Tensile Testing of Polymer Material Specimens Obtained by Fused Deposition Modeling †

Abstract

1. Introduction

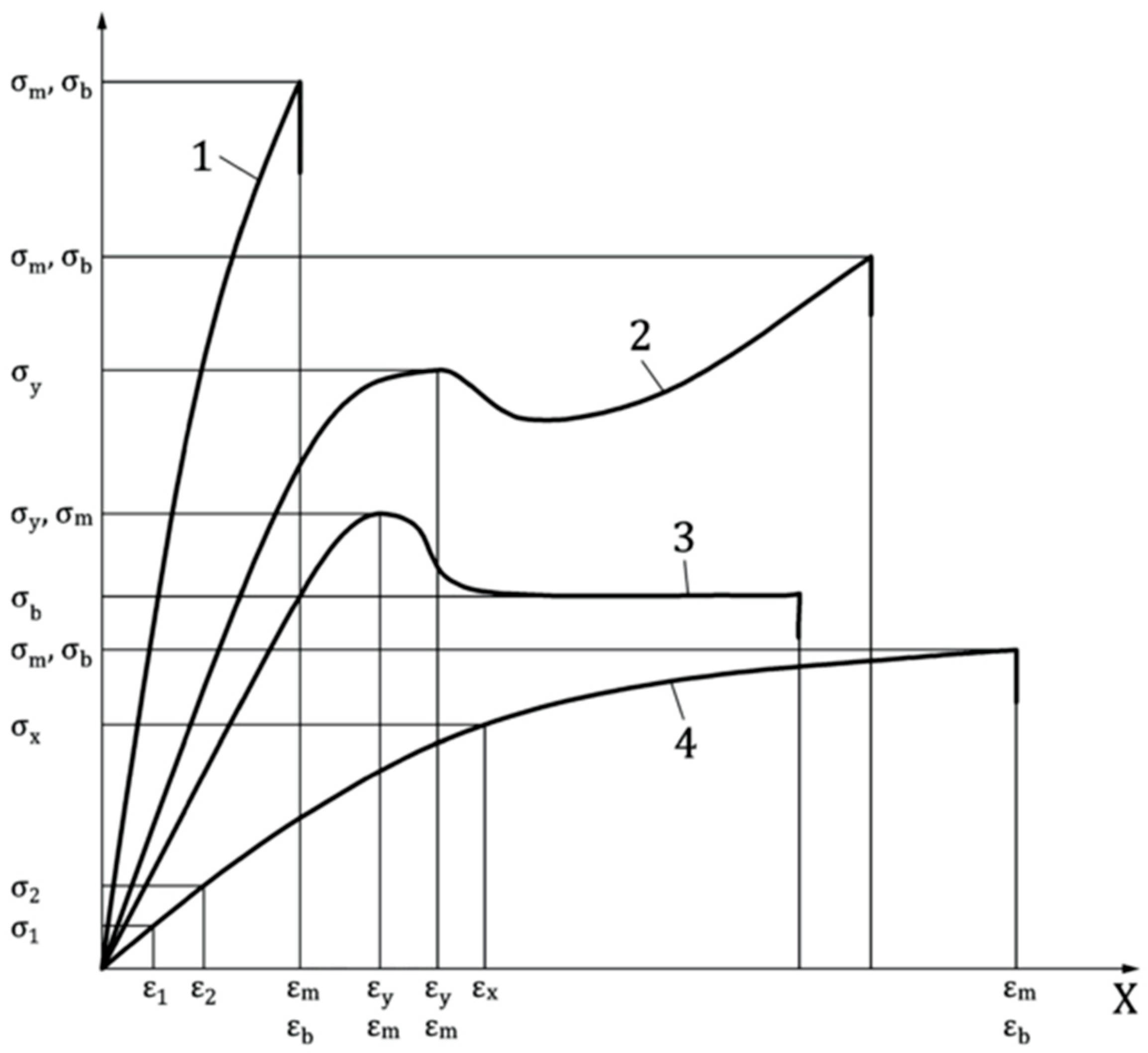

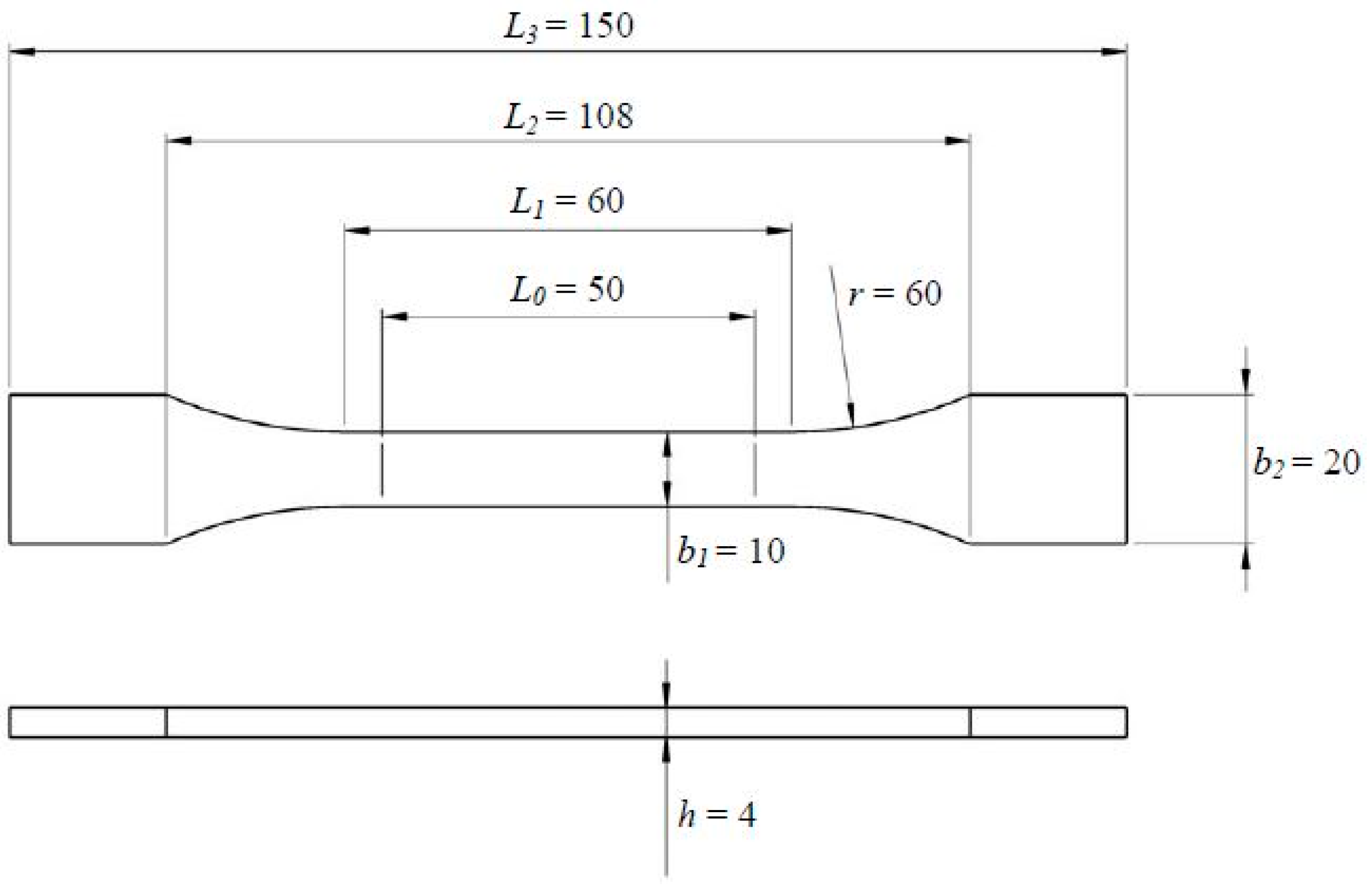

2. Materials and Methods

2.1. Used Materials

2.2. Methods and Equipment Used

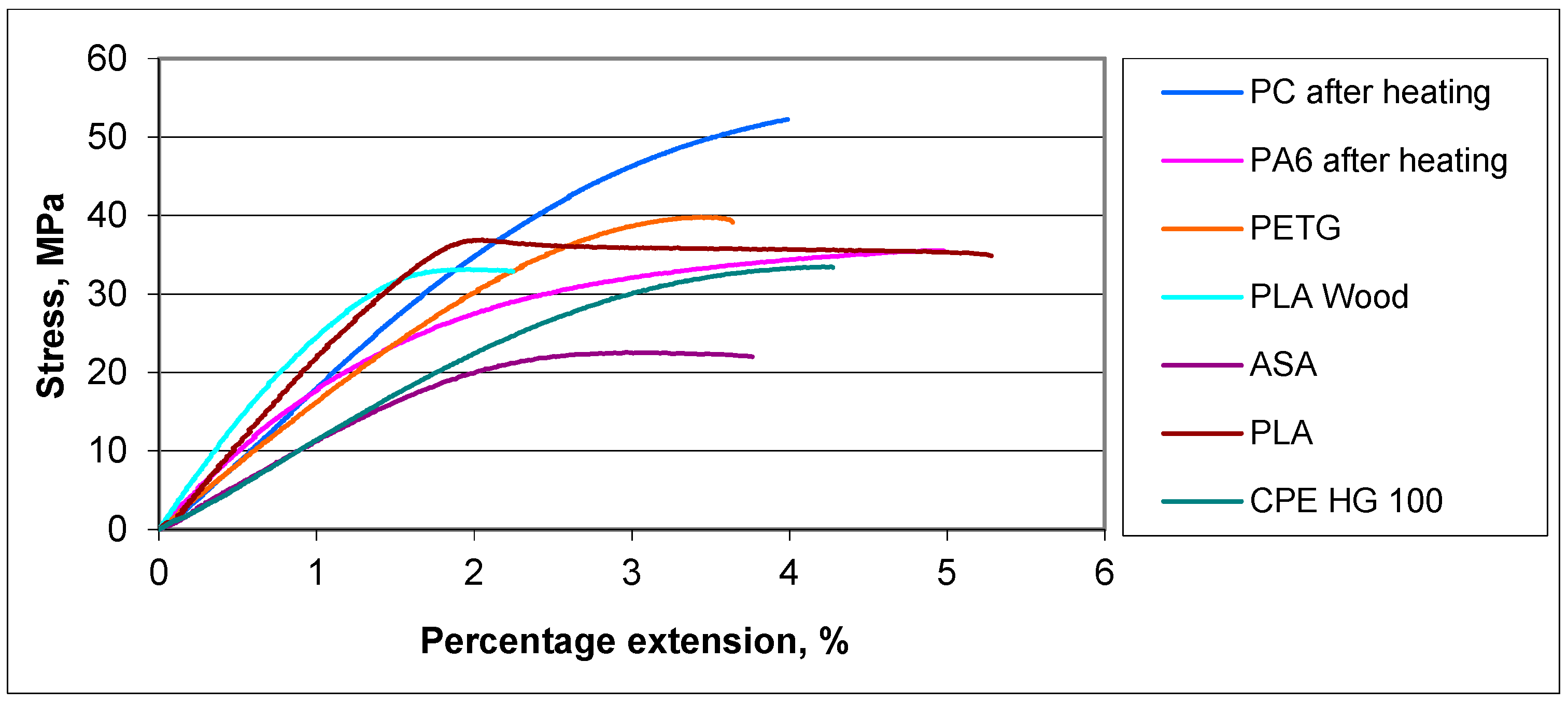

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| FDM | Fused Deposition Modeling |

| 3D | Three-Dimensional |

| PLA | Polylactic Acid |

| PLA Wood | Polylactic Acid + Wood |

| PETG | Polyethylene Terephthalate Glycol |

| PC | polycarbonate |

| PA6 | Polyamide 6 |

| ASA | Acrylonitrile Styrene Acrylate |

| CPE HG100 | Co-Polyester, Modified PET-G |

| FilaFlex SEBS | FilaFlex Styrene-Ethylene-Butylene-Styrene |

| CAD | Computer-Aided Design |

| MPa | Mega Pascals |

| GPa | Giga Pascals |

References

- Sun, J.; Zhou, W.; Huang, D.; Fuh, J.Y.H.; Hong, G.-S. An Overview of 3D Printing Technologies for Food Fabrication. Food Bioprocess Technol. 2015, 8, 1605–1615. [Google Scholar] [CrossRef]

