Design and Optimization of a Solar Parabolic Dish for Steam Generation in a Blue Hydrogen Production Plant

Abstract

1. Introduction

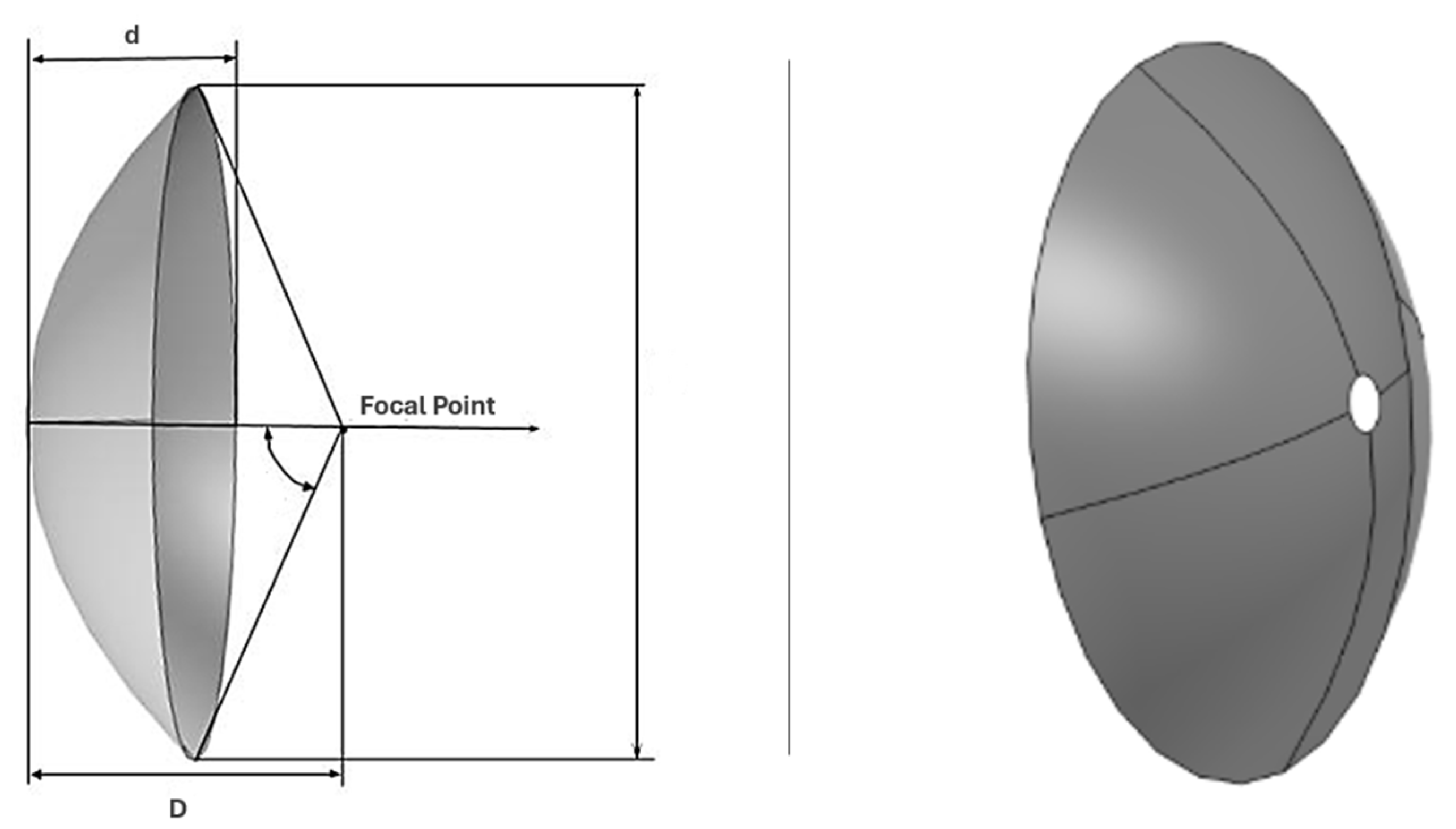

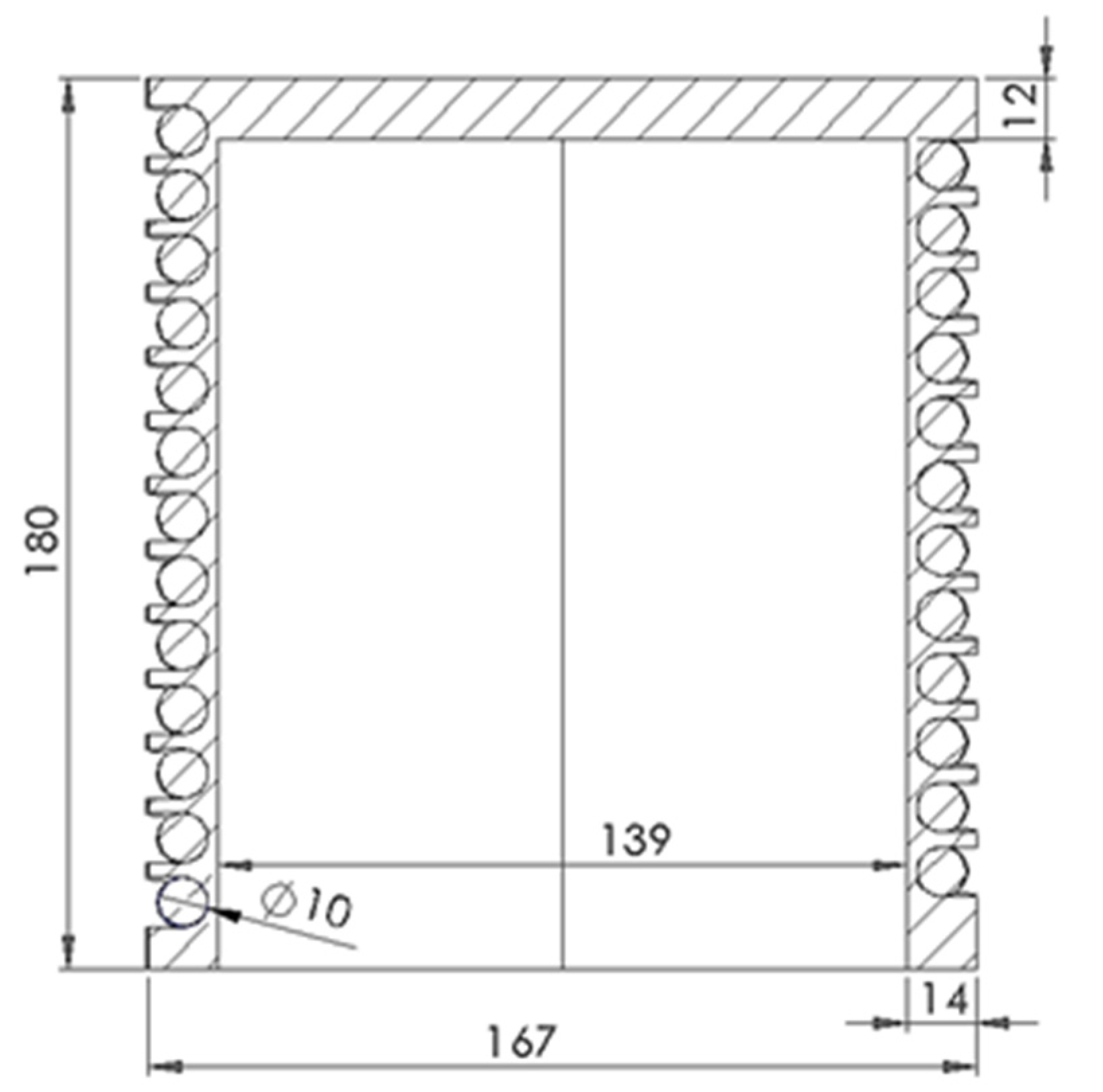

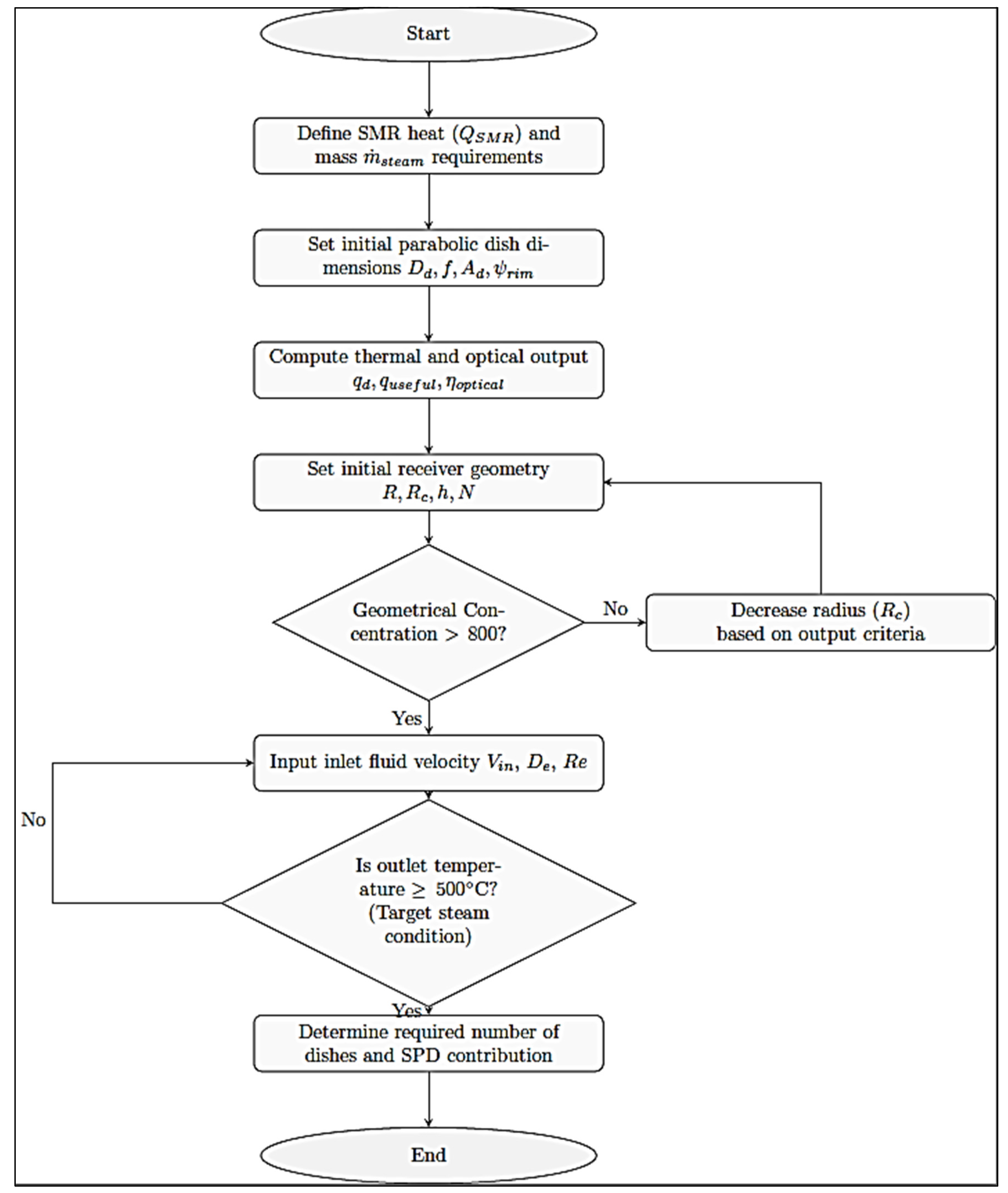

2. Geometrical Modelling

Optimization Strategy for SMR Integration

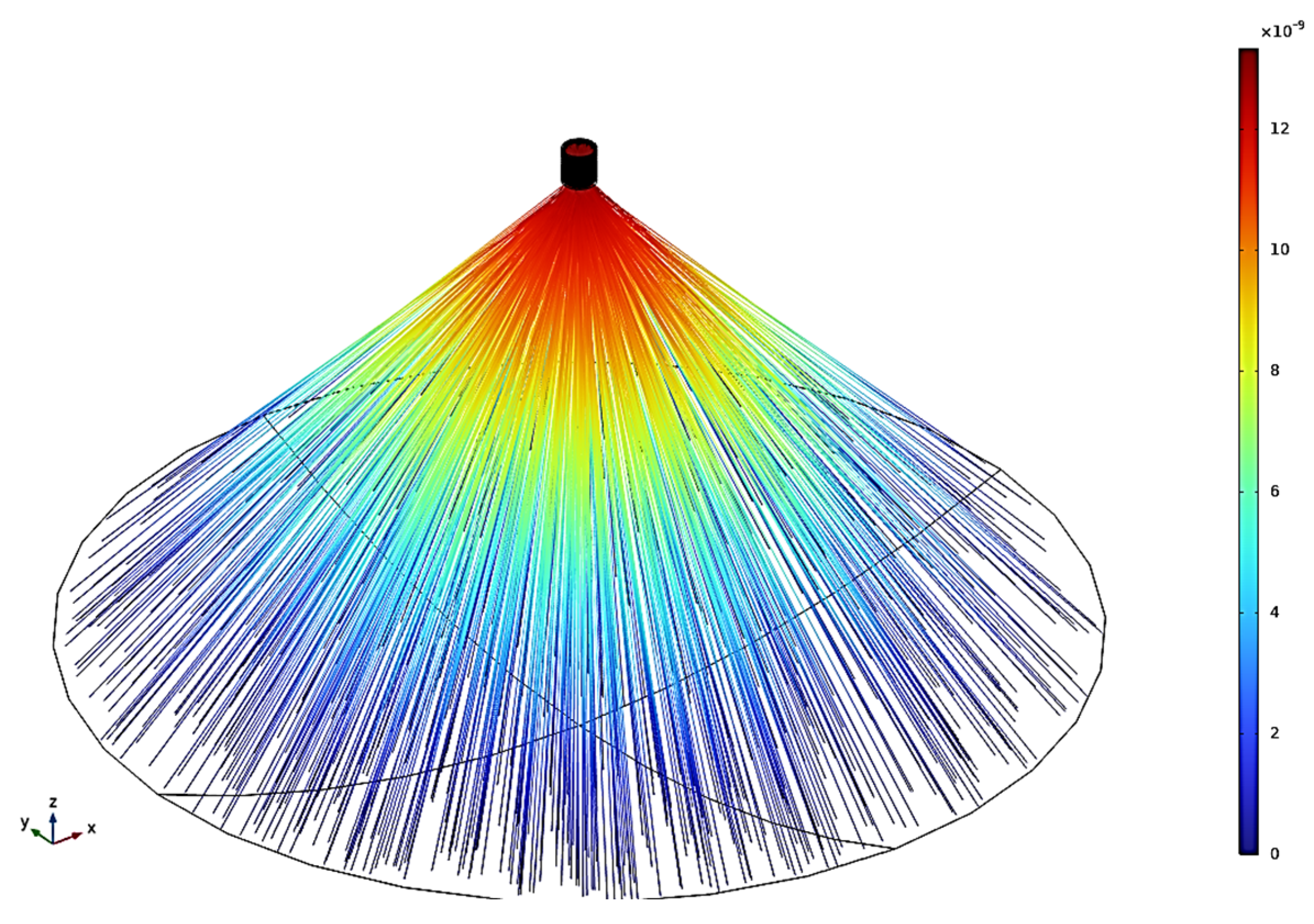

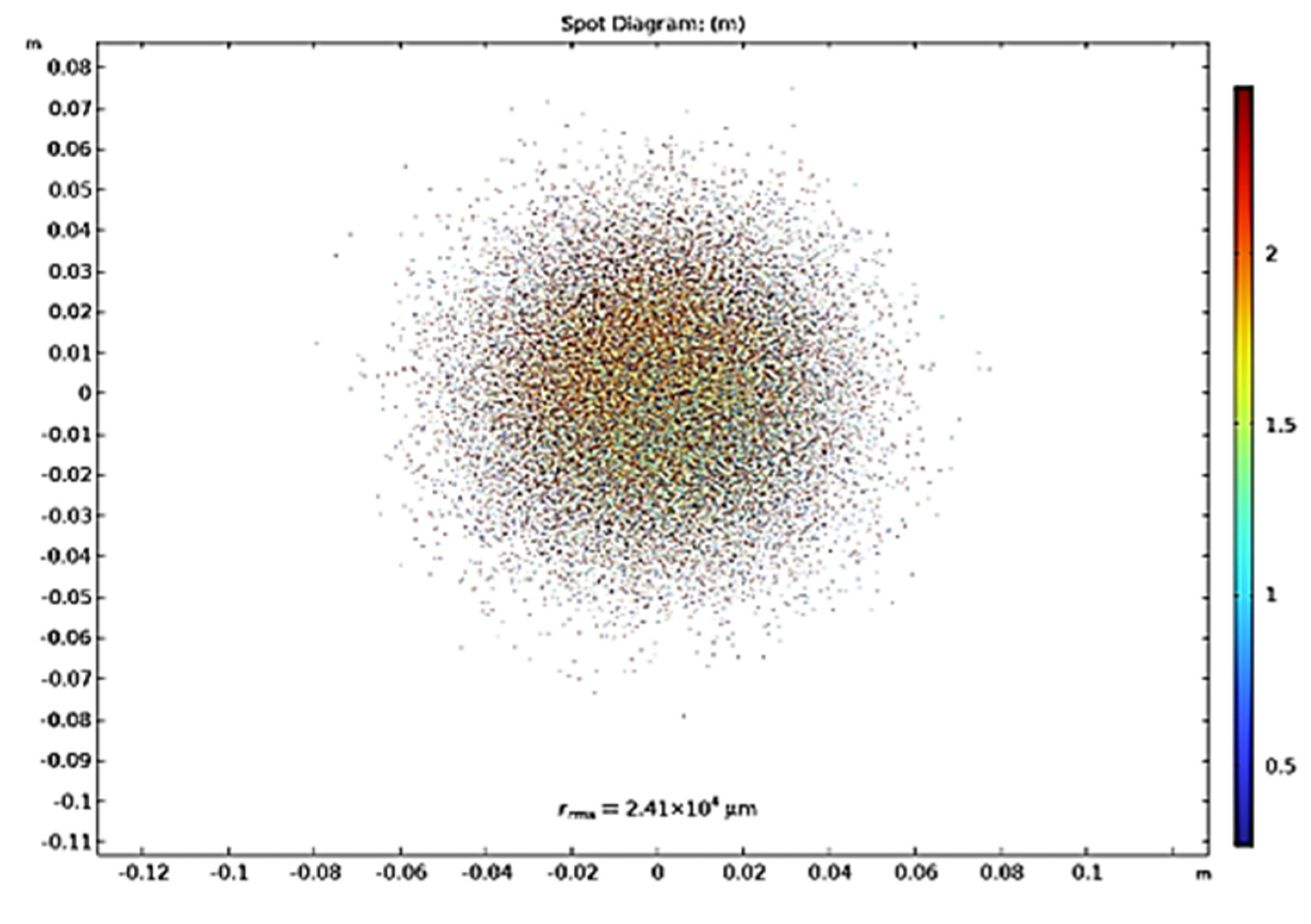

3. Optical Analysis

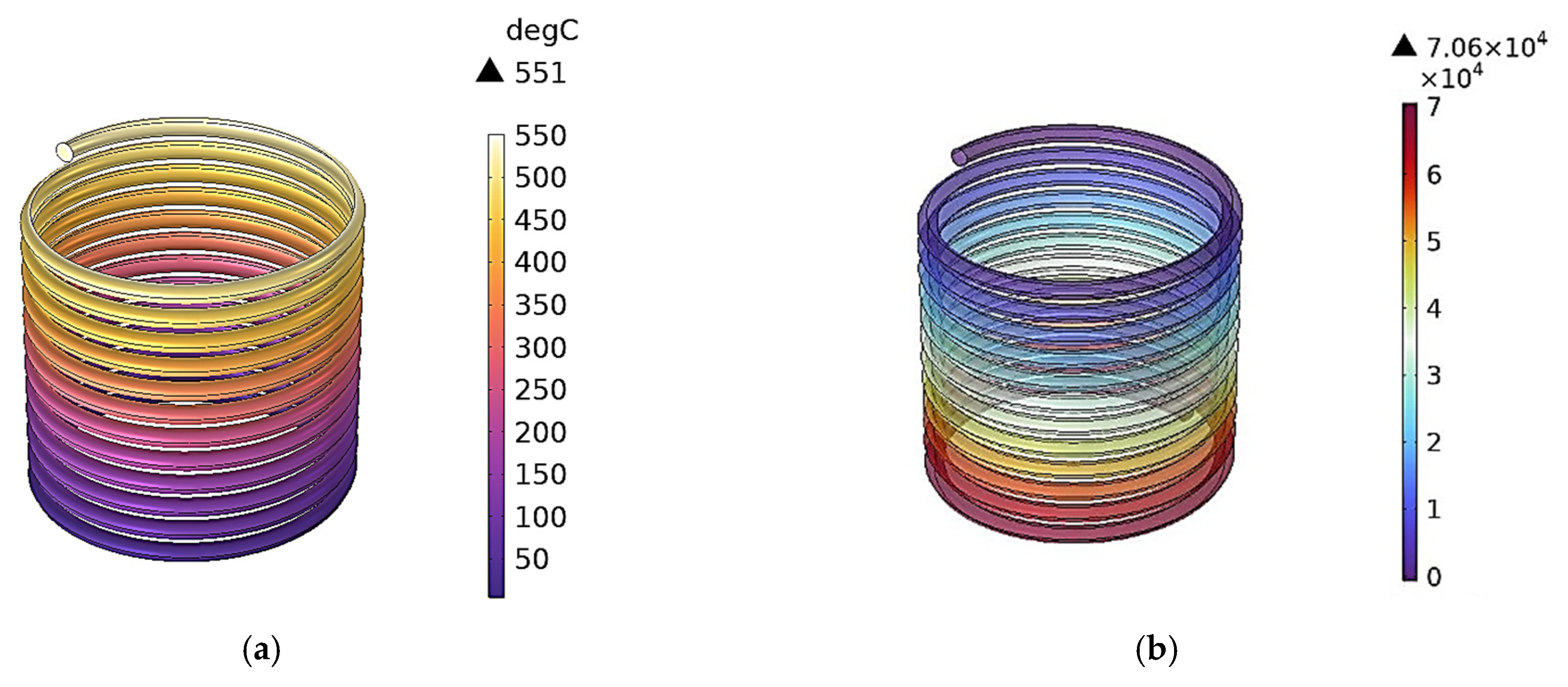

