Preservation of Rabbit Meat in High-Density Polyethylene Packaging Bags Reinforced with Ethyl Cellulose Nanoparticles Loaded with Rosemary Extract

Abstract

1. Introduction

2. Materials and Methods

2.1. TPC, DPPH, and FRAP Activity Analysis of Rosemary Extract

2.2. Synthesis, Characterization, Encapsulation Efficiency (EE), and Stability of RCL-NPs

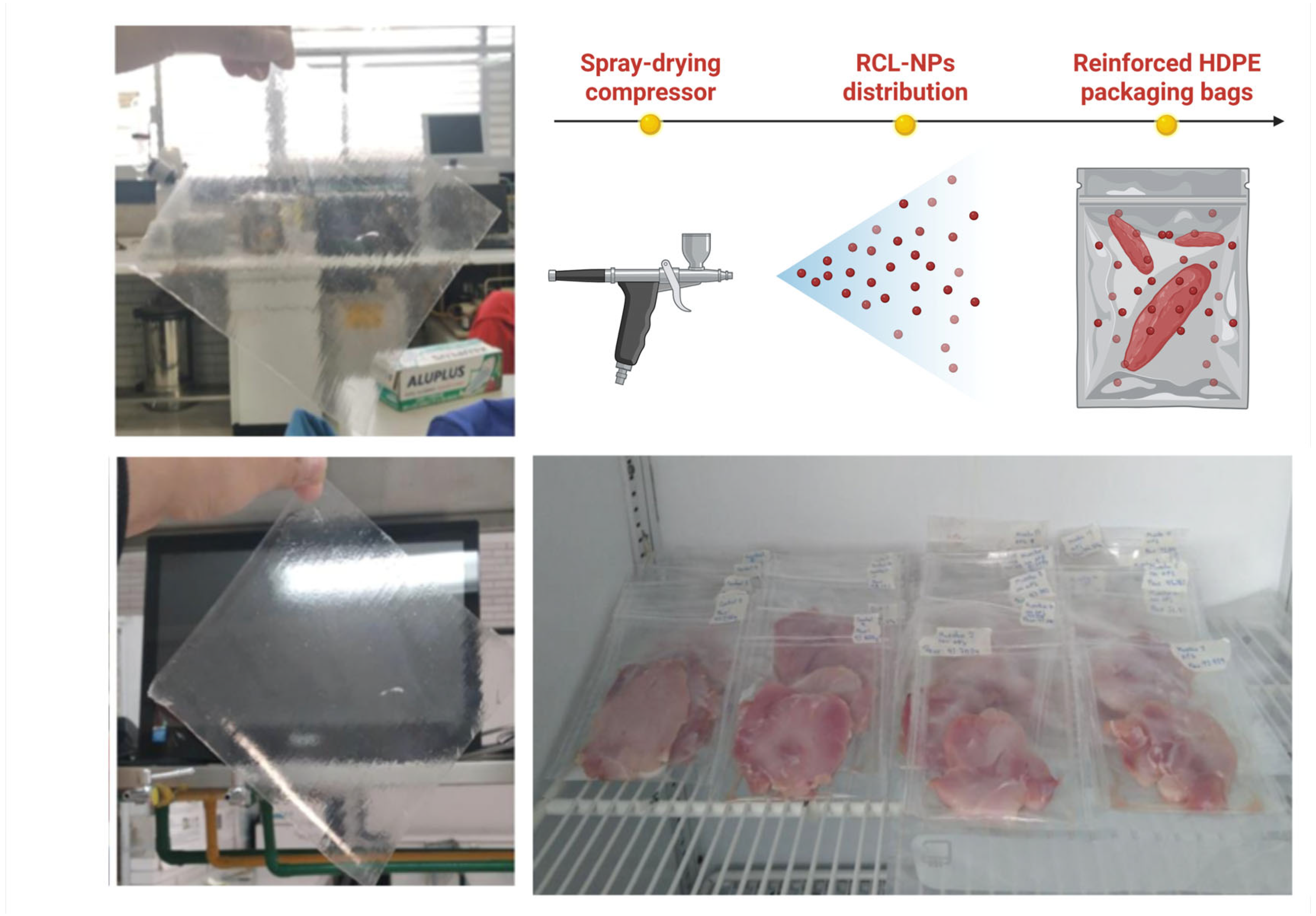

2.3. Incorporation of RCL-NPs into HDPE Packaging Bags, Packaging of Rabbit Meat, and Release Rate Analysis

2.4. Drained Liquid and Weight Loss Analysis

2.5. Color and pH Analysis

2.6. Texture and Hardness Analysis

2.7. Statistical Analysis

3. Results

3.1. TPC and Antioxidant Activity of Rosemary Extract

3.2. Synthesis and Characterization of RCL-NPs

3.3. EE and Release Profile of RCL-NPs

3.4. Drained Liquid and Weight Loss Analysis

3.5. Color and pH Analysis

3.6. Texture and Hardness Analysis

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Siddiqui, S.A.; Gerini, F.; Ikram, A.; Saeed, F.; Feng, X.; Chen, Y. Rabbit Meat—Production, Consumption and Consumers’ Attitudes and Behavior. Sustainability 2023, 15, 2008. [Google Scholar] [CrossRef]

- Kim, J.M.; Park, H.J.; Bae, H. Study on the Impact of Reducing Aluminium Foil Thickness on the Barrier Properties of Retort Pouches During Shelf Life: Simulated Physical Stress Considering Distribution Environment. Packag. Technol. Sci. 2025, 38, 333–341. [Google Scholar] [CrossRef]

