1. Introduction

Insulation devices play a key role in electrical power systems and their failures can impair the quality of electrical energy supply. For this reason, the industry has been growing attention to developing systems whose objective is diagnosing incipient failures in these components aiming to guarantee efficiency in the energy supply with planned maintenance [

1,

2,

3].

However, insulation devices such as bushings can suffer unexpected failures originated by heat, moisture, dielectric contamination by dust, thermal and electrical stresses, etc. [

1,

4]. These critical issues can lead the insulation system to Partial Discharge (PD) activity, which is defined as electric pulses that emit UV radiation, current, heat, acoustic and electromagnetic waves, causing a progressive deterioration of dielectrics [

5,

6]. Therefore, several methodologies have been proposed to extract features of PD activity such as acoustic emission [

7], current analysis [

8], capacitive divider [

3], UHF measurement [

9], etc. However, as PD imposes a progressive deterioration to the insulation system, it is crucial to assess its evolution to enhance control, safety, and maintenance planning.

One of the most traditional techniques applied to monitor failures in electrical machines and insulation systems is the thermal analysis, which can assess flaws such as bad contacts and overload by using an infrared camera [

10,

11,

12,

13]. The basis of this technology is to detect the infrared wavelengths emitted by objects which are subjected to a temperature above the absolute zero (−273 °C) [

14]. Although it has proven to be a promising tool to perform fault detection, the assessment of partial discharges in insulation systems has not been previously performed using this technique.

Based on this issue, this article proposed a new approach to perform the identification of PD severity evolution in bushings by applying infrared thermal analysis and image processing. In this sense, two new indexes were developed to characterize the PD levels: The Area Ratio Coefficient (ARC) and the RGB Ratio Coefficient (RGBRC).Therefore, these two statistical parameters are the contribution of the work for literature since the assessment of PD evolution can be an improvement for maintenance planning infrared-based.

This paper is organized as follows:

Section 2 presents the new indexes applied to characterize the PD evolution by infrared analysis. The experimental setup is described in

Section 3, and then, in

Section 4, the results are presented and discussed.

Section 5 reports the conclusions of this article.

2. Infrared Thermal Analysis Applied to PD

All objects below the absolute zero (−273 °C) radiate infrared wavelengths, which consists of a kind of electromagnetic wave, out of human eyes perception that relates to the field of the temperature of the object. In this scenario, infrared thermal cameras have set of sensors which can measure the infrared rays emitted by the surface of objects. This device can acquires infrared radiation from an object and digitize the radiation pattern into an image or video. After that, a hot spot caused by nonconformity can be identified [

14,

15].

Once several types of flaws can change the heat emission pattern, the infrared analysis is a promising tool to assess nonconformity in electrical machines and insulation systems [

14]. Due to the advantages of being non-destructive sensors, thermal cameras have been widely used in the industry, electric power systems, etc. [

15].

For example, in [

11] a prediction of transformer fault in cooling system using combining advanced thermal model and thermography. Shanker et al. (2017) proposed a transformer breather thermal image decomposition for fault diagnosis [

16]. Wang et al. (2020) applied thermal images to assess an insulator condition under extreme operation conditions [

17]. Besides the applicability of thermal images in the power system, infrared thermography can also used to monitor aerospace components according to [

18].

Several methodologies combine infrared with imaging processing techniques to improve the effectiveness of the monitoring systems. Zhao et al. (2016) [

15] applied a Support Vector Machine (SVM) to detect the insulator strings in infrared images. The objective is to perform temperature analysis with complex background. An insulator fault detection method based on spatial features of aerial images was proposed by [

19] to identify flaws in ceramics. The recognition accuracy of thermal spots was improved by [

20] by Hough Transform. The major contributions in infrared analysis are focused on the improvement of the accuracy in complex backgrounds and perform detection of hot spots caused by bad contacts. However, PD activity is an important indicative of the condition of the insulation system, and, therefore, the incipient assessment of this issue by thermal images can be a promising contribution to avoid unexpected stoppages of the electrical power systems.

By analyzing thermal images of insulators, this article proposed two indexes to perform the identification of PD evolution: the area ratio coefficient and the RGB ratio coefficient.

The ARC index is defined as:

where

is the area of hot spots and

is the total area of the insulator. The hot spots were defined as the spots with a temperature different from the ambient temperature.

The RGBRC index is defined as:

where

is the number of pixels orange or red in the image, and

is the total number of pixels in the whole image. The number of pixels orange or red represents 30% of the highest temperatures of the thermal camera scale.

