A Comparative Analysis of Waste-as-a-Feedstock Accounting Methods in Life Cycle Assessments

Abstract

1. Introduction

2. Materials and Methods

2.1. Life Cycle Assessment Framework

2.1.1. Principles of LCA

2.1.2. The Zero-Burden Assumption

2.1.3. The Neutrality Assumption

2.1.4. The Benchmark Assumption

2.2. Illustrative Example: MSW Gasification to Hydrogen

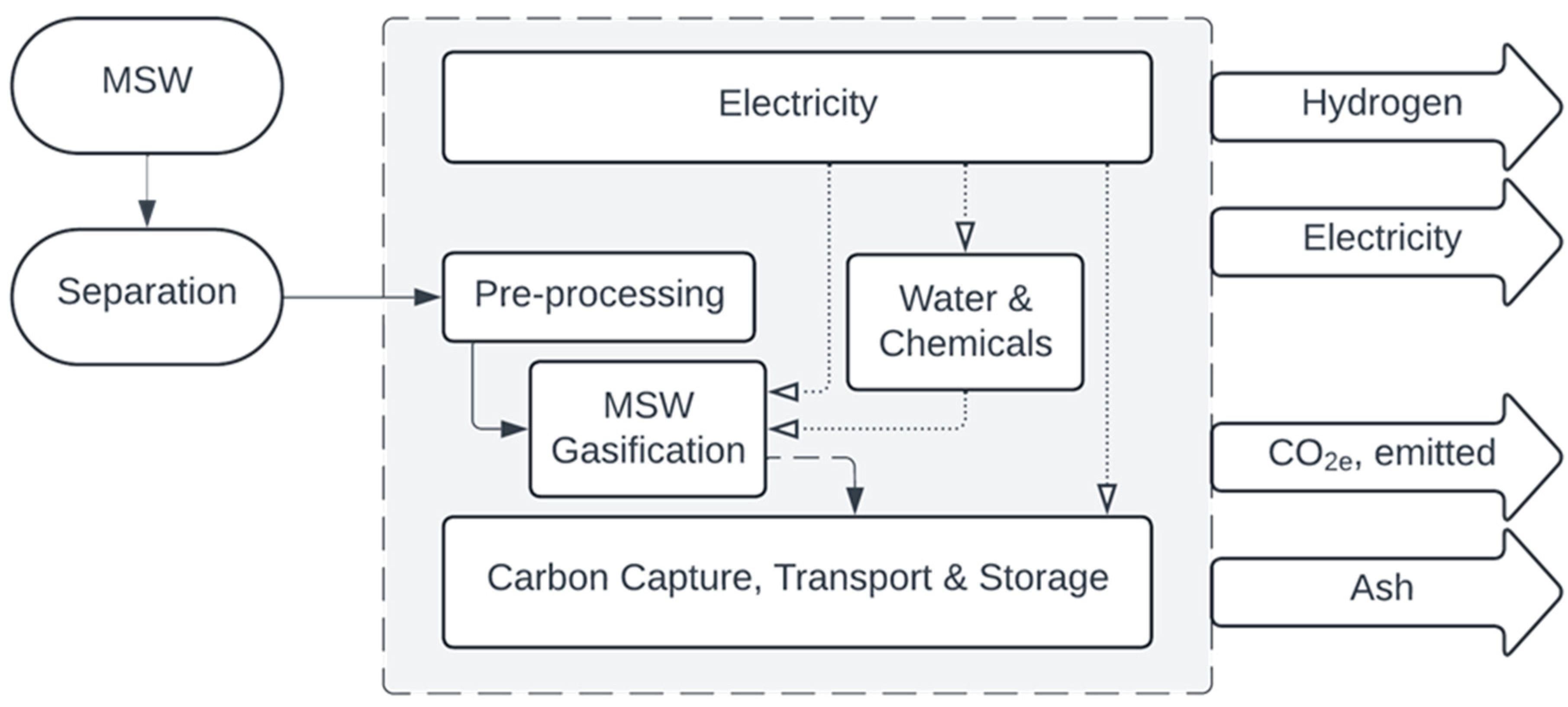

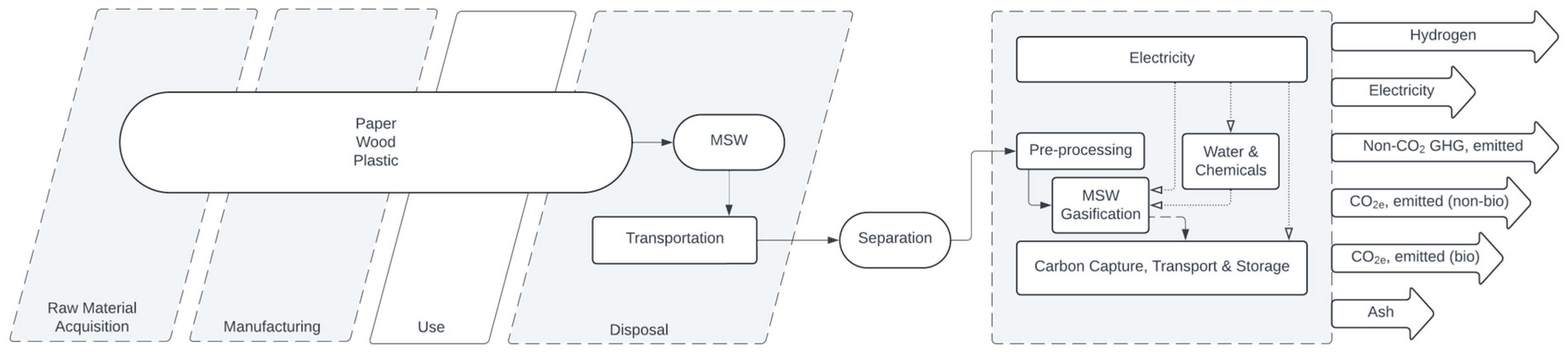

2.2.1. System Description

2.2.2. Life Cycle Modeling Software and Impact Assessment Method

