1. Introduction

As a high-risk artificial accumulation body, a tailings dam is essentially an artificial-debris-flow risk source with high potential energy. Across the long-term operation cycle, natural factors, such as geological activities and climate changes, improper management, and other human-related errors continuously act upon the dam’s structure, forming a dynamic superposition of potential safety hazards, posing a continuous threat to the surrounding ecological environment, human life, and property safety. Mining-associated waste and tailings (including mine rubble, fly ash, and slag) are characterized by their content of heavy metals and various toxic compounds. Substandard disposal methods or inadequate containment can easily result in the mobilization and dispersion of these contaminants in the environment [

1]. It is worth noting that the total amount of waste rock and tailings produced by the current mining production is far more than the actual utilization rate. Most of the unused solid waste is eventually accumulated in tailings reservoir areas. After years of continuous accumulation, these artificial accumulation bodies gradually evolve into geological structures with significant environmental risks. As mineral resource extraction intensifies, the rising accumulation of tailings and waste rock—coupled with deficiencies in the design and management of tailings dams and waste dumps—has led to frequent failures of these structures [

2,

3,

4].

In order to study the scientificity and reliability of the physical model test of the tailings pond, many scholars have carried out a large number of experiments and achieved corresponding research results. Aubertin et al. [

5] have verified that waste-rock inclusions (WRI) can effectively improve the stability of tailings ponds, accelerate the consolidation and drainage of tailings, and enhance seismic performance through field monitoring, laboratory testing, physical modeling, and numerical simulation. Ma et al. [

6], aiming to improve the scientificity and reliability of physical modeling of tailings dams, further studied the feasibility of such modeling from four aspects: dam break, downstream evolution, stability evaluation, and protection tests.

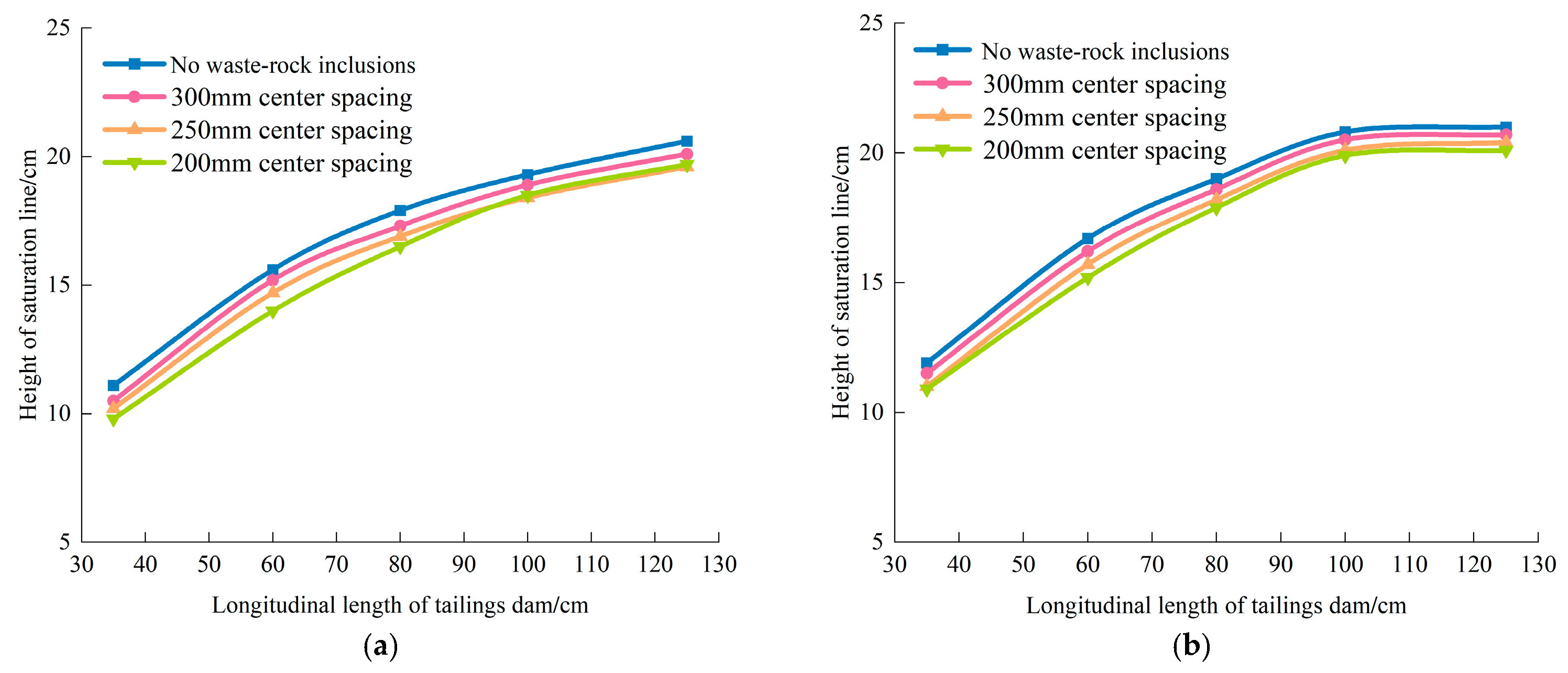

Gao et al. [

7] conducted a scale model test by constructing waste-rock columns in a tailings dam. They concluded that the particle gradation of waste rock and the spacing of waste-rock columns have significant influences on the dam’s saturation line. Saleh-Mbemba et al. [

8] studied the effect of WRI in tailings dams through physical model tests and found that WRI can accelerate drainage and reduce pore water pressure, thereby affecting the consolidation of tailings. Zhou et al. [

9] investigated the combined discharge method of tailings and waste rock. They demonstrated that the reasonable arrangement of waste rock can shorten the deep seepage path of tailings and reduce the height of the phreatic line, thus improving dam stability. Li et al. [

10] found that adding vertical waste-rock drainage walls in the dam body can effectively control the burial depth of the phreatic line and improve the dam’s drainage capacity.