- Ferri, M.; Lenzi, L.; Degli Esposti, M.; Martellosio, L.; Benítez, J.J.; Hierrezuelo, J.; Grifé-Ruiz, M.; Romero, D.; Guzmán-Puyol, S.; Heredia-Guerrero, J.A.; et al. Triphenyl Acetic Glyceroate as a Sustainable Multifunctional Additive for Developing Transparent, Biodegradable, and Flexible Polylactide Green Alternative to Polyethylene-Based Films for Food Packaging. Chem. Eng. J. 2025, 508, 160887. [Google Scholar] [CrossRef]

- Xavier, J.R.; Vinodhini, S.P.; Priyadharshini, A. Multifunctional Epoxy-Based Nanocomposite Coating for Tinplate: Enhancing Food Packaging with Superior Mechanical, Anticorrosion, and Antimicrobial Properties. Int. J. Biol. Macromol. 2025, 309, 142671. [Google Scholar] [CrossRef]

- Contreras-López, G.; Morales-Rodríguez, S.; Alarcon-Rojo, A.D.; Carrillo-Lopez, L.M. Effect of Packaging Thickness and Muscle Type on Ultrasound-Assisted Beef Quality. Ultrason. Sonochemistry 2024, 103, 106777. [Google Scholar] [CrossRef]

- Zain Ul Abidin, M.; Ikram, M.; Moeen, S.; Nazir, G.; Kanoun, M.B.; Goumri-Said, S. A Comprehensive Review on the Synthesis of Ferrite Nanomaterials via Bottom-up and Top-down Approaches Advantages, Disadvantages, Characterizations and Computational Insights. Coord. Chem. Rev. 2024, 520, 216158. [Google Scholar] [CrossRef]

- Chang, R.-Y.; Geng, W.-H.; Jing, L.-C.; Feng, J.-Y.; Wang, Y.-X.; Qian, P.-F.; Bao, Z.-L.; Wang, W.; Zhang, D.; Geng, H.-Z. Construction and Application of Antimicrobial Ultrafiltration Membranes Based on Electro-Stimulated Hollow Mesoporous Carbon Spheres and Carbon Nanotubes. J. Environ. Chem. Eng. 2025, 13, 115773. [Google Scholar] [CrossRef]

