Mechanisms of Overburden and Surface Damage Conduction in Shallow Multi-Seam Mining

Abstract

1. Introduction

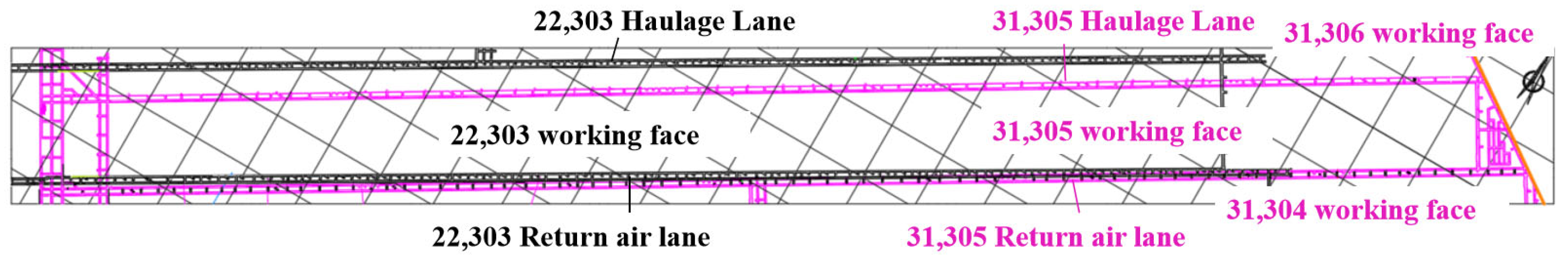

2. Overview of the Coal Mine

3. Similarity Simulation Test of Shallow Buried Multi Seam Mining

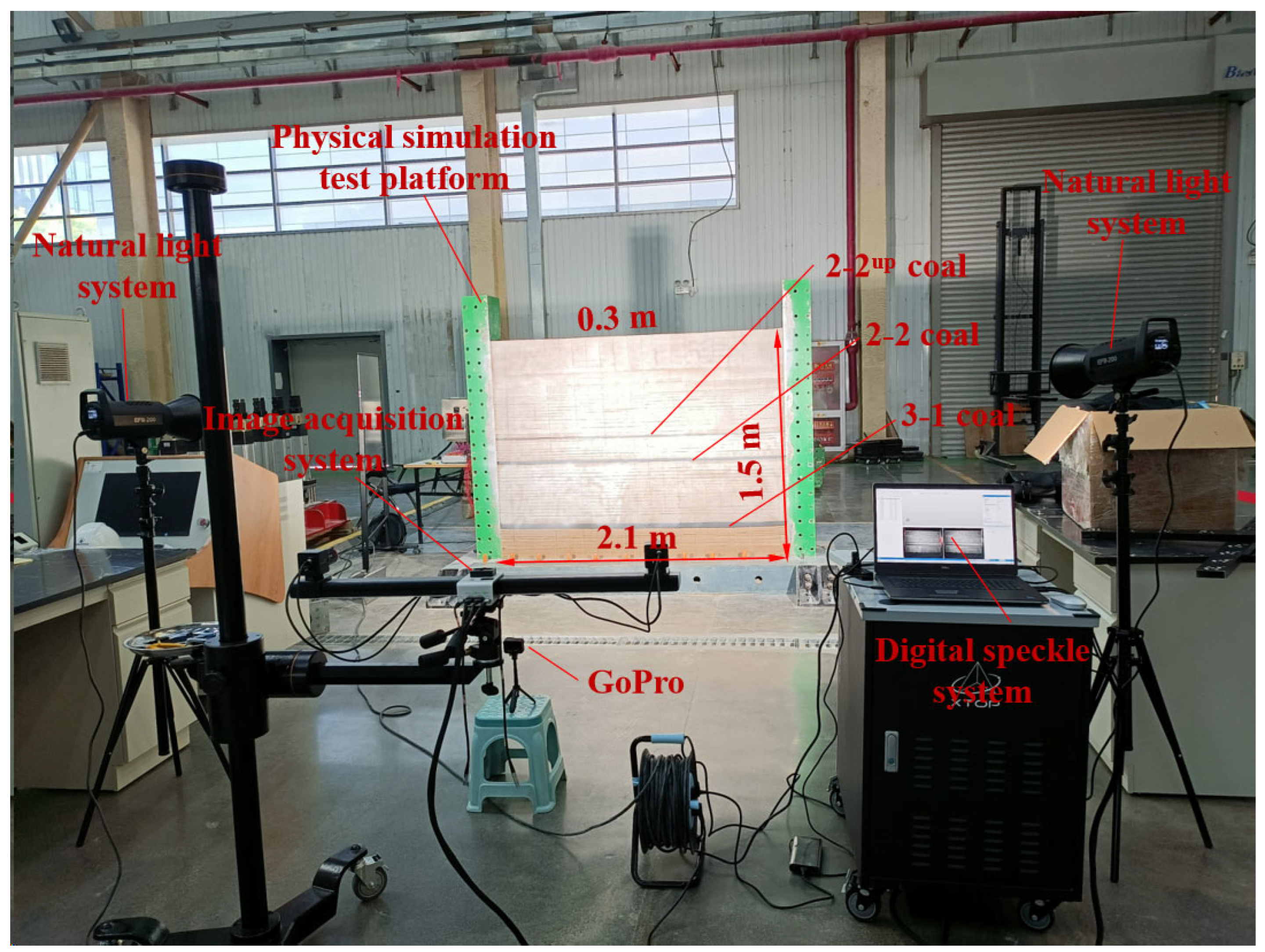

3.1. Design of Similarity Simulation Test

3.1.1. Similarity Simulation Test System

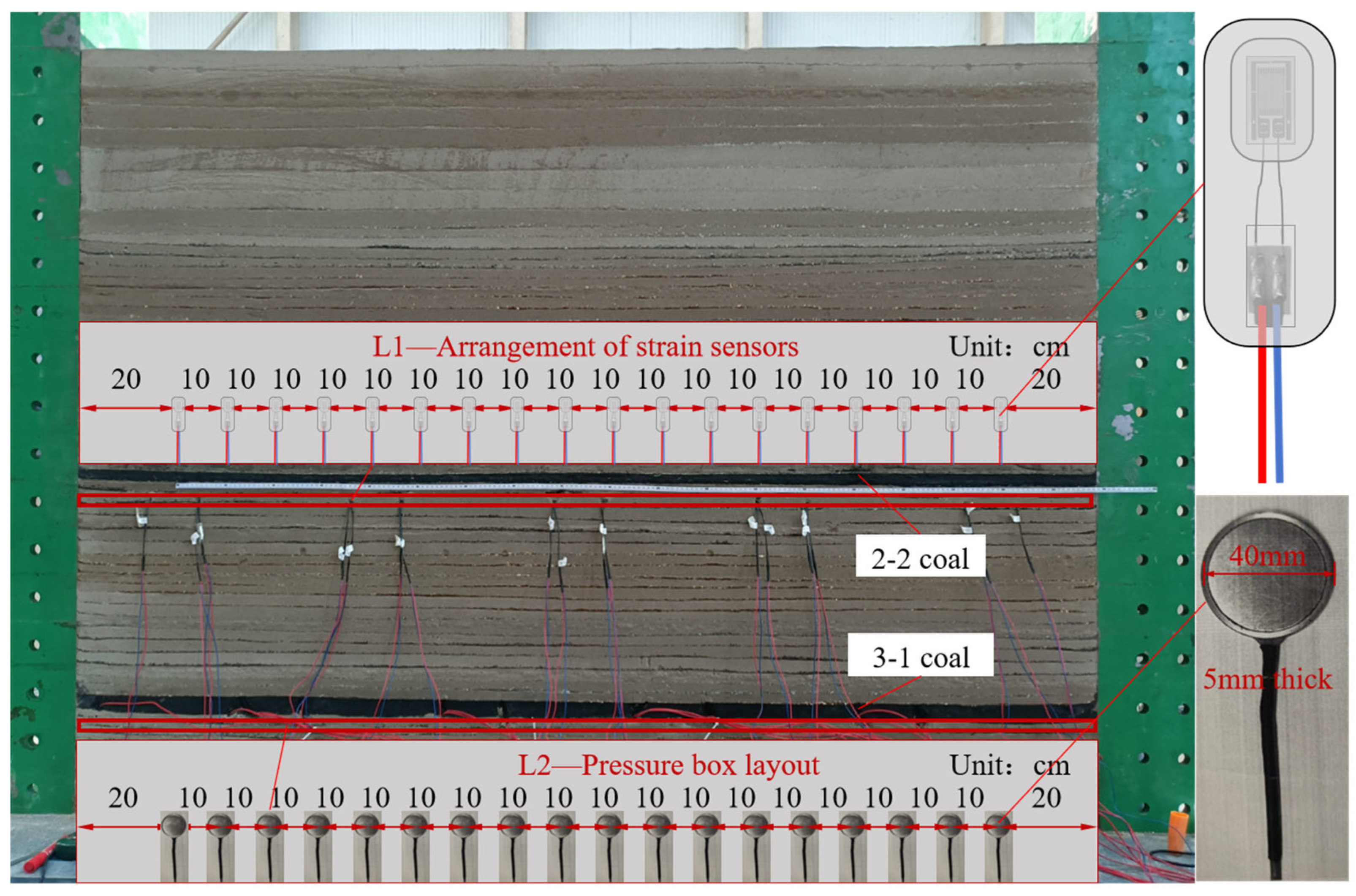

3.1.2. Sensor Arrangement

3.1.3. Experimental Proportioning and Mining Scheme

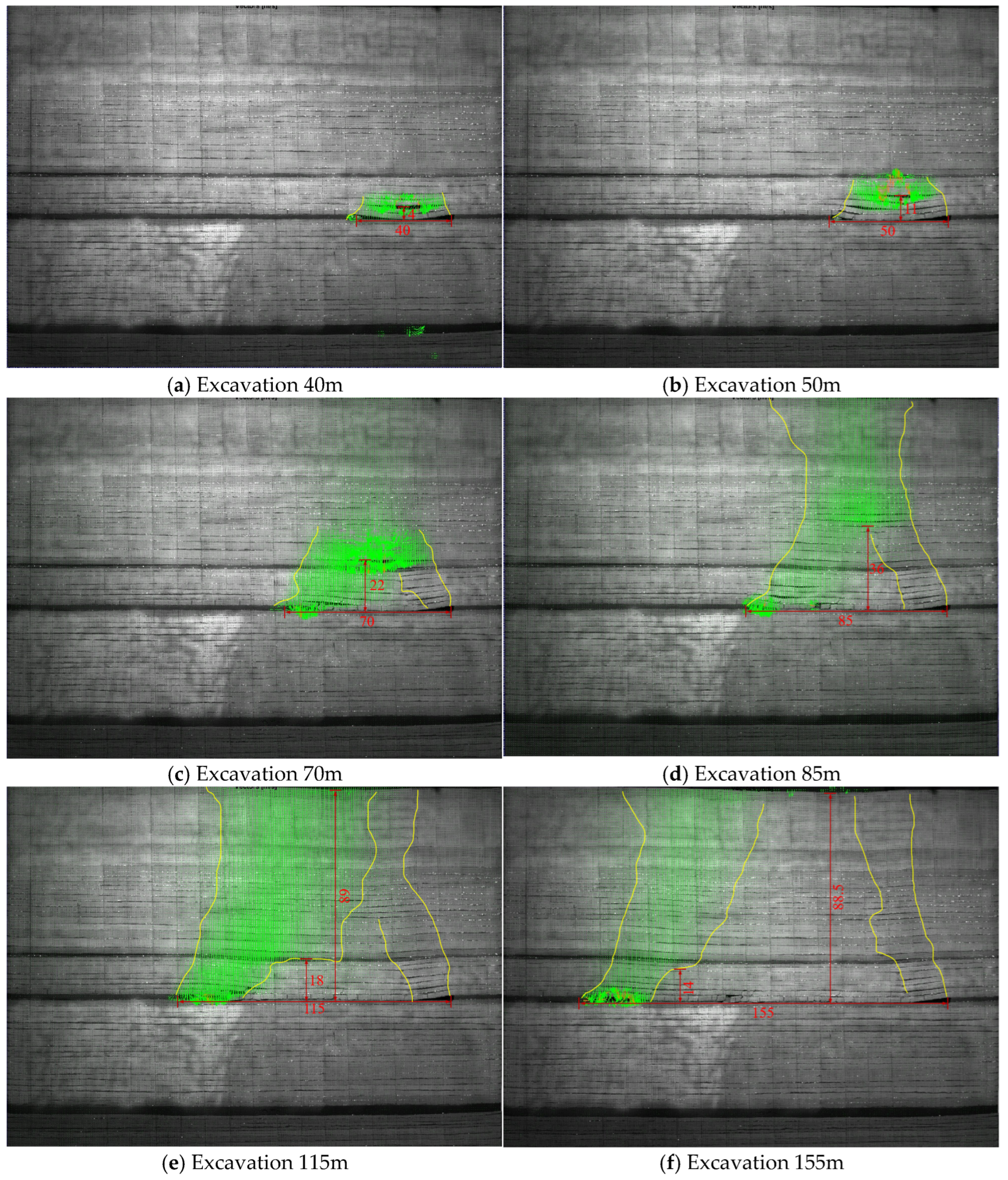

3.2. Strata Collapse Characteristics

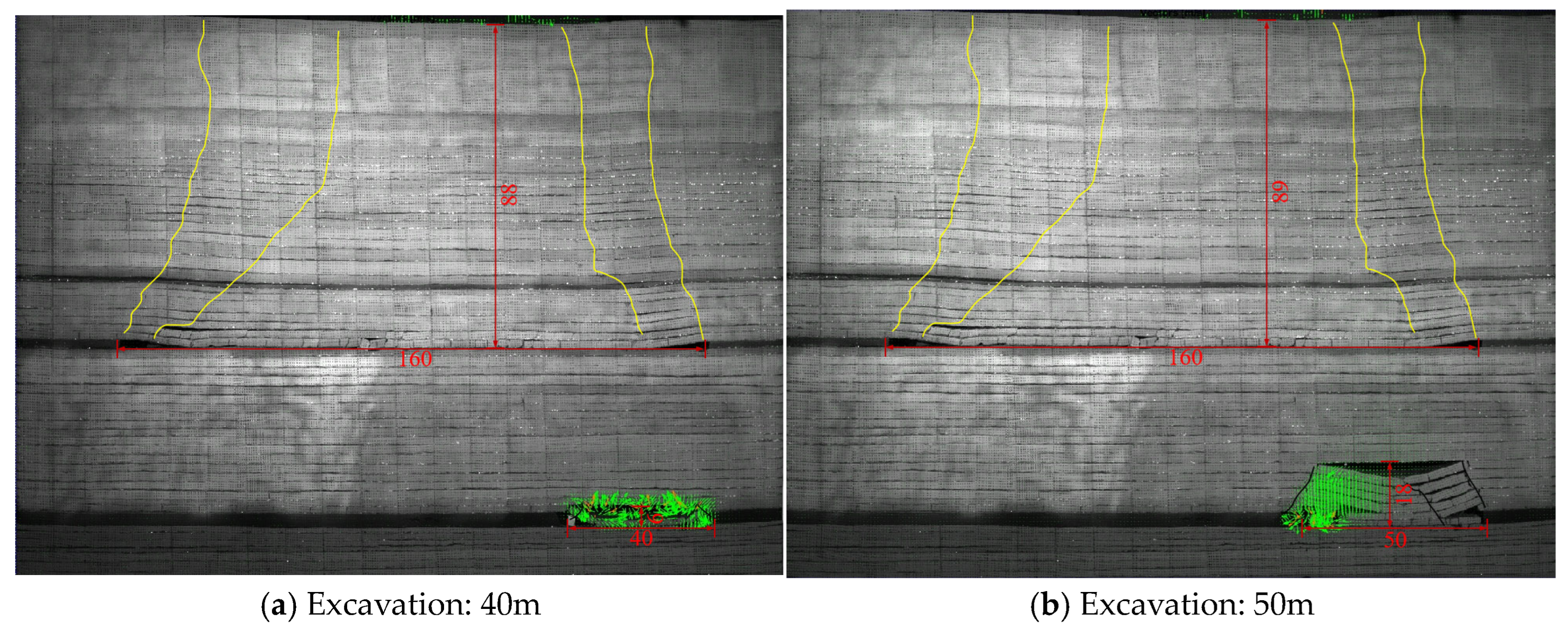

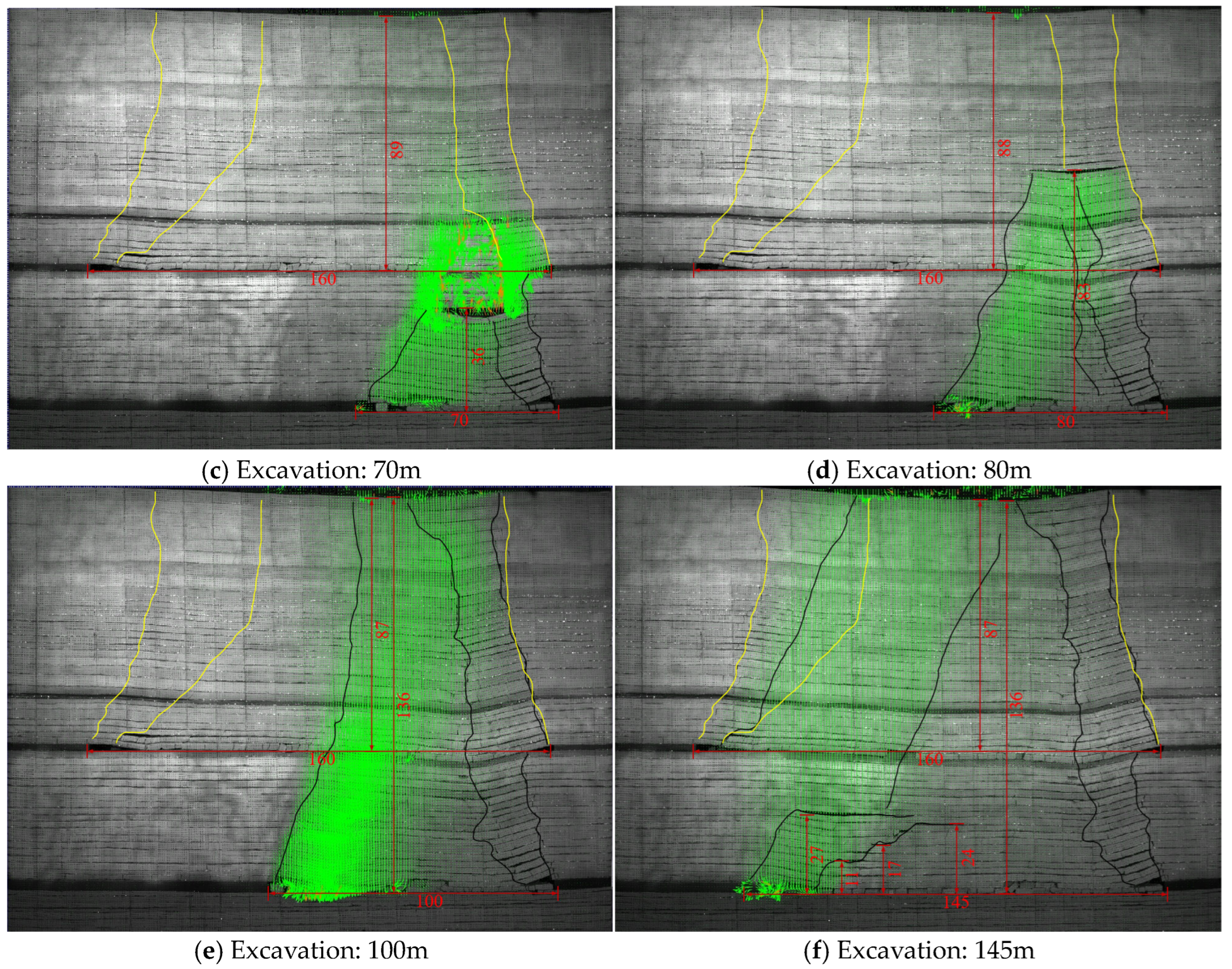

3.2.1. Overburden Caving Characteristics of 2-2 Coal Mining

3.2.2. Overburden Caving Characteristics of 3-1 Coal Mining

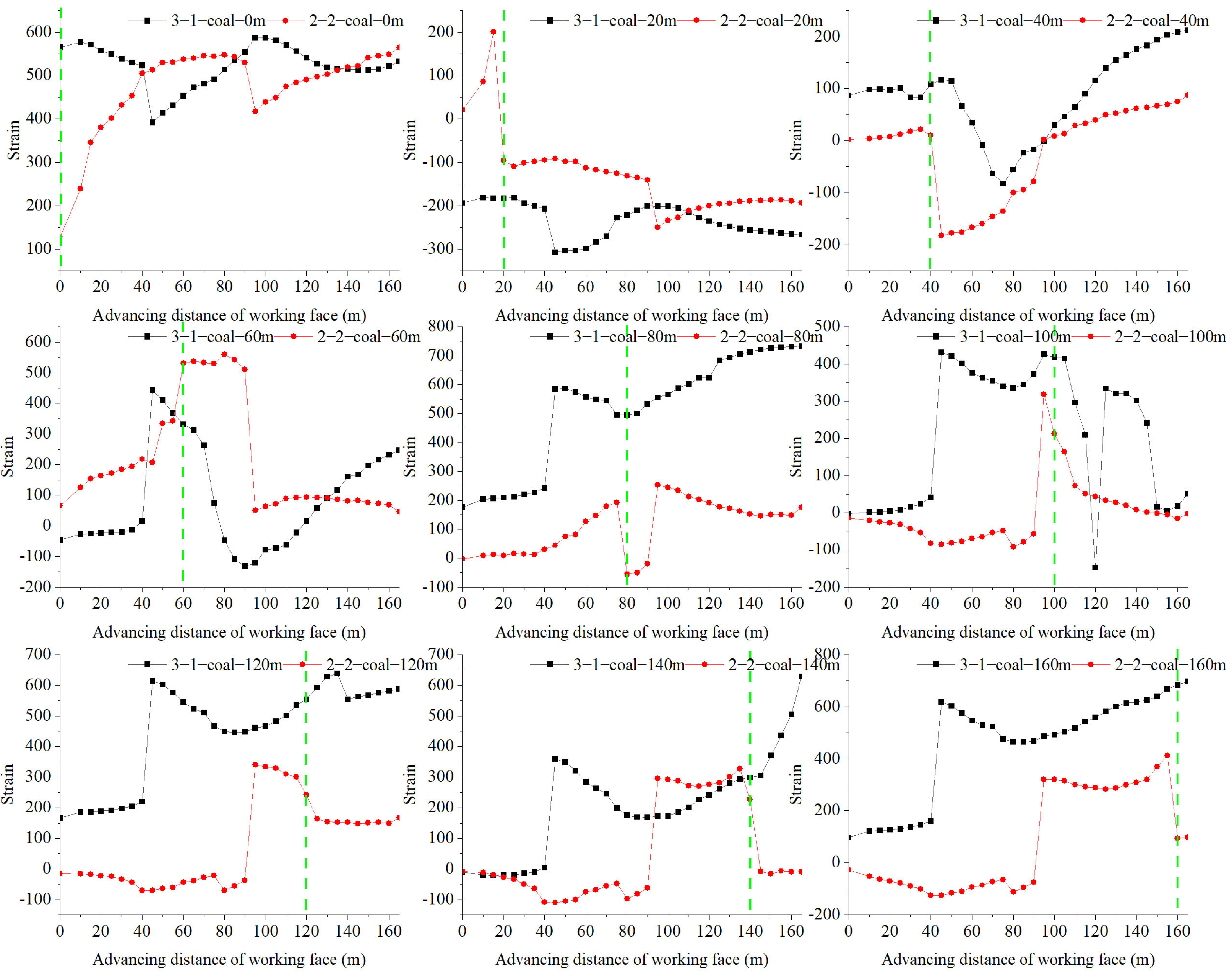

