1. Introduction

The transport system has immense significance and has played a critical role in shaping the settlement pattern of human civilization; thus, it can be inferred that its infrastructure transforms the landscape and regional economy [

1], especially due to the fact that almost one-third of all energy is consumed by the transport sector, particularly in countries like the United States, resulting in huge emissions influencing air quality [

2]. The global transport sector emits a significant amount of environmentally harmful gases, accounting for one-quarter of greenhouse gas emissions, which are hazardous to humans and the environment, as 95% of the world’s transport still uses fossil fuels. To achieve both, a biennial environment which uses clean transportation is essential [

3]. Both battery electric vehicles (BEVs) and hydrogen-powered fuel cell electric vehicles (FCEVs) are the two with zero tailpipe emissions, representing promising alternatives to conventional fossil fuel-powered vehicles [

4]. Hydrogen-powered fuel cell electric vehicles (FCEVs) offer several advantages over battery electric vehicles, such as a longer driving range of more than 300 miles on a single tank of hydrogen, comparable to traditional gasoline vehicles, a quick refueling time similar to conventional vehicles [

5], and a low degradation rate. However, a hydrogen-powered fuel cell will only be considered green if hydrogen is produced through water electrolysis powered by renewable energy, which can contribute to the transition towards sustainable energy [

6]. Electrolyzers just need water and electricity to produce hydrogen, and their operating efficiency varies between 70% to 80% during operation [

7]. Among electrolyzers, Proton Exchange Membrane (PEM) electrolyzers are gaining popularity due to their simplicity and efficiency, along with compact design, their ability to achieve high-purity hydrogen, and their rapid response to fluctuating power inputs [

8,

9,

10]. They have the potential to integrate with renewable energy sources such as solar and wind power, and their fast response to an intermittent energy supply and operational flexibility make them well suited for coupling with variable renewables, enabling sustainable and scalable green hydrogen production [

11,

12].

Simultaneously, solar photovoltaic technology has evolved through different generations, and currently, three generations of solar PV systems exist: the first, second, and third. The first generation consists of monocrystalline and multicrystalline. In the second generation, thin films are very popular and first- and second-generation systems dominate the market. The bifacial solar module is a type of solar module where electricity is converted from photons collected from incident and albedo radiation reaching both sides of the module. Though bifacial solar cells have been known since the 1960s, it was only in 1981 that the first commercial bifacial photovoltaic system was developed by ISOFOTON, in a Spanish academic spin-off [

13]. The cell working temperature has decreased, and the maximum power output has increased due to the absence of aluminum back metallization, which results in the reduction [

14]. Bifacial solar cells have applications in many areas, including ground-mounted PV, BIPV, Agrivoltatics, and floating photovoltaics (FPV) [

15]. With some investigation, it can be concluded that covering 1% of the globally reserved areas can result in a potential capacity of 404 GWp electricity production [

16]. Some studies focused on the direct comparison between the ground-mounted PV and the floating PV [

17]. The implications of bifacial technology have not only been studied for FPV but also for BIPV, enabling electricity production from the weakest envelope of a building [

18]. Another interesting system is agrivoltaics, where bifacial modules take advantage of the height between the ground and the panel [

19]. Research found that with bifacial modules, the NPV of such systems can increase to as high as 80,713.73 in the UK [

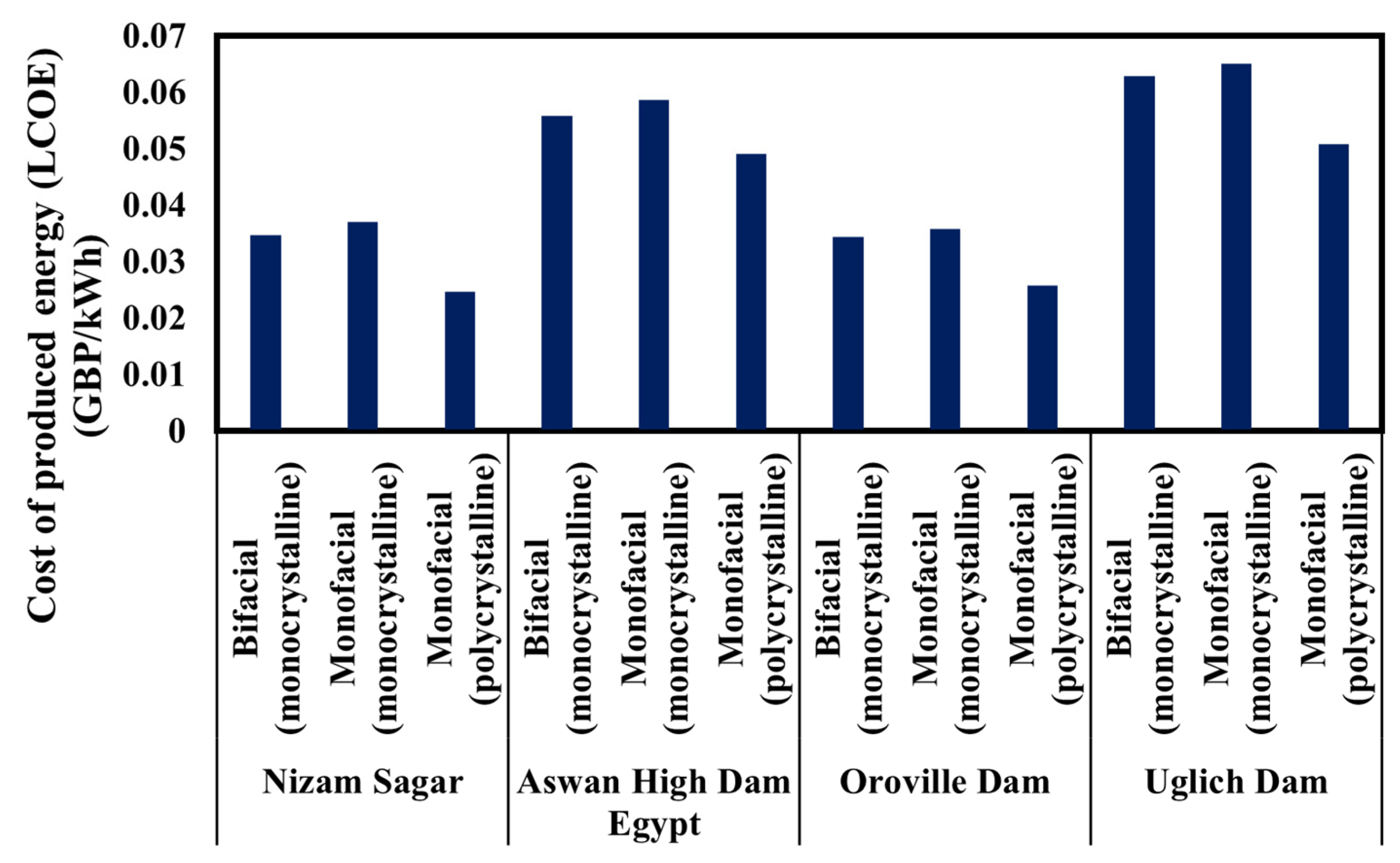

20], whereas another study comparing bifacial with monofacial for tracking and fixed axis found that the tracking bifacial is able to have as low LCOE as GBP 0.048/kWh for the UK in agrivoltaics [

21]. Thus, the use of bifacial technology in different applications has enabled new opportunities with surplus electricity production. It has been estimated that if bifacial photovoltaics are used for floating photovoltaics, then they can convert up to 55% more sunlight as compared to monofacial photovoltaics [

15]. In an experiment carried out, it was observed that the cell efficiency of the bifacial is 22.38%, while the fill factor is 82.58%. The open circuit voltage was estimated to be 677.4 V, and the short circuit current was 10.46 A [

22]. Due to this, bifacial solar cells are used for this simulation while addressing various UN sustainability goals, including SDG 7 (ensuring affordable, reliable, and sustainable clean energy), SDG 9 (fostering innovation), SDG 13 (addressing climate change by offsetting CO

2), and SDG 15 (protecting land, forest, and ecosystems by eliminating the direct competition with the energy sector) [

23,

24,

25].