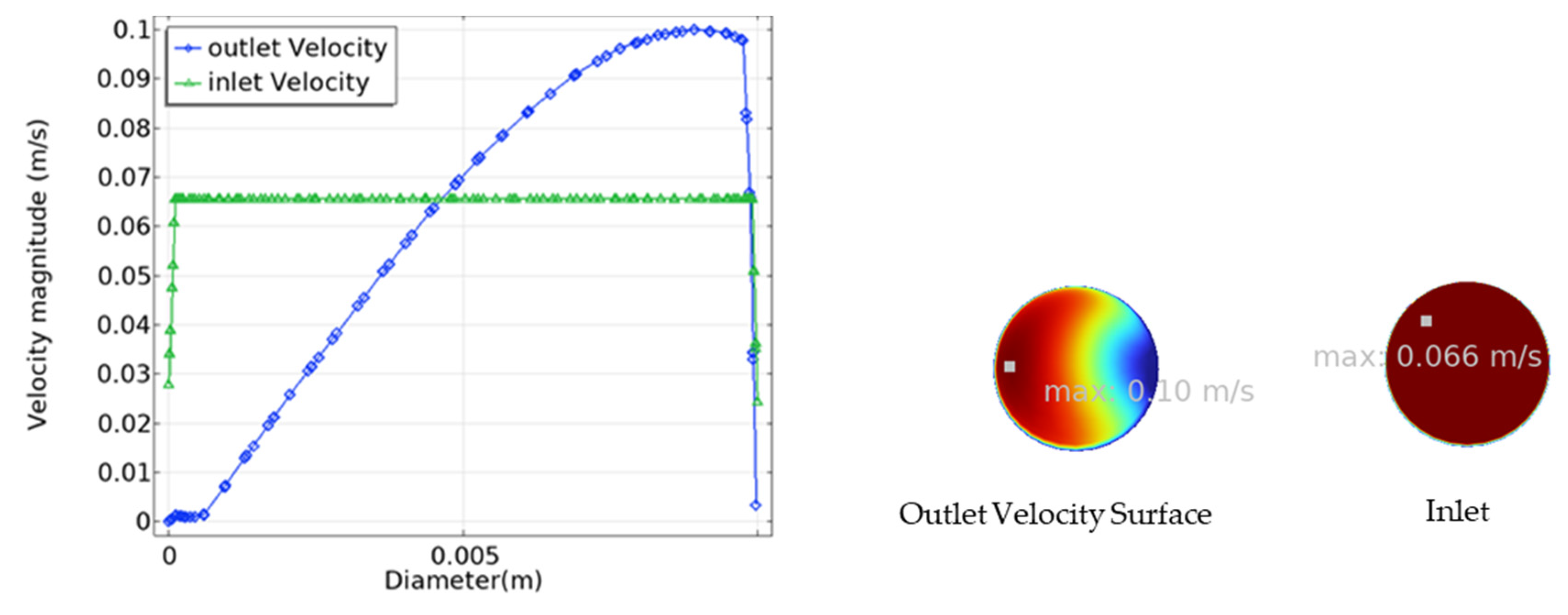

4. Thermal Analysis for Cavity Receiver

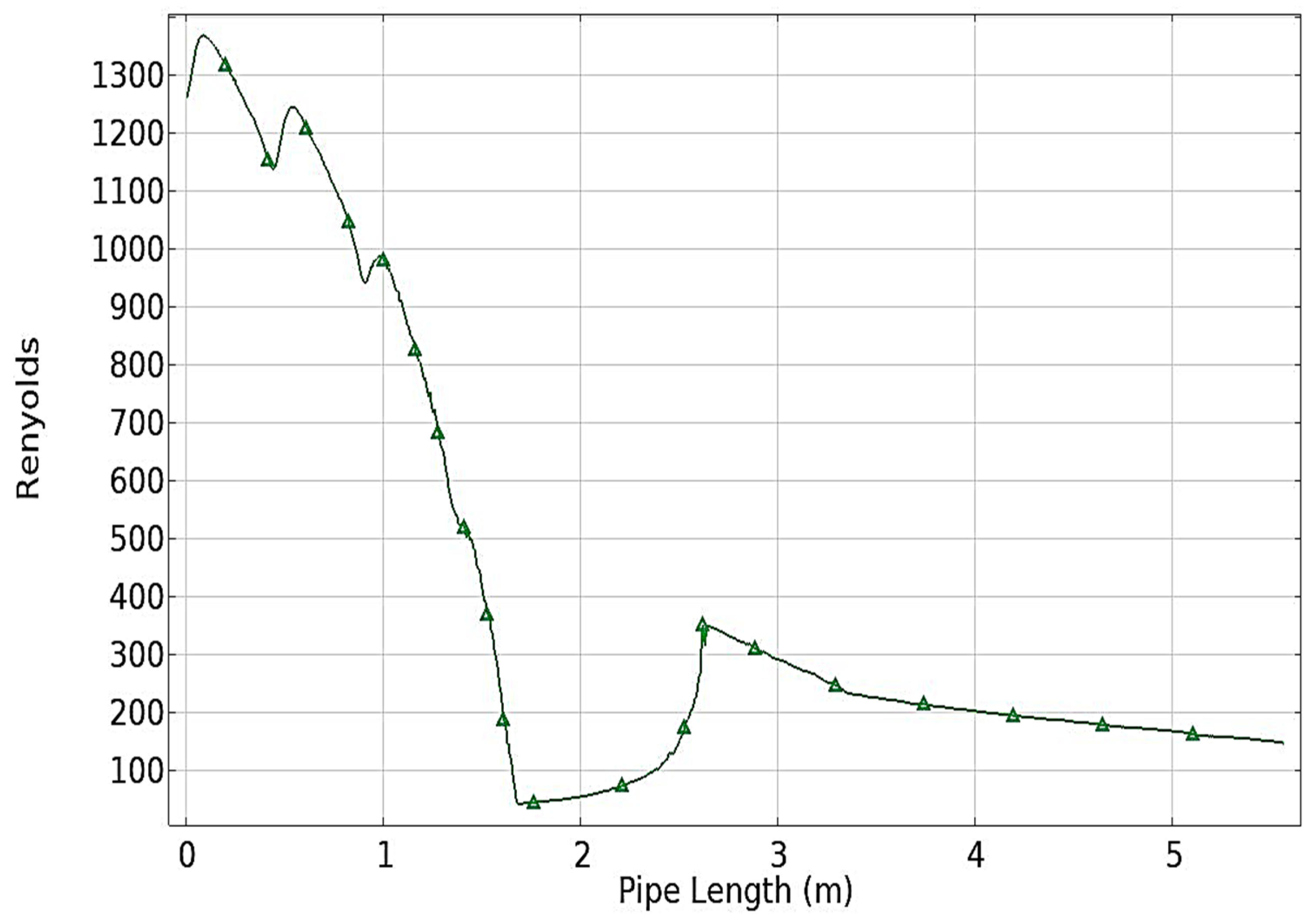

5. Results and Discussion

- The SPD system was designed to supply 10% of the total heat duty for the HEAT-H2O unit.

- This contribution translates to a solar thermal input of 778.5 kW for this specific duty.

- The remaining 90% of the heat required by the HEAT-H2O unit, along with other process heaters (HEAT-CH4 and HEAT-MIX), is supplied by conventional natural gas boilers.

- Annual Fuel Savings: 328,500 SAR/year (based on natural gas at 5.31 SAR/GJ)

- Annualized SPD Cost: 187,500 SAR/year (based on a 3.75 M SAR capital cost over 20 years)

- Net Annual Savings: 141,000 SAR/year

6. Conclusions and Recommendations

- Demonstrated Technical Feasibility: The optimized SPD system consistently delivers superheated steam at 551 °C, proving that concentrated solar thermal technology can reliably meet the high-temperature, high-pressure demands of major industrial processes like hydrogen production.

- Precision Engineering through Integration: The SPD was not designed in isolation. Its specifications were directly derived from the ASPEN Plus process model to meet a precise heating load of 778.5 kW, covering 10% of the duty for the water preheater (HEAT-H2O unit). This ensures seamless and efficient integration into the overall plant layout.

- Proven Economic and Environmental Value: The system generates net annual savings of 141,000 SAR by offsetting natural gas consumption, demonstrating that decarbonization can be economically advantageous. This directly reduces the carbon footprint of the blue hydrogen produced.

- A Paradigm Shift in Solar Application: The core innovation of this work is a new application for CSP. We moved beyond power generation to demonstrate CSP’s role as a direct process heating partner for conventional industry, offering a pragmatic and scalable path to decarbonization.

- A Replicable Blueprint for Industry: This study provides a generalizable design and integration framework. The methodology of linking process simulation with solar component design can be adapted for other energy-intensive sectors (e.g., cement, metals, chemicals), significantly amplifying its impact.