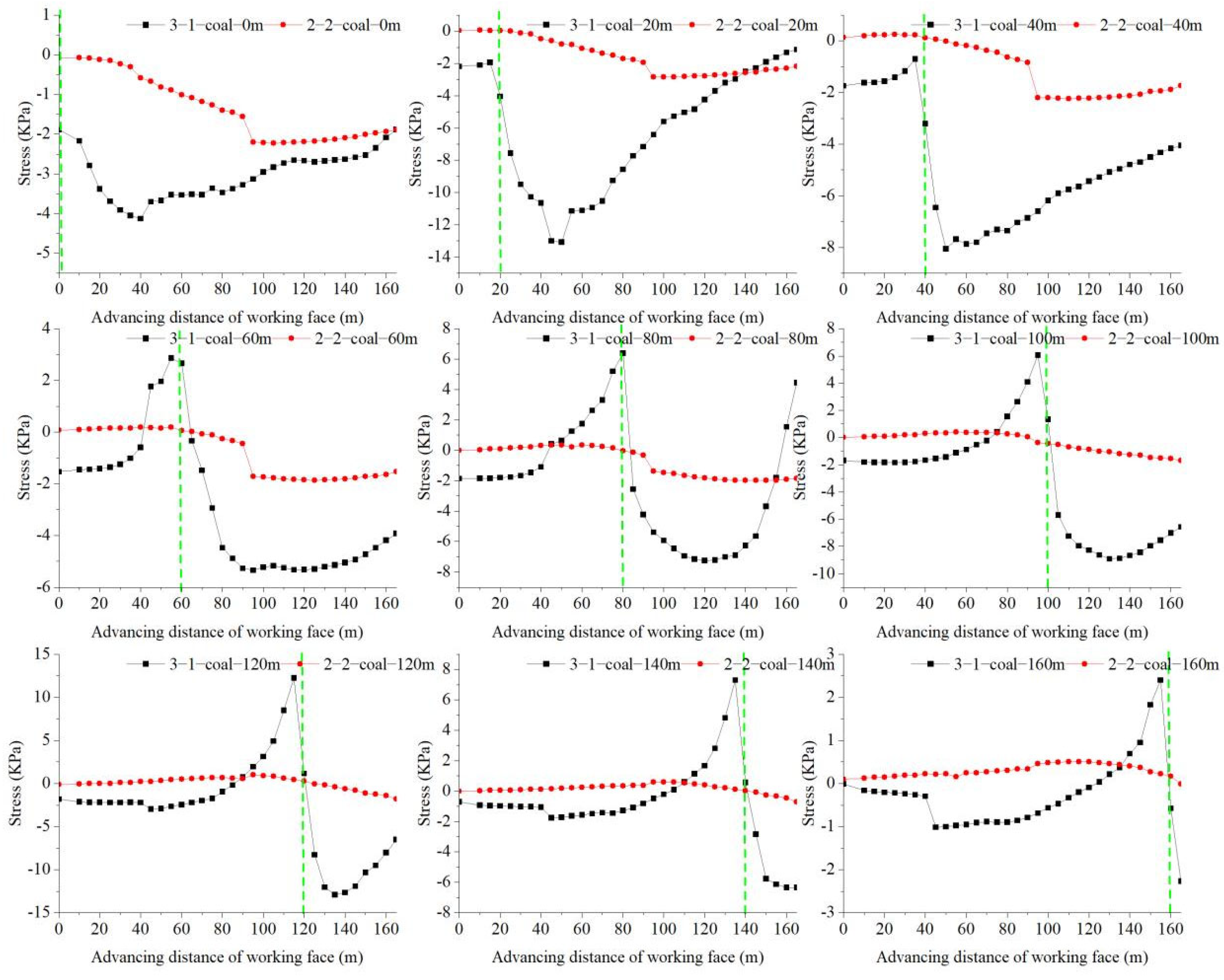

3.3. Stress Strain Data Analysis

- (1)

- Sensor at 0 m: During the excavation of the 2-2 coal seam, when the working face advanced to 40 m, the initial collapse of the roof above the working face occurred. The upward propagation of fractures at the cut hole interrupted the stress transfer from the overlying strata to the cut hole, resulting in a gradual increase in subsequent stress. At an advance of 90 m, the roof above the goaf collapsed to the surface, disrupting the arch-shaped structure of the overlying strata and causing a sudden release of stress, as indicated by a sharp drop in sensor readings. As the working face continued to advance, the collapsed overlying strata were further compacted, leading to a gradual increase in stress at