The traditional systems face challenges, particularly in terms of negative temperature coefficients, resulting in compromised efficiency and huge land requirements for installation. To abate these issues, PV can now be installed on water bodies and has emerged as a promising solution known as water-based PV. A water-based PV system includes FPV (onshore and offshore), canal top PV, and underwater [

26]. Among these, FPV systems are gaining significant popularity because FPV systems benefit from the cooling effect of surrounding water bodies, which can increase efficiency by 5–15% compared to land-based systems [

27]. The panels cover the water surface, reducing evaporation and conserving about 42% of water resources [

13], they are exposed to solar radiation directly (unlike underwater), and not exposed to harsh environments such as saline ambient water and heavy waves, which can damage the structure of the PV [

26]. Studies have indicated that there is a reduction of up to 70% in water evaporation depending on the location and system design, while some research claims this to be as high as 50–90%, especially in the arid region, with a potential of saving of up to 1.5 million gallons of water annually with 1 MW system [

28]. In Greece, it was found that covering 10–30% of the surface of 128 reservoirs with FPV can save 71.55 mil.m

3 to 214.65 mil.m

3 of water lost annually due to evaporation and improve the water quality [

29]. Thus, the FPV system installed directly on the water surface (having contact with water bodies) outperforms a canal top as they are surrounded by water. This proximity provides additional cooling effect from the water body, which enhances energy efficiency, an advantage not present for canal top PVs due to the distance between the water and the photovoltaics [

30]. Incorporating bifacial solar panels in FPV systems can further enhance their benefits by generating electricity from both the front and back sides, potentially increasing energy production as water has a static reflection coefficient (albedo) of 5–7% which can contribute to additional electricity generation from the rear side of the bifacial, whereas an offshore water body has less reflection [

31]. González et al. explored the enhanced electricity production and evaporation reduction, with a water saving reduction of up to 2066.15 mm/year in a dry climate and a median evaporation saving of up to 1085.24 mm/year which is due to the shading provided by the photovoltaics over the water body resulting in reduced direct exposure of sun and wind. Exploring the climate-driven performance of floating photovoltaic systems [

32], it has been seen that the degradation rate of PV modules is significant in warm and humid climates, as high humidity is associated with corrosion and can also lead to interconnection failures and cracks [

33]. At the same time, humidity can also lead to a reduction in the solar irradiance reaching the panel, as the available water vapor particles cause scattering of the solar light, thus resulting in reduced electricity generation [

34,

35,

36]. Interestingly, in a study in Malaysia, the presence of wind enhanced PV output by lowering the temperature increase due to heat dissipation during the operations, especially for FPV, acting as a cooling agent, though high humidity continued to be the limiting factor [

37]. Humidity and wind speed are also playing a significant role in influencing the soiling that adheres to PV, as high wind speeds can result in a 10.9% reduction in dust accumulation [

38]. Temporary shading due to the presence of clouds in some regions is associated with reduced electricity production due to the reduction in the amount of direct irradiance reaching the PV, along with cloud movement, with experimental studies showing a reduced impact factor related to power output of 0.86 due to 75% shading [

39,

40,

41].

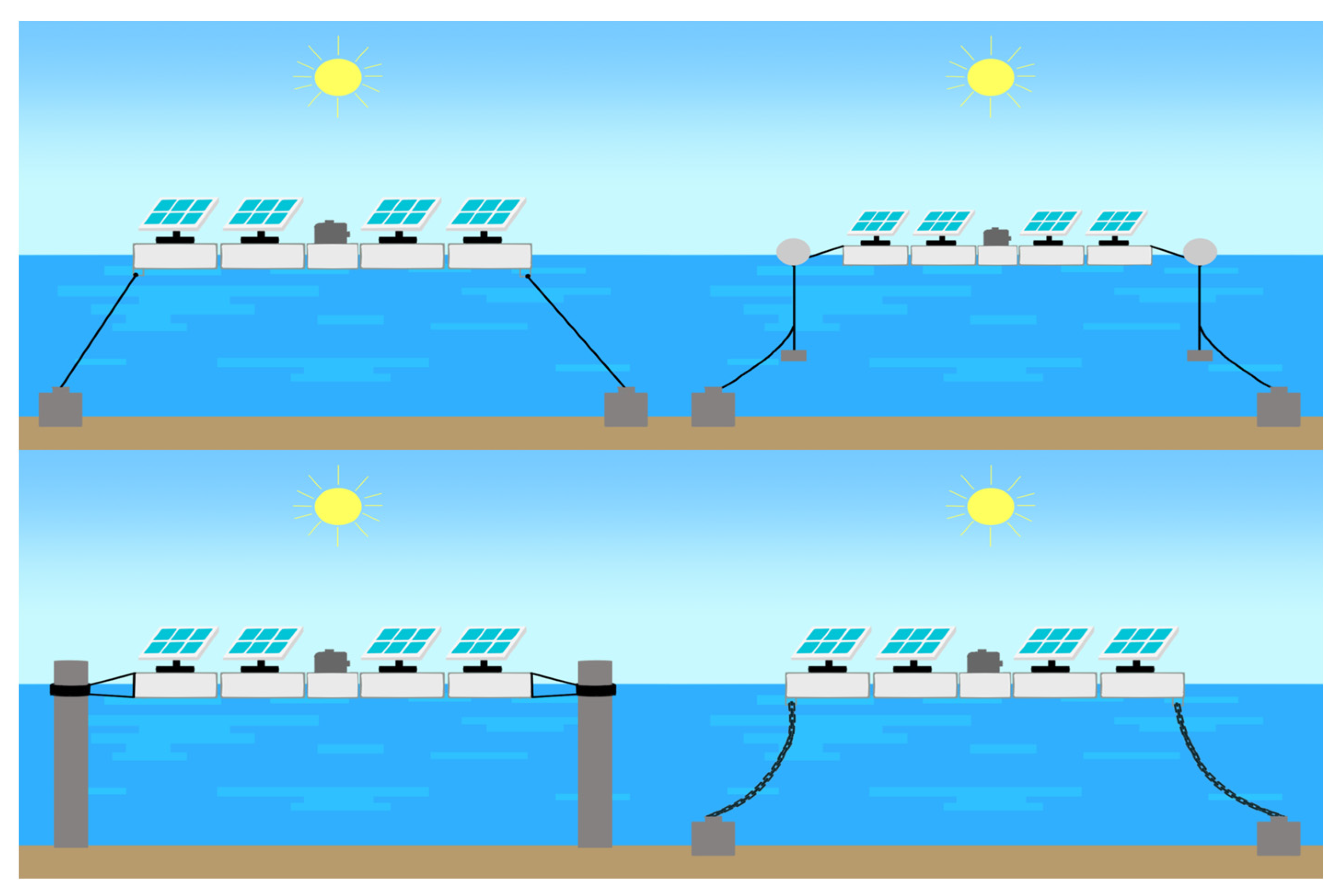

FPV, an emerging technology where solar panels are placed on water bodies such as lakes, reservoirs, and ponds to generate electricity, can have different mooring systems as shown in

Figure 1. An observation by the owner of a 500 kW plant in Bubano, Italy, claimed, an increase of 20–26% in electricity output due to the cooling effect [

42]. This consists of solar panels, floaters, inverters, mooring and anchoring, cables, and transformers. There are different advantages of this technology, such as a reduction in the land use, a cooling effect, a reduction in water evaporation, and a reduction in the risk of fire. Due to the increase in demand for electricity and the availability of free water bodies, it has attracted the attention of many, with some taking steps further by integrating this technology with an energy storage system to further enhance the performance [

43].