- Bal, K.; Gök, M.K.; Demir, K.; Özgümüş, S. Building Effective Nanocarriers Based on β-Ionone Loaded 2nd and 3rd Generation L-Arginine Dendrimers: In Vitro Evaluation of Cytotoxicity and Antiproliferative Activity for HeLa Cells. Mater. Today Chem. 2025, 44, 102545. [Google Scholar] [CrossRef]

- Zare, I.; Zahed Nasab, S.; Rahi, A.; Ghaee, A.; Koohkhezri, M.; Ramezani Farani, M.; Madadi Gholipour, H.; Atabaki, A.H.; Hamblin, M.R.; Mostafavi, E.; et al. Antimicrobial Carbon Materials-Based Quantum Dots: From Synthesis Strategies to Antibacterial Properties for Diagnostic and Therapeutic Applications in Wound Healing. Coord. Chem. Rev. 2025, 522, 216211. [Google Scholar] [CrossRef]

- Surya, S.; Soman, A.; Krishnan, A.; Suresh, M.P.; Neenu, K.V.; Ajithkumar, T.G.; Parameswaranpillai, J.; Sabura Begum, P.M.; Midhun Dominic, C.D. Sustainable Cellulose Nanofiber Extraction from Borassus flabellifer: A Comprehensive Study and Analytical Insights. Biomass Conv. Bioref. 2025. [Google Scholar] [CrossRef]

- Zou, Y.; Liao, Z.; Zhang, R.; Song, S.; Yang, Y.; Xie, D.; Liu, X.; Wei, L.; Liu, Y.; Song, Y. Cellulose Nanofibers/Liquid Metal Hydrogels with High Tensile Strength, Environmental Adaptability and Electromagnetic Shielding for Temperature Monitoring and Strain Sensors. Carbohydr. Polym. 2025, 348, 122788. [Google Scholar] [CrossRef]

- Nandi, S.; Nayak, P.P.; Guha, P. Valorization of Betel Leaf Industry Waste: Extraction of Cellulose Nanocrystals and Their Compatibility with Starch-Based Composite Films. Biomass Bioenergy 2025, 194, 107678. [Google Scholar] [CrossRef]

- Baron, R.I.; Biliuta, G.; Bejan, D.; Darie-Nita, R.-N.; Coseri, S.; Dinu, M.V. Advancing the Design of Conductive Composite Cryogels Based on Hydroxypropyl Cellulose Derivatives for Improving the Compressibility and Anti-Freezing Properties. Int. J. Biol. Macromol. 2025, 296, 139764. [Google Scholar] [CrossRef] [PubMed]

- Huang, L.; Zhou, Y.; Feng, Y.; Jia, S.; Wang, S.; Zhong, C. Tailoring Bacterial Cellulose through the CRISPR/Cas9-Mediated Gene Editing Tool in Komagataeibacter xylinus. ACS Synth. Biol. 2025, 14, 1161–1172. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Z.; Zhao, Y.; Zhang, Y.; Zhang, S.; Li, W.; Ye, G.; Ma, X.; Zhang, X.; Bi, H. Self-Healing, Highly Stretchable, and 3D Printable Thiol-Functionalized Cellulose Nanofibers/Waterborne Polyurethane Composites for Flexible Electronic Monitoring. Chem. Eng. J. 2025, 506, 159835. [Google Scholar] [CrossRef]

- Brugnoli, M.; Carvalho, J.P.F.; Arena, M.P.; Oliveira, H.; Vilela, C.; Freire, C.S.R.; Gullo, M. Co-Cultivation of Komagataeibacter Sp. and Lacticaseibacillus Sp. Strains to Produce Bacterial Nanocellulose-Hyaluronic Acid Nanocomposite Membranes for Skin Wound Healing Applications. Int. J. Biol. Macromol. 2025, 299, 140208. [Google Scholar] [CrossRef]