the cut hole. During the excavation of the 3-1 coal seam, the sensor readings initially decreased due to stress relief caused by the underlying mining activity. At an advance of 40 m, the roof collapsed, resulting in a sudden drop in sensor readings. As the working face progressed, the readings gradually increased. At an advance of 100 m, the roof above the goaf collapsed again to the surface, causing a decrease in sensor readings.

- (2)

- Sensor at 20 m: During the excavation of the 2-2 coal seam, a sudden drop in sensor readings was observed at an advance of 20 m. As the working face continued to advance, the readings stabilized due to the formation of a lower-arch structure in the fractured rock strata above the sensor. At an advance of 90 m, the readings dropped sharply and then increased slowly. During the excavation of the 3-1 coal seam, a sudden drop in sensor readings occurred at an advance of 40 m. As the working face progressed, the readings gradually increased. At an advance of 100 m, the readings decreased.

- (3)

- Sensor at 40 m: During the excavation of the 2-2 coal seam, a sudden drop in sensor readings was observed at an advance of 40 m. As the working face advanced, the readings gradually increased, showing a step-like rise at an advance of 90 m. During the excavation of the 3-1 coal seam, the readings gradually decreased at an advance of 50 m. Then, at an advance of 75 m, the readings transitioned from decreasing to increasing.

- (4)

- Sensor at 60 m: During the excavation of the 2-2 coal seam, step-like increases in sensor readings were observed at advances of 50 and 60 m, followed by stabilization. At an advance of 95 m, the readings dropped sharply and then stabilized. During the excavation of the 3-1 coal seam, the readings increased sharply at an advance of 50 m, then gradually decreased, reaching a minimum at an advance of 90 m, after which they gradually increased.

- (5)

- Sensor at 80 m: During the excavation of the 2-2 coal seam, a sudden drop in sensor readings occurred at an advance of 80 m, followed by a gradual increase. The readings peaked at an advance of 95 m and then gradually decreased. During the excavation of the 3-1 coal seam, the readings increased sharply at an advance of 45 m, then gradually decreased, reaching a minimum at an advance of 80 m, after which they gradually increased. A step-like increase was observed at an advance of 115 m.