Though hydrogen-powered FCEVs offer an advantage in terms of the environment, their widespread adoption faces challenges, particularly in refueling infrastructure, which is essential for fostering this new technology. The significantly small number of battery refueling stations and high charging times are among the main challenges for battery electric vehicles, hindering the uptake of traditional technology [

44,

45,

46]. To mitigate these challenges, people utilizing home charging as an alternative have often been witnessed [

20,

22]. However, hydrogen refueling requires specialized stations due to safety concerns because of the unwanted risk of combustion due to the nature of its lower ignition point [

47]. Home charging has still not been considered the safest charging option; hence, external roadside refueling stations are the only solution. The challenge arises in producing hydrogen for a hydrogen refueling station using a PV system, which requires a significant amount of land, causing two major issues: land competition and high capital expenditure (CAPEX) as a result of land prices being significantly high. These challenges can be resolved by implementing hydrogen-powered refueling stations, which eliminates land acquisition costs, significantly lowering capital expenditure and competition with other sectors, especially the food sector which globally covers approximately 37% of the global land surface [

43,

48], while water-cooling effects increased PV efficiency by 5–15% compared to land-based systems as an added benefit [

49]; proximity to water sources simplifies the electrolysis process, significantly reducing the operating cost, as water can be directly sourced from the supporting water body and can reduce water evaporation from reservoirs simultaneously.

FPV systems combined with hydrogen production and utilization represent a promising avenue for sustainable energy generation and storage, and a 26.57 MWp FPV system with a 22 MW PEM electrolyzer and 60,000 kg hydrogen tank can generate up to 65.5 GWh of clean electricity annually [

50]. FPV systems have gained significant attention due to their ability to utilize underused water surfaces while offering several advantages over land-based solar installations, as they can generate about 15% more electricity as compared to ground-based solar systems, primarily due to the cooling effects of water [

51]. These systems are of utmost benefit in areas with limited land resources, such as coastal regions and island nations that struggle due to land competition between different sectors [

52]. A 2024 study proposed a conceptual design for green hydrogen production using proton exchange membrane electrolysis powered by a floating solar photovoltaic system. This design addresses the challenge of supplying a continuous green hydrogen flow for industrial users. The proposed system requires a floating solar photovoltaic installation with a nominal capacity of 518.4 megawatts and Li-ion batteries with 780.8 megawatt-hours capacity to produce 7.5 million standard cubic feet of green hydrogen per day [

53]. In another attempt at investigation, it was found that a fuel cell generator with a hydrogen production and accumulation unit can compensate through reducing the unmet electricity of a floating PV system from 49.34% to 0.57% for the Aegean Region of Turkey [

54]. An investigation in Ontario, Canada, explored the possibility of hydrogen ferries with a capacity of 100 passengers and found that the average hydrogen fuel consumption was 3.05 kg/hour, which would have a payback of 7.25 years [

55]. In India, it was found that, with annual average solar radiation of 3.95–4.79 kWh/m

2/d and a daily annual average load demand of 138 kWh/d, the optimal energy was in the range of 30,100–25,639 kWh/yr using a 110–120 kW rated PV array, 15 kW FC, 30–60 kW electrolyzer, 40–60 kg hydrogen tank capacity, and a 15 kW inverter [

56]. A study carried out to analyze the techno-economic evaluation of a hydrogen refueling station in İzmir-Çeşme, Turkey, with an aim of refueling 25 vehicles per day, required 125 kg of hydrogen production for which a 271 kW PV module, two wind turbines, and a 71 kW battery were used [

53]. In another study in Turkey, a hybrid renewable power generation system for the hydrogen refueling station with a wind–PV–battery system accounted for as low a levelized cost of hydrogen (LCOH) as USD 8.92/kg, with the NPC and percentage of excess electricity being USD 8.4 million and 29.6%, respectively [

57]. In 2020, the results showed that in order to supply 100% of the taxi fleet with hydrogen in the State of São Paulo, Brazil, composed of a fleet of 112 ICE vehicles run on gasoline and ethanol, approximately 185.4 kgH

2/day is necessary, while only 19.8 kgH

2/day is enough to supply 10% of the total fleet. The peak demand for each scenario is 44.36 kgH

2/day and 4.94 kgH

2/day, respectively [

58]. A photovoltaic system with a green hydrogen system produces 58,615 kg of green hydrogen per year, reducing carbon dioxide emissions by 8209 kg per year [

59].