- He, R.; Gai, L.; Zhu, Z.; Gu, H.; Sun, P. Industrial By-Products of Tiger Nut Starch as a Source of Cellulose Nanocrystals for Biodegradable Packaging Materials. Int. J. Biol. Macromol. 2025, 306, 141422. [Google Scholar] [CrossRef]

- Wu, B.; Abdalkarim, S.Y.H.; Li, Z.; Lu, W.; Yu, H.-Y. Synergistic Enhancement of High-Barrier Polylactic Acid Packaging Materials by Various Morphological Carbonized Cellulose Nanocrystals. Carbohydr. Polym. 2025, 351, 123118. [Google Scholar] [CrossRef]

- Mahboub, N.; Cherfi, I.; Laouini, S.E.; Bouafia, A.; Benaissa, A.; Alia, K.; Alharthi, F.; Al-Essa, K.; Menaa, F. GC/MS and LC Composition Analysis of Essential Oil and Extracts from Wild Rosemary: Evaluation of Their Antioxidant, Antimicrobial, and Anti-Inflammatory Activities. Biomed. Chromatogr. 2025, 39, e70084. [Google Scholar] [CrossRef]

- Yeddes, W.; Rybak, K.; Rebey, I.B.; Pietrzak, D.; Adamczak, L.; Hammami, M.; Wannes, W.A.; Witrowa-Rajchert, D.; Tounsi, M.S.; Tixier, A.S.F.; et al. Lipid Oxidation and Barrier Properties of the Coated Freeze-Dried Chicken Meat with Gelatin-Chitosan Film Enriched with Rosemary (Rosmarinus officinalis L.) Extract. Foods 2025, 14, 1127. [Google Scholar] [CrossRef]

- Fard, G.C.; Parvinzadeh Gashti, M.; Dehdast, S.A.; Shabani, M.; Zarinabadi, E.; Seifi, N.; Berenjian, A. Novel Polyamide/Chitosan Nanofibers Containing Glucose Oxidase and Rosemary Extract: Fabrication and Antimicrobial Functionality. Coatings 2024, 14, 411. [Google Scholar] [CrossRef]

- Ghasemian, S.O.; Ahmadi-Dastgerdi, A.; Abdollahi, A.; Tirtashi, F.E.; Zokaei, M.; Fallah, N.; NajafAbadi, P.I.; Dolatyari, F. The Effect of Active Packaging Film Based on Chitosan Containing Rosemary (Rosmarinus officinalis L.) Extract on Cheese Shelf Life. J. Food Biochem. 2024, 2024, 2108707. [Google Scholar] [CrossRef]

- Jastaniah, S.D. Using Nisin-Chitosan Films Enriched with Rosemary Extract on Listeria innocua, Escherichia coli O157:H7 and Pseudomonas aeruginosa in Cold-Smoked Salmon during Cold Storage. Appl. Food Res. 2025, 5, 100693. [Google Scholar] [CrossRef]

- Hoelscher, H.; Fell, E.L.; Colet, R.; Nascimento, L.H.; Backes, Â.S.; Backes, G.T.; Cansian, R.L.; Valduga, E.; Steffens, C. Antioxidant Activity of Rosemary Extract, Acerola Extract and a Mixture of Tocopherols in Sausage during Storage at 8 °C. J. Food Sci. Technol. 2024, 61, 69–83. [Google Scholar] [CrossRef]

- Sahunie, A. Effect of Rosmarinus officinalis and Origanum majorana Extracts on Stability of Sunflower Oil during Storage and Repeated Heating. Oil Crop Sci. 2024, 9, 29–37. [Google Scholar] [CrossRef]

- Giannakas, A.; Salmas, C.; Leontiou, A.; Tsimogiannis, D.; Oreopoulou, A.; Braouhli, J. Novel LDPE/Chitosan Rosemary and Melissa Extract Nanostructured Active Packaging Films. Nanomaterials 2019, 9, 1105. [Google Scholar] [CrossRef] [PubMed]