- (6)

- Sensor at 100 m: During the excavation of the 2-2 coal seam, minor fluctuations in sensor readings were observed at advances of 40 and 75 m. At an advance of 95 m, the readings transitioned from increasing to decreasing and continued to decline. During the excavation of the 3-1 coal seam, the readings increased sharply at an advance of 45 m, then gradually decreased. At an advance of 80 m, the readings transitioned from decreasing to increasing. The readings dropped sharply between advances of 110 and 120 m, the readings dropped sharply, followed by a sudden increase at an advance of 125 m, after which they gradually decreased.

- (7)

- Sensor at 120 m: During the excavation of the 2-2 coal seam, the readings increased sharply at an advance of 90 m, then gradually decreased, stabilizing after an advance of 125 m. During the excavation of the 3-1 coal seam, the readings increased sharply at an advance of 45 m, then gradually decreased. At an advance of 80 m, the readings transitioned from decreasing to increasing. At an advance of 125 m, the readings dropped sharply and then gradually increased.

- (8)

- Sensor at 140 m: During the excavation of the 2-2 coal seam, the readings increased sharply at an advance of 90 m and then stabilized. At an advance of 135 m, the readings dropped sharply and then stabilized. During the excavation of the 3-1 coal seam, the readings increased sharply at an advance of 45 m, then gradually decreased. At an advance of 90 m, the readings transitioned from decreasing to increasing. A step-like increase was observed at an advance of 135 m, followed by an accelerated rise.

- (9)

- Sensor at 160 m: During the excavation of the 2-2 coal seam, the readings increased sharply at an advance of 90 m and then stabilized. At an advance of 155 m, the readings dropped sharply. During the excavation of the 3-1 coal seam, the readings increased sharply at an advance of 45 m, then gradually decreased. At an advance of 90 m, the readings transitioned from decreasing to increasing.

