Flexible Wireless Vibration Sensing for Table Grape in Cold Chain

Abstract

1. Introduction

2. Materials and Methods

2.1. Overall Design

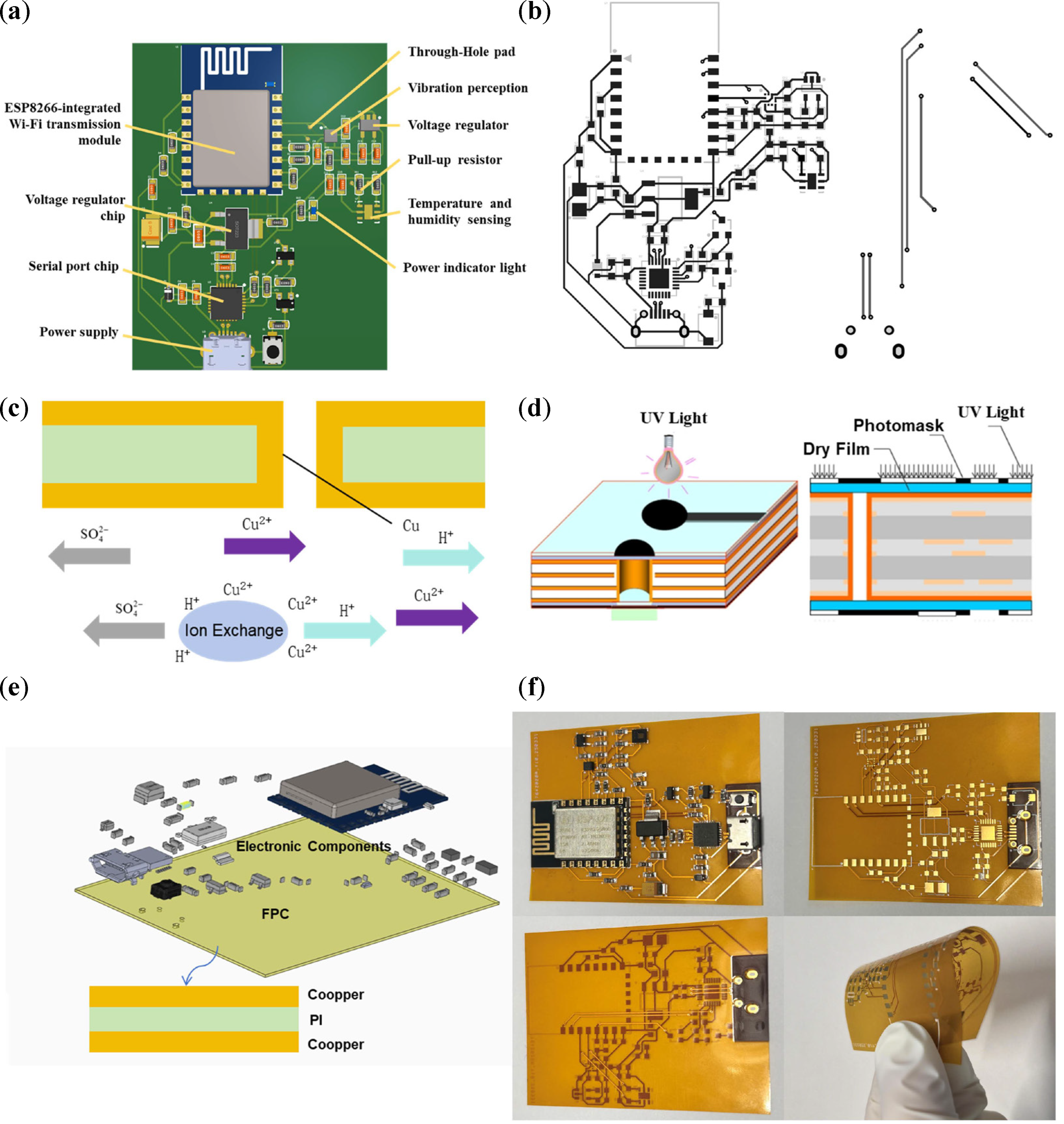

2.2. Flexible Wireless Vibration Sensing Preparation

2.3. Experimental Scheme

- (1)

