key findings covering the publication trends, the evolution of impacts, the technological drivers and the data mapping analysis.

3.1. Publication Trends

Publication trends from 1998 to 2025 highlight a growing interest in Supply Chain X.0 (see

Figure 2: The evolution of supply chain articles). Between 1998 and 2016, research output was minimal (0–1 documents per year), reflecting the early stages of SCM (0.0–2.0). A significant increase began in 2019 (34 documents), peaking at 250 documents in 2024, driven by the rise of Supply Chain 4.0 and 5.0. The partial-year data for 2025 (85 documents as of April) suggests sustained interest, potentially exceeding 400 documents if annualized. This trend emphasizes the focus on digital and human-centric supply chains in recent literature, justifying this review’s emphasis on stages 4.0 and 5.0.

3.2. Evolution of Impacts

The impacts of Supply Chain X.0 stages were synthesized from the 83 studies identified through PRISMA, with key insights drawn from foundational works

Table 2.

3.3. Technological Drivers

Early SCM (0.0–2.0) relied on basic machinery, progressing to software solutions in 3.0, interconnected digital platforms in 4.0, and smart robotics in 5.0. Ref. [

3] highlights 4.0’s networked efficiency, while Ref. [

4] emphasizes 5.0’s human–machine synergy.

3.4. Data Mapping Analysis

To map the relationship between concepts or keywords in the literature, a network visualization is generated using VOSViewer version 1.6.20. This visualization of keywords co-occurrence offers a comprehensive overview of the thematic landscape surrounding Supply chain X.0. The clustering of terms reveals the multidisciplinary nature of the field, bridging technology, management, and sustainability. The prominence of “blockchain” and “cybersecurity” within the red cluster highlights the critical role of secure and decentralized systems. The green cluster, centered on “digital transformation” and “performance,” reflects the adoption of technologies such as the “internet of things” to enhance efficiency and innovation in production processes. The yellow cluster, featuring “sustainability” and “supply chain”, indicates an intersection between technological advancement and environmental responsibility, as a growing concern in research. Meanwhile, the blue cluster’s focus on “machine learning” and “artificial intelligence” points to the role of advanced analytics in enabling predictive maintenance, quality control, and automation (

Figure 5).

The network’s structure also reveals potential research gaps. For instance, terms like “decision making”, “human-centric approach”, and “worker satisfaction” appear on the periphery, suggesting that the human element in Industry 4.0 may be underexplored compared to technological aspects. This could indicate an opportunity for future studies to investigate how automation and digitalization impact the workforce.

4. Discussion

In this Section, key insights, trends, research gaps, and future directions are identified based on the results of this bibliometric review and discussed in detail.

4.1. Key Insights

4.1.1. Performance Trends

The evolution of SCM demonstrates a progression from modest efficiency gains in 1.0–2.0 to optimized networks in 3.0–4.0, culminating in 5.0’s enhanced resilience. Ref. [

2] attributes 3.0’s improvements to better visibility through IT systems, such as real-time inventory tracking, which streamlined operations across global supply chains. Ref. [

4] highlights 5.0’s ability to withstand disruptions through human–robot collaboration, noting its effectiveness during events such as the COVID-19 pandemic, where adaptive systems maintained operational continuity.

4.1.2. Sustainability Shifts

Sustainability was largely overlooked in 0.0–3.0 but gained traction in 4.0 with greener logistics practices, such as route optimization and energy-efficient warehousing. These efforts were further advanced in 5.0 through sustainable cycles, including closed-loop systems that repurpose materials [

5]. This shift marks a critical turning point in SCM toward environmental responsibility, aligning with global sustainability goals.

4.1.3. Challenges Across Stages

Early stages (0.0–2.0) were constrained by labor dependency, leading to inefficiencies and high operational costs. The transition to 3.0–4.0 introduced technology adoption challenges, such as integrating legacy systems with new digital platforms, often requiring significant capital investment. In 5.0, workforce training demands emerged as a key hurdle, as employees needed to adapt to collaborating with advanced robotics and AI systems. Ref. [

3] notes persistent cost challenges in later stages, particularly with digital infrastructure investments, which can strain budgets for small and medium enterprises (SMEs) adopting 4.0 and 5.0 technologies.

4.2. Trends in Research Activity

Publication trends from 1998 to 2025 (see

Figure 2: The evolution of supply chain articles) reveal a significant shift in research focus, informing future directions. From 1998 to 2016, publication activity was minimal (0–10 documents per year), reflecting limited academic interest in Supply Chain X.0 during its early stages (0.0–2.0). A marked increase began in 2017 (8 documents), escalating to a peak of 250 documents in 2024, with 85 documents in 2025 (partial year, up to April). This surge corresponds with the rise of Supply Chain 4.0, driven by digitalization, IoT, and AI, and the emergence of 5.0, which emphasizes human–robot collaboration and AI-driven resilience [

2]. The concentration of research in 2017–2025 underscores the growing relevance of digital technologies in SCM, particularly as global disruptions (e.g., COVID-19) highlighted the need for agile and technology-driven supply chains.

4.3. Research Gaps

4.3.1. Historical Data Deficiency

Limited empirical studies on 0.0–2.0 hinder understanding of foundational SCM dynamics, making comparisons with modern stages challenging [

1]. This gap complicates efforts to assess long-term evolutionary trends.

4.3.2. Empirical Shortfall

As an emerging stage, 5.0 lacks longitudinal data, leaving its resilience and scalability claims untested beyond pilot studies [

4]. This limits confidence in its applicability across diverse industries.

4.3.3. Sustainability Measurement Variability

Inconsistent metrics for 4.0–5.0 environmental impacts (e.g., varying carbon accounting methods) impede cross-study comparisons [

5]. Standardized metrics are needed for reliable evaluations.