3. Materials and Methods

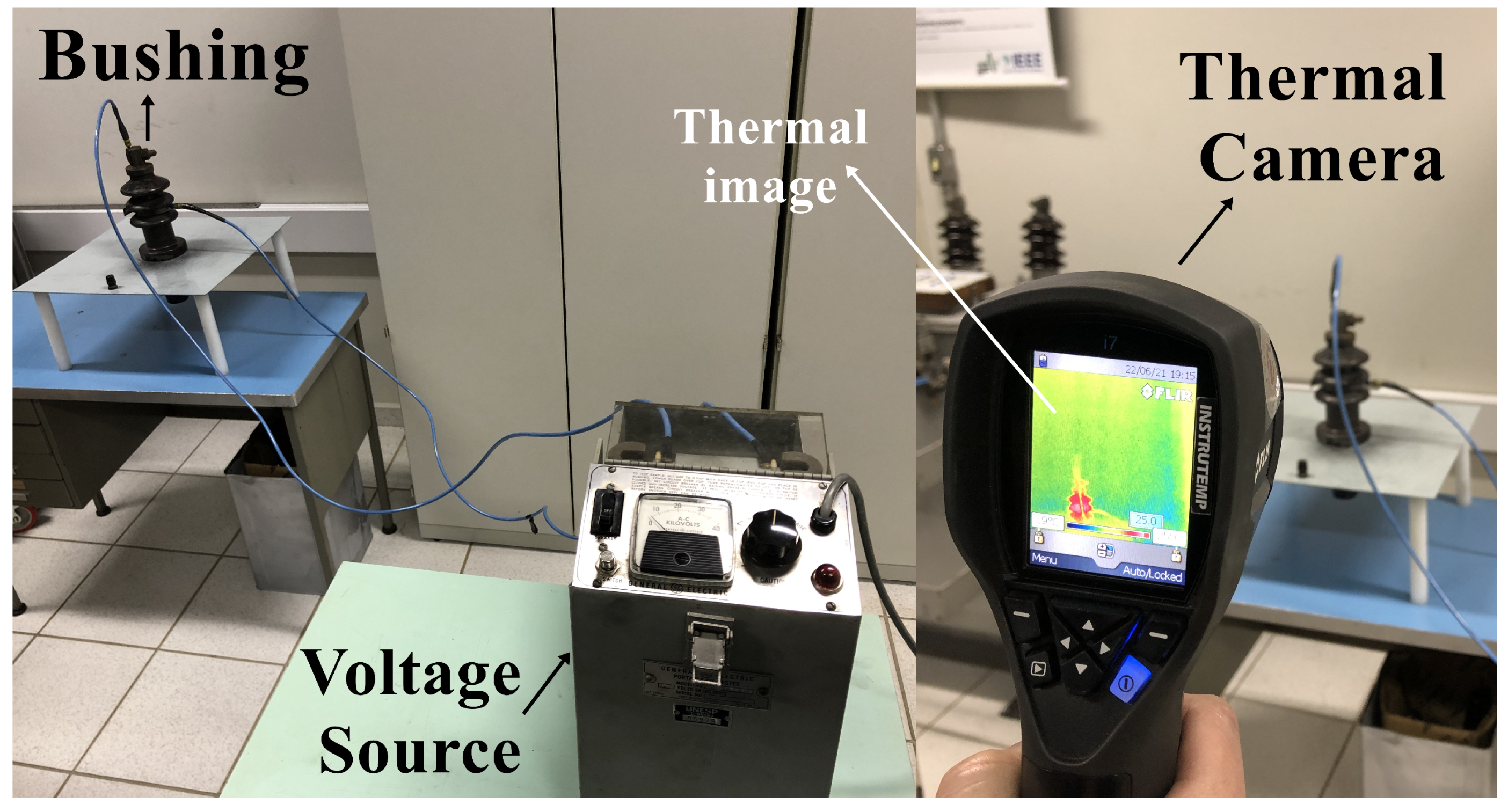

In real-life scenarios, insulation systems are constantly contaminated with dust, which can promote PD activity. Therefore, a transformer’s bushing was contaminated with powdered graphite to emulate this condition. Additionally, a high voltage AC source (0–40 kV) was connected to the extremities of the component to induce partial discharges. One of the most relevant steps for the improvement of maintenance planning is the PD evolution assessment. Due to material deterioration, the electrical charges produced by the failure increase. Based on this behavior, the PD evolution was carried out by increasing the voltage level for the same contamination pattern. The PD started at 13 kV, and, after that, the voltage was increased by a step of 2 kV up to 23 kV, totaling six different flaw levels. For each level, 20 images were taken using a thermal camera (FLIR, −20 °C to +400 °C, 19.200 (120 × 160) pixels). Additionally, 20 more images were taken when the insulator was without PD activity (0 kV) to assess the effectiveness of thermal analysis for PD evolution.