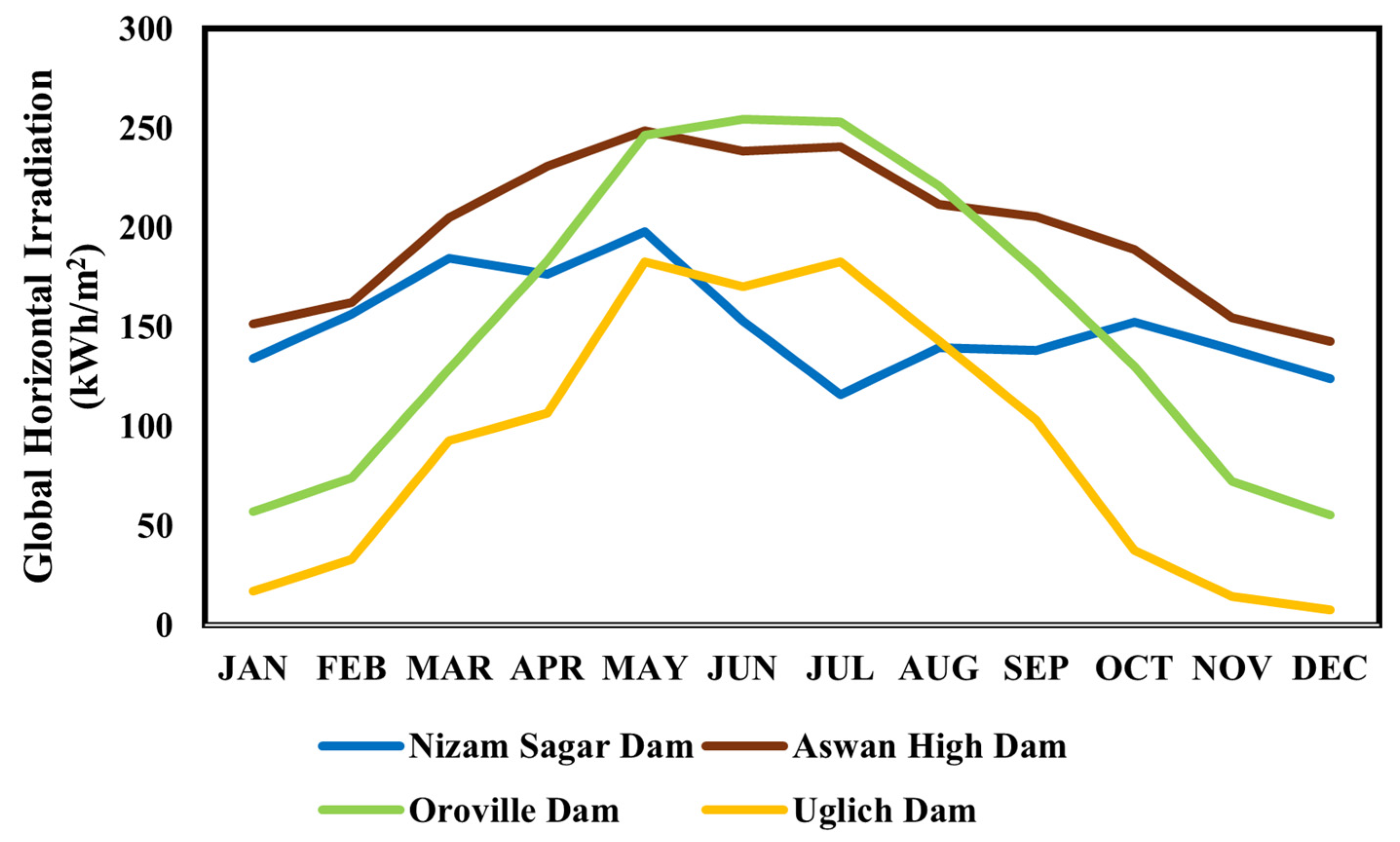

When discussing solar electricity, it is of paramount importance to consider that the solar radiation and climatic conditions are not uniform throughout the planet, which results in substantial variation in energy production, especially solar energy, even with the exact same setup [

60]. To classify this variation, the Koppen climate system came into existence for a better understanding based on some basic parameters [

61]. The integration of photovoltaic (PV) systems for hydrogen production is significantly influenced by climatic conditions, as outlined by the Koppen climate, as green hydrogen production is dependent on renewable energy, which is linked to climate [

62,

63]. Research indicates that different PV technologies, such as monocrystalline, polycrystalline, and amorphous silicon, exhibit varied performance based on local climate characteristics [

64,

65]. A study based on the African continent found that there is a significant variation in green hydrogen production, ranging from 12,247,278 kg to 511,245 kg, due to the difference in the climatic conditions as one of the key factors [

66]. Mazzeo et al. illustrated the dependence on solar and wind electricity production, where multiple locations categorized into different Koppen climate zones were investigated, including New Delhi in India, Arizona in the US, Kano in Nigeria, and Ontario, along with other places. The results clearly demonstrated the variation in electricity production due to the Koppen climate, with the site at Baghdad able to produce maximum electricity with PV, while Reykjavik generates minimum electricity with PV [

67]. Another study where green hydrogen was produced with a solar and wind hybrid system found significant variation in the green hydrogen sent to the load, ranging from 29,316 kg/MW to 16,201 kg/MW [

68]. Hernández-Nochebuena et al. also highlighted the relationship between PV-Hydrogen and climate, considering tropical, dry, and temperate climates for rooftop PV, emphasizing the direct relation between the three [

69].

Therefore, even though there is a presence of some literature on green hydrogen production and utilization, a direct comparison of such a system for different Koppen climates with various commercially available modules is not available, especially with an estimation of the number of cars that can be refueled each day with a detailed economic analysis.

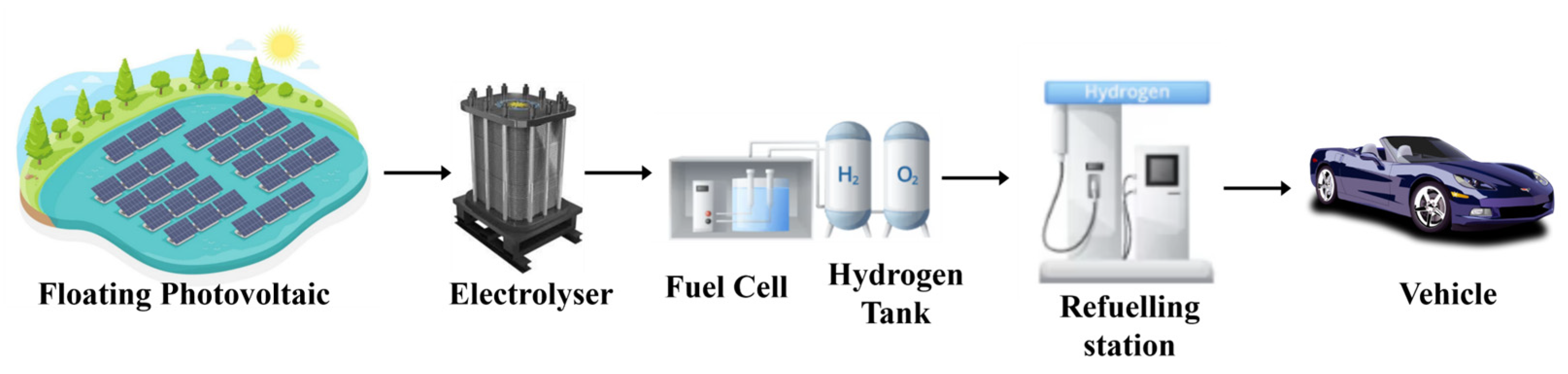

Figure 2 further elaborates on the novelty of this paper, especially the system considered. This paper is divided into different sections starting from the introduction, followed by methods, results, discussion, and finally concluding with conclusion.

2. Methods

In order to evaluate the proposed system, four different locations were selected to evaluate the performance and the viability of the project. The sites were selected based on the Koppen climatic conditions. In 1936, a system was developed by Wladimir Peter Köppen, which divides the climates into five major groups based on the vegetation type that is determined by seasonality of precipitation and critical temperature and is the most widely used climatic classification [

70]. This link between climate and vegetation gives a practical and understandable connection between a detailed, multivariate explanation of climate and a visually accessible representation of the natural landscape [

71]. In the first publication by Köppen and Geiger, climate was classified into five classes: (a) tropical rainy climates, (b) dry climates, (c) temperate climates, (d) continental climates, and (e) polar climates, as illustrated in

Figure 3, and the criteria for classification are illustrated in

Table 1. This is the basic classification of the Köppen climate; though there are further classifications, this classification is considered for the simplicity of the paper.

For this paper, four different locations in different Köppen climates and different continents are considered and compared. The first one is the Nizam Sagar Dam in India, which represents the tropical climate along with its significance in the irrigation of about 275,000 acres while contributing to socio-economic impact on locals [

72]. The second one is the Aswan High Dam in Lake Naseer, in Egypt, which comes under a dry climate with classification Bwh, built to cater to different demands, including power demand and agriculture expansion plans, while controlling floods [

73]. The third one is Oroville Dam in California, in the United States, known to provide irrigation and control floods; simultaneously, it generates three billion kWh of electricity and falls in the category of humid mesothermal climates [

74]. The last one is Uglich Dam on the Volga River in Yaroslavl Oblast in Russia. This reservoir has a significant role in providing hydropower along with the climatic conditions and location.

Table 2 shows the details of the site selected. Dams were selected for this project as they have the potential to minimize the electricity generation cost due to the existing infrastructure available, simultaneously enhancing sustainability by providing renewable energy to the local load demand [

75,

76].

