A Case Study for Implementing a Plant Corrosion Inspection and Maintenance Anomaly and Integrity Management System on the Sabratha Gas Production Offshore Platform in the Mediterranean Sea †

Abstract

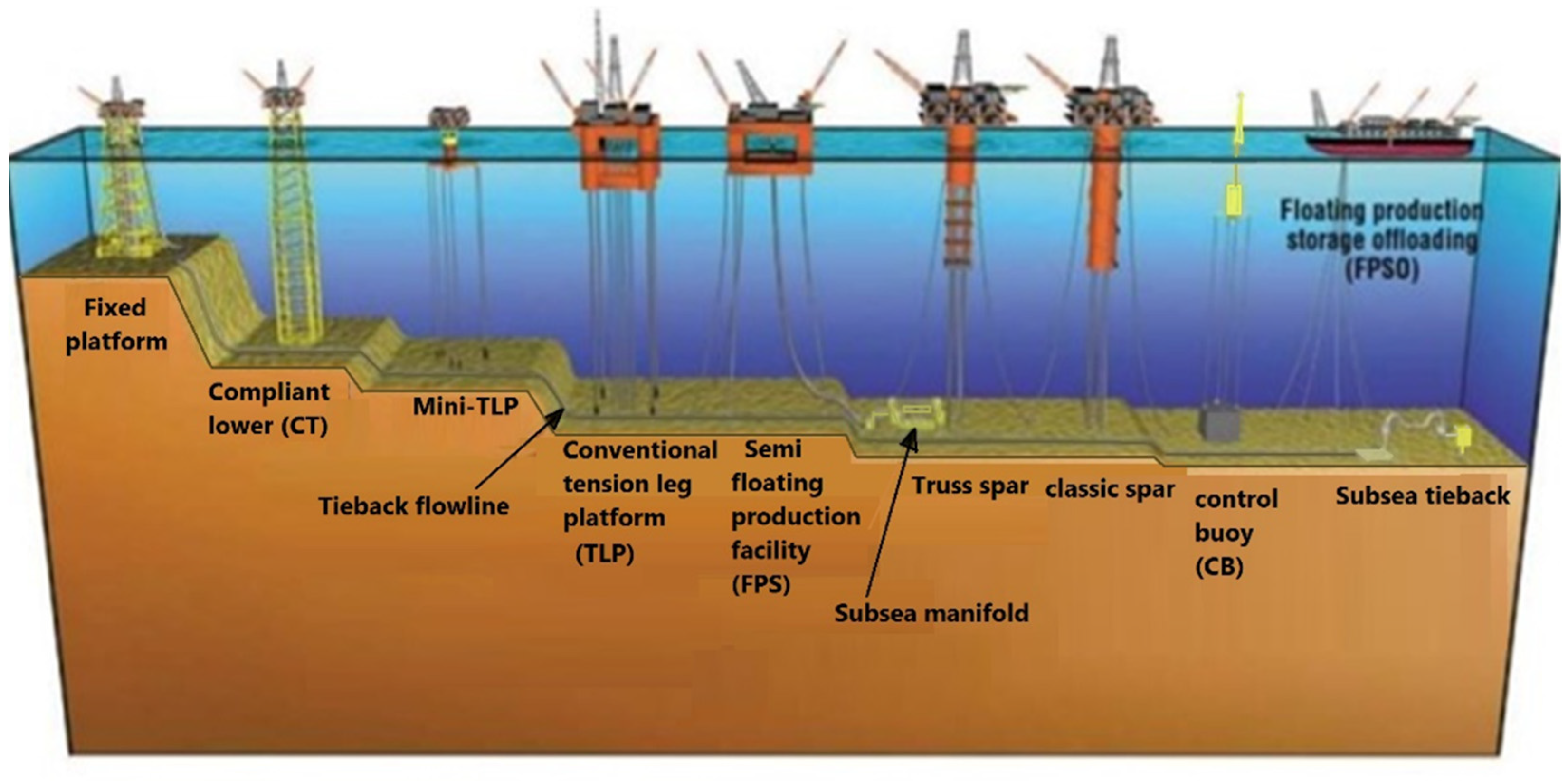

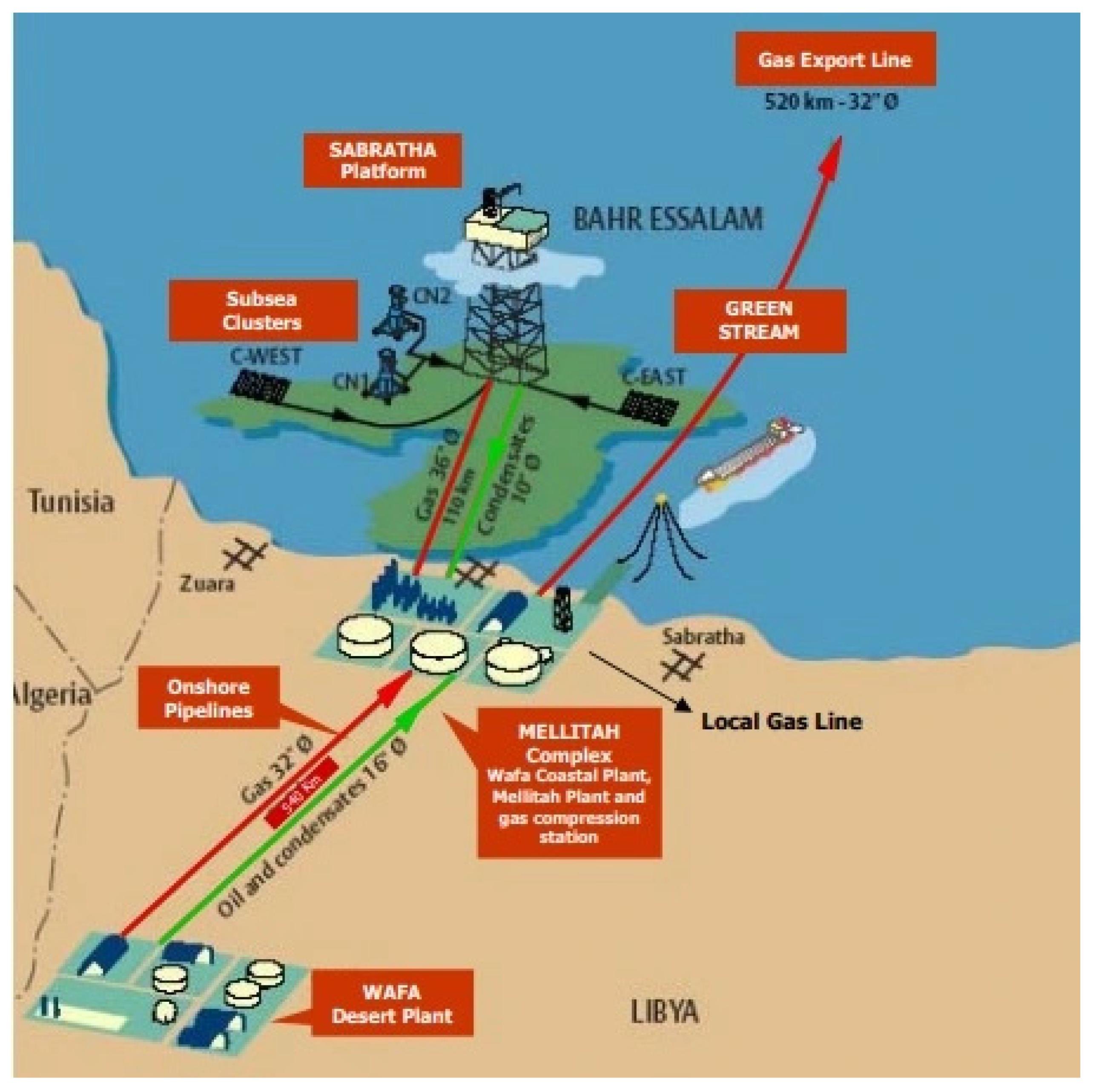

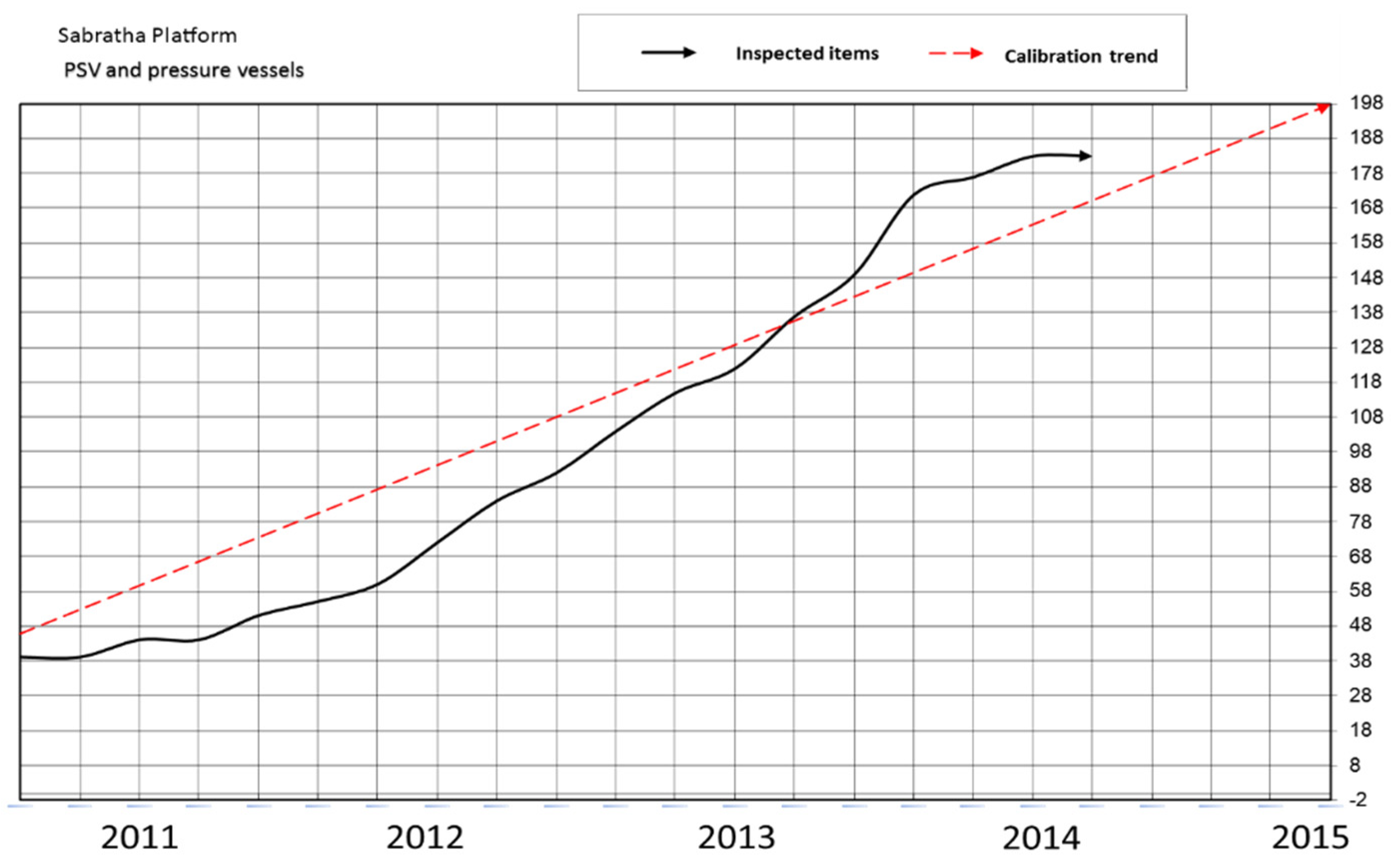

:1. Introduction