- Cold-chain quality data acquisition

- (a)

- Measurement of Berry Drop Rate

- (b)

- Measurement of Flesh Firmness

- (c)

- Measurement of Pedicle Pull Force

- (d)

- Measurement of Skin Firmness

- (2)

- Correlation model between vibration data and cold-chain quality damage

- (3)

- Cold-chain quality monitoring model

- (4)

- Flexible wireless vibration sensing performance

3. Results and Discussion

3.1. Cold-Chain Quality Data Analysis

3.2. Correlation Analysis Between Vibration Data and Cold-Chain Quality Damage

3.3. Cold-Chain Quality Monitoring Model Evaluation

3.4. Flexible Wireless Vibration Sensing Performance Evaluation

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Correction Statement

References

- Yang, C.; Fan, X.; Lao, F.; Huang, J.; Giusti, M.M.; Wu, J.; Lu, H. A Comparative Study of Physicochemical, Aroma, and Color Profiles Affecting the Sensory Properties of Grape Juice from Four Chinese Vitis vinifera× Vitis labrusca and Vitis vinifera Grapes. Foods 2024, 13, 3889. [Google Scholar] [CrossRef] [PubMed]

- Zhao, X.; Zhu, A.L.; Liu, X.; Li, H.; Tao, H.; Guo, X.; Liu, J. Current status, challenges, and opportunities for sustainable crop production in Xinjiang. iScience 2025, 28, 112114. [Google Scholar] [CrossRef] [PubMed]

- Xing, J.L.; Song, Y.L.; Li, Y.G.; Yang, L.; Duan, K.Y.; Zuo, D.D.; Zhang, J.; Liu, H.; Wei, T.; Pei, M.; et al. Metabolomic profiling unveils biochemical dynamics in spontaneously fermented grape leaf by-products: Towards sustainable agricultural waste valorization. Food Biosci. 2025, 71, 107237. [Google Scholar] [CrossRef]

- De Simone, N.; Pace, B.; Grieco, F.; Chimienti, M.; Tyibilika, V.; Santoro, V.; Capozzi, V.; Colelli, G.; Spano, G.; Russo, P.; et al. Botrytis cinerea and table grapes: A review of the main physical, chemical, and bio-based control treatments in post-harvest. Foods 2020, 9, 1138. [Google Scholar] [CrossRef]

- Câmpean, Ș.I.; Beșchea, G.A.; Tăbăcaru, M.B.; Scutaru, L.M.; Dragomir, G.; Brezeanu, A.I.; Șerban, A.; Năstase, G. Preservation of black grapes by isochoric freezing. Heliyon 2023, 9, 1138. [Google Scholar] [CrossRef]

- Tao, S.; Wang, J.; Xie, J. Influence of different pre-cooling methods on the postharvest storage of ‘Kyoho’grapes (Vitis labrusca× vinifera ‘Kyoho’). Food Qual. Saf. 2024, 8, fyae033. [Google Scholar] [CrossRef]

- Gong, D.; Yang, F.; Han, Y.; Jiang, Y.; Sun, J.; Zhao, R.; Tan, L. Development of Vitamin C/polyurethane composite films for efficient preservation of grapes with controllable respiration. LWT 2023, 184, 115086. [Google Scholar] [CrossRef]

- Liu, F.; Huang, W.; Fan, Y.; He, W.; Tao, Y.; Wang, C. Effects of dehydration speed on the metabolism of membrane lipids and its relation to the browning of the Thompson seedless grape. Food Qual. Saf. 2022, 6, fyac025. [Google Scholar] [CrossRef]

- An, Y.; Lu, W.; Li, W.; Pan, L.; Lu, M.; Cesarino, I.; Li, Z.; Zeng, W. Dietary fiber in plant cell walls—The healthy carbohydrates. Food Qual. Saf. 2022, 6, fyab037. [Google Scholar] [CrossRef]