2.2.3. Case Model Descriptions

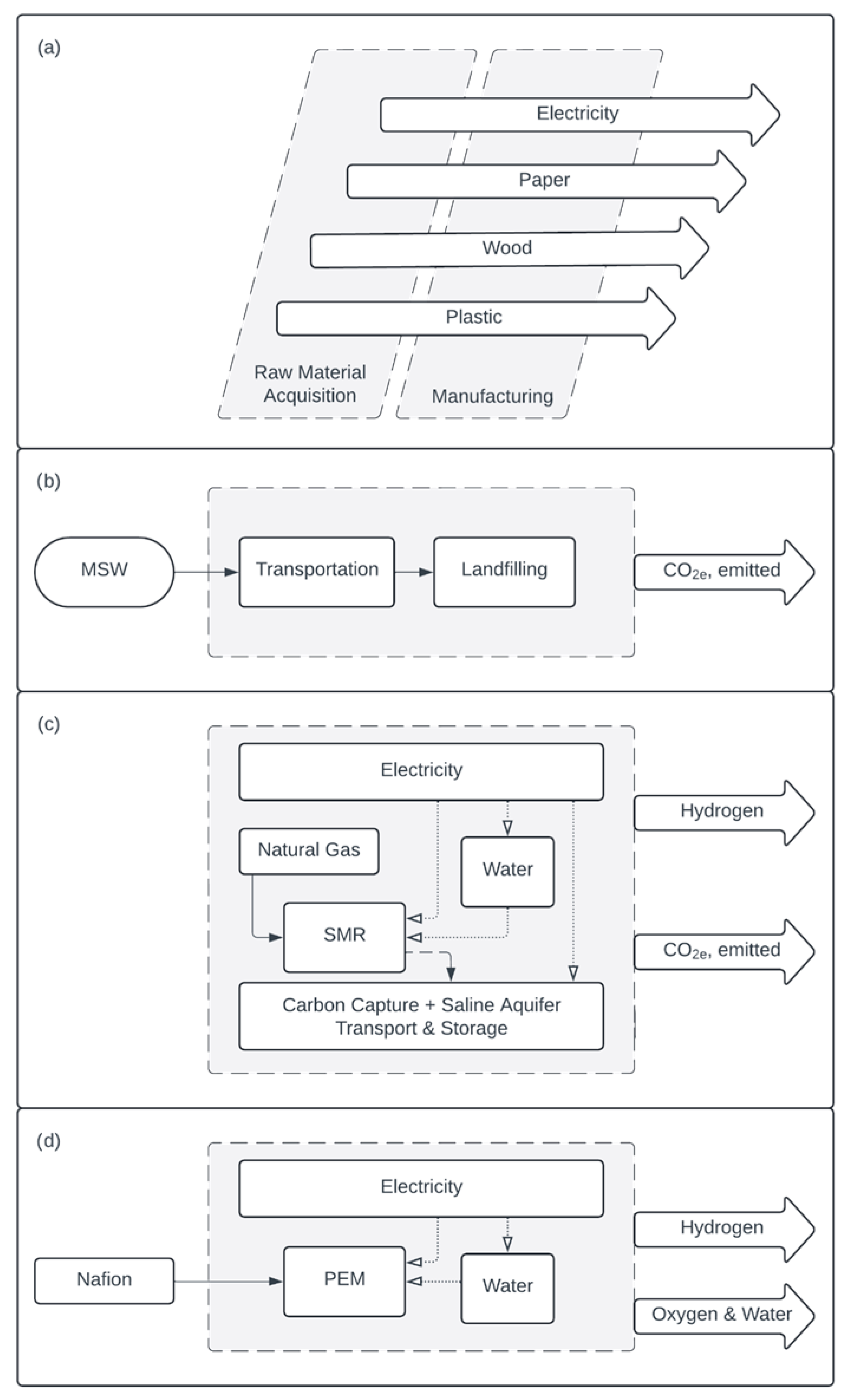

- Base case (i.e., the zero-burden assumption)

- Biogenic (i.e., neutrality assumption)

- Burdened (i.e., shared burden with paper, wood, and plastic production)

- Business-as-usual benchmark (i.e., SMR with electricity generation; paper, wood, and plastic production and MSW landfilling)

- Counterfactual benchmark (i.e., PEM with electricity generation; paper, wood, and plastic production and MSW landfilling)