Jahanbakhshzadeh et al. [

11] have shown that WRI can accelerate the drainage and consolidation of tailings, thereby improving the short-term and long-term safety factors of tailings dams. Bolduc et al. [

12] discovered that WRI can provide horizontal drainage paths, accelerate the dissipation of pore water pressure, and enhance the consolidation performance of tailings. Nguyen N D et al. [

13] analyzed that WRI can increase the consolidation rate of tailings by 3.3 times, and the influence range of tailings consolidation varies with the properties of the tailings.

Based on the relevant literature, the research on the performance and construction technology of waste rock and the synergistic effect between the dam body and waste rock is still limited. Scholars across the globe mainly study the evolution law of the saturation line through numerical simulations of waste-rock inclusions in tailings dams. Only the problem of whether or not there are waste-rock inclusions in the dam is considered. In order to analyze the influence of waste-rock inclusions on the saturation line of a tailings dam, a physical model of a tailings dam with waste-rock inclusion structure is constructed in this paper. GeoStudio numerical simulation software is used to explore the influence of waste-rock inclusion gradation and center spacing on the permeability of the dam body and the distribution of the saturation line through the SEEP/W analysis module, which provides a technical path for maintaining seepage safety control of tailings dams.

2. Physical Model Test of Tailings Dam Construction

2.1. Overview of Tailings Dam Project

This study selects a specific tailings dam in Yunnan Province as its research subject, motivated by two primary considerations. First, the dam is highly representative. Located in the rainy region of Southern China, it faces the prevalent challenge of a consistently high saturation line, making it a valuable case for developing solutions to this common issue. Second, data accessibility was a key factor. Through our collaboration with the mine operator, we acquired comprehensive data, including the geological survey report, construction drawings, and monitoring records, which provided a solid foundation for our numerical modeling and reliability analysis.

The total height of the tailings dam is 64.50 m, mainly composed of an initial dam, an accumulation dam, etc. For the initial dam, the characteristics are as follows: the dam height is 20.50 m, the foundation cleaning depth is 7.50 m, the dam crest width is 4.00 m, and the dam axis length is 162.60 m. The slope ratio of the inner and outer slopes of the dam body is 1:2.0. The initial dam is a permeable accumulation dam, constructed using hard rock debris. For the stacked dam, the characteristics are as follows: the height of the stacked dam is 44.00 m, the total height of the dam is 64.50 m, and the overall slope ratio of the stacked dam is 1:4.0. The total storage capacity is 8.36 million m3, and the effective storage capacity is 7.108 million m3, belonging to the third-class reservoir.