- A Foundation for the Future: This work lays the groundwork for next-stage innovations, most notably the integration of thermal energy storage to extend operational hours and further increase the solar fraction, moving closer to a fully sustainable industrial heat supply.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Abbreviation | Full Term |

| DNI | Direct Normal Irradiance (W/m2) |

| ψm | Maximum solar dish angle |

| Cp-in | Heat Capacity (kJ/kg·K) |

| ψrim | Rim angle of the dish |

| Rc | Radius of the receiver tube |

| γ | Curvature ratio |

| F | Focal length of the dish |

| Optical Efficiency (%) | |

| ṁ | Mass flow rate (kg/s) |

| Re | Reynold number |

| Inlet Temperature (°C) | |

| Outlet Temperature |

References

- Alami, A.H.; Olabi, A.G.; Mdallal, A.; Rezk, A.; Radwan, A.; Rahman, S.M.A.; Shah, S.K.; Abdelkareem, M.A. Concentrating Solar Power (CSP) Technologies: Status and Analysis. Int. J. Thermofluids 2023, 18, 100340. [Google Scholar] [CrossRef]

- Kopeinig, H. Renewable Energy Generation and Consumption in the Aggregate Sector. Master’s Thesis, Technical University of Leoben, Leoben, Austria, 2025. [Google Scholar]

- Sofiane, M. Design and Performance Optimization of Future Concentrated Solar Power Plants for Long-Duration Thermal Energy Storage: A Case Study. J. Renew. Energy Environ. 2025, 12, 56–70. [Google Scholar]

- Al-Amayreh, M.I.; Alahmer, A.; Manasrah, A. A Novel Parabolic Solar Dish Design for a Hybrid Solar Lighting-Thermal Applications. Energy Rep. 2020, 6, 1136–1143. [Google Scholar] [CrossRef]

- Shboul, B.; Khawaldeh, H.A.; Al-Smairan, M.; Alrbai, M.; Ali, H.H.; Almomani, F. Perspectives of New Solar Energy Option for Sustainable Residential Electricity Generation: A Comparative Techno-Economic Evaluation of Photovoltaic and Solar Dish Systems. Energy Rep. 2025, 13, 4514–4527. [Google Scholar] [CrossRef]

- Kumar, V.; Singh, U.R.; Bhogilla, S.S. Experimental Investigation of an Innovative PV/T Collector in Jammu Climatic Conditions. Therm. Sci. Eng. Prog. 2025, 59, 103312. [Google Scholar] [CrossRef]

- Pavlović, S.R.; Vasiljević, D.M.; Stefanović, V.P.; Stamenković, Z.M.; Bellos, E.A. Optical Analysis and Performance Evaluation of a Solar Parabolic Dish Concentrator. Therm. Sci. 2016, 20, 1237–1249. [Google Scholar] [CrossRef]

- Pavlovic, S.; Bellos, E.; Loni, R. Exergetic Investigation of a Solar Dish Collector with Smooth and Corrugated Spiral Absorber Operating with Various Nanofluids. J. Clean. Prod. 2018, 174, 1147–1160. [Google Scholar] [CrossRef]

- Ubando, A.T.; Conversion, A.; Barroca, R.B.; Enano, N.H., Jr.; Espina, R.U. Computational Fluid Dynamics on Solar Dish in a Concentrated Solar Power: A Bibliometric Review. Solar 2022, 2, 251–273. [Google Scholar] [CrossRef]

- Malik, M.Z.; Shaikh, P.H.; Zhang, S.; Lashari, A.A.; Leghari, Z.H.; Baloch, M.H.; Memon, Z.A.; Caiming, C. A Review on Design Parameters and Specifications of Parabolic Solar Dish Stirling Systems and Their Applications. Energy Rep. 2022, 8, 4128–4154. [Google Scholar] [CrossRef]

- Abed, A.A.; El-Marghany, M.R.; El-Awady, W.M.; Hamed, A.M. Recent Advances in Parabolic Dish Solar Concentrators: Receiver Design, Heat Loss Reduction, and Nanofluid Optimization for Enhanced Efficiency and Applications. Sol. Energy Mater. Sol. Cells 2024, 273, 112930. [Google Scholar] [CrossRef]

- Korawan, A.D. Karakteristik penyimpan kalor laten pada parabolic mirror dish. J. Penelit. dan Pengabdi. Kpd. Masy. UNSIQ 2023, 10, 8–12. [Google Scholar] [CrossRef]

- Alkhalaf, Q.; Lee, D.; Kumar, R.; Thapa, S.; Singh, A.R.; Akhtar, M.N.; Asif, M.; Ağbulut, Ü. Experimental Investigation of the Thermal Efficiency of a New Cavity Receiver Design for Concentrator Solar Technology. Case Stud. Therm. Eng. 2024, 53, 103848. [Google Scholar] [CrossRef]

- Kopalakrishnaswami, A.S.; Natarajan, S.K. Comparative Study of Modified Conical Cavity Receiver with Other Receivers for Solar Paraboloidal Dish Collector System. Environ. Sci. Pollut. Res. 2022, 29, 7548–7558. [Google Scholar] [CrossRef]

- Arjun Singh, K.; Natarajan, S.K. Thermal Analysis of Modified Conical Cavity Receiver for a Paraboloidal Dish Collector System. Energy Sources Part A Recovery Util. Environ. Eff. 2021, 47, 1–12. [Google Scholar]

- Bellos, E.; Bousi, E.; Tzivanidis, C.; Pavlovic, S. Optical and Thermal Analysis of Different Cavity Receiver Designs for Solar Dish Concentrators. Energy Convers. Manag. X 2019, 2, 100013. [Google Scholar] [CrossRef]

- Malviya, R.; Baredar, P.V.; Kumar, A. Thermal Performance Improvement of Solar Parabolic Dish System Using Modified Spiral Coil Tubular Receiver. Int. J. Photoenergy 2021, 2021, 4517923. [Google Scholar] [CrossRef]