3. Results

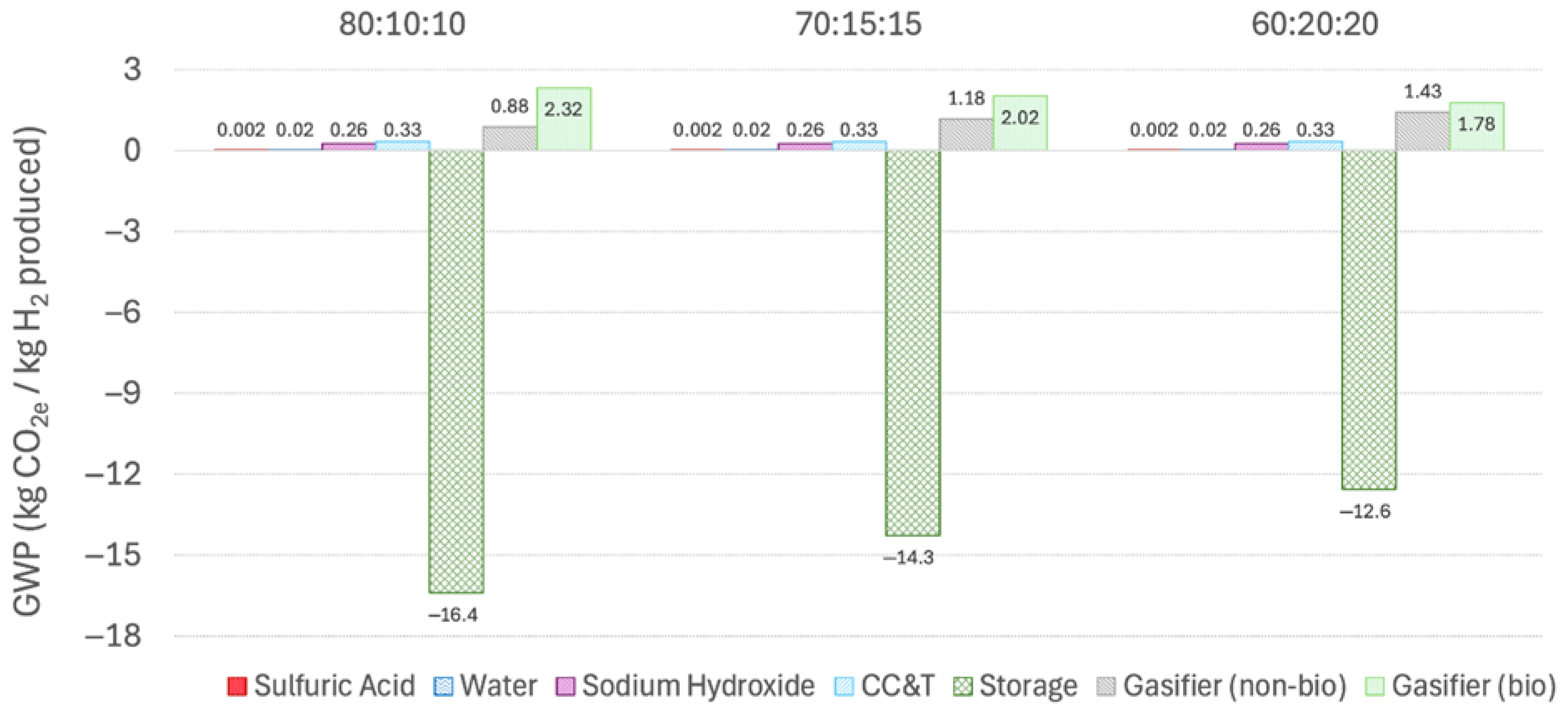

3.1. Sensitivity to Feedstock Composition and Functional Unit Perspective

3.2. Biogenic Carbon Sensitivity to Feedstock Composition

3.3. Benchmark Sensitivity to Paper Under Extended Burden

4. Discussion

4.1. Biogenic Carbon Accounting

4.2. Extended Burden Accounting

4.3. Emission Avoidance Accounting

4.4. Functional Unit Perspective

4.5. Assumptions and Limitations

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- EPA National Overview: Facts and Figures on Materials, Wastes and Recycling. Available online: https://www.epa.gov/facts-and-figures-about-materials-waste-and-recycling/national-overview-facts-and-figures-materials (accessed on 2 July 2024).

- Sharma, K.D.; Jain, S. Municipal Solid Waste Generation, Composition, and Management: The Global Scenario. Soc. Responsib. J. 2020, 16, 917–948. [Google Scholar] [CrossRef]

- United Nations Environment Programme. Global Waste Management Outlook 2024: Beyond an Age of Waste-Turning Rubbish into a Resource; United Nations Environment Programme: Nairobi, Kenya, 2024; ISBN 978-92-807-4129-2. [Google Scholar]

- Matheson, T. Disposal Is Not Free: Fiscal Instruments to Internalize the Environmental Costs of Solid Waste. Int. Tax Public Finance 2022, 29, 1047–1073. [Google Scholar] [CrossRef]

- Bekchanov, M.; Gondhalekar, D. Business Climate for Energy Regaining and Environmentally Sustainable Waste-to-Resource Technologies. In Handbook of Energy and Environmental Security; Elsevier: Amsterdam, The Netherlands, 2022; pp. 501–530. ISBN 978-0-12-824084-7. [Google Scholar]

- Barles, S. History of Waste Management and the Social and Cultural Representations of Waste. In The Basic Environmental History; Agnoletti, M., Neri Serneri, S., Eds.; Springer International Publishing: Cham, Switzerland, 2014; Volume 4, pp. 199–226. ISBN 978-3-319-09179-2. [Google Scholar]

- Slaveikova Nikolova, A.; Ness, D. ‘The Impossible Dream’. In The Impossibilities of the Circular Economy; Routledge: London, UK, 2022; pp. 23–36. ISBN 978-1-003-24419-6. [Google Scholar]

- Oo, P.Z.; Prapaspongsa, T.; Strezov, V.; Huda, N.; Oshita, K.; Takaoka, M.; Ren, J.; Halog, A.; Gheewala, S.H. The Role of Global Waste Management and Circular Economy towards Carbon Neutrality. Sustain. Prod. Consum. 2024, 52, 498–510. [Google Scholar] [CrossRef]

- Ribul, M.; Lanot, A.; Tommencioni Pisapia, C.; Purnell, P.; McQueen-Mason, S.J.; Baurley, S. Mechanical, Chemical, Biological: Moving towards Closed-Loop Bio-Based Recycling in a Circular Economy of Sustainable Textiles. J. Clean. Prod. 2021, 326, 129325. [Google Scholar] [CrossRef]

- Balasbaneh, A.T.; Sher, W.; Li, J.; Ashour, A. Systematic Review of Construction Waste Management Scenarios: Informing Life Cycle Sustainability Analysis. Circ. Econ. Sustain. 2025, 5, 529–553. [Google Scholar] [CrossRef]