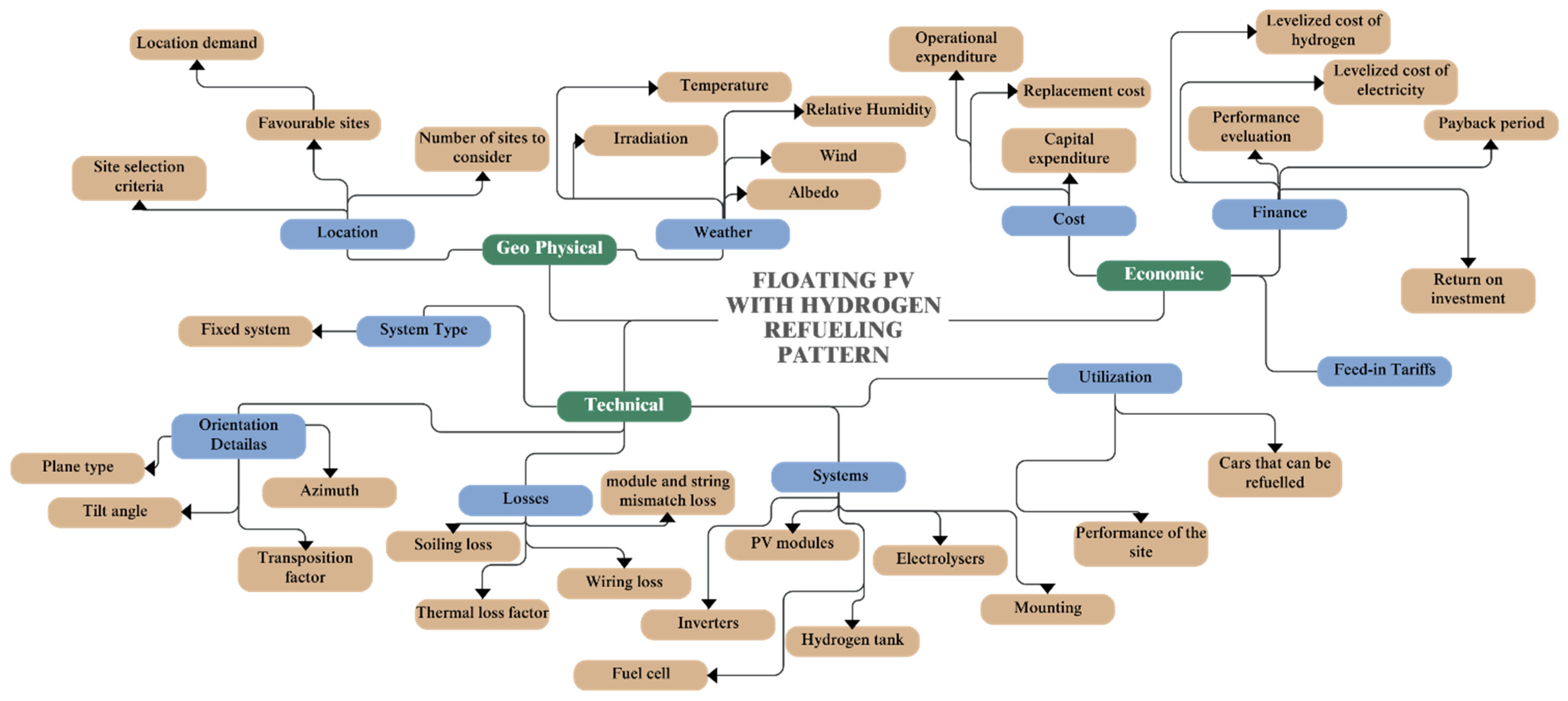

System Design

Floating Array System

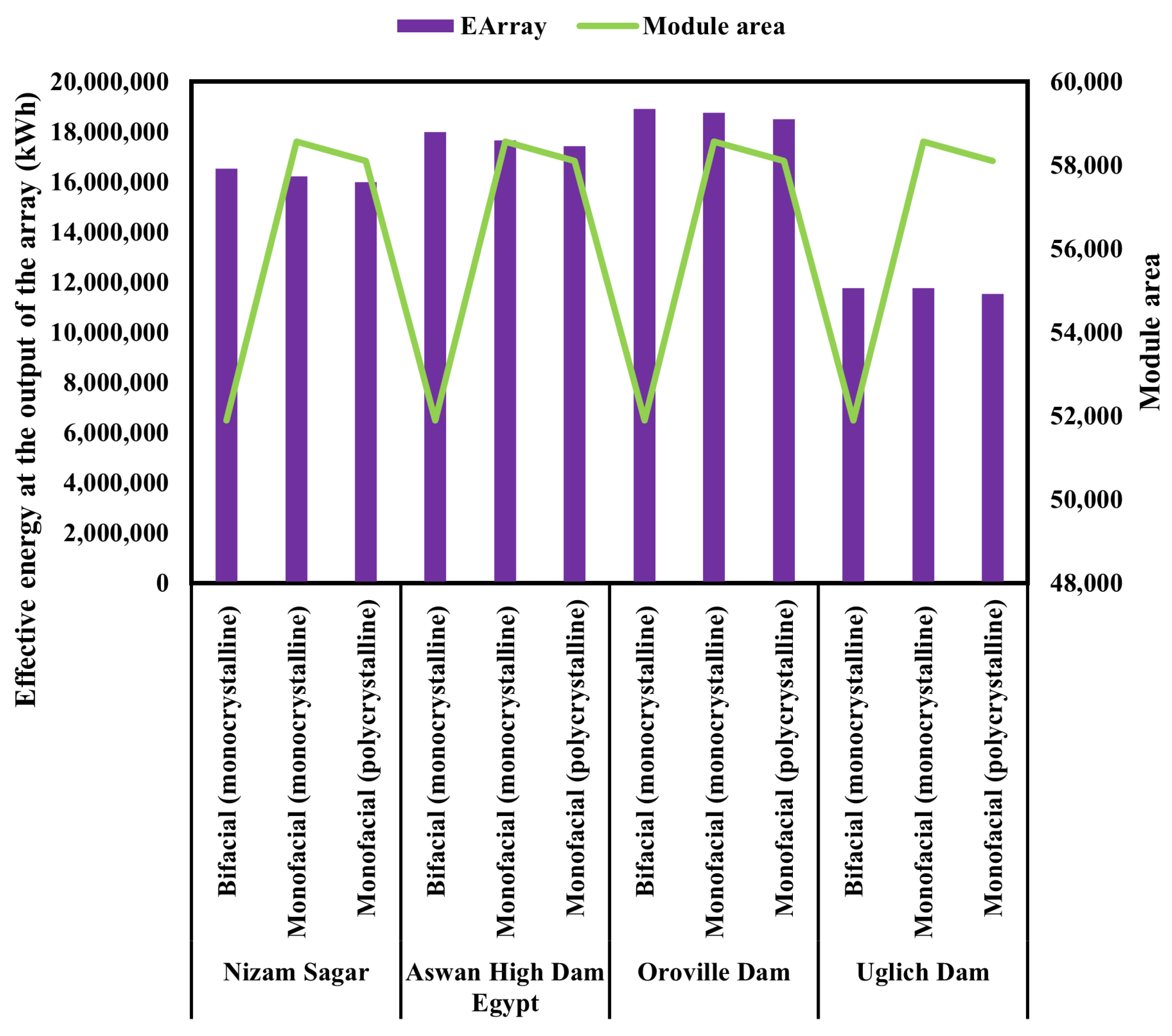

Figure 4 illustrates the overall system with a detail of different parameters that were considered during the simulation of this work, from site selection to economic feasibility. The PV array was designed and simulated using PVsyst 7.4, which is widely accepted by industry because of its advanced algorithms and database, helping to simulate with accuracy while simultaneously providing flexibility to customize them based on the requirement [