Figure 1 shows the experimental setup.

After that, the thermal images were transferred to a computer. The image processing analysis was performed according to the Area Ratio Coefficient (ARC) and RGB Ratio Coefficient (RGBRC) indexes. Furthermore, the maximum temperature of the insulator was analyzed.

4. Results and Discussion

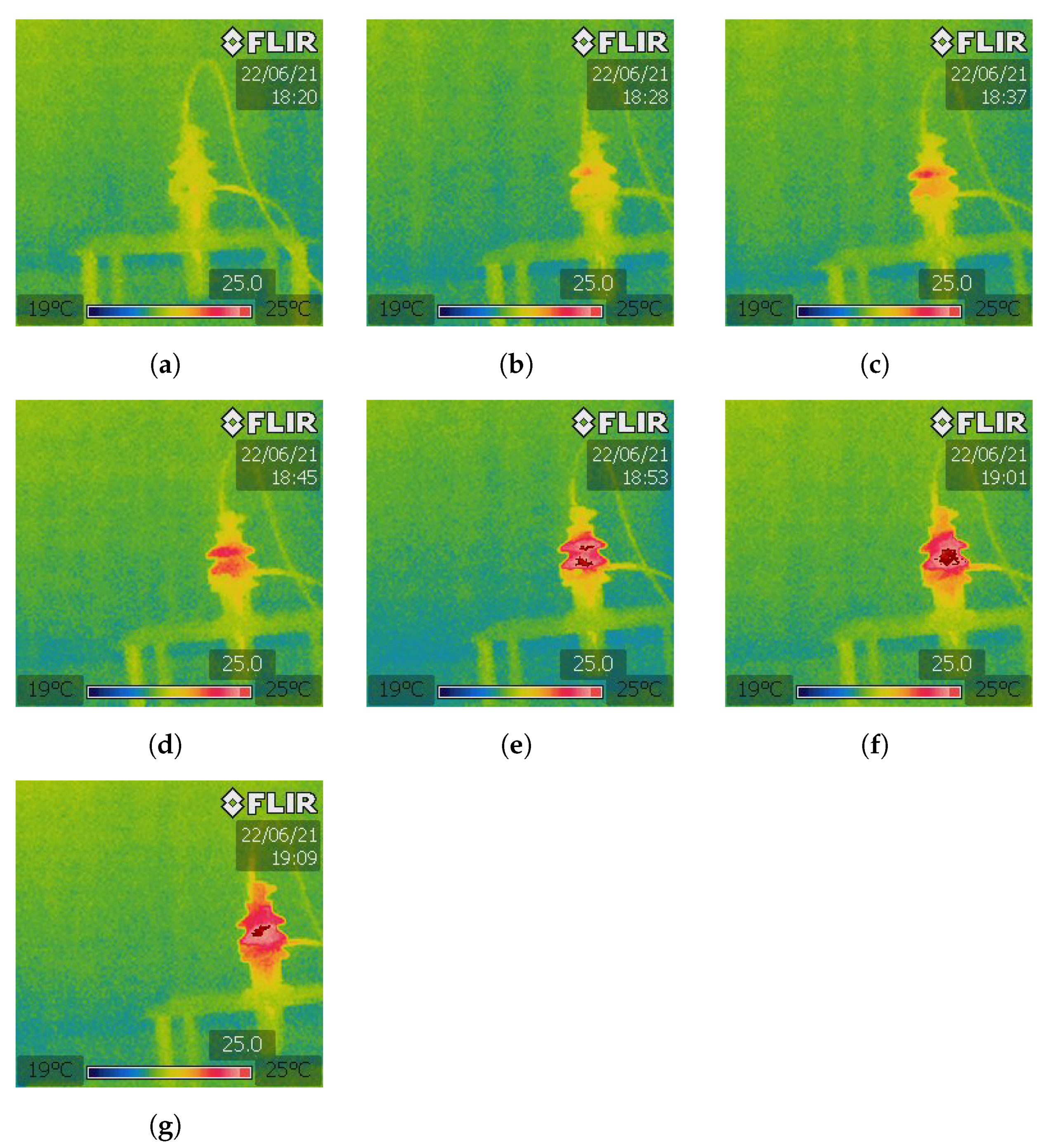

Figure 2 presents the thermal images taken for all PD levels. It can be noted that the thermal analysis is suitable to perform PD evolution detection since the temperature increases with the PD activity. By