- Shovon, S.M.; Akash, F.A.; Rahman, W.; Rahman, M.A.; Chakraborty, P.; Hossain, H.M.Z.; Monir, M.U. Strategies of Managing Solid Waste and Energy Recovery for a Developing Country—A Review. Heliyon 2024, 10, e24736. [Google Scholar] [CrossRef]

- Otoo, M.; Drechsel, P. (Eds.) Resource Recovery from Waste: Business Models for Energy, Nutrient and Water Reuse in Low- and Middle-Income Countries, 1st ed.; Routledge: Oxfordshire, UK, 2018; ISBN 978-1-315-78086-3. [Google Scholar]

- De Filippis, P.; Borgianni, C.; Paolucci, M.; Pochetti, F. Prediction of Syngas Quality for Two-Stage Gasification of Selected Waste Feedstocks. Waste Manag. 2004, 24, 633–639. [Google Scholar] [CrossRef]

- Mayer, F.; Bhandari, R.; Gäth, S. Critical Review on Life Cycle Assessment of Conventional and Innovative Waste-to-Energy Technologies. Sci. Total Environ. 2019, 672, 708–721. [Google Scholar] [CrossRef]

- ISO 14040:2006; Environmental Management-Life Cycle Assessment-Principles and Framework. ISO: Geneva, Switzerland, 2006.

- ISO 14044:2006; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. ISO: Geneva, Switzerland, 2006.

- Mulya, K.S.; Zhou, J.; Phuang, Z.X.; Laner, D.; Woon, K.S. A Systematic Review of Life Cycle Assessment of Solid Waste Management: Methodological Trends and Prospects. Sci. Total Environ. 2022, 831, 154903. [Google Scholar] [CrossRef]

- Antelava, A.; Damilos, S.; Hafeez, S.; Manos, G.; Al-Salem, S.M.; Sharma, B.K.; Kohli, K.; Constantinou, A. Plastic Solid Waste (PSW) in the Context of Life Cycle Assessment (LCA) and Sustainable Management. Environ. Manag. 2019, 64, 230–244. [Google Scholar] [CrossRef]

- Abagnato, S.; Rigamonti, L.; Grosso, M. Life Cycle Assessment Applications to Reuse, Recycling and Circular Practices for Textiles: A Review. Waste Manag. 2024, 182, 74–90. [Google Scholar] [CrossRef] [PubMed]

- Nurzhan, A.; Ruan, X.; Chen, D. A Review of Life Cycle Assessment Application in Municipal Waste Management: Recent Advances, Limitations, and Solutions. Sustainability 2025, 17, 302. [Google Scholar] [CrossRef]

- He, Y.; Kiehbadroudinezhad, M.; Hosseinzadeh-Bandbafha, H.; Gupta, V.K.; Peng, W.; Lam, S.S.; Tabatabaei, M.; Aghbashlo, M. Driving Sustainable Circular Economy in Electronics: A Comprehensive Review on Environmental Life Cycle Assessment of e-Waste Recycling. Environ. Pollut. 2024, 342, 123081. [Google Scholar] [CrossRef]

- Bala, A.; Raugei, M.; Teixeira, C.A.; Fernández, A.; Pan-Montojo, F.; Fullana-i-Palmer, P. Assessing the Environmental Performance of Municipal Solid Waste Collection: A New Predictive LCA Model. Sustainability 2021, 13, 5810. [Google Scholar] [CrossRef]

- Tagliaferri, C.; Evangelisti, S.; Clift, R.; Lettieri, P.; Chapman, C.; Taylor, R. Life Cycle Assessment of Conventional and Advanced Two-Stage Energy-from-Waste Technologies for Methane Production. J. Clean. Prod. 2016, 129, 144–158. [Google Scholar] [CrossRef]

- Bianco, I.; Panepinto, D.; Zanetti, M. Environmental Impacts of Electricity from Incineration and Gasification: How the LCA Approach Can Affect the Results. Sustainability 2022, 14, 92. [Google Scholar] [CrossRef]

- Nordahl, S.L.; Scown, C.D. Recommendations for Life-Cycle Assessment of Recyclable Plastics in a Circular Economy. Chem. Sci. 2024, 15, 9397–9407. [Google Scholar] [CrossRef]

- Ekvall, T.; Assefa, G.; Björklund, A.; Eriksson, O.; Finnveden, G. What Life-Cycle Assessment Does and Does Not Do in Assessments of Waste Management. Waste Manag. 2007, 27, 989–996. [Google Scholar] [CrossRef]

- Gupt, Y.; Sahay, S. Review of Extended Producer Responsibility: A Case Study Approach. Waste Manag. Res. 2015, 33, 595–611. [Google Scholar] [CrossRef]

- Grassel, J.T.; Escobedo, A.R.; Buch, R. Predicting the Composition of Solid Waste at the County Scale. Waste Manag. 2025, 193, 293–306. [Google Scholar] [CrossRef]

- Cai, H.; Cooney, G.; Shell, M. Best Practices for Life Cycle Assessment (LCA) of Biomass Carbon Removal and Storage (BiCRS) Technologies; U.S. Department of Energy: Washington, DC, USA, 2025; p. 56.

- Wiloso, E.I.; Heijungs, R.; Huppes, G.; Fang, K. Effect of Biogenic Carbon Inventory on the Life Cycle Assessment of Bioenergy: Challenges to the Neutrality Assumption. J. Clean. Prod. 2016, 125, 78–85. [Google Scholar] [CrossRef]

- Schivley, G.; Ingwersen, W.W.; Marriott, J.; Hawkins, T.R.; Skone, T.J. Identifying/Quantifying Environmental Trade-Offs Inherent in GHG Reduction Strategies for Coal-Fired Power. Environ. Sci. Technol. 2015, 49, 7562–7570. [Google Scholar] [CrossRef]

- Baker, S.E.; Stolaroff, J.K.; Peridas, G.; Pang, S.H.; Goldstein, H.M.; Lucci, F.R.; Li, W.; Slessarev, E.W.; Pett-Ridge, J.; Ryerson, F.J.; et al. Getting to Neutral: Options for Negative Carbon Emissions in California; Lawrence Livermore National Laboratory: Livermore, CA, USA, January 2020; LLNL-TR-796100.