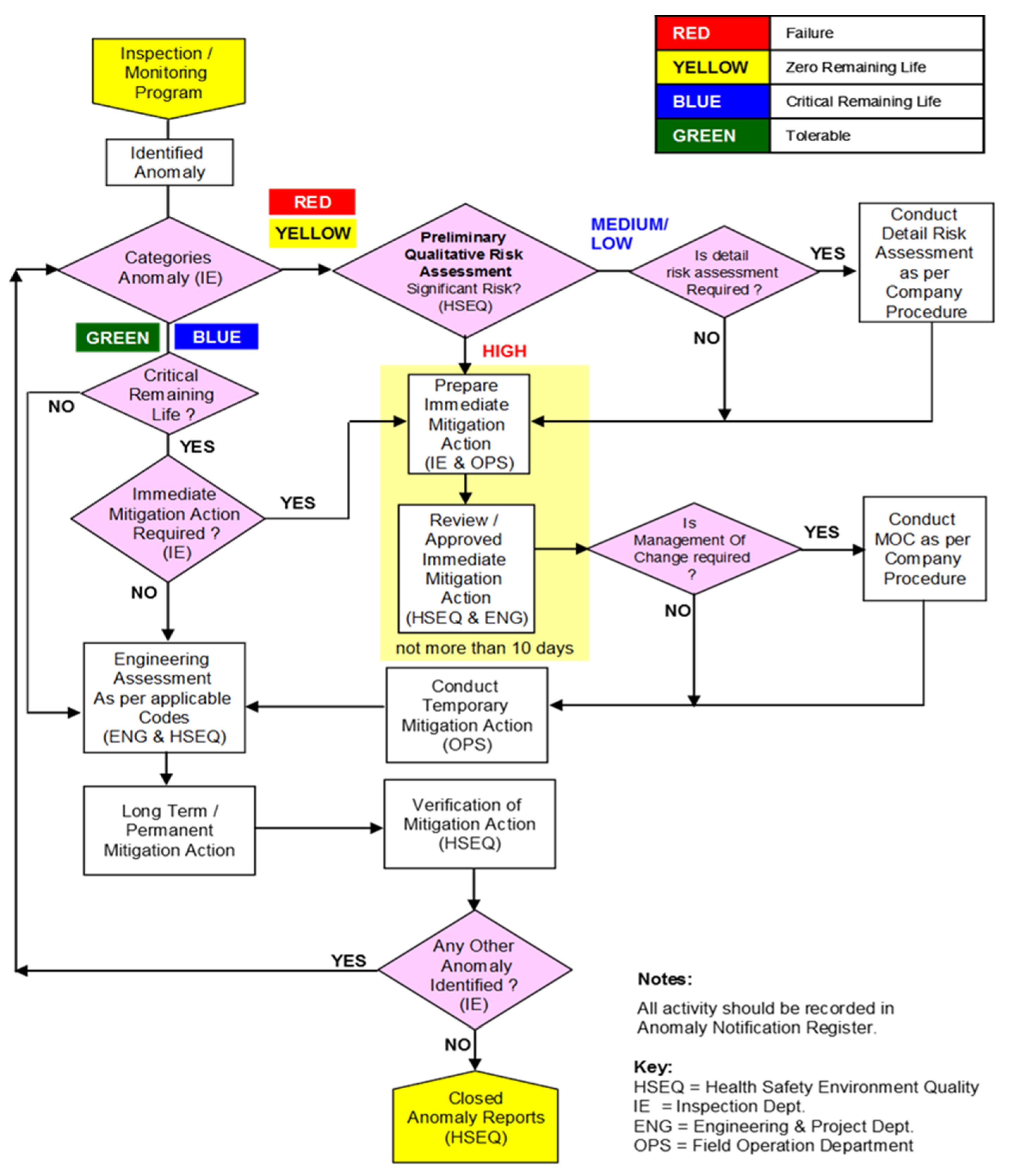

2. Methodology and Procedure

2.1. AIMS System Overview

- to brief the requirements to record anomalies occurring in the pressure system.

- to inspect the critical facilities following up the mitigation (including maintenance and replacement),

- to resolve any anomaly that might threaten the integrity of the offshore facility.