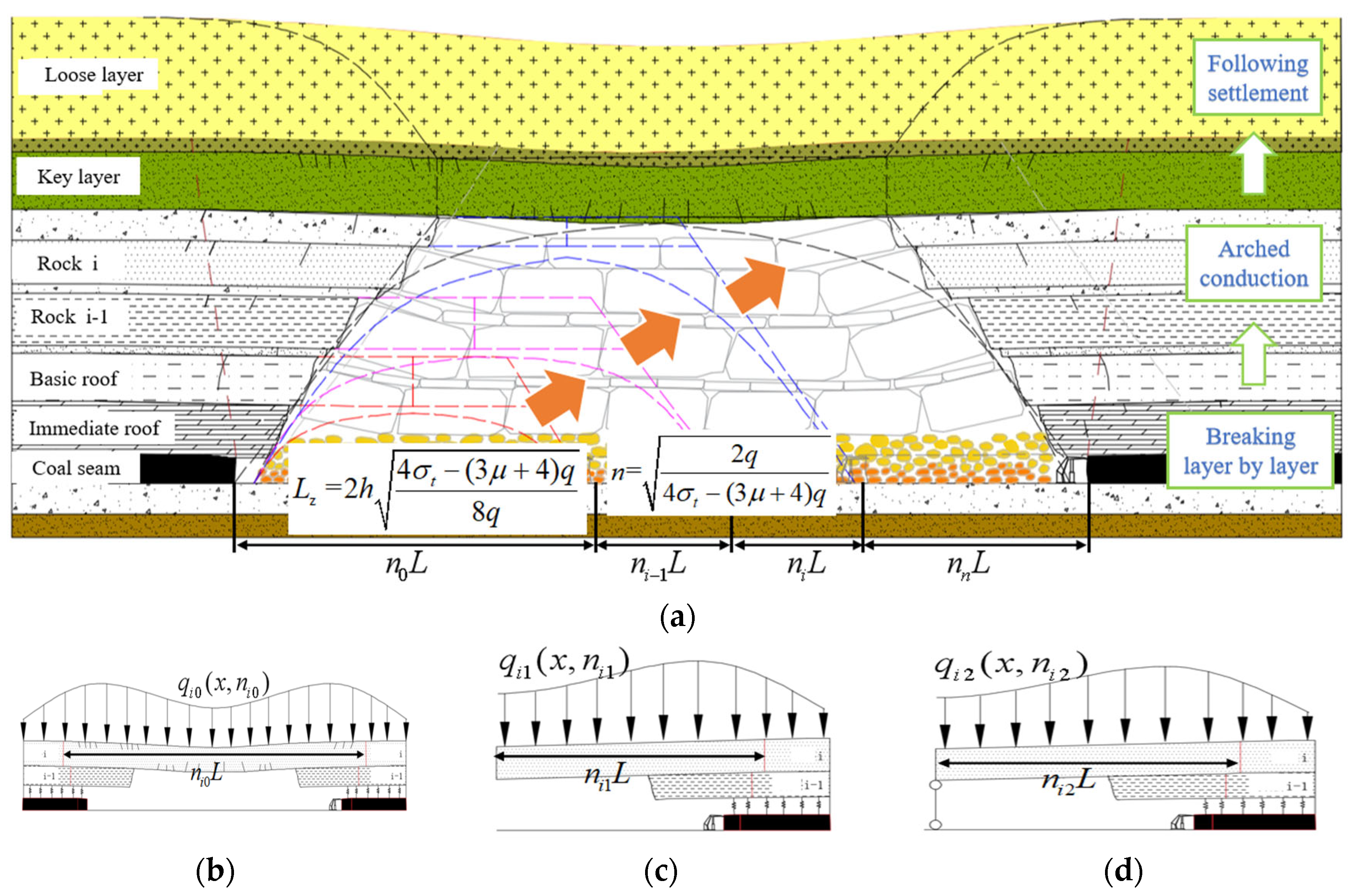

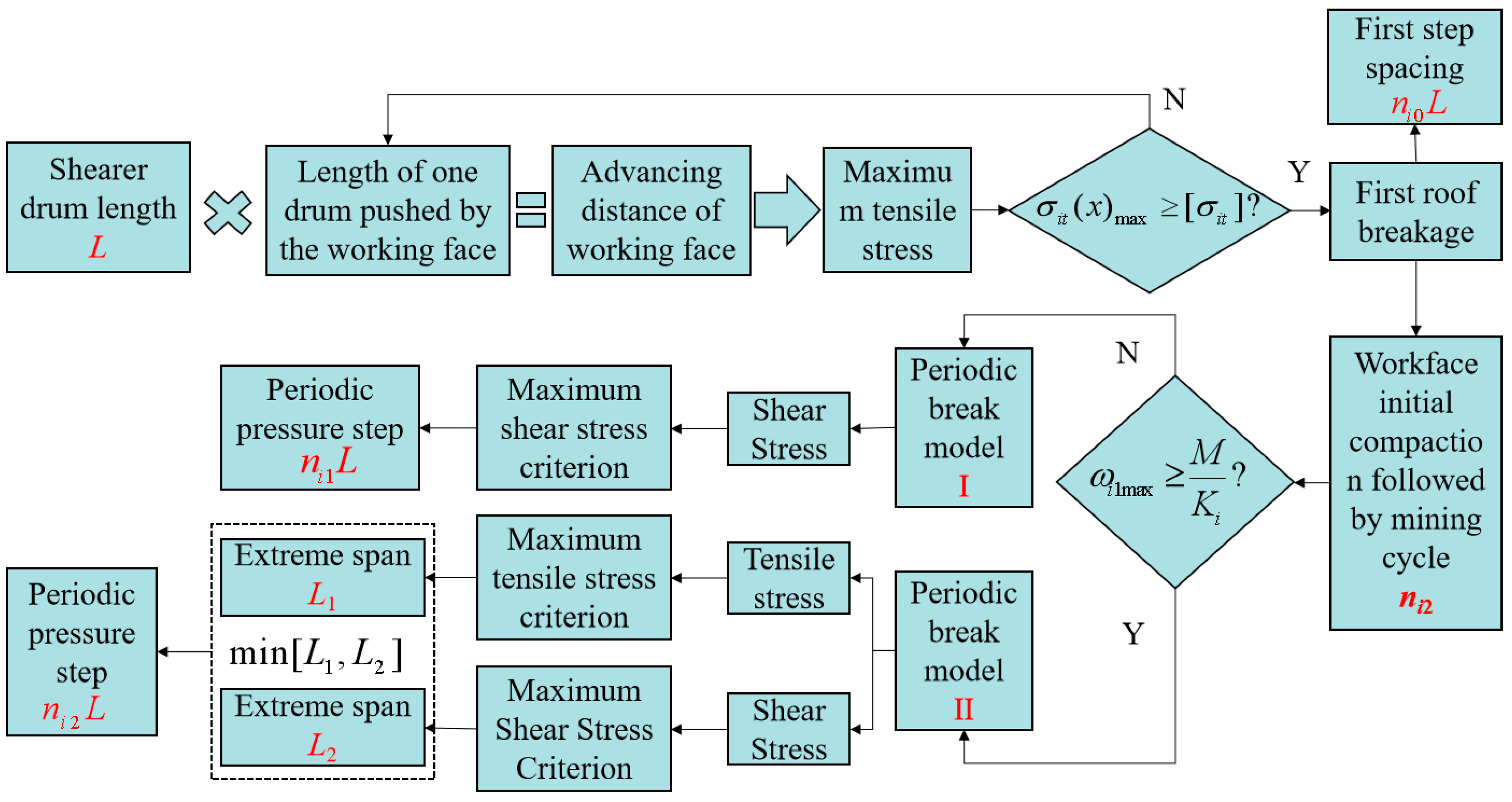

4. Mining Overburden Damage Conduction Model

4.1. Construction of Overburden Damage Conduction Model

4.2. First Fracture Model of the i-th Stratum

4.3. Periodic Fracture Model of the i-th Stratum-I

4.4. Periodic Fracture Model of the i-th Stratum-II

4.5. Criteria for Rock and Surface Fracture and Conduction

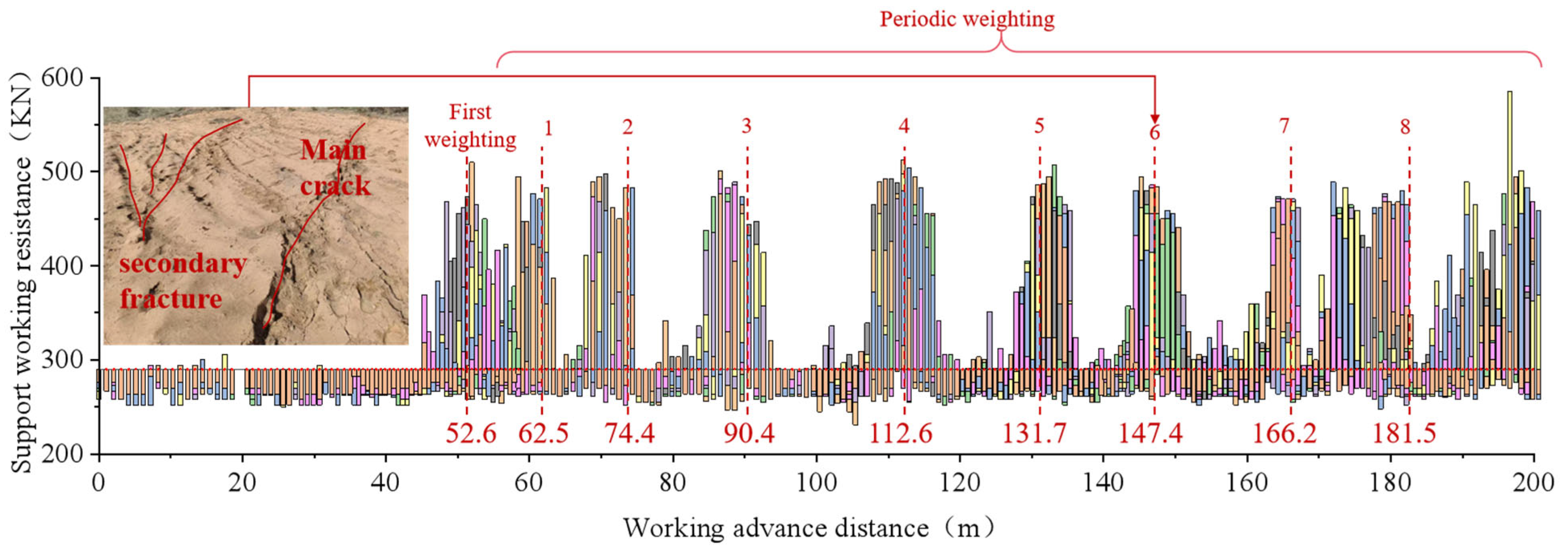

5. Engineering Verification

6. Discussion

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ministry of Natural Resources, PRC. China Mineral Resources 2024; PRC: Beijing, China, 2024. [Google Scholar]