2.2. Similarity Model Material

2.2.1. Tailings Particle Gradation

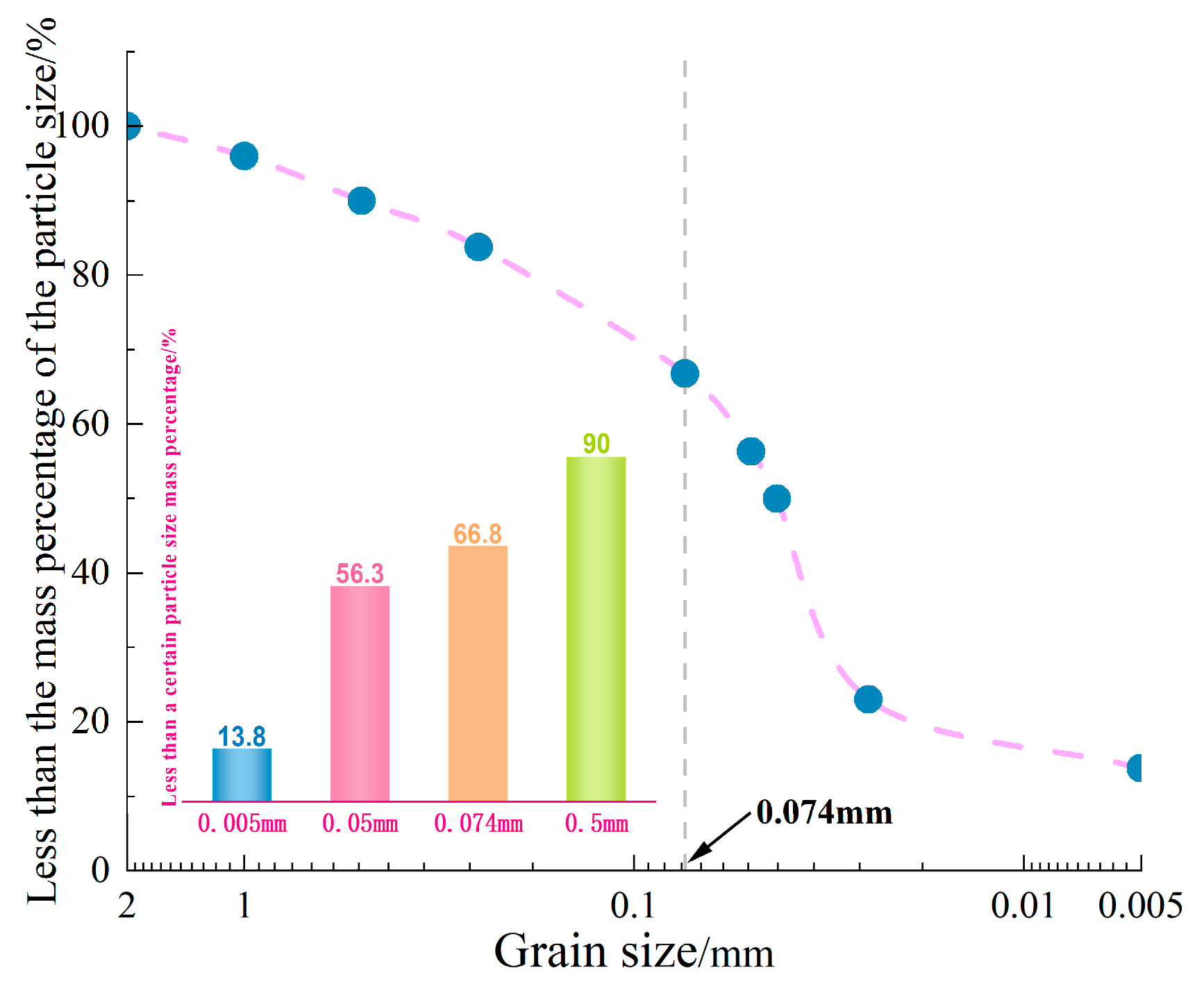

The particle size distribution of tailings has an important influence on the physical and mechanical properties of tailings. The tailings materials of the accumulation dam used in the physical model are four kinds of medium sand, fine sand, silty sand, and silty clay. The model tailings are all taken from the tailings of a tailings reservoir in Yunnan, China. Before the test, the physical and mechanical properties of the accumulated tailings were obtained through geotechnical tests and analysis. The content of tailings particles with particle size less than 0.074 mm in the whole tailings was 66.8%. The natural bulk density of each tailings particle was 1.99 g/cm

3, 2.02 g/cm

3, 2.04 g/cm

3, and 1.89 g/cm

3. The natural void ratios were 0.535, 0.525, 0.676, and 0.929. The plasticity index of the tail silty clay was 14.89. The whole tailings D

10 was 0.005 mm, D

50 was 0.043 mm, the non-uniformity coefficient C

u was 11.2, and the curvature coefficient C

c was 3.66. The grain size grading curve of the whole tailings is shown in

Figure 1.

2.2.2. Waste-Rock Particle Gradation

The value of the permeability coefficient greatly affects the burial depth (buried depth refers to the distance from the dam crest to the saturation line) of the saturation line of the tailings dam. In the test, the optimal particle gradation of waste rock is determined by the content of fine particles and coarse particles. In engineering practice, particles with a particle size less than 5 mm are usually defined as fine particles. The sieve analysis method and permeability test stipulated in the “standard of geotechnical test method” are adopted. Firstly, the waste rock is classified according to particle size, and then three gradation samples of A, B, and C are artificially prepared according to the proportion of different particle size ranges. Finally, the penetration test was performed with a constant head penetration test device. The gradation of waste rock A was as follows: D

10 was 0.089 mm, D

50 was 8.47 mm, the coefficient of uniformity C

u was 129.55, and the curvature coefficient C

c was 3.90. The gradation of waste rock B was as follows: D

10 was 0.25 mm, D

50 was 11.49 mm, the coefficient of uniformity C

u was 60.64, and the curvature coefficient C

c was 8.84. The gradation of waste rock C was as follows: D

10 was 0.083 mm, D

50 was 10.55 mm, the coefficient of uniformity C

u was 165.9, and the curvature coefficient C

c was 28.1. The relevant parameters are shown in

Table 1.

2.3. Model Testing Device

2.3.1. Determination of Model Similarity Parameters

According to the engineering survey data of the tailings pond, combined with the indoor test conditions, the geometric scale of the physical model is determined to be 1:300 [

14]. According to the similarity theory [

15,

16], the similarity scale of the physical model was set, as shown in

Table 2. According to the engineering data of a tailings dam in Yunnan, combined with the principle of similar scale, the total size of the physical model was determined to be 2000 mm long and 900 mm wide. In the model, the design height of the initial dam was 70 mm, the total height of the whole dam was 215 mm, and the length of the dam was 1670 mm.

2.3.2. Model Building

The high position of the saturation line affects the stability of the tailings dam [

17]. When the saturation line dropped by 1 m, the stability coefficient of the tailings reservoir increased by more than 0.05 [

18]. Therefore, in testing the physical model of the tailings dam, when the waste rock and tailings were stacked together, the layered stacking method was adopted, and the stacking started from the bottom of the reservoir area, and the height increased synchronously with the increase in the dam body. When the tailings deposit filled the waste-rock inclusions, a new layer of waste rock was piled on the top of the existing waste-rock inclusions to heighten the entire waste-rock inclusions system. This process was repeated until the final dam height was reached, resulting in the formation of an internal supporting structure composed of waste rock. According to the environmental protection and anti-seepage design of “tailings pond facilities design specification”, clay was used to carry out anti-seepage treatment of the tailings reservoir before tailings dam construction. As shown in