Figure 2a, when the failure is not present at the component, the average temperature was 22 °C. After the PDs started, it can be observed hot spots promoted by failure heat emission. However, the visual analysis was not enough to perform a quantitative estimation of PD evolution. Furthermore, in some figures, the effects of the faults in the thermography are too subtle (e.g.,

Figure 2b) and may not be detected without the development of a specific index. On the other hand, in

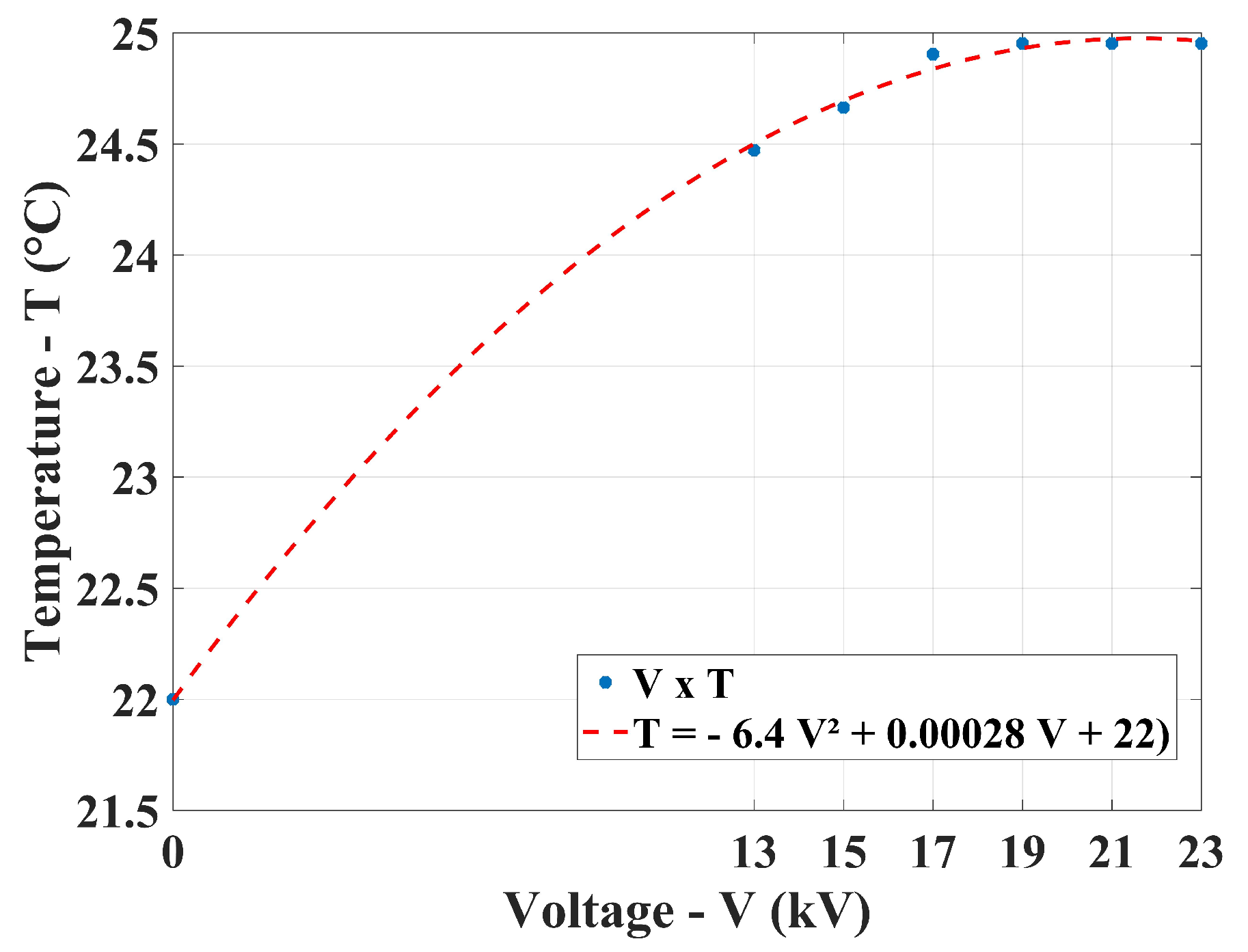

Figure 2e–g, it is hard to define which one represents the highest PD level, reiterating the creation of new imaging processing approaches. A basic analysis of the maximum temperature value is not sufficient to assess the PD evolution since the maximum temperature spot of the image remains at 25 °C for PDs higher than 17 kV, as shown in

Figure 3.