80]. The software takes input for site location in the form of a weather database to select the panel orientation for optimum output and system components and arrangements, which include photovoltaic modules, inverters, and other components. It calculates and generates a detailed report of system performance based on the system configuration. A 10 MWp system was designed in the PVsyst considering the albedo of water as 0.05 for the water surface. The NASA Surface Meteorology and Solar Energy (SSE) program was utilized to generate satellite-derived meteorological data files for the specified site locations. This comprehensive dataset employs mean irradiance measurements for the year 2024, offering a robust climatological perspective. The SSE dataset discretizes the Earth’s surface into a grid of 1° latitude by 1° longitude cells, providing global coverage with a spatial resolution of approximately 111 km at the equator [

81,

82,

83]. Based on the weather file, the orientation, including the optimum tilt angle azimuth angle of the system, was chosen to produce the maximum electricity. Different tilt angles were considered for different sites depending on the latitude and longitude of the system; however, for all the systems, fixed plane was considered. To better understand the performance of the system, different PV modules were considered, which included the LG 355 n1k-n6 monocrystalline bifacial module, LG 280 S1C-B3 monocrystalline monofacial, and AS6P30-280 polycrystalline monofacial with their technical specification in

Table 3. Thus, one bifacial and two monofacial modules were considered. In 2023, monocrystalline bifacial solar panels dominated the market compared to polycrystalline bifacial solar panels [

84]. A Soleaf DSP-3375K inverter by Dasstech from Shenzhen, China was used, which has a nominal power of 75 kW and an operating voltage of 200–820 V while the ratio of the PV array’s nominal power (PNom STC [kWp]) to the inverter’s nominal power (PNom [kWac]) was 1.2 [

85]. The total number of bifacial modules required to design a 10 MWp system was 28,169 units, while this target was achieved with 35,714 units for monocrystalline monofacial and polycrystalline monofacial.

At the same time, different losses are encountered by the array, including soiling and thermal loss; soiling loss is different for every region, which was considered while doing the simulation according to the available data [

86,

87,

88]. The results are obtained using Equations (1) and (2).

where

EarrMPP is the energy generated by the PV array operating at the maximum power point,

ILPmax is the power loss due to the maximum load condition, and

is the energy lost due to mismatch [

89].

The performance ratio is the ratio of energy that is produced for consumption with respect to the energy that would have been produced if the system were working continuously at STC efficiency. This suggests the efficiency of the module and the performance of the system. It can be expressed as follows:

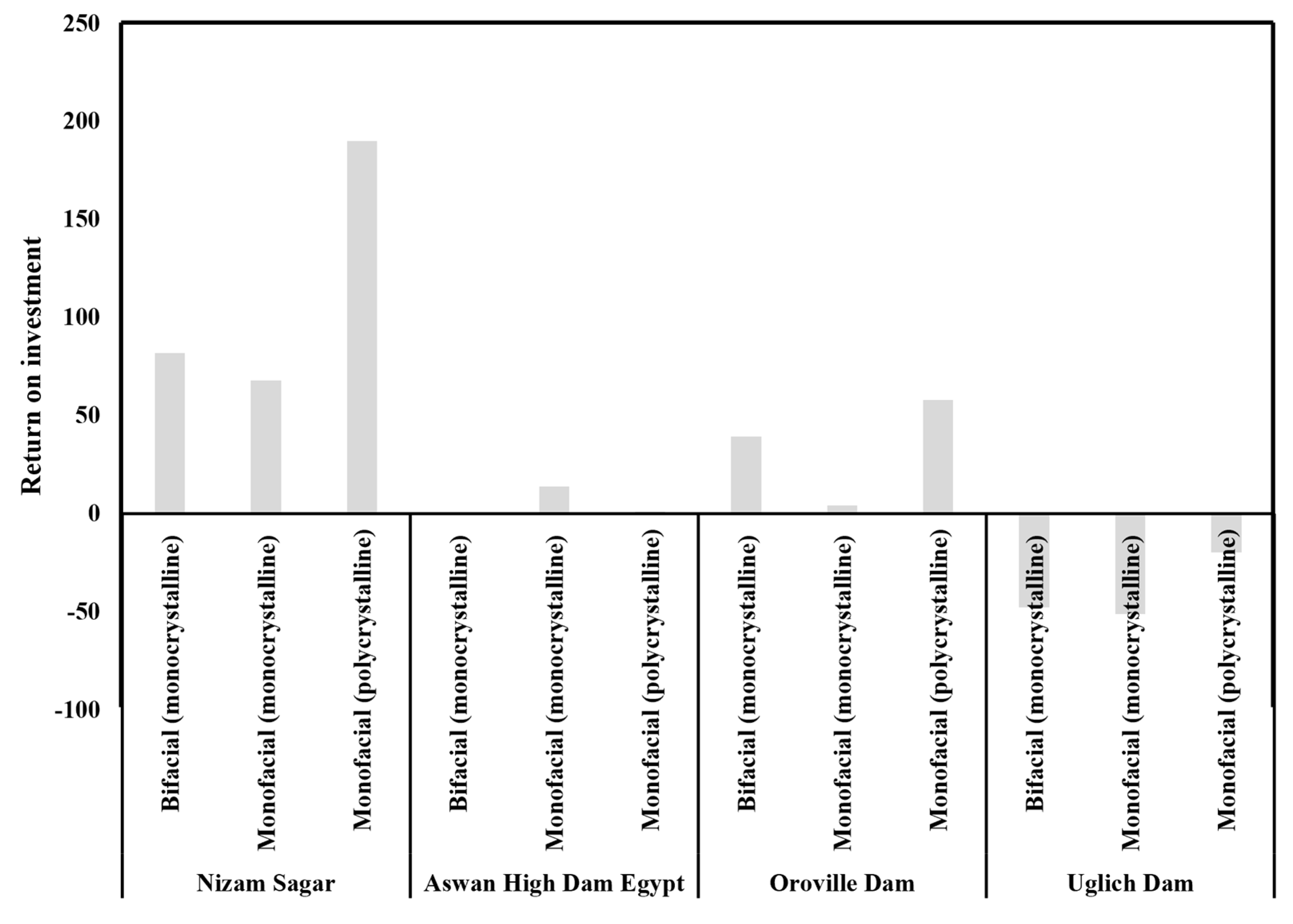

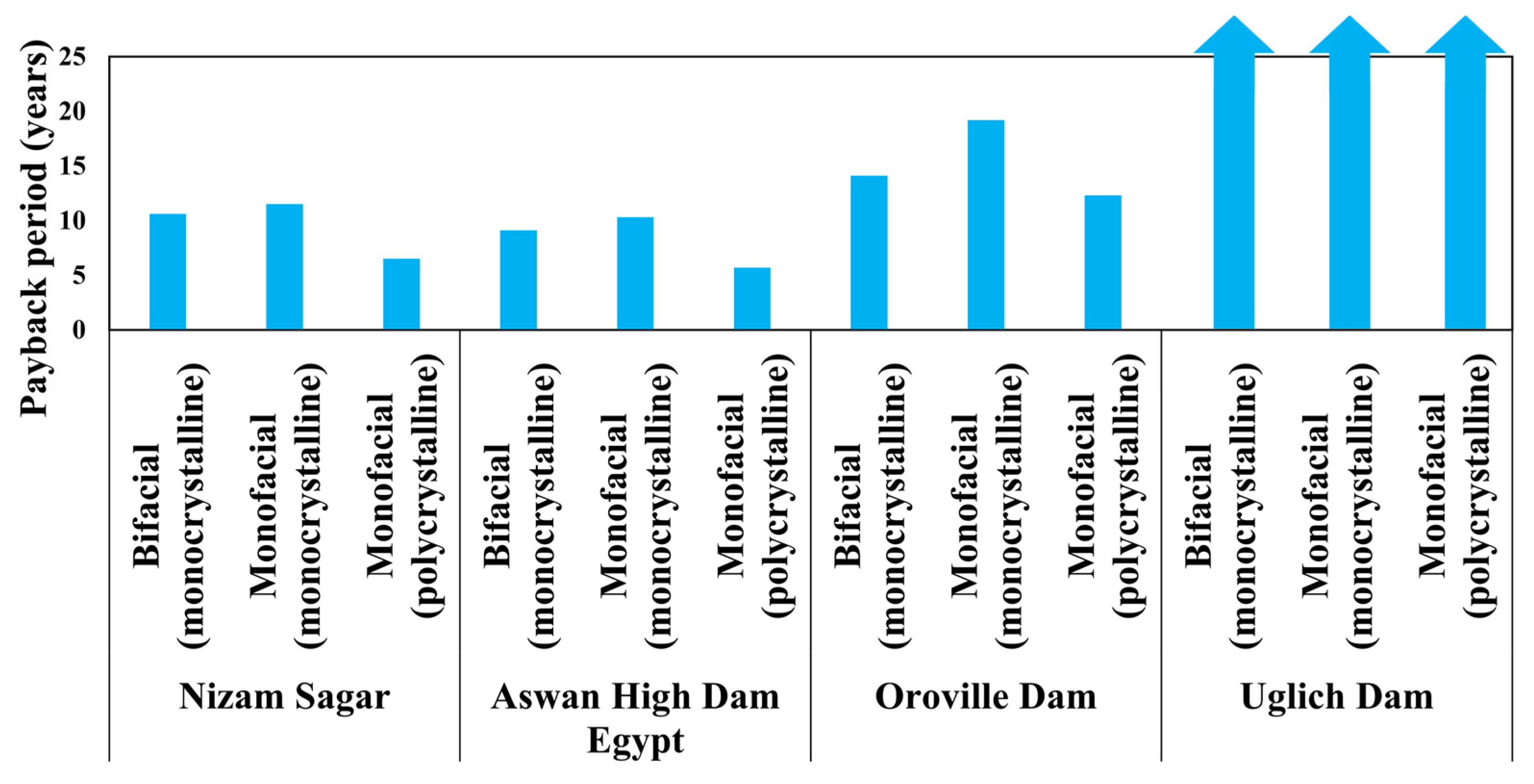

In order to quantify the significance of this system, an economic analysis was conducted, where the cost of different components was considered, as illustrated in

Table 4, which includes the cost of the major components, whereas

Table 5 displays the varying values in different regions, which were considered based on the market values for FPV systems.

To generate green hydrogen from the total electricity produced by the FPV, a system was designed to address this using HOMER Pro Version 3.16.2. It is an optimizing software, Hybrid Optimisation of Multiple Energy Resources, commonly referred to as HOMER Pro developed by UL Solutions to navigate a project’s designing complexities, cost-effectiveness, and reliability [

110]. In this work, a 100% renewable system was designed using the HOMER Pro software, which utilizes solar rays to produce electricity without wasting land by using FPV to meet the assumed electric load as shown in

Figure 5 with different components along with the energy flow directions. Additionally, the use of a PEM electrolyzer and fuel cell complements the system as electricity produced by the FPV is stored and used later to eliminate the intermittent nature of the PV. Each selected location represents different climatic conditions, which will enable us to study the system’s performance around the world. For each location, three types of simulations are performed with three types of PV representing Scenario 1, scenario 2, and Scenario 3. Scenario 1 is a system using monofacial (monocrystalline) PV, scenario 2 uses monofacial (polycrystalline) PV, and scenario 3 uses bifacial (monocrystalline) PV. The project was simulated in this software using the results from PVsyst and panel specifications. The PEM electrolyzer with an efficiency of 85% was considered to check the feasibility of the for various geographical locations and photovoltaic modules [

111,

112,

113,

114]. The PEM electrolyzer was considered due to its advanced technology, commercial availability, high efficiency ranging between 50 and 83 kWh/kgH

2, lifetime of 50–80 thousand hours, and its capability to produce enhanced purity of the gas [

115]. Sensitive analysis of the electrolyzer capacity is an essential parameter, as the design and sizing of the electrolyzer directly influence system performance, thereby affecting hydrogen production output, capital costs, and operational dynamics. An experimental study has demonstrated that electrolyzer sensitivity analysis for a 5 kW scale green hydrogen production system has an energy conversion efficiency between 73.3% and 86.2%, with the electrolyzer consuming a minimum specific electricity of 45.77 kWh/kg. In this study, a sensitive analysis was conducted over a range of electrolyzer sizes (0–30 kW) and minimum load percentages (10–50%) to determine their impact on surplus energy use [

116]. A fuel cell has also been incorporated into the system to directly convert the chemical energy in hydrogen to electricity with water and potentially useful heat as the only byproducts [

117]. The efficiency of the fuel cell for this has been considered as 40% and the lifetime of the proposed system fuel cell is assumed to be 40,000 h [

118,

119,

120].

Based on the input data, HOMER Pro carried out simulations which have been analyzed. The size of the modelled system is given in

Table 6. The size of the system in 1 and 3 came out to be the same. However, there is a slight change in the size of the electrolyzer and storage tank for system 2.

The electrolyzer is operational during the period of sunlight from 7 am to approximately 6 pm. The produced hydrogen is stored in a hydrogen tank, which has an initial tank level of 30% relative to tank size, while the hydrogen tank size is 10,000 kg [

121]. Using Equations (3) and (4)

where

represents total annualized cost (GBP),

i annual real discount rate (%),

is the project lifetime in years, and

is the capital recovery factor [

122].

LCOH is the levelized cost of hydrogen, where

, value of electricity;

, primary electrical load;

deferrable load;

total energy sold to the grid; and

total hydrogen production [

123]. The input values for financial analysis of different components are listed in

Table 7.