4.3.4. Geographic Imbalance

Research primarily focuses on developed nations, overlooking the applicability of X.0 stages in regions with limited resources or infrastructure, such as parts of Africa or Southeast Asia.

4.3.5. Cost–Benefit Analysis Gaps

Few studies provide a financial evaluation of 4.0–5.0 technologies, leaving practitioners without clear investment guidance [

3]. This gap is particularly critical for SMEs with limited resources.

4.4. Future Directions

4.4.1. Focus on 2017–2025 for Digitalization and AI Impacts

The increase in publications from 2017 to 2025 (

Figure 2: The evolution of supply chain articles) highlights the dominance of Supply Chain 4.0 and 5.0, driven by digitalization and artificial intelligence. Future research should focus on this period to assess the long-term impacts of AI on supply chain resilience, efficiency, and personalization. For example, studies could explore how AI algorithms enhance demand forecasting in 4.0 or improve human–robot collaboration in 5.0, particularly in high-disruption scenarios such as pandemics. Methodologies could include case studies of AI implementations in global firms or simulations of AI-driven supply chain responses to disruptions.

4.4.2. Longitudinal Validation

Conduct multi-year studies to evaluate 5.0’s long-term resilience, especially under global disruptions like pandemics or trade conflicts. Longitudinal approaches, such as tracking 5.0 implementations over 5–10 years, could provide robust data on scalability and adaptability.

4.4.3. Standardized Eco-Metrics

Develop consistent sustainability metrics (e.g., unified benchmarks for waste reduction or energy efficiency) to assess 4.0–5.0 environmental impacts. Collaborative efforts between academia and industry could establish these standards, ensuring comparability across studies.

4.4.4. Inclusive Regional Studies

Expand research to developing economies to examine the adaptability of Supply Chain X.0 stages in diverse infrastructural and economic contexts. Comparative studies between developed and developing regions could highlight barriers and opportunities for X.0 adoption.

4.4.5. Advanced Tech Exploration

Investigate the integration of AI, robotics, and blockchain in 5.0 to enable hyper-personalized and transparent supply chains. Experimental studies, such as pilot projects testing blockchain for supply chain transparency, could validate these technologies’ potential.

4.4.6. Economic Impact Analysis

Perform detailed cost–benefit analyses of 4.0–5.0 implementations to provide firms with clear investment and payback guidance. Quantitative methods, such as return-on-investment (ROI) calculations for AI or IoT adoption, could inform decision-making for practitioners.

5. Conclusions

The evolution from Supply Chain 0.0’s manual processes to 5.0’s innovative human–robot collaboration demonstrates significant advancements in efficiency, resilience, and sustainability. While early stages establish the foundation, 4.0 and 5.0 have redefined SCM through digital integration and human-centric technologies, offering a model for future supply chain innovation. These advancements have broader implications for global trade, allowing firms to manage disruptions, reduce environmental impacts, and meet evolving consumer demands for transparency and sustainability. As SCM continues to evolve, the lessons from Supply Chain X.0 provide a roadmap for balancing technological innovation with human and environmental considerations.

Author Contributions

Conceptualization, F.Z.H. and A.Y.; methodology, F.Z.H. and A.Y.; software, F.Z.H. and A.Y.; validation, F.Z.H. and A.Y.; formal analysis, F.Z.H. and A.Y.; investigation, F.Z.H. and A.Y.; resources, F.Z.H. and A.Y.; data curation, F.Z.H. and A.Y.; writing—original draft preparation, F.Z.H. and A.Y.; writing—review and editing, F.Z.H. and A.Y.; visualization, F.Z.H. and A.Y.; supervision, F.Z.H. and A.Y.; project administration, F.Z.H. and A.Y.; funding acquisition, F.Z.H. and A.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| SCM | Supply Chain Management |

| PRISMA | Preferred Reporting Items for Systematic Reviews and Meta-Analyses |

| AI | Artificial Intelligence |

| AS | Automated Storage |

| RS | Retrieval System |

| ERP | Enterprise Resource Planning |

| IoT | Internet of Things |

| SLR | Systematic Literature Review |

| PSALSAR | Protocol, Search, AppraisaL, Synthesis, Analysis, Report |

| PICOC | Population, Intervention, Comparaison, Outcome, Context |

| SMEs | Small and Medium Enterprises |

| ROI | Return-on-Investment |

References

- Mentzer, J.T.; DeWitt, W.; Keebler, J.S.; Min, S.; Nix, N.W.; Smith, C.D.; Zacharia, Z.G. Defining supply chain management. J. Bus. Logist. 2001, 22, 1–25. [Google Scholar] [CrossRef]

- Chopra, S.; Meindl, P. Supply Chain Management. Strategy, Planning & Operation, 6th ed.; Pearson Education India: Chennai, India, 2016. [Google Scholar]

- Büyüközkan, G.; Göçer, F. Digital Supply Chain: Literature review and a proposed framework for future research. Comput. Ind. 2018, 97, 157–177. [Google Scholar] [CrossRef]

- Ivanov, D. The Industry 5.0 framework: Viability-based integration of the resilience, sustainability, and human-centricity perspectives. Int. J. Prod. Res. 2023, 61, 1683–1695. [Google Scholar] [CrossRef]

- Winkelhaus, S.; Grosse, E.H. Logistics 4.0: A systematic review towards a new logistics system. Int. J. Prod. Res. 2020, 58, 18–43. [Google Scholar] [CrossRef]

- Alshahrani, S.T. Industry 4.0 in “major emerging markets”: A systematic literature review of benefits, use, challenges, and mitigation strategies in supply chain management. Sustainability 2023, 15, 14811. [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).