Therefore, based on these issues, the feature extraction of PD evolution was achieved by the novel indexes ARC and RGBRC, according to

Figure 4. By analyzing the results, it can be noted that ARC and RGBRC indexes increase with the PD evolution. The strong correlation between the voltage levels and the indexes allows a linear regression. Then, the regression equations presented in

Figure 4a,b can be applied to estimate the PD level based on the thermal images.

The ARC increased from 0 to 80%, which means that the intensity of the PD activity can change the thermal pattern in the whole insulator. Furthermore, the relation between the high-temperature pixels and the total number of pixels can be a promising tool to detect the failure evolution once the red and orange patterns increased as presented in

Figure 4.

5. Conclusions

The bushings are crucial components of the power systems. Therefore, industry and science seek to develop monitoring systems aiming to enhance the maintenance plans and avoid failures. Partial discharges are characterized by incipient flaws that can lead the insulation system to total failures. Therefore, their earlier diagnosis can avoid financial loss and stoppages in the electrical system. Furthermore, the assessment of PD evolution can be an improvement for maintenance planning.

In this context, this work proposed the creation of two new indexes to monitor the evolution of PDs in bushings. After the experiments which imposed several PD levels to an insulator, the results pointed to a strong correlation between the ARC and RGBRC indexes values and the voltage levels applied to the bushing. For both cases, the indexes increased with the failure intensity. Although this work used simple tools as infrared cameras, the results proved that the indexes provided robust and reliable estimations for PD evolution, adding a new feature for thermal analysis.

Author Contributions

Supervision, B.A.d.C.; project administration, B.A.d.C. and A.L.A.; methodology, G.B.L. and G.S.F.; formal analysis, G.S.F.; software, G.S.F., B.A.d.C. and G.B.L.; validation, J.R.C.P.F. and R.R.R.; writing, J.R.C.P.F. and R.R.R.; resources, A.L.A.; writing—review and editing B.A.d.C. and G.B.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available upon reasonable request.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| PD | Partial Discharge |

| UHF | Ultra High Frequency |

| RGB | Red, Green, and Blue |

| ARC | Area Ratio Coefficient |

| RGBRC | RGB Ratio Coefficient |

| SVM | Support Vector Machine |

References

- Gu, Z.; Zhu, W.; Zhu, M.; Xu, W.; Gao, Z.; Yi, F. Analysis on the Influences of Temperature on the Moisture Detection of Transformer Bushings. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2020; Volume 526, p. 012027. [Google Scholar]

- dos Santos, V.V.; de Castro, B.A.; Binotto, A.; Rey, J.A.A.; Lucas, G.B.; Andreoli, A.L. An application of wavelet analysis to assess partial discharge evolution by acoustic emission sensor. In Proceedings of the 7th Electronic Conference on Sensors and Applications, Online, 15–30 November 2020; Volume 15, p. 30. [Google Scholar]

- Montanari, G.C.; Ghosh, R.; Cirioni, L.; Galvagno, G.; Mastroeni, S. Partial Discharge Monitoring of Medium Voltage Switchgears: Self-condition Assessment using an Embedded Bushing Sensor. IEEE Trans. Power Deliv. 2021, 37, 1. [Google Scholar] [CrossRef]

- Binotto, A.; de Castro, B.A.; Rey, J.A.A.; Andreoli, A.L. Partial Discharge Detection of Transformer Bushing Based on Acoustic Emission and Current Analysis. In Proceedings of the IEEE XXVIII International Conference on Electronics, Electrical Engineering and Computing—INTERCON, Lima, Peru, 5–7 August 2021; Volume 2, pp. 1–4. [Google Scholar]

- Ilkhechi, H.D.; Samimi, M.H. Applications of the Acoustic Method in Partial Discharge Measurement: A Review. IEEE Trans. Dielectr. Electr. Insul. 2021, 28, 42–51. [Google Scholar] [CrossRef]