- LaRiviere, M. Methodology for Allocating Municipal Solid Waste to Biogenic and Non-Biogenic Energy; Energy Information Administration Office of Coal, Nuclear, Electric and Alternate Fuels U.S. Department of Energy: Washington, DC, USA, 2007; p. 18.

- California Air Resources Board (CARB). Analysis of Progress Toward Achieving the 2030 Dairy and Livestock Sector Methane Emissions Target; California Air Resources Board (CARB): Sacramento, CA, USA, 2022; p. 63.

- Fruergaard, T.; Astrup, T. Optimal Utilization of Waste-to-Energy in an LCA Perspective. Waste Manag. 2011, 31, 572–582. [Google Scholar] [CrossRef]

- Heijungs, R.; Allacker, K.; Benetto, E.; Brandão, M.; Guinée, J.; Schaubroeck, S.; Schaubroeck, T.; Zamagni, A. System Expansion and Substitution in LCA: A Lost Opportunity of ISO 14044 Amendment 2. Front. Sustain. 2021, 1–3. [Google Scholar] [CrossRef]

- Burnley, S.; Coleman, T.; Peirce, A. Factors Influencing the Life Cycle Burdens of the Recovery of Energy from Residual Municipal Waste. Waste Manag. 2015, 39, 295–304. [Google Scholar] [CrossRef][Green Version]

- Fujii, M.; Dou, Y.; Sun, L.; Ohnishi, S.; Maki, S.; Dong, H.; Dong, L.; Chandran, R. Contribution to a Low-Carbon Society from Improving Exergy of Waste-to-Energy System by Upgrading Utilization of Waste. Resour. Conserv. Recycl. 2019, 149, 586–594. [Google Scholar] [CrossRef]

- Afzal, S.; Singh, A.; Nicholson, S.R.; Uekert, T.; DesVeaux, J.S.; Tan, E.C.D.; Dutta, A.; Carpenter, A.C.; Baldwin, R.M.; Beckham, G.T. Techno-Economic Analysis and Life Cycle Assessment of Mixed Plastic Waste Gasification for Production of Methanol and Hydrogen. Green Chem. 2023, 25, 5068–5085. [Google Scholar] [CrossRef]

- Chanthakett, A.; Arif, M.T.; Khan, M.M.K.; Oo, A.M.T. Chapter 8-Hydrogen Production from Municipal Solid Waste (MSW) for Cleaner Environment. In Bioenergy Resources and Technologies; Azad, A.K., Khan, M.M.K., Eds.; Academic Press: Cambridge, MA, USA, 2021; pp. 219–247. ISBN 978-0-12-822525-7. [Google Scholar]

- Office of Fossil Energy. Hydrogen Strategy: Enabling a Low-Carbon Economy; Office of Fossil Energy, U.S. Department of Energy: Washington, DC, USA, 2020.

- Pasternak, A.D.; Richardson, J.H.; Rogers, R.S.; Thorsness, C.B.; Wallman, H.; Richter, G.N.; Wolfenbarger, J.K. MSW to Hydrogen. In Proceedings of the 1994 DOE/NREL Hydrogen Program Review; B/T Books: Livermore, CA, USA, 1994; pp. 433–450. ISBN 0-89934-262-0. [Google Scholar]

- United States Internal Revenue Service. Credit for Production of Clean Hydrogen; United States Internal Revenue Service: Washington, DC, USA, 2022; Volume 26.

- Lui, J.; Chen, W.-H.; Tsang, D.C.W.; You, S. A Critical Review on the Principles, Applications, and Challenges of Waste-to-Hydrogen Technologies. Renew. Sustain. Energy Rev. 2020, 134, 110365. [Google Scholar] [CrossRef]

- Das, S.; Lee, S.-H.; Kumar, P.; Kim, K.-H.; Lee, S.S.; Bhattacharya, S.S. Solid Waste Management: Scope and the Challenge of Sustainability. J. Clean. Prod. 2019, 228, 658–678. [Google Scholar] [CrossRef]

- Christensen, T.H.; Damgaard, A.; Levis, J.; Zhao, Y.; Björklund, A.; Arena, U.; Barlaz, M.A.; Starostina, V.; Boldrin, A.; Astrup, T.F.; et al. Application of LCA Modelling in Integrated Waste Management. Waste Manag. 2020, 118, 313–322. [Google Scholar] [CrossRef]

- Austin Resource Recovery. 2023 Austin Resource Recovery Comprehensive Plan: Working Toward an Austin Without Waste; City of Austin, Burns McDonnell: Austin, TX, USA, 2023; p. 23. [Google Scholar]

- National Renewable Energy Laboratory. U.S. Life Cycle Inventory Database: eLCI Library. GitHub. 2024. Available online: https://github.com/FLCAC-admin/uslci-content/blob/e8177dd601e2141ee056c9a46fbf4662bf9f6fc4/downloads/elci_6_2024%20for%20uslci_q2_2024_final.zip (accessed on 19 June 2025).

- Bare, J. TRACI 2.0: The Tool for the Reduction and Assessment of Chemical and Other Environmental Impacts 2.0. Clean Technol. Environ. Policy 2011, 13, 687–696. [Google Scholar] [CrossRef]

- IPCC. Managing the Risks of Extreme Events and Disasters to Advance Climate Change Adaptation. A Special Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK, 2012; ISBN 978-1-107-02506-6. [Google Scholar]

- ERCE IPCC Sixth Assessment Report Global Warming Potentials. Available online: https://erce.energy/erceipccsixthassessment/ (accessed on 19 June 2025).