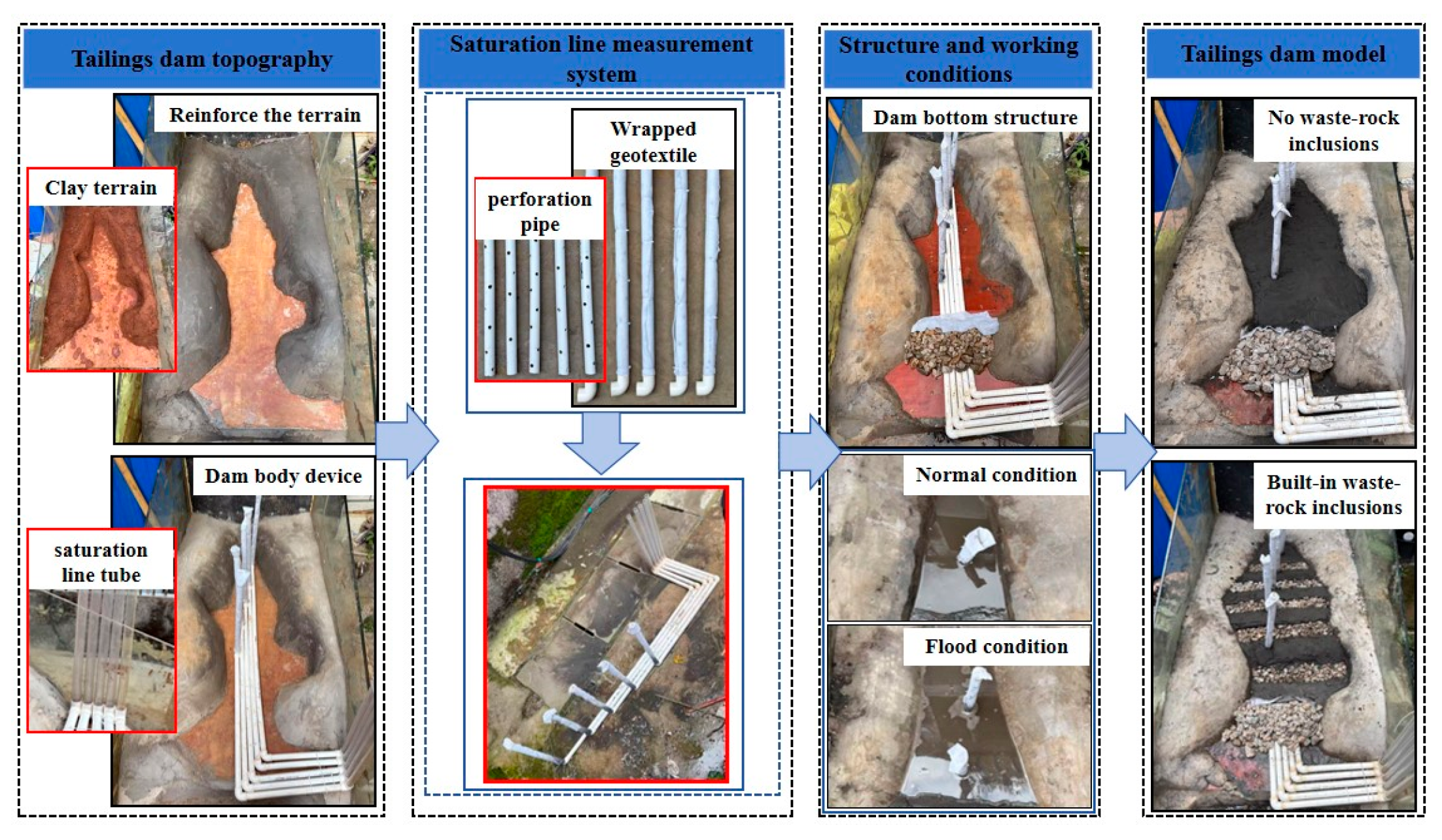

Figure 2, the influence of waste-rock inclusions on the buried depth of the saturation line was studied.