- Ambaw, A.; Fadiji, T.; Opara, U.L. Thermo-mechanical analysis in the fresh fruit cold chain: A review on recent advances. Foods 2021, 10, 1357. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, M.; Law, C.L.; Ma, Y. Effect of vibration and broken cold chain on the evolution of cell wall polysaccharides during fruit cucumber (Cucumis sativus L.) shriveling under simulated transportation. Food Packag. Shelf Life 2023, 38, 101126. [Google Scholar] [CrossRef]

- Xu, B.; Liu, J.; Jin, Y.; Yang, K.; Zhao, S.; Peng, Y. Vibration–Collision Coupling Modeling in Grape Clusters for Non-Damage Harvesting Operations. Agriculture 2025, 15, 154. [Google Scholar] [CrossRef]

- Yan, D.; Luo, L.; Zhang, P.; Liu, W.; Wang, J.; Lu, Q.; Luo, S. Vibration analysis and experimental study of the effects of mechanised grape picking on the fruit–stem system. Biosyst. Eng. 2023, 227, 82–94. [Google Scholar] [CrossRef]

- Yin, M.; Huo, L.; Li, N.; Zhu, H.; Zhu, Z.; Hu, J. Packaging performance evaluation and freshness intelligent prediction modeling in grape transportation. Food Control. 2024, 165, 110684. [Google Scholar] [CrossRef]

- Idaszewska, N.; Szymański, G.M.; Bieńczak, K. Effect of vibration stress on selected chemical parameters of “bluecrop” highbush blueberry (Vaccinium corymbosum L.) and Grape (Vitis vinifera L.). Sustainability 2024, 16, 715. [Google Scholar] [CrossRef]

- Chen, Q.; Li, J.; Feng, J.; Qian, J. Dynamic comprehensive quality assessment of post-harvest grape in different transportation chains using SAHP–CatBoost machine learning. Food Qual. Saf. 2024, 8, fyae007. [Google Scholar] [CrossRef]

- Wang, X.; Xia, J.; Zou, J.; Huang, W.; Matetic, M.; Bakarić, M.B.; Zhang, X. Pathways toward precise monitoring and low-carbon sustainability in fruit cold chain logistics: A solution enabled by flexible temperature sensing. Mater. Today Sustain. 2023, 24, 100592. [Google Scholar] [CrossRef]

- Jianying, F.; Bianyu, Y.; Xin, L.; Dong, T.; Weisong, M. Evaluation on risks of sustainable supply chain based on optimized BP neural networks in the fresh grape industry. Comput. Electron. Agric. 2021, 183, 105988. [Google Scholar] [CrossRef]

- Wang, M.; Luo, D.; Liu, M.; Zhang, R.; Wu, Z.; Xiao, X. Flexible wearable optical wireless sensing system for fruit monitoring. J. Sci. Adv. Mater. Devices 2023, 8, 100555. [Google Scholar] [CrossRef]

- Wang, M.; Zhang, R.; Wu, Z.; Xiao, X. Flexible wireless in situ optical sensing system for banana ripening monitoring. J. Food Process Eng. 2023, 46, e14474. [Google Scholar] [CrossRef]

- Xiao, X.; Mu, B.; Cao, G.; Yang, Y.; Wang, M. Flexible battery-free wireless electronic system for food monitoring. J. Sci. Adv. Mater. Devices 2022, 7, 100430. [Google Scholar] [CrossRef]

- Zhang, R.; Wang, M.; Zhu, T.; Wan, Z.; Chen, X.; Xiao, X. Wireless charging flexible in-situ optical sensing for food monitoring. Chem. Eng. J. 2024, 488, 150808. [Google Scholar] [CrossRef]

- Song, D.; Chen, X.; Wang, M.; Wu, Z.; Xiao, X. 3D-printed flexible sensors for food monitoring. Chem. Eng. J. 2023, 474, 146011. [Google Scholar] [CrossRef]

- Bai, L.; Liu, M.; Sun, Y. Overview of food preservation and traceability technology in the smart cold chain system. Foods 2023, 12, 2881. [Google Scholar] [CrossRef]

- Centobelli, P.; Cerchione, R.; Ertz, M. Food cold chain management: What we know and what we deserve. Supply Chain Manag. Int. J. 2021, 26, 102–135. [Google Scholar]