- Karastoyanov, D.; Blagoeva, E. 3D Printing of Biological Materials. In Proceedings of the 9th International Conference on Mathematics and Computers in Sciences and Industry (MCSI), Rhodes Island, Greece, 22–24 August 2024; pp. 188–191. [Google Scholar] [CrossRef]

- Wang, J.; Shaw, L.L.; Cameron, T.B. Solid Freeform Fabrication of Permanent Dental Restorations via Slurry Micro-Extrusion. J. Am. Ceram. Soc. 2006, 89, 346–349. [Google Scholar] [CrossRef]

- Pedram, P.; Dong, L. A review on additive manufacturing of polymer-fiber composites. Compos. Struct. 2017, 182, 36–53. [Google Scholar] [CrossRef]

- Hideo, K. A Scheme for Three-Dimensional Display by Automatic Fabrication of Three-Dimensional Model. IEICE Trans. Electron. (Jpn. Ed.) 1981, J64-C, 237–241. [Google Scholar]

- Hideo, K. Automatic method for fabricating a three-dimensional plastic model with photo-hardening polymer. Rev. Sci. Instrum. 1981, 52, 1770–1773. [Google Scholar]

- Hu, Y.; Mouritz, A.P.; Ladani, R.B.; Li, Y.; Zhao, S.; Zhang, H. 3D printing of curved continuous fibre filaments using fused deposition modelling. Mater. Des. 2025, 252, 113762. [Google Scholar] [CrossRef]

- Ning, F.; Cong, W.; Qiu, J.; Wei, J.; Wang, S. Additive manufacturing of carbon fiber reinforced thermoplastic composites using fused deposition modeling. Compos. Part B Eng. 2015, 80, 369–378. [Google Scholar] [CrossRef]

- Sobrado, O.; Visniakov, N.; Bureika, G.; Losada, R.; Rodriguez, E. Effect of the chemical surrounding environment on the physical and mechanical properties of aged thermoplastic polymers. Heliyon 2024, 10, e24146. [Google Scholar] [CrossRef] [PubMed]

- Chrysanthos, M.; Kyrtopoulos, I.V.; Arvanitis, K.G.; Bartzanas, T. The Aging of Polymers under Electromagnetic Radiation. Polymers 2024, 16, 689. [Google Scholar] [CrossRef]

- Atakok, G.; Kam, M.; Koc, H.B. Tensile, three-point bending and impact strength of 3D printed parts using PLA and recycled PLA filaments: A statistical investigation. J. Mater. Res. Technol. 2022, 18, 1542–1554. [Google Scholar] [CrossRef]

- Kumar, G.S.P.; Keshavamurthy, R.; Panigrahi, S.P.; Thomas, S.; Thejaraju, R.; Hebbar, G.S.; Prasad, C.D.; Aden, A.A. Enhanced mechanical properties of CNT/Graphene reinforced PLA-based composites fabricated via fused deposition modelling. Results Eng. 2025, 25, 104472. [Google Scholar] [CrossRef]

- Lederle, F.; Meyer, F.; Brunotte, G.-P.; Kaldun, C.; Hübner, E.G. Improved mechanical properties of 3D-printed parts by fused deposition modeling processed under the exclusion of oxygen. Prog. Addit. Manuf. 2016, 1, 3–7. [Google Scholar] [CrossRef][Green Version]

- Frigione, M.; Rodríguez-Prieto, A. Can accelerated aging procedures predict the long term behavior of polymers exposed to different environments? Polymers 2021, 13, 2688. [Google Scholar] [CrossRef] [PubMed]