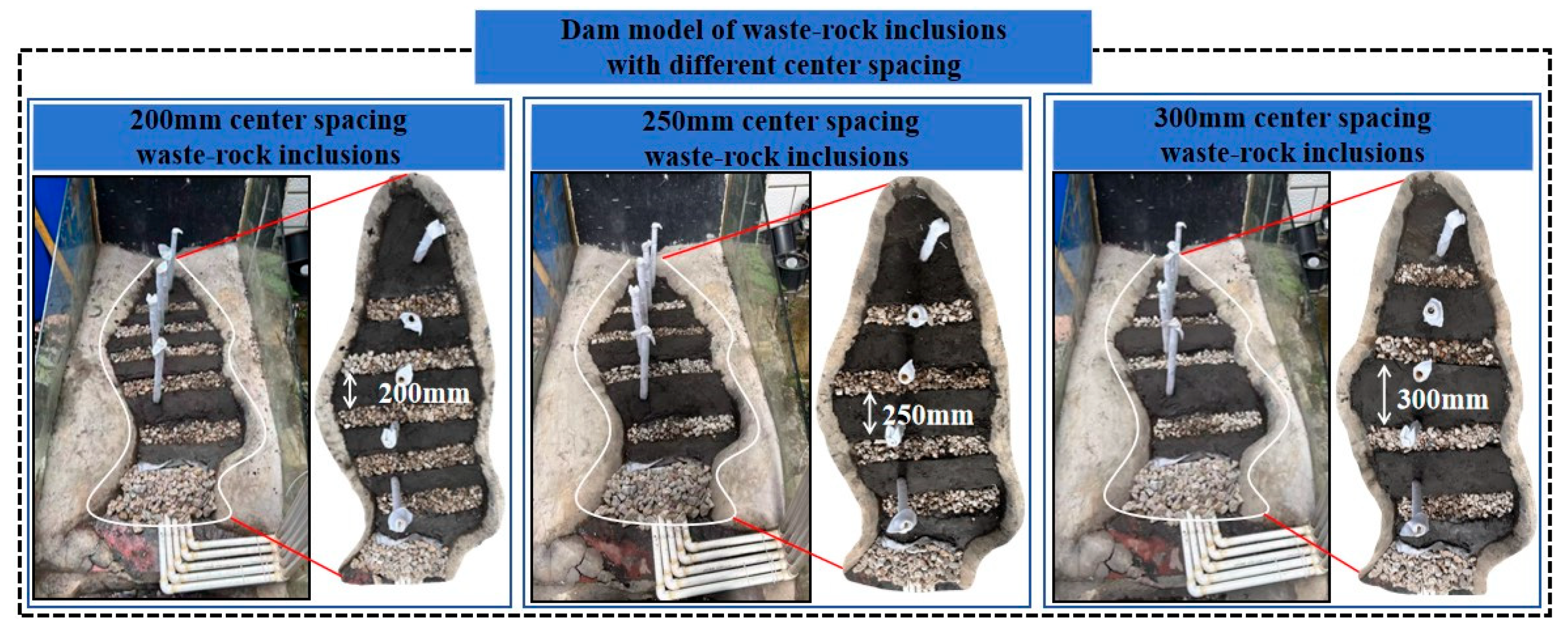

The test used a model with a geometric similarity scale of 1:300. The model test device was mainly composed of the test tank, saturation line measurement system, and drainage system. In order to clearly observe the buried depth of the saturation line, a vertical transparent saturation line measuring tube is arranged at the edge of the test tank. The immersion line measurement system was composed of a vertical perforated PVC tube in the test tank, extended to a transparent tube connection at the edge of the tank. The circumferential equidistant drilling of the pipe wall was measured, and the geotextile was wrapped to effectively block the tailings particles from entering the pipe, resulting in the blockage of the water flow channel and the distortion of the test results. The two sides of the inner edge of the test tank were piled with soil. There were a total of five transparent tubes used as saturation line tubes. During the test, the measured data were read according to the arrangement order of the saturation line measuring tube, and the points were connected with a smooth line. The obtained curve was approximately regarded as the saturation line of the dam body. The drainage system referred to a system that relied solely on the initial dam in front of the dam for drainage when there was no waste-rock inclusion. After the waste-rock inclusion was built in, the waste-rock inclusion and the initial dam in front of the dam formed an integrated drainage system for the dam body.

In the seepage model test of the tailings dam, the dam body was first adjusted to reach a stable seepage state, and the saturation line and seepage flow data were recorded. Then, the water level of the model reservoir was raised to 52 cm to simulate and study the seepage morphology and stability of the dam under extreme floods.

4. GeoStudio Introduction and Numerical Simulation Analysis

4.1. Introduction of GeoStudio

The SEEP/W module in GeoStudio software was used to simulate and analyze the seepage conditions under various engineering conditions, and supported the solution of the basic problems of saturated and unsaturated seepage under steady and transient conditions. In this experiment, the SEEP/W module in GeoStudio software was used to simulate the saturation line of steady seepage.