- American Chemistry Council. Sodium Hydroxide; Chlor-Alkali Average, Membrane Cell; at Plant; 50% Solution State. Federal LCA Commons. 2021. Available online: https://lcacommons.gov/lca-collaboration/National_Renewable_Energy_Laboratory/USLCI_Database_Public/dataset/PROCESS/344a7ac0-8c18-4869-bb63-3e44e811a1d9?commitId=7d7143983462ce7c48bf8d64bccbe5cafda11c45?gladview=true (accessed on 19 June 2025).

- Eastern Research Group. Sulfuric Acid, at Plant. Federal LCA Commons. 2011. Available online: https://lcacommons.gov/lca-collaboration/National_Renewable_Energy_Laboratory/USLCI_Database_Public/dataset/PROCESS/1b6afe73-a064-33a3-87b0-265ae10851e9 (accessed on 19 June 2025).

- EPA. Drinking Water Treatment Technology Unit Cost Models. Available online: https://www.epa.gov/node/110567 (accessed on 19 June 2025).

- Skone, T.J.; James III, R.E.; Cooney, G.; Jamieson, M.; Littlefield, J.; Marriott, J. Gate-to-Grave Life Cycle Analysis Model of Saline Aquifer Sequestration of Carbon Dioxide; Report No. DOE/NETL-2013/1600; National Energy Technology Laboratory: Pittsburgh, PA, USA, 2013; p. 15. [CrossRef]

- Skone, T.J.; Schivley, G.; Jamieson, M.; Marriott, J.; Cooney, G.; Littlefield, J.; Mutchek, M.; Krynock, M.; Shih, C.Y. Life Cycle Analysis: Supercritical Pulverized Coal (SCPC) Power Plants; National Energy Technology Laboratory: Pittsburgh, PA, USA, 2018; p. 132.

- EPA. Wood: Material-Specific Data. Available online: https://www.epa.gov/node/190621 (accessed on 19 June 2025).

- EPA. What Is Embodied Carbon? Available online: https://www.epa.gov/node/285469 (accessed on 19 June 2025).

- Hammond, G.; Jones, C. Embodied Carbon; Building Services Research and Information Association (BSRIA): Bath, UK, 2011; ISBN 978-0-86022-703-8. [Google Scholar]

- McDonnell, B.; Matters, C. Recycling Market Development Plan; Texas Commission on Environmental Quality: Austin, TX, USA, 2021; p. 318.

- Triassi, M.; De Simone, B.; Montuori, P.; Russo, I.; De Rosa, E.; Di Duca, F.; Crivaro, C.; Cerullo, V.; Pontillo, P.; Díez, S. Determination of Residual Municipal Solid Waste Composition from Rural and Urban Areas: A Step toward the Optimization of a Waste Management System for Efficient Material Recovery. Sustainability 2023, 15, 13378. [Google Scholar] [CrossRef]

- Canals, L.M.i.; Azapagic, A.; Doka, G.; Jefferies, D.; King, H.; Mutel, C.; Nemecek, T.; Roches, A.; Sim, S.; Stichnothe, H.; et al. Approaches for Addressing Life Cycle Assessment Data Gaps for Bio-Based Products. J. Ind. Ecol. 2011, 15, 707–725. [Google Scholar] [CrossRef]

- Argonne National Laboratory & UChicago Argonne. R&D GREET; Version 2024, rev1; EERE: Lemont, IL, USA, 2024.

- U.S. Environmental Protection Agency Office of Resource Conservation and Recovery. Documentation for Greenhouse Gas Emission and Energy Factors Used in the Waste Reduction Model (WARM): Background Chapters; EPA: Washington, DC, USA, 2023; p. 61.

- US Environmental Protection Agency. Waste Reduction Model (WARM); Version 16; EPA: Washington, DC, USA, 2023.

- Boguski, T.K. Life Cycle Carbon Footprint of the National Geographic Magazine. Int. J. Life Cycle Assess. 2010, 15, 635–643. [Google Scholar] [CrossRef]

- Shi, F.; Means, N.C.; Lekse, J.W.; Gray, M.; Wang, P. Gasification of Waste Plastic to Enable a Circular Economy: Literature Review Focusing on H2/Syngas Production; National Energy Technology Laboratory: Pittsburgh, PA, USA, 2022; p. 25.

- Lopez, G.; Artetxe, M.; Amutio, M.; Alvarez, J.; Bilbao, J.; Olazar, M. Recent Advances in the Gasification of Waste Plastics. A Critical Overview. Renew. Sustain. Energy Rev. 2018, 82, 576–596. [Google Scholar] [CrossRef]

- Franklin Associates. Cradle-to-Gate Life Cycle Inventory of Nine Plastic Resins and Four Polyurethane Precursors; The Plastics Division of the American Chemistry Council: Prairie Village, KA, USA, 2011; p. 198. [Google Scholar]

- Alanya-Rosenbaum, S.; Bergman, R.D.; Gething, B. Assessing the Life-Cycle Environmental Impacts of the Wood Pallet Sector in the United States. J. Clean. Prod. 2021, 320, 128726. [Google Scholar] [CrossRef]

- U.S. Environmental Protection Agency Office of Resource Conservation and Recovery. Documentation for Greenhouse Gas Emission and Energy Factors Used in the Waste Reduction Model (WARM): Construction Materials Chapters; EPA: Washington, DC, USA, 2023; p. 124.

- US Environmental Protection Agency. Using WARM Emission Factors for Materials and Pathways Not in WARM. Available online: https://www.epa.gov/sites/default/files/2016-03/documents/using_warm_efs_for_materials_and_pathways.pdf (accessed on 19 June 2025).