2.2. Responsibilities of Departments

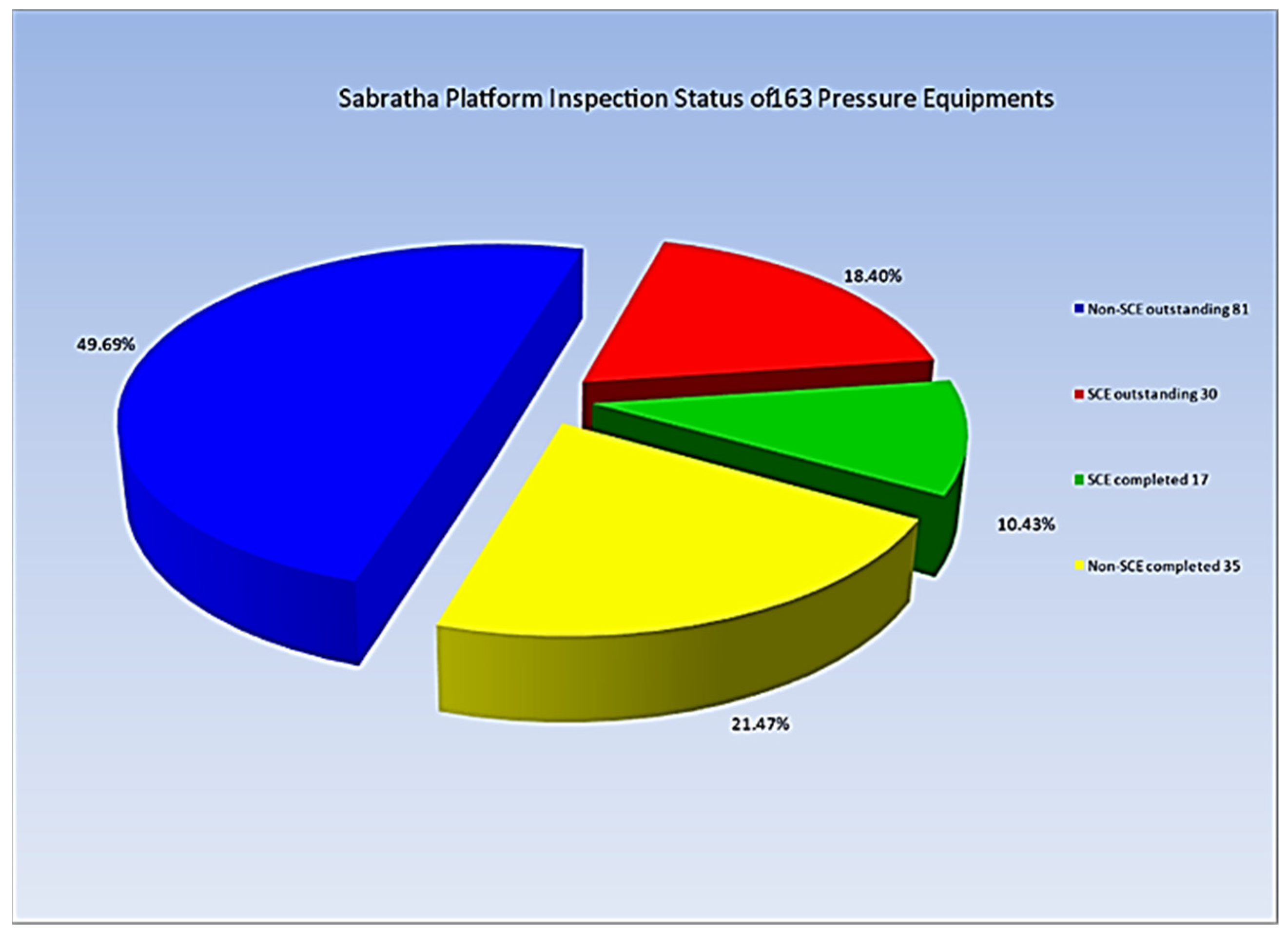

2.3. Evaluation of Using the Database Results

3. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tan, Y.; Li, H.X.; Cheng, J.C.P.; Wang, J.; Jiang, B.; Song, Y.; Wang, X. Cost and environmental impact estimation methodology and potential impact factors in offshore oil and gas platform decommissioning: A review. Environ. Impact Assess. Rev. 2021, 87, 106536. [Google Scholar] [CrossRef]

- Kaiser, M.J. Offshore oil and gas records circa 2020. Ships Offshore Struct. 2020, 1–37. [Google Scholar] [CrossRef]

- Guédé, F. Risk-based structural integrity management for offshore jacket platforms. Mar. Struct. 2019, 63, 444–461. [Google Scholar] [CrossRef]

- NOIA. The Basics of Offshore Oil & Gas—NOIA. Available online: https://www.noia.org/basics-offshore-oil-gas/ (accessed on 20 July 2021).