- Mishra, A.; Alzoubi, Y.I.; Gill, A.Q.; Anwar, M.J. Cybersecurity enterprises policies: A comparative study. Sensors 2022, 22, 538. [Google Scholar] [CrossRef]

- Wang, M.; Wang, B.; Zhang, R.; Wu, Z.; Xiao, X. Flexible Vis/NIR wireless sensing system for banana monitoring. Food Qual. Saf. 2023, 7, fyad025. [Google Scholar] [CrossRef]

- Chen, Q.; Qian, J.; Yang, H.; Wu, W. Sustainable food cold chain logistics: From microenvironmental monitoring to global impact. Compr. Rev. Food Sci. Food Saf. 2022, 21, 4189–4209. [Google Scholar] [CrossRef] [PubMed]

| Parameter | Sample Size | Preprocessing Method | R2 | RMSEC | RPD |

|---|---|---|---|---|---|

| Berry-drop rate | 240 | Z-score standardization | 0.8997 | 0.0047 | 3.1917 |

| Pulp firmness | 0.8767 | 68.4084 | 2.7692 | ||

| Peel hardness | 0.8894 | 25.2233 | 2.8963 | ||

| Peduncle tensile force | 0.9155 | 0.4612 | 3.4764 |

| Parameter | Sample Size | Preprocessing Method | MLR | PLSR | BPNN |

|---|---|---|---|---|---|

| Berry-drop rate | 240 | Z-score Standardization | 0.8997 | 0.8069 | −1.0909 |

| Pulp firmness | 0.8767 | 0.7541 | −0.4698 | ||

| Peel hardness | 0.8894 | 0.8219 | −2.2659 | ||

| Peduncle tensile force | 0.9155 | 0.7683 | −0.3131 |

| Evaluation items | Evaluation Metric | Comparison | |

|---|---|---|---|

| Traditional Monitoring System | Flexible Wireless Vibration Sensing | ||

| Data acquisition | Acceleration data acquisition accuracy | ±(0.1% ~ 5%) | ±2 g: ~0.0005 g/LSB ±4 g: ~0.001 g/LSB |

| Temperature & humidity data acquisition accuracy | Temperature: ±(1~3) °C Relative humidity: ±(3~10)% | Temperature: ±0.2 °C Relative humidity: ±2% | |

| Data processing | Data processing speed | Data points per second: tens to thousands (1 byte each) | Up to 150 Mbps |

| Data processing accuracy | 90% ~ 99% | >99% | |

| Communication | Signal loss rate | 1% ~ 10% | 1% |

| Communication range | 10 m~5 km | 70 m (open field) | |

| System stability | Long-term operation stability | Depends on system type, application scenario, Technology level, and maintenance | Stable |

| Stability under varying working conditions | Adapts well to diverse operating conditions | ||

| System usability | User interface friendliness | Subject to multiple factors, including design philosophy and technical level | Cloud dashboard clear; full-featured |

| Ease of the system configuration | Code updates are easy; the platform functions complete | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Z.; Wang, Y.; Ma, L.; Chen, X.; Zhang, R.; Xiao, X. Flexible Wireless Vibration Sensing for Table Grape in Cold Chain. Eng 2025, 6, 236. https://doi.org/10.3390/eng6090236

Yang Z, Wang Y, Ma L, Chen X, Zhang R, Xiao X. Flexible Wireless Vibration Sensing for Table Grape in Cold Chain. Eng. 2025; 6(9):236. https://doi.org/10.3390/eng6090236

Chicago/Turabian StyleYang, Zhencan, Yun Wang, Longgang Ma, Xujun Chen, Ruihua Zhang, and Xinqing Xiao. 2025. "Flexible Wireless Vibration Sensing for Table Grape in Cold Chain" Eng 6, no. 9: 236. https://doi.org/10.3390/eng6090236

APA StyleYang, Z., Wang, Y., Ma, L., Chen, X., Zhang, R., & Xiao, X. (2025). Flexible Wireless Vibration Sensing for Table Grape in Cold Chain. Eng, 6(9), 236. https://doi.org/10.3390/eng6090236