- IEC Standard. High-Voltage Test Techniques: Partial Discharge Measurements; IEC-60270; IEC Standard: London, UK, 2000; pp. 13–31. [Google Scholar]

- Sikorski, W.; Walczak, K.; Gil, W.; Szymczak, C. On-Line partial discharge monitoring system for power transformers based on the simultaneous detection of high frequency, ultra-high frequency, and acoustic emission signals. Energies 2020, 13, 3271. [Google Scholar] [CrossRef]

- Ardila-Rey, J.A.; Barrueto, A.; Zerene, A.; de Castro, B.A.; Ulson, J.A.C.; Mas’ud, A.A.; Valdivia, P. Behavior of an inductive loop sensor in the measurement of partial discharge pulses with variations in its separation from the primary conductor. Sensors 2018, 18, 2324. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jiang, J.; Chen, J.; Li, J.; Yang, X.; Bie, Y.; Ranjan, P.; Zhang, C.; Schwarz, H. Partial Discharge Detection and Diagnosis of Transformer Bushing Based on UHF Method. IEEE Sens. J. 2021, 21, 16798–16806. [Google Scholar] [CrossRef]

- Mariprasath, T.; Kirubakaran, V. A real time study on condition monitoring of distribution transformer using thermal imager. Infrared Phys. Technol. 2018, 90, 78–86. [Google Scholar] [CrossRef]

- Shiravand, V.; Faiz, J.; Samimi, M.H.; Mehrabi-Kermani, M. Prediction of transformer fault in cooling system using combining advanced thermal model and thermography. IET Gener. Transm. Distrib. 2021, 15, 1972–1983. [Google Scholar] [CrossRef]

- Tang, W.; Wu, B.; Lu, W.; Zhao, W.; Li, L.; Yin, H. Fault diagnosis of the external insulation infrared images based on Mask Region convolutional neural network and perceptual hash joint algorithm. In Proceedings of the 2021 IEEE International Conference on the Properties and Applications of Dielectric Materials (ICPADM), Johor Bahru, Malaysia, 12–14 July 2021; pp. 111–114. [Google Scholar]

- Duan, J.; He, Y.; Du, B.; Ghandour, R.M.R.; Wu, W.; Zhang, H. Intelligent Localization of Transformer Internal Degradations Combining Deep Convolutional Neural Networks and Image Segmentation. IEEE Access 2019, 7, 62705–62720. [Google Scholar] [CrossRef]

- Chen, Q.; Li, Y.; Liu, Z.; Gao, J.; Li, X.; Zhang, S. Fault Detection and Analysis of Voltage Transformer Secondary Terminal based on Infrared Temperature Measurement Technology. In Proceedings of the 2019 IEEE 4th Advanced Information Technology, Electronic and Automation Control Conference (IAEAC), Chengdu, China, 20–22 December 2019. [Google Scholar] [CrossRef]

- Zhao, Z.; Xu, G.; Qi, Y. Representation of binary feature pooling for detection of insulator strings in infrared images. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 2858–2866. [Google Scholar] [CrossRef]

- Vidhya, R.; Ranjan, P.V.; Shanker, N. Transformer breather thermal image decomposition for fault diagnosis. In Proceedings of the 2021 7th International Conference on Electrical Energy Systems (ICEES), Chennai, India, 11–13 February 2021; pp. 448–453. [Google Scholar]

- Wang, T.; Long, M.C.; Zhao, H.B.; Liu, B.W.; Shi, H.G.; An, W.L.; Li, S.L.; Xu, S.M.; Wang, Y.Z. An ultralow-temperature superelastic polymer aerogel with high strength as a great thermal insulator under extreme conditions. J. Mater. Chem. A 2020, 8, 18698–18706. [Google Scholar] [CrossRef]

- Ciampa, F.; Mahmoodi, P.; Pinto, F.; Meo, M. Recent advances in active infrared thermography for non-destructive testing of aerospace components. Sensors 2018, 18, 609. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhai, Y.; Chen, R.; Yang, Q.; Li, X.; Zhao, Z. Insulator fault detection based on spatial morphological features of aerial images. IEEE Access 2018, 6, 35316–35326. [Google Scholar] [CrossRef]

- Zhao, H.; Zhang, Z. Improving Neural Network Detection Accuracy of Electric Power Bushings in Infrared Images by Hough Transform. Sensors 2020, 20, 2931. [Google Scholar] [CrossRef] [PubMed]

| Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).