- Mejía-Méndez, J.L.; Bach, H.; Lorenzo-Leal, A.C.; Navarro-López, D.E.; López-Mena, E.R.; Hernández, L.R.; Sánchez-Arreola, E. Biological Activities and Chemical Profiles of Kalanchoe Fedtschenkoi Extracts. Plants 2023, 12, 1943. [Google Scholar] [CrossRef] [PubMed]

- García-Betanzos, C.I.; Hernández-Sánchez, H.; Bernal-Couoh, T.F.; Quintanar-Guerrero, D.; Zambrano-Zaragoza, M.d.l.L. Physicochemical, Total Phenols and Pectin Methylesterase Changes on Quality Maintenance on Guava Fruit (Psidium guajava L.) Coated with Candeuba Wax Solid Lipid Nanoparticles-Xanthan Gum. Food Res. Int. 2017, 101, 218–227. [Google Scholar] [CrossRef]

- Dhiman, S.; Kumari, A.; Kumari, S.; Sharma, R. Advanced Biodegradable Starch-Based Nanocomposite Films Incorporating Zinc Oxide Nanoparticles: Synthesis, Characterization, and Efficacy in Antibacterial Food Packaging Applications. J. Environ. Chem. Eng. 2025, 13, 116296. [Google Scholar] [CrossRef]

- Shah, S.; Oh, J.; Bang, Y.; Jung, S.; Kim, H.-C.; Jeong, K.S.; Park, M.H.; Lee, K.A.; Ryoo, J.-H.; Kim, Y.-J.; et al. Pregnant Women’s Lifestyles and Exposure to Endocrine-Disrupting Chemicals: A Machine Learning Approach. Environ. Pollut. 2025, 366, 125309. [Google Scholar] [CrossRef]

- Wyrwisz, J.; Moczkowska-Wyrwisz, M.; Kurek, M.A. Development of Modified Gas Composition for Atmosphere Packaging of Sliced Apple Chips. Appl. Sci. 2025, 15, 2832. [Google Scholar] [CrossRef]

- Karaogul, E.; Ugurtay, A.; Kelley, S.S.; Alma, M.H. Modelling on Extractions and Micro Nano Encapsulation of Pistacia Terebintus Cambium Layer Gum Essential Oil; Antioxidant Activity and Structural Approach Via XRD, SEM and TGA/DSC. Plant Foods Hum. Nutr. 2025, 80, 57. [Google Scholar] [CrossRef] [PubMed]

- Huerta-Vera, K.; Flores-Andrade, E.; Arévalo-Galarza, M.d.L.C.; Cadena-Iñiguez, J.; Castillo-Morales, M.; Vivar-Vera, G.; Jiménez-Guzmán, J.; Soto-Hernández, R.M. Optimal Storage Conditions for Spray-Dried Chayote Juice (Sechium edule (Jacq.) Sw. Cv. Perla Negra) Microencapsulated with Gum Arabic. Food Bioprod. Process. 2025, 150, 296–309. [Google Scholar] [CrossRef]

- Gómez-Gaete, C.; Avendaño-Godoy, J.; Escobar-Avello, D.; Campos-Requena, V.H.; Rogel-Castillo, C.; Estevinho, L.M.; Martorell, M.; Sharifi-Rad, J.; Calina, D. Revolutionizing Fruit Juice: Exploring Encapsulation Techniques for Bioactive Compounds and Their Impact on Nutrition, Flavour and Shelf Life. Food Prod. Process Nutr. 2024, 6, 8. [Google Scholar] [CrossRef]

- Kamalpour, R.; Koocheki, A.; Ghorani, B. Encapsulation of D-Limonene in Lepidium perfoliatum Seed Gum/PVA Electrospun Nanofibers: Physicochemical Characterization and Modeling the Kinetics of Release. Curr. Res. Food Sci. 2025, 10, 100966. [Google Scholar] [CrossRef]