- Littlefield, J.; Roman-White, S.; Augustine, D.; Pegallapati, A.; Zaimes, G.G.; Rai, S.; Cooney, G.; Skone, T. Life Cycle Analysis of Natural Gas Extraction and Power Generation; National Energy Technology Laboratory: Pittsburgh, PA, USA, 2019; p. 374.

- National Energy Technology Laboratory. Electricity; at User; Consumption Mix–Electric Reliability Council of Texas, Inc.–BA; Version: 01.00.001. Federal LCA Commons. 2020. Available online: https://www.lcacommons.gov/lca-collaboration/Federal_LCA_Commons/US_electricity_baseline/dataset/PROCESS/b42ca74f-a649-32d5-9a9f-6a9846e7af51?commitId=feae44943f7984498ed2aad7d931b74f34f8bca4 (accessed on 19 June 2025).

- EIA Annual Energy Outlook 2023. Available online: https://www.eia.gov/outlooks/aeo/ (accessed on 19 June 2025).

- National Energy Technology Laboratory. Steam Methane Reforming (SMR) operations with carbon capture (CCS). EDX. 2022. Available online: https://edx.netl.doe.gov/dataset/lca-up-steam-methane-reforming-smr-operations-with-carbon-capture-ccs (accessed on 19 June 2025).

- U.S. Environmental Protection Agency Office of Resource Conservation and Recovery. Documentation for Greenhouse Gas Emission and Energy Factors Used in the Waste Reduction Model (WARM): Containers, Packaging, and Non-Durable Good Materials Chapters; EPA: Washington, DC, USA, 2023; p. 82.

- Henriksen, M.S.; Matthews, H.S.; White, J.; Walsh, L.; Grol, E.; Jamieson, M.; Skone, T.J. Tradeoffs in Life Cycle Water Use and Greenhouse Gas Emissions of Hydrogen Production Pathways. Int. J. Hydrogen Energy 2024, 49, 1221–1234. [Google Scholar] [CrossRef]

- Campuzano, R.; González-Martínez, S. Characteristics of the Organic Fraction of Municipal Solid Waste and Methane Production: A Review. Waste Manag. 2016, 54, 3–12. [Google Scholar] [CrossRef]

| Greenhouse Gas Emission (to Atmosphere) | Characterization Factor (100-Year) | ||

|---|---|---|---|

| AR4 2007 | AR5 2014 | AR6 2021 | |

| Carbon dioxide | 1 | 1 | 1 |

| Methane | 25 | 36 | 30 |

| Nitrous oxide | 298 | 265 | 273 |

| Sulfur hexafluoride | 22,800 | 26,087 | 25,200 |

| Input Flow | Amount | Unit (per kg H2) | Provider |

|---|---|---|---|

| Processed (sorted + dried) MSW | 18.7 | kg | None (included with gasifier) |

| Sodium hydroxide | 0.34 | kg | Sodium hydroxide; chlor-alkali average, membrane cell; at plant; 50% solution state [52] |

| Sulfuric acid | 6.0 × 10−3 | kg | Sulfuric acid, at plant—RNA [53] |

| Water, raw | 32.0 | kg | Not modeled (elementary flow) |

| Water, treated by cation exchange | 32.0 | kg | Cation exchange [54] |

| Carbon dioxide, captured product | 23.6 | kg | Saline aquifer transport and storage—U.S. [55] |

| Output Flow | Amount | Unit (per kg H2) | Comment |

| Hydrogen (product) | 1 | kg | >99.9 vol%, 6.38 MPa |

| Ash | 1.93 | kg | Ash has 3.8 wt% carbon content |

| Electricity (co-product) | 1.63 | kWh | 345 kV, alternating current (AC) |

| Carbon dioxide | 3.34 | kg | Emission to air |

| Water | 13.7 | kg | Emission to water |

| MSW Feedstock Material | Proxy Product | Data Source |

|---|---|---|

| Paper | Magazine/third-class mail | WARM 2023 |

| Plastic | LDPE resin | WARM 2023 |

| Wood | Dimensional lumber | WARM 2023 |

| Input Flow | Amount | Unit (per kg H2) | Provider |

|---|---|---|---|

| Natural gas, delivered | 3.75 | kg | Natural gas, delivery—U.S. [73] |

| Electricity, AC, 120 V | 2.03 | kWh | Electricity; at user; consumption mix—ERCOT—2030 [74,75] |

| Water, raw | 29 | kg | Not modeled (elementary flow) |

| Water, treated by cation exchange | 1.56 | kg | Cation exchange [54] |

| Carbon dioxide, captured product | 9.56 | kg | Saline aquifer transport and storage—U.S. [73] |

| Output Flow | Amount | Unit (per kg H2) | Comment |

| Hydrogen (product) | 1 | kg | >99.9%, 6.38 MPa |

| Carbon dioxide | 0.38 | kg | Emission to air |

| Nitrogen | 22.3 | kg | Emission to air |

| Nitrogen oxides | 1.9 × 10−4 | kg | Emission to air |

| Water | 6.5 | kg | Emission to water |

| Water | 0.56 | kg | Emission to air |

| Fuel Category | Mix Percentage (Relative to Projected Future Generation of All Fuels) |

|---|---|

| Natural gas | 30.9 |

| Wind | 27.6 |

| Solar photovoltaic | 25.9 |

| Nuclear | 9.73 |

| Coal | 5.57 |

| Hydroelectric | 0.25 |

| Biomass | 0.03 |

| Petroleum | 0.02 |

| Input Flow | Amount | Unit (per kg H2) | Provider |

|---|---|---|---|

| Electricity, AC, 120 V | 55.0 | kWh | Electricity; at user; consumption mix—ERCOT—2030—wind [74,75] |