- Wang, F.; Shuai, Y.; Yuan, Y.; Liu, B. Effects of Material Selection on the Thermal Stresses of Tube Receiver under Concentrated Solar Irradiation. Mater. Des. 2012, 33, 284–291. [Google Scholar] [CrossRef]

- Hameed, H.G.; Diabil, H.A.N.; Al-Fahham, M.A. Performance Study on a Solar Concentrator System for Water Distillation Using Different Water Nanofluids. Heliyon 2023, 9, e16535. [Google Scholar] [CrossRef]

- Abu-Zeid, M.A.-R.; Elhenawy, Y.; Toderaș, M.; Bassyouni, M.; Majozi, T.; Al-Qabandi, O.A.; Kishk, S.S. Performance Enhancement of Solar Still Unit Using V-Corrugated Basin, Internal Reflecting Mirror, Flat-Plate Solar Collector and Nanofluids. Sustainability 2024, 16, 655. [Google Scholar] [CrossRef]

- Sigalotti, L.D.G.; Alvarado-Rodríguez, C.E.; Rendón, O. Fluid Flow in Helically Coiled Pipes. Fluids 2023, 8, 308. [Google Scholar] [CrossRef]

- Avargani, V.M.; Zendehboudi, S. Parametric Analysis of a High-Temperature Solar-Driven Propane Steam Reformer for Hydrogen Production in a Porous Bed Catalytic Reactor. Energy Convers. Manag. 2023, 276, 116539. [Google Scholar] [CrossRef]

- Thakkar, V.; Doshi, A.; Rana, A. Performance Analysis Methodology for Parabolic Dish Solar Concentrators for Process Heating Using Thermic Fluid. J. Mech. Civ. Eng. 2015, 12, 101–114. [Google Scholar]

| Symbol | Value | Unit | Description |

|---|---|---|---|

| F | 3 | m | Focal length of the dish |

| ψrim | 0.7854 | rad | Rim angle of the dish |

| D | 5 | m | Dish diameter |

| A | 19.6350 | m2 | Dish projected surface area |

| ψm | 0.00465 | rad | Maximum solar dish angle |

| R | 5 | mm | Radius of the receiver tube |

| Rc | 139 | mm | Receiver cavity radius |

| 0.0327 | - | Curvature ratio (tube radius to helical radius) | |

| Β | 0.0208 | - | Dimensionless pitch |

| Symbol | Value | Description |

|---|---|---|

| DNI | 1000 W/m2 | Solar irradiance |

| N | 10,000 | Number of Rays |

| GC | 896× | Geometrical concentration ratio |

| σ | 0.00175 rad | Surface slope error |

| Reflectivity of Dish | 0.9 | Reflectivity of the mirror surface |

| Transmissivity | 0.98 | Transmission through cover |

| Optical Efficiency | 0.882 | Overall Efficiency |

| Symbol | Value | Unit |

|---|---|---|

| Tin | 23 | °C |

| Tout | 551 | °C |

| Cp-in | 4.18 | kJ/kg·K |

| ṁ | 0.005134 | kg/s |

| Re | 701.8 | - |

| De | 179.41 | - |

| Pr | 6.44 | - |

| Nu | 22.8 | - |

| h | 1380.3 | W/m2 K |

| V | 0.0655 | m/s |

| Component | Heat Duty [kW] | SPD Contribution | Notes |

|---|---|---|---|

| HEAT-H2O | 7785.2 | 778.5 kW (10%) | Preheats water to 500 °C |

| HEAT-CH4 | 407.1 | 0 kW | Preheats methane to 500 °C |

| HEAT-MIX | 3282 | 0 kW | Heats mixed feed to 900 °C |

| Reformer | 8459 | 0 kW | Provides endothermic reaction heat |

| Total SPD Contribution | 778.5 kW |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maatallah, T.; Al-Zahrani, M.; Hilal, S.; Alsubaie, A.; Aljohani, M.; Alghamdi, M.; Almansour, F.; Awad, L.; Ali, S. Design and Optimization of a Solar Parabolic Dish for Steam Generation in a Blue Hydrogen Production Plant. Hydrogen 2025, 6, 85. https://doi.org/10.3390/hydrogen6040085

Maatallah T, Al-Zahrani M, Hilal S, Alsubaie A, Aljohani M, Alghamdi M, Almansour F, Awad L, Ali S. Design and Optimization of a Solar Parabolic Dish for Steam Generation in a Blue Hydrogen Production Plant. Hydrogen. 2025; 6(4):85. https://doi.org/10.3390/hydrogen6040085

Chicago/Turabian StyleMaatallah, Taher, Mussad Al-Zahrani, Salman Hilal, Abdullah Alsubaie, Mohammad Aljohani, Murad Alghamdi, Faisal Almansour, Loay Awad, and Sajid Ali. 2025. "Design and Optimization of a Solar Parabolic Dish for Steam Generation in a Blue Hydrogen Production Plant" Hydrogen 6, no. 4: 85. https://doi.org/10.3390/hydrogen6040085

APA StyleMaatallah, T., Al-Zahrani, M., Hilal, S., Alsubaie, A., Aljohani, M., Alghamdi, M., Almansour, F., Awad, L., & Ali, S. (2025). Design and Optimization of a Solar Parabolic Dish for Steam Generation in a Blue Hydrogen Production Plant. Hydrogen, 6(4), 85. https://doi.org/10.3390/hydrogen6040085