- Guo, Z.; Ren, J.; Song, C. Enhanced Thermal and Storage Stability of Glucose Oxidase via Encapsulation in Chitosan-Coated Alginate and Carboxymethyl Cellulose Gel Particles. Foods 2025, 14, 664. [Google Scholar] [CrossRef]

- Sattari, A.; Basirattalab, A.; Alemzadeh, I. Fabrication of pH-Sensitive Bacterial Cellulose/Carboxymethyl Cellulose Hybrid Hydrogel Beads in Agitated Culture for Oral Drug Delivery. Can. J. Chem. Eng. 2025, 203, 3521–3530. [Google Scholar] [CrossRef]

- Siddiqui, S.A.; Singh, S.; Bahmid, N.A.; Mehany, T.; Shyu, D.J.H.; Assadpour, E.; Malekjani, N.; Castro-Muñoz, R.; Jafari, S.M. Release of Encapsulated Bioactive Compounds from Active Packaging/Coating Materials and Its Modeling: A Systematic Review. Colloids Interfaces 2023, 7, 25. [Google Scholar] [CrossRef]

- Abdullah; Cai, J.; Hafeez, M.A.; Wang, Q.; Farooq, S.; Huang, Q.; Tian, W.; Xiao, J. Biopolymer-Based Functional Films for Packaging Applications: A Review. Front. Nutr. 2022, 9, 1000116. [Google Scholar] [CrossRef]

- Maphosa, B.; Tsige, A.A.; Van Breda, V.; Caleb, O.J.; Opara, U.L. Investigating the Effects of Pre-Treatment, Drying Techniques and Packaging on Nutritional Quality and Shelf-Life of Pomegranate Arils. LWT 2025, 215, 117240. [Google Scholar] [CrossRef]

- Panthi, K.P.; Shahi, D.K.; Sharma, M.L.; Li, Z.; Pandey, L.M.; Joshi, M.K. Gluten-Based Composite Film for Smart Food Packaging Applications. Food Bioprocess. Technol. 2025, 18, 2882–2898. [Google Scholar] [CrossRef]

- Yang, L.; Yuan, F.; Zhou, M.; Zhou, X.; Ahmmed, M.K.; Wu, H. Insights into Low-Temperature Strategies for Preserving Cooked Pork Quality in Ready-to-Eat Meat Products through Processing and Reheating Studies. Food Chem. 2025, 487, 144696. [Google Scholar] [CrossRef] [PubMed]

- Lee, I.; Lee, J.; Kim, M. Inhibition of Salmonella Growth in Exudates Drained from Poultry Meat by Bacteriophage Cocktail-Containing Absorbent Food Pad. LWT 2024, 197, 115908. [Google Scholar] [CrossRef]

- Li, Z.; He, Q.; Lai, J.; Lin, J.; Wu, S.; Guo, Z.; Zheng, H. Effect of Stepwise Cooking on the Water-Retention Capacity and Protein Denaturation Degree of Chicken Breast. Int. J. Gastron. Food Sci. 2024, 38, 101012. [Google Scholar] [CrossRef]

- Xu, S.; Falsafi, S.R. Juiciness of Meat, Meat Products, and Meat Analogues: Definition, Evaluation Methods, and Influencing Factors. Food Rev. Int. 2024, 40, 2344–2377. [Google Scholar] [CrossRef]

- Wang, B.; Wang, S.; Xu, Y.; Jiang, Q.; Xia, W. Colour Stability Improving of Yellowfin Tuna Slices by Compound Antioxidant against Oxidation of Myoglobin. Int. J. Food Sci. Technol. 2024, 59, 5616–5629. [Google Scholar] [CrossRef]

- Bueno, L.O.; Massingue, A.A.; Ramos, A.d.L.S.; Ferreira, D.D.; Ramos, E.M. Meat Color by Numbers: Evaluation of the Myoglobin Redox Forms by Different Methods and Its Relationship to CIE Color Indices. J. Food Compos. Anal. 2024, 133, 106365. [Google Scholar] [CrossRef]