- Baghaei, B.; Skrifvars, M.; Rissanen, M.; Ramamoorthy, S.K. Mechanical and thermal characterization of compression moulded polylactic acid natural fiber composites reinforced with hemp and lyocell fibers. J. Appl. Polym. Sci. 2014, 131, 39. [Google Scholar] [CrossRef]

- Dochev, B.; Dimova, D.; Panov, I.; Boichev, Y. Investigation of the structure and mechanical properties of alloys AlSi25Cu4Cr and AlSi25Cu5Cr alloyed with refractory metals. AIP Conf. Proc. 2024, 3129, 040001. [Google Scholar] [CrossRef]

- Panov, I.; Dochev, B.; Dimova, D. Investigation of the Influence of the Modifiers P, Sr, Ti and Combinations of them on the Structure and Mechanical Properties of AlSi25 Alloy. In Proceedings of the International Scientific And Practical Conference, Rezekne, Latvia, 17–18 June 2021; Volume 3, pp. 256–260. [Google Scholar]

- Chybiński, M.; Dębiński, J.; Glema, A.; Grzymisławska, J.; Jezierski, D.; Polus, Ł.; Szymkuć, W. A comparison of elasto-plastic parameters of S355 steel obtained in tensile tests using an extensometer, a strain gauge and an ARAMIS 3D DIC system. Arch. Civ. Eng. 2022, 68, 199–217. [Google Scholar] [CrossRef]

- Majewski, C.; Hopkinson, N. Effect of section thickness and build orientation on tensile properties and material characteristics of laser sintered nylon-12 parts. Rapid Prototyp. J. 2011, 17, 176–180. [Google Scholar] [CrossRef]

- Malley, S.; Reina, C.; Nacy, S.; Gilles, J.; Koohbor, B.; Youssef, G. Predictability of mechanical behavior of additively manufactured particulate composites using machine learning and data-driven approaches. Comput. Ind. 2022, 142, 103739. [Google Scholar] [CrossRef]

- BDS EN ISO 527-1:2020; Plastics—Determination of Tensile Properties—Part 1: General Principles. Bulgarian Institute of Standardization: Sofia, Bulgaria, 2020.

- BDS EN ISO 527-2:2012; Plastics—Determination of tensile Properties—Part 2: Test Conditions for Molding and Extrusion Plastics. Bulgarian Institute of Standardization: Sofia, Bulgaria, 2012.

- Paneva, M.; Panev, P. Features of FDM printing of test specimens. In Proceedings of the International Conference Automatics and Informatics (ICAI), Varna, Bulgaria, 10–12 October 2024; pp. 266–270. [Google Scholar] [CrossRef]

- ASTM D3045; Standard Practice for Heat Aging of Plastics Without Load. ASTM International: West Conshohocken, PA, USA, 2003. Available online: https://file.yizimg.com/175706/2012061422210706.pdf (accessed on 20 June 2025).

- Paneva, M.; Panev, P. An Approach for the Accelerated Heat Aging of Test Specimens Produced Using 3D Additive Materials. Eng. Proc. 2025, 100, 47. [Google Scholar]