4.2. Model Establishment

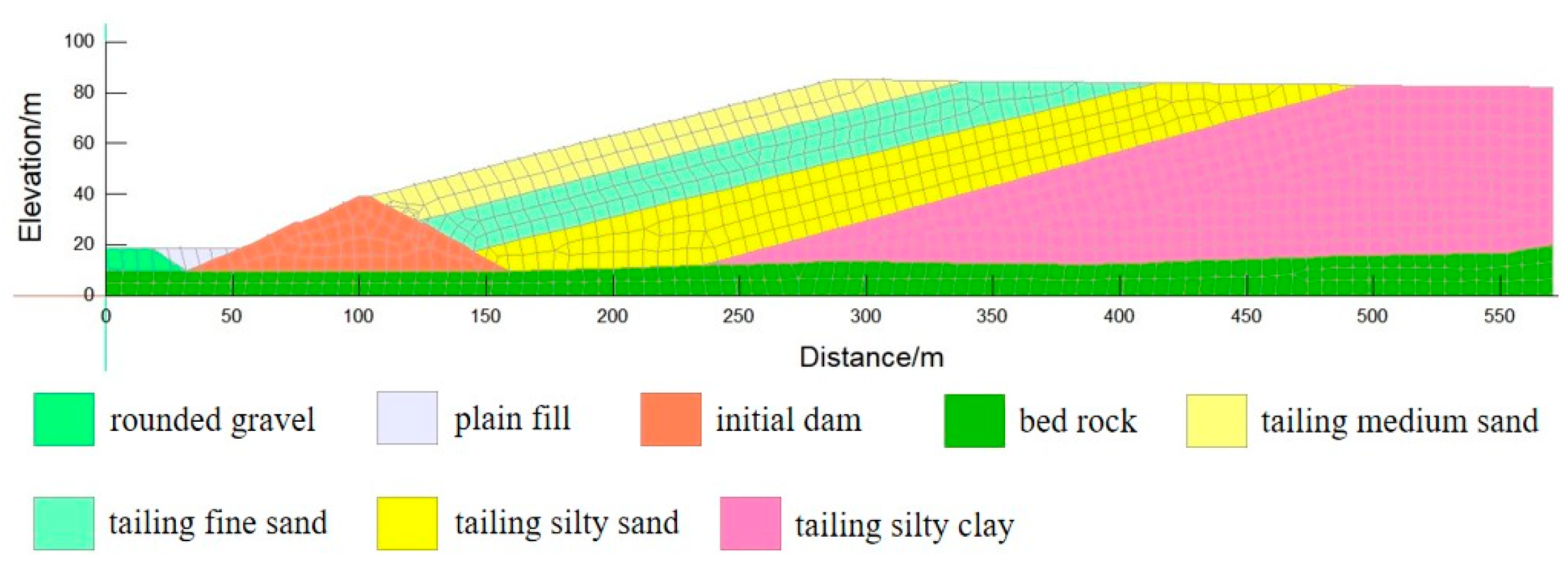

Based on the exploration data and field test, the generalized analysis was carried out. On this basis, a layered numerical model partition was established for the tailings reservoir. According to the indoor physical model test results and the field tailings reservoir exploration data, the tailings dam profile was generated. The partition materials were eight kinds of tailing medium sand, tailing fine sand, tailing silty sand and tailing silty clay, plain fill, initial dam, rounded gravel, and bedrock. The established two-dimensional model is shown in

Figure 7. Based on the center spacing of the waste-rock inclusions selected by the physical model test, the tailings dam models with center spacings of 60 m, 75 m, and 90 m were simulated, after amplification according to a similar scale.

In this study, given that the analysis focused on steady-state seepage, the Soil–Water Characteristic Curve (SWCC) was not considered. Accordingly, the numerical model employed a saturated permeability model for the materials. For the steady-state analysis conducted herein, the convergence tolerance was set with a significant figure of 3 and a head difference of 1 × 10−3 m. The maximum number of iterations for the computation was set to 200. The model boundary conditions were as follows: the bottom of the model and the right side of the bedrock were impermeable boundaries, the rear and right sides of the dry beach on the dam crest were constant head boundaries, the top of the accumulation dam (and initial dam) was a potential infiltration surface, and the total flow Q was zero. The drainage ditch located at the foot of the dam downstream of the initial dam was set to zero pressure head. The upstream dry length of the tailings dam was 208.5 m from the top of the accumulation dam.

In the seepage simulation of the tailings dam, the physical and mechanical parameters of each material of the dam were key to the analysis; they played a decisive role in the accuracy and reliability of the simulation results. According to the survey report and indoor geotechnical test, the index parameters of each partition material in the model were calculated and are shown in

Table 5.