- Orkusz, A.; Rampanti, G.; Michalczuk, M.; Orkusz, M.; Foligni, R. Impact of Refrigerated Storage on Microbial Growth, Color Stability, and pH of Turkey Thigh Muscles. Microorganisms 2024, 12, 1114. [Google Scholar] [CrossRef]

- Liao, Z.; Parumasivam, T.; Zhu, X.; Tan, T.-C. Selected Medium-Chain Dicarboxylic Acid Combinations: Improving the Shelf Life and Quality of Beef During Chilled Storage. Food Bioprocess. Technol. 2025, 18, 3521–3537. [Google Scholar] [CrossRef]

- Lee, Y.Y.; Lee, S.; Ham, S.H.; Lee, M.G.; Hahn, J.; Kim, Y.; Choi, Y.J. Relationship between Sensory Attributes and Instrumental Texture Properties in Meat Analog Patty System Substituted with Sweet Potato Stem. J. Sci. Food Agric. 2024, 104, 7002–7012. [Google Scholar] [CrossRef]

- Hao, D.; Tu, X.; Zhang, X.; Guo, S.; Sun, L.; Li, J.; Wang, D.; Xu, W.; Li, P. Effects of Proteases Inactivation on Textural Quality of Yellow-Feathered Chicken Meat and the Possible Mechanism Based on Myofibrillar Protein. Food Control 2024, 166, 110713. [Google Scholar] [CrossRef]

| Model | Equation | Kinetic Constants | R2 |

|---|---|---|---|

| Zero-order | K0 = 0.0629 | 0.871 | |

| First-order | k1 = 0.139 | 0.789 | |

| Higuchi | kH = 0.216 | 0.9469 | |

| Korsmeyer-Peppas | k = 0.636; n = 0.459 | 0.951 | |

| Weibull | α = 0.3566; β = 0.491 | 0.968 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sánchez-Camacho, B.; de la Luz Zambrano-Zaragoza, M.; Aguilar-Toalá, J.E.; Cruz-Monterrosa, R.G.; Rosas-Espejel, M.; Mejía-Méndez, J.L. Preservation of Rabbit Meat in High-Density Polyethylene Packaging Bags Reinforced with Ethyl Cellulose Nanoparticles Loaded with Rosemary Extract. Polysaccharides 2025, 6, 76. https://doi.org/10.3390/polysaccharides6030076

Sánchez-Camacho B, de la Luz Zambrano-Zaragoza M, Aguilar-Toalá JE, Cruz-Monterrosa RG, Rosas-Espejel M, Mejía-Méndez JL. Preservation of Rabbit Meat in High-Density Polyethylene Packaging Bags Reinforced with Ethyl Cellulose Nanoparticles Loaded with Rosemary Extract. Polysaccharides. 2025; 6(3):76. https://doi.org/10.3390/polysaccharides6030076

Chicago/Turabian StyleSánchez-Camacho, Brenda, María de la Luz Zambrano-Zaragoza, José Eleazar Aguilar-Toalá, Rosy Gabriela Cruz-Monterrosa, Monzerrat Rosas-Espejel, and Jorge L. Mejía-Méndez. 2025. "Preservation of Rabbit Meat in High-Density Polyethylene Packaging Bags Reinforced with Ethyl Cellulose Nanoparticles Loaded with Rosemary Extract" Polysaccharides 6, no. 3: 76. https://doi.org/10.3390/polysaccharides6030076

APA StyleSánchez-Camacho, B., de la Luz Zambrano-Zaragoza, M., Aguilar-Toalá, J. E., Cruz-Monterrosa, R. G., Rosas-Espejel, M., & Mejía-Méndez, J. L. (2025). Preservation of Rabbit Meat in High-Density Polyethylene Packaging Bags Reinforced with Ethyl Cellulose Nanoparticles Loaded with Rosemary Extract. Polysaccharides, 6(3), 76. https://doi.org/10.3390/polysaccharides6030076