| Polymer | Test Piece № | E, GPa | σm, MPa |

|---|---|---|---|

| PC unannealed | 1 | 1.75 | 44 |

| PC | 1 | 1.83 | 46 |

| 2 | 1.91 | 51 | |

| 3 | 1.87 | 48 | |

| Average | 1.87 | 48 | |

| PC after aging | 1 | 1.97 | 45 |

| 2 | 1.84 | 48 | |

| 3 | 1.95 | 48 | |

| Average | 1.92 | 47 |

| Polymer | Test Piece № | E, GPa | σm, MPa |

|---|---|---|---|

| PA6 unannealed | 1 | 1.71 | 34 |

| PA6 | 1 | 1.93 | 37 |

| 2 | 2.04 | 38 | |

| 3 | 1.80 | 36 | |

| Average | 1.92 | 37 | |

| PA6 after aging | 1 | 1.87 | 35 |

| 2 | 1.81 | 36 | |

| 3 | 1.89 | 36 | |

| Average | 1.86 | 36 |

| Polymer | Test Piece № | E, GPa | σm, MPa |

|---|---|---|---|

| PETG | 1 | 1.60 | 35 |

| 2 | 1.64 | 34 | |

| 3 | 1.59 | 40 | |

| Average | 1.61 | 36 | |

| PETG after aging | 1 | 1.62 | 35 |

| 2 | 1.66 | 36 | |

| 3 | 1.61 | 34 | |

| Average | 1.63 | 35 |

| Polymer | Test Piece № | E, GPa | σm, MPa |

|---|---|---|---|

| PLA Wood | 1 | 2.73 | 33 |

| 2 | 2.67 | 33 | |

| 3 | 2.52 | 33 | |

| Average | 2.64 | 33 | |

| PLA Wood after aging | 1 | 2.52 | 35 |

| 2 | 2.48 | 33 | |

| 3 | 2.58 | 34 | |

| Average | 2.53 | 34 |

| Polymer | Test Piece № | E, GPa | σm, MPa |

|---|---|---|---|

| ASA | 1 | 1.14 | 22 |

| 2 | 1.16 | 21 | |

| 3 | 1.12 | 23 | |

| Average | 1.14 | 22 | |

| ASA after aging | 1 | 1.17 | 23 |

| 2 | 1.16 | 23 | |

| 3 | 1.16 | 23 | |

| Average | 1.16 | 23 |

| Polymer | Test Piece № | E, GPa | σm, MPa |

|---|---|---|---|

| FilaFlex SEBS | 1 | 0.11 | 3.73 |

| 2 | 0.13 | 3.51 | |

| 3 | 0.15 | 4.02 | |

| Average | 0.13 | 3.75 | |

| FilaFlex SEBS after aging | 1 | 0.12 | 3.65 |

| 2 | 0.14 | 3.78 | |

| 3 | 0.16 | 3.81 | |

| Average | 0.14 | 3.75 |

| Polymer | Test Piece № | E, GPa | σm, MPa |

|---|---|---|---|

| PLA | 1 | 2.33 | 40 |

| 2 | 2.27 | 36 | |

| 3 | 2.31 | 37 | |

| Average | 2.30 | 38 | |

| PLA after aging | 1 | 2.22 | 38 |

| 2 | 2.26 | 38 | |

| 3 | 2.25 | 39 | |

| Average | 2.24 | 38 |

| Polymer | Test Piece № | E, GPa | σm, MPa |

|---|---|---|---|

| CPE HG 100 | 1 | 1.19 | 33 |

| 2 | 1.20 | 27 | |

| 3 | 1.15 | 28 | |

| Average | 1.18 | 29 | |

| CPE HG 100 after aging | 1 | 1.17 | 33 |

| 2 | 1.18 | 32 | |

| 3 | 1.17 | 26 | |

| Average | 1.17 | 30 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Paneva, M.; Panev, P.; Tsonev, V. Tensile Testing of Polymer Material Specimens Obtained by Fused Deposition Modeling. Eng. Proc. 2025, 100, 50. https://doi.org/10.3390/engproc2025100050

Paneva M, Panev P, Tsonev V. Tensile Testing of Polymer Material Specimens Obtained by Fused Deposition Modeling. Engineering Proceedings. 2025; 100(1):50. https://doi.org/10.3390/engproc2025100050

Chicago/Turabian StylePaneva, Miglena, Peter Panev, and Veselin Tsonev. 2025. "Tensile Testing of Polymer Material Specimens Obtained by Fused Deposition Modeling" Engineering Proceedings 100, no. 1: 50. https://doi.org/10.3390/engproc2025100050

APA StylePaneva, M., Panev, P., & Tsonev, V. (2025). Tensile Testing of Polymer Material Specimens Obtained by Fused Deposition Modeling. Engineering Proceedings, 100(1), 50. https://doi.org/10.3390/engproc2025100050