4.3. Simulation Results and Analysis

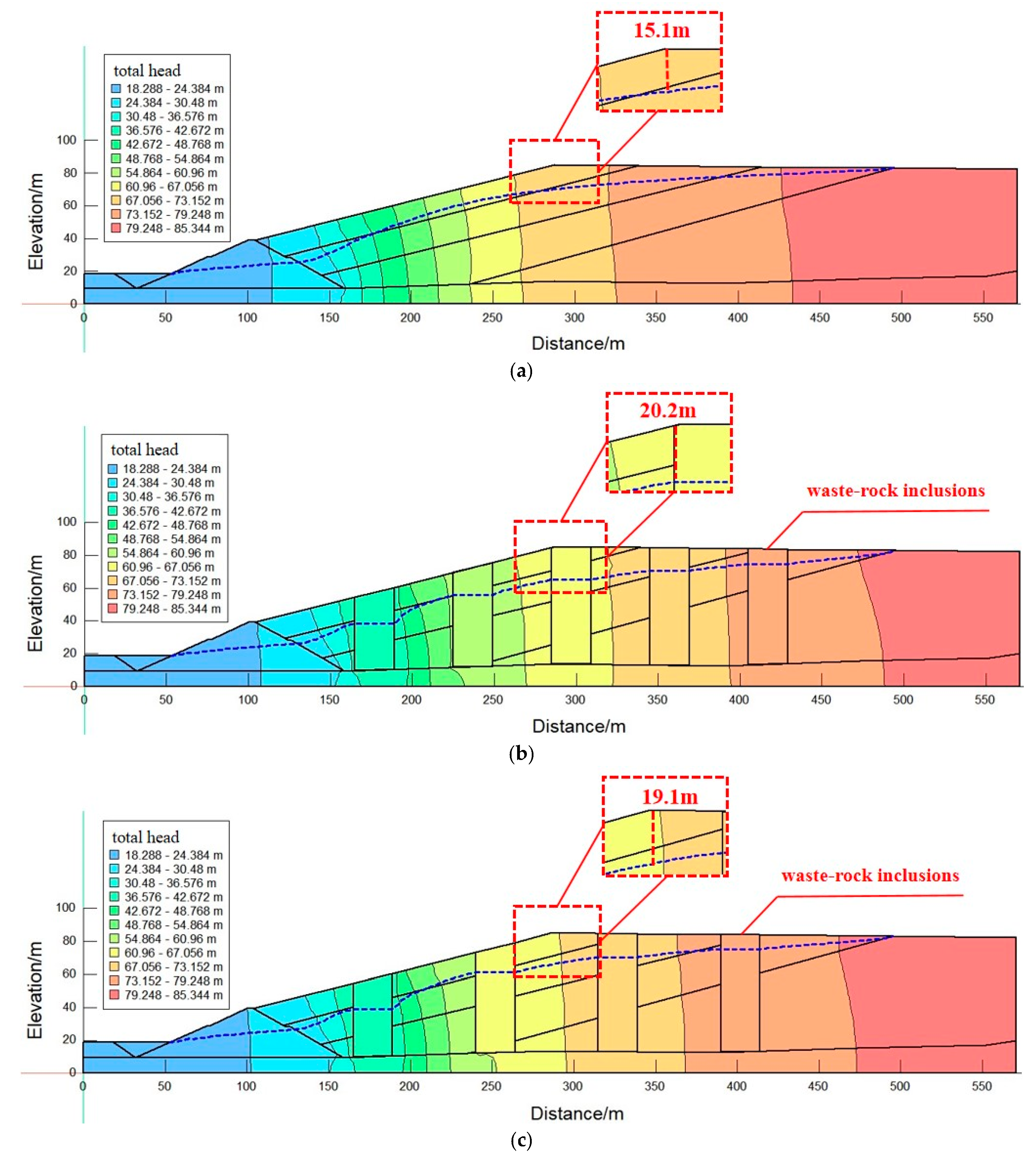

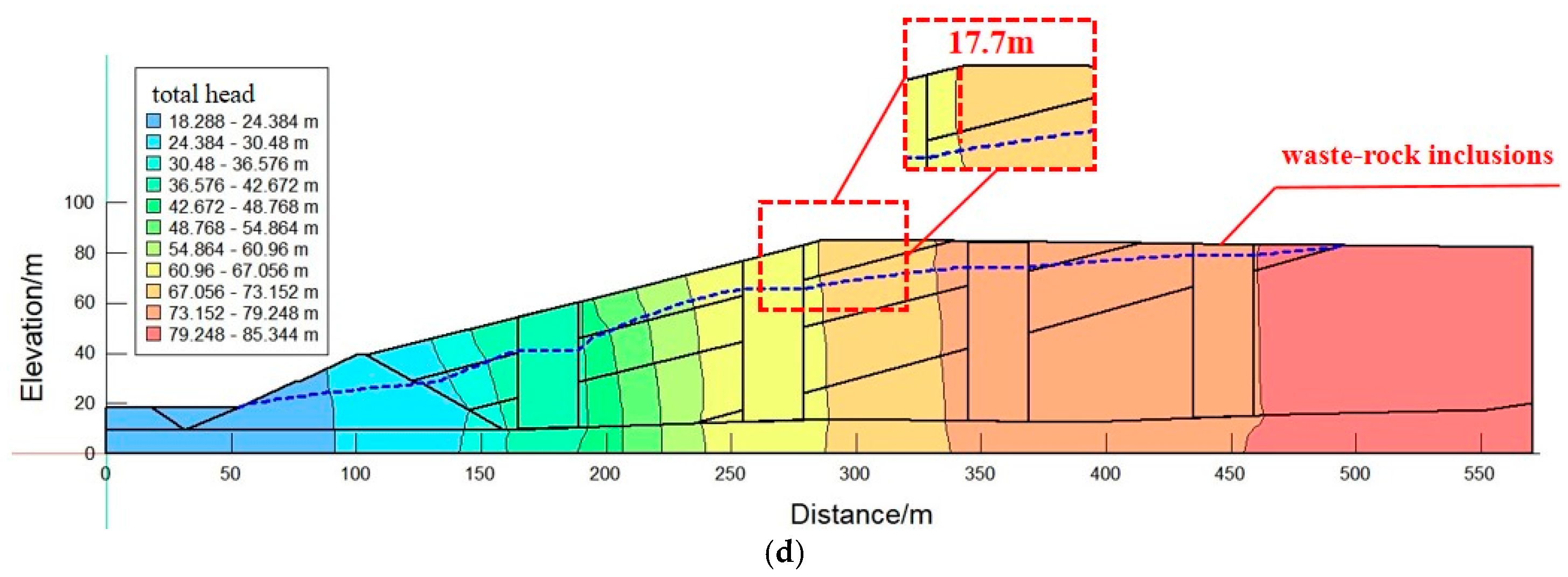

According to the physical model test, the distribution of the saturation line of the dam body under normal and flood conditions was similar. In the numerical simulation process, the SEEP/W module of GeoStudio software was used to analyze the seepage characteristics of the dam body under normal conditions, and the following results were obtained, as shown in

Figure 8. The width of the waste-rock inclusion was 24 m. The contour line of pore water pressure = 0 kPa was the saturation line.

The simulation results showed that the saturation line of the dam body without waste-rock inclusions was relatively high, and the saturation line of the dam body decreased under the waste-rock inclusions with different center spacing. Intuitively, it can be seen that the saturation line of the waste-rock inclusions was below the saturation line of the dam without waste-rock inclusions. With the change in the center spacing, the saturation line changed obviously, and there was an obvious sudden drop near the waste-rock inclusions. This phenomenon was mainly due to the addition of a waste-rock embankment structure in the dam body. Because the waste-rock medium had large pores and a high permeability coefficient, the seepage rate of the area was significantly higher than that of the adjacent tailings layer when the seepage fluid flowed through the waste-rock area. Under the action of the dominant seepage channel formed by such coarse-grained materials, the water body mainly migrated to the dam foundation along the construction path of waste rock. In the tailings dam with waste-rock inclusions, the distribution of the saturation line showed obvious regional differences. In the area of waste-rock accumulation, the saturation line approximately maintained a horizontal trend, and after entering the tailings accumulation area, the saturation line decreased, forming a fluctuating form as a whole. This phenomenon was mainly due to the significant difference in permeability between waste rock and tailings. Due to the high permeability coefficient of the waste rock, the seepage velocity of water in it was faster. In contrast, the permeability coefficient of tailings was lower, resulting in a relatively slow water flow. In addition, the existence of the waste-rock inclusions effectively improves the seepage condition of the dam body, not only accelerating the process of seepage reaching a stable state, but also significantly reducing the stable height of the saturation line by enhancing the drainage capacity of the dam body, thereby improving the seepage stability of the tailings dam.