| Water, raw | 163.2 | kg | Not modeled (elementary flow) |

| Water, treated by reverse osmosis | 8.9 | kg | Reverse osmosis [54] |

| Nafion membrane | 1.4 × 10−5 | kg | Not modeled (cutoff) |

| Output Flow | Amount | Unit (per kg H2) | Comment |

| Hydrogen (product) | 1 | kg | >99.9%, 435 psig, 60 °C |

| Water | 160.0 | kg | Emission to water |

| Case | Paper Product | Wood Product | Plastic Product | NaOH Product | H2SO4 Product | Elec. Use | Natural Gas Use | Water Use | CC&T | Bio. C Storage | MSW Gasification (bio) | MSW Gasification (fossil) | SMR/MSW Gasification | Elec. Product | Landfill | Total * | Total |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 80:10:10 Output Scenario | |||||||||||||||||

| Base | 0.26 | 2.1 × 10−3 | 0.02 | 0.33 | 3.21 | 3.82 | |||||||||||

| Biogenic | 0.26 | 2.1 × 10−3 | 0.02 | 0.33 | −16.4 | 2.32 | 0.88 | 3.82 | −14.9 | ||||||||

| Burdened | 142 | 4.20 | 3.58 | 0.26 | 2.1 × 10−3 | 0.02 | 0.33 | −17.1 | 2.32 | 0.88 | 0.16 | 154 | 135 | ||||

| BU (SMR) | 142 | 4.20 | 3.58 | 0.61 | 3.06 | 1.0 × 10−3 | 0.14 | 0.38 | 0.47 | −9.10 | 154 | 146 | |||||

| CF (PEM) | 142 | 4.20 | 3.58 | 1.49 | 4.2 × 10−3 | 0.47 | −9.10 | 152 | 142 | ||||||||

| 70:15:15 Output Scenario | |||||||||||||||||

| Biogenic | 0.26 | 2.1 × 10−3 | 0.02 | 0.33 | −14.3 | 2.02 | 1.18 | 3.82 | −12.5 | ||||||||

| Burdened | 124 | 6.31 | 5.37 | 0.26 | 2.1 × 10−3 | 0.02 | 0.33 | −14.9 | 2.02 | 1.18 | 0.16 | 140 | 123 | ||||

| BU (SMR) | 124 | 6.31 | 5.37 | 0.61 | 3.06 | 1.0 × 10−3 | 0.14 | 0.38 | 0.47 | −9.14 | 140 | 132 | |||||

| CF (PEM) | 124 | 6.31 | 5.37 | 1.49 | 4.2 × 10−3 | 0.47 | −9.14 | 138 | 129 | ||||||||

| 60:20:20 Output Scenario | |||||||||||||||||

| Biogenic | 0.26 | 2.1 × 10−3 | 0.02 | 0.33 | −12.6 | 1.78 | 1.43 | 3.82 | −10.5 | ||||||||

| Burdened | 107 | 8.41 | 7.16 | 0.26 | 2.1 × 10−3 | 0.02 | 0.33 | −13.1 | 1.78 | 1.43 | 0.16 | 126 | 111 | ||||

| BU (SMR) | 107 | 8.41 | 7.16 | 0.61 | 3.06 | 1.0 × 10−3 | 0.14 | 0.38 | 0.47 | −9.18 | 126 | 118 | |||||

| CF (PEM) | 107 | 8.41 | 7.16 | 1.49 | 4.2 × 10−3 | 0.47 | −9.18 | 124 | 115 | ||||||||

| 80:10:10 Input Scenario (kg CO2e/kg MSW managed) | |||||||||||||||||

| Base | 0.01 | 1.2 × 10−4 | 1.1 × 10−3 | 0.02 | 0.18 | 0.21 | |||||||||||

| Biogenic | 0.01 | 1.1 × 10−3 | 0.02 | −0.91 | 0.13 | 0.05 | 0.21 | −0.83 | |||||||||

| Burdened | 7.92 | 0.23 | 0.20 | 0.01 | 1.1 × 10−3 | 0.02 | −0.91 | 0.13 | 0.05 | 0.01 | 8.57 | 7.53 | |||||

| BU (SMR) | 7.92 | 0.23 | 0.20 | 0.03 | 0.16 | 5.4 × 10−5 | 7.5 × 10−3 | 0.02 | 0.03 | −0.49 | 8.58 | 8.12 | |||||

| CF (PEM) | 7.92 | 0.23 | 0.20 | 0.08 | 2.3 × 10−4 | 0.03 | −0.49 | 8.43 | 7.97 | ||||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Davis, T.W.; Mahmud, R.; McNaul, S.; Jamieson, M.; Lewis, E. A Comparative Analysis of Waste-as-a-Feedstock Accounting Methods in Life Cycle Assessments. Hydrogen 2025, 6, 74. https://doi.org/10.3390/hydrogen6040074

Davis TW, Mahmud R, McNaul S, Jamieson M, Lewis E. A Comparative Analysis of Waste-as-a-Feedstock Accounting Methods in Life Cycle Assessments. Hydrogen. 2025; 6(4):74. https://doi.org/10.3390/hydrogen6040074

Chicago/Turabian StyleDavis, Tyler W., Roksana Mahmud, Shannon McNaul, Matthew Jamieson, and Eric Lewis. 2025. "A Comparative Analysis of Waste-as-a-Feedstock Accounting Methods in Life Cycle Assessments" Hydrogen 6, no. 4: 74. https://doi.org/10.3390/hydrogen6040074

APA StyleDavis, T. W., Mahmud, R., McNaul, S., Jamieson, M., & Lewis, E. (2025). A Comparative Analysis of Waste-as-a-Feedstock Accounting Methods in Life Cycle Assessments. Hydrogen, 6(4), 74. https://doi.org/10.3390/hydrogen6040074