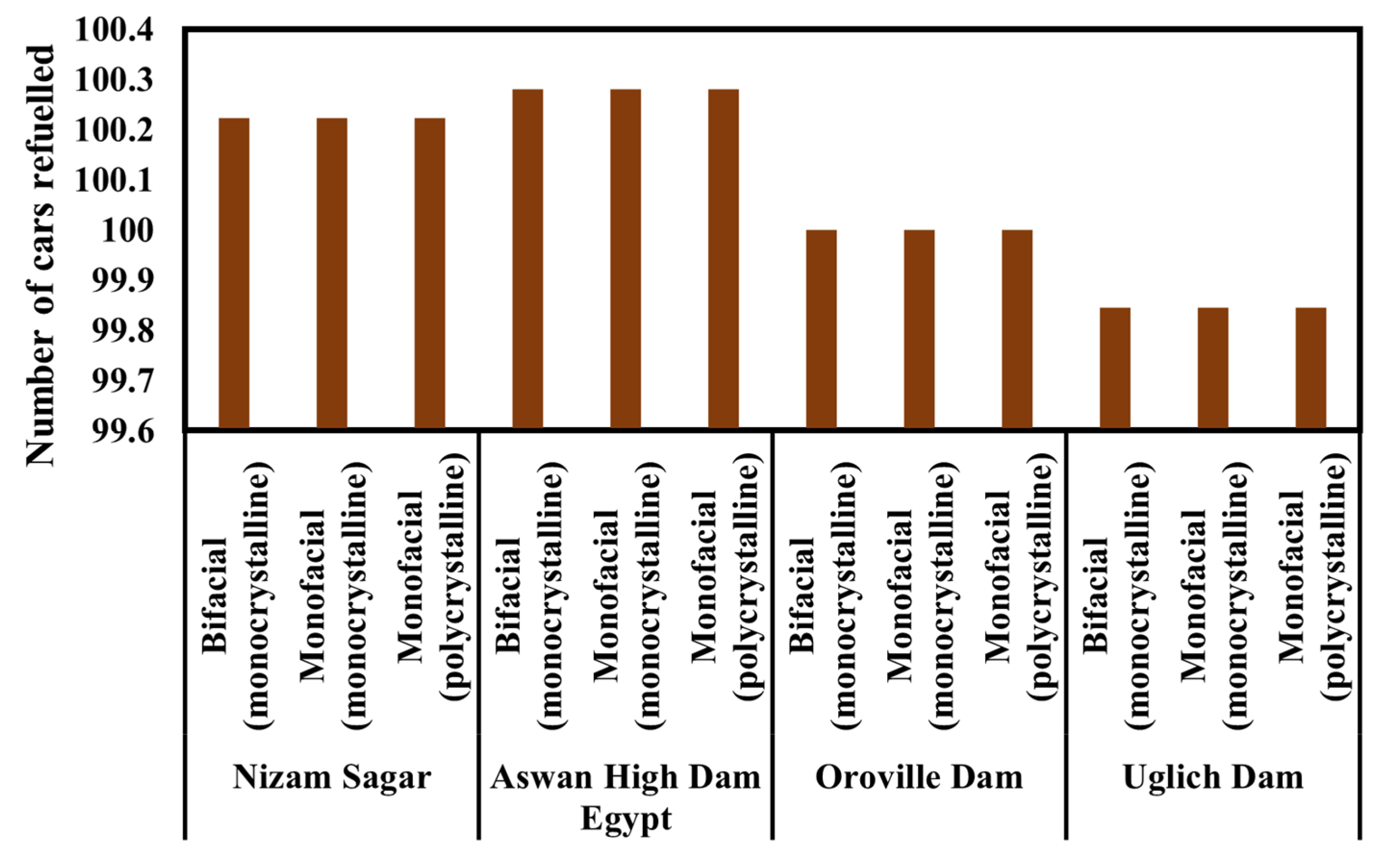

This hydrogen can be utilized to refuel the vehicles for which it is essential to find scale factors which can be conducted using Equation (5)

where it is assumed that 8 kg of hydrogen is required to refuel one [

125] and is divided by 100 since this is the unscaled daily demand of each refueling pattern. To calculate the refueling demand, Equation (6) can be used.

Cars refueled can be calculated using Equation (7), where it is assumed that 8 kg of hydrogen is required to refuel one car [

125].

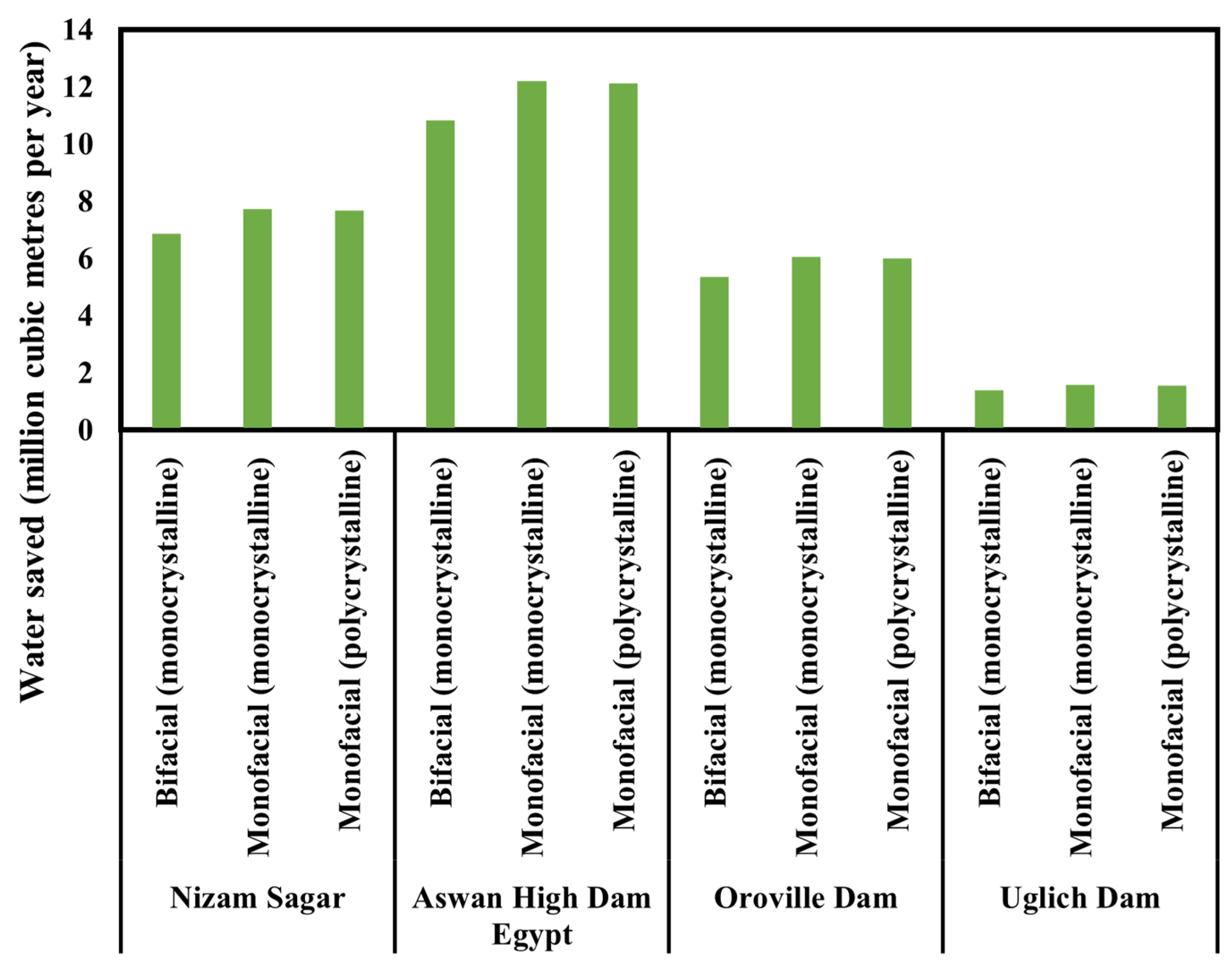

The potential water that can be saved due to evaporation was calculated using Equation (8)

where

is the daily evaporation rate,

is the adjusted temperature calculated using Equation (9), while

is the dew point temperature,

T is the mean temperature, and

A is the latitude.

where h is the elevation. The potential water saving was calculated using Equation (10) [

126].

where

is the reservoir surface area,

is a surface covered by floating photovoltaics,

is the annual evaporation rate, and

β is the evaporation reduction rate.