- American Petroleum Institute. API- RECOMMENDED PRACTICE 581: Risk-Based Inspection Technology; American Petroleum Institute: Washington, DC, USA, 2016; Volume 7056. [Google Scholar]

- Tang, Y.; Yao, J.; Wang, G.; Zhang, Z.; He, Y.; Jing, J. Risk Identification and Quantitative Evaluation Method for Asset Integrity Management of Offshore Platform Equipment and Facilities. Math. Probl. Eng. 2019, 19, 1–14. [Google Scholar] [CrossRef]

- Olsen, E.; Næss, S.; Høyland, S. Exploring relationships between organizational factors and hydrocarbon leaks on offshore platform. Saf. Sci. 2015, 80, 301–309. [Google Scholar] [CrossRef]

- Mussa, M. Development of Hybrid Sol-Gel Coatings on AA2024-T3 with Environmentally Benign Corrosion Inhibitors. Ph.D. Thesis, Sheffield Hallam University, Sheffield, UK, 2020. [Google Scholar]

- Mussa, M.H.; Rahaq, Y.; Takita, S.; Farmilo, N. Study the Enhancement on Corrosion Protection by Adding PFDTES to Hybrid Sol-Gel on AA2024-T3 Alloy in 3.5% NaCl Solutions. Albahit J. Appl. Sci. 2021, 2, 61–68. [Google Scholar]

- El-Reedy, M.A. Practical risk management for offshore projects. In Offshore Projects and Engineering Management; Elsevier: Amsterdam, The Netherlands, 2021; pp. 215–238. ISBN 9780323857956. [Google Scholar]

- Hogenboom, S.; Vinnem, J.E.; Utne, I.B.; Kongsvik, T. Risk-based decision-making support model for offshore dynamic positioning operations. Saf. Sci. 2021, 140, 105280. [Google Scholar] [CrossRef]

- Mellitah Oil & Gas B.V. Sabratha Platform—Mellitah Oil & Gas. Available online: https://mellitahog.ly/en/sites/sabratha-platform/ (accessed on 2 July 2021).

- Mellitah Oil & Gas B.V. Management Corporate Procedure Anomaly Management System MG-HSEQ-P-035; Mellitah Oil & Gas B.V.: Tripoli, Libya, 2010; Volume 5, pp. 1–17. [Google Scholar]

| Equipment and Facilities | Operation Errors | Artificial Damage | Natural Disaster | Unknown Reasons |

|---|---|---|---|---|

| 40% | 20% | 12% | 10% | 18% |

| HSEQ Department |

|

| Engineering Department |

|

| Inspection Section |

|

| Operation, maintenances, and production Department |

|

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mussa, M.H.; Dukali, M.; Rahaq, Y. A Case Study for Implementing a Plant Corrosion Inspection and Maintenance Anomaly and Integrity Management System on the Sabratha Gas Production Offshore Platform in the Mediterranean Sea. Eng. Proc. 2021, 11, 9. https://doi.org/10.3390/ASEC2021-11153

Mussa MH, Dukali M, Rahaq Y. A Case Study for Implementing a Plant Corrosion Inspection and Maintenance Anomaly and Integrity Management System on the Sabratha Gas Production Offshore Platform in the Mediterranean Sea. Engineering Proceedings. 2021; 11(1):9. https://doi.org/10.3390/ASEC2021-11153

Chicago/Turabian StyleMussa, Magdi H., Mahmoud Dukali, and Yaqub Rahaq. 2021. "A Case Study for Implementing a Plant Corrosion Inspection and Maintenance Anomaly and Integrity Management System on the Sabratha Gas Production Offshore Platform in the Mediterranean Sea" Engineering Proceedings 11, no. 1: 9. https://doi.org/10.3390/ASEC2021-11153

APA StyleMussa, M. H., Dukali, M., & Rahaq, Y. (2021). A Case Study for Implementing a Plant Corrosion Inspection and Maintenance Anomaly and Integrity Management System on the Sabratha Gas Production Offshore Platform in the Mediterranean Sea. Engineering Proceedings, 11(1), 9. https://doi.org/10.3390/ASEC2021-11153