According to the data shown in

Figure 8, when there were no waste-rock inclusions, the maximum burial depth of the saturation line of the tailings dam from the top of the accumulation dam was 15.1 m. After adding the waste-rock inclusions, and the center spacing of the waste-rock inclusions was 90 m, the maximum burial depth of the saturation line was 17.7 m. When the center spacing of the waste-rock inclusions was 75 m, the maximum burial depth of the saturation line was 19.1 m. When the center spacing of the waste-rock inclusions was 60 m, the maximum burial depth of the saturation line was 20.2 m. The buried depth increased by 2.6~5.1 m compared with that of the model without waste-rock inclusions. The test results showed that the central spacing affected the burial depth of the saturation line of the tailings dam; that is, the smaller the spacing, the deeper the burial depth of the saturation line from the top of the accumulation dam.

5. Comparative Analysis of Numerical Simulation and Model Test Results

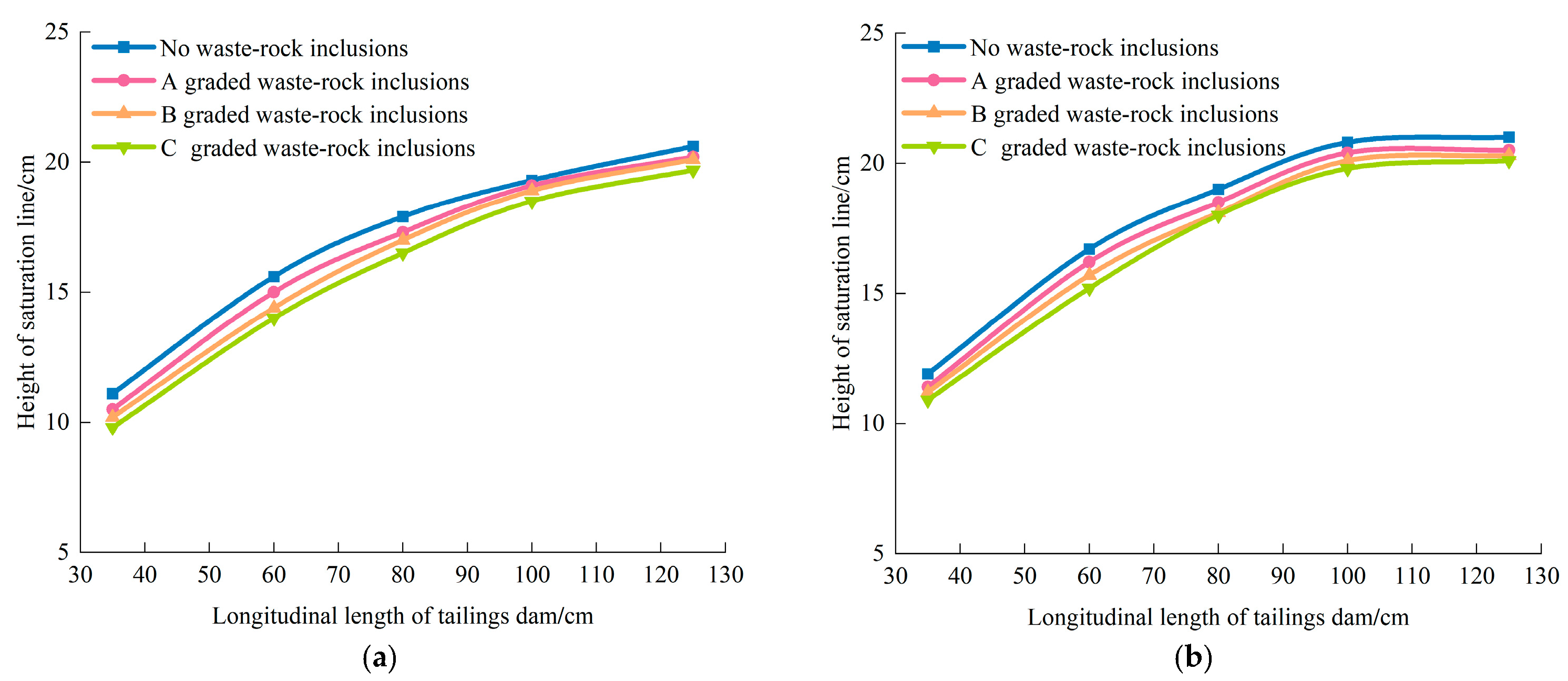

According to the model test results, the overall trend of the saturation line of the two was close to that of the numerical simulation results after amplification according to a similar scale, as shown in

Figure 9. The setting of the tailings dam drainage system had a significant effect on the buried depth of the saturation line. When the dam body was not set with waste-rock inclusions, due to the lack of effective drainage channels, it was difficult for the seepage water to be discharged smoothly through the tailings layer with weak permeability, resulting in the uplift of the saturation line in the dam body. After setting up the waste-rock inclusions, there was a significant difference in permeability between the waste-rock material and the tailings, and the permeability of the waste rock was significantly stronger than that of the tailings. This permeability advantage formed an efficient drainage channel, which made the seepage preferentially migrate and quickly discharge in the waste-rock inclusions, and promoted the effective reduction in the dam saturation line. Through comparative analysis, it was found that the indoor physical model test results were in good agreement with the saturation line obtained by numerical simulation in terms of morphological characteristics and spatial distribution. This correspondence fully proves that the numerical simulation technology can be effectively applied to the analysis of the seepage field, and its calculation model has engineering credibility for the characterization of dam seepage characteristics, which proves that the calculation model can effectively reflect the actual working condition characteristics of tailings dam seepage.