- Wang, S.; Liu, L.; Zhu, M.; Shen, Y.; Shi, Q.; Sun, Q.; Fang, Z.; Ruan, S.; He, W.; Yang, P.; et al. New way for green and low-carbon development of coal industry under the target of “daul-carbon”. J. China Coal Soc. 2024, 49, 152–171. [Google Scholar] [CrossRef]

- Li, Q.; Li, L.; Fang, J.; Guo, J.; Li, J.; Xu, Z.; Li, X. Ecological protection coal mining technology system and engineering practice. Coal Sci. Technol. 2024, 52, 28–37. [Google Scholar] [CrossRef]

- Li, Q. Reduction theory and technical system of underground coal mining. J. China Coal Soc. 2024, 49, 988–1002. [Google Scholar] [CrossRef]

- Li, Q.; Guo, J.; Zhang, K.; Yan, Y.; Zhang, C.; Xu, Z. Damage conduction mechanism and key technology of damage reduction in source for intensive coal mining in western China. J. China Coal Soc. 2021, 46, 3636–3644. [Google Scholar] [CrossRef]

- Li, Q.; Zhang, C. Damage conduction model of high intensity mining in western mining area based on conservation of mining space and its application. J. Min. Saf. Eng. 2021, 38, 1–8. [Google Scholar] [CrossRef]

- Zhang, G.; Li, Q.; Zhang, Y.; Du, F. Failure characteristics of roof in working face end based on stress evolution of goaf. Geomech. Geophys. Geo-Energy Geo-Resour. 2021, 7, 53. [Google Scholar] [CrossRef]

- Zhang, G.; Li, Q.; Xu, Z.; Zhang, Y. Roof fractures of near-vertical and extremely thick coal seams in horizontally grouped top-coal drawing method based on the theory of a thin plate. Sustainability 2022, 14, 10285. [Google Scholar] [CrossRef]

- Huang, Q.; Wang, X.; He, Y.; Li, K.; Li, J.; Liu, J.; Wang, S. Activated roof structure and support dynamic load in shallow-buried close coal seam mining. J. Min. Saf. Eng. 2022, 39, 857–866. [Google Scholar] [CrossRef]

- Zhou, J.L.; Huang, Q.X. Stability analysis of key structure structures of large mining height longwall face in shallow coal seam. Chin. J. Rock Mech. Eng. 2019, 38, 1396–1407. [Google Scholar] [CrossRef]

- Huang, Q.X.; Zhao, M.Y.; Huang, K.J. Study of roof double key strata structure and support resistance of shallow coal seams group mining. J. China Univ. Min. Technol. 2019, 48, 71–77+86. [Google Scholar] [CrossRef]

- Huang, K.; Huang, Q.; Wang, S.; Deng, Z.; Zhao, M. Research on roof structure and support resistance during periodic weighting in shallow group coal seams mining face. J. China Coal Soc. 2018, 43, 2687–2693. [Google Scholar] [CrossRef]

- Huang, Q.; Han, J. Study on fracture evolution mechanism of shallow-buried close coal seam mining. J. Min. Saf. Eng. 2019, 36, 706–711. [Google Scholar] [CrossRef]

- Huang, Q.; Cao, J.; Du, J.; Li, X. Research on three-field evolution and rational coal pillar staggered distance in shallow buried closely spaced multi-seam mining. J. China Coal Soc. 2019, 44, 681–689. [Google Scholar] [CrossRef]

- Huang, Q.; Du, J.; Hou, E.; Yang, F. Research on overburden and ground surface cracks distribution and formation mechanism in shallow coal seams group mining. J. Min. Saf. Eng. 2019, 36, 7–15. [Google Scholar] [CrossRef]

- Xu, F.; Guo, W.; Wang, C. Research on surface subsidence law in high-intensity mining of shallow buried with thick coal seam. Coal Sci. Technol. 2023, 51, 11–20. [Google Scholar] [CrossRef]

- Guo, W.; Bai, E.; Zhao, G. Current status and progress on overburden and surface damage and prevention technology of high-intensity mining. J. China Coal Soc. 2020, 45, 509–523. [Google Scholar] [CrossRef]

- Yang, D.; Guo, W.; Tan, Y.; Wang, Y.; Ma, X.; Li, Z. Lithology and fissure characteristics of overburden in high-intensity mining. J. China Coal Soc. 2019, 44, 786–795. [Google Scholar] [CrossRef]

- Guo, W.; Bai, E.; Yang, D. Study on the technical characteristics and index of thick coal seam high-intensity mining in coalmine. J. China Coal Soc. 2018, 43, 2117–2125. [Google Scholar] [CrossRef]

- Liu, C.; Li, J.; Zhao, J.; Chen, Y.; Zhang, H.; Yu, X. Dynamic strata pressure mechanism and distribution characteristics of overburden air leakage fissures in the condition of shallow thick coal seam in gully area. J. Min. Saf. Eng. 2023, 40, 965–971. [Google Scholar] [CrossRef]

- Li, J.W.; Liu, C.Y.; Bu, Q.W. Spatio-temporal evolution of overburden fissures in shallow thick coal seam mining. J. Min. Saf. Eng. 2020, 37, 238–246. [Google Scholar] [CrossRef]

- Zhao, J.; Liu, C.; Li, J.; Wang, W. Three-dimensional geological modeling and surface damage in gully area due to shallow coal seam mining. J. Min. Saf. Eng. 2018, 35, 969–977. [Google Scholar] [CrossRef]

- Zhao, J.; Liu, C.; Li, J. Stress field distribution and strata behavior characteristicsin shallow thick coal seam mining in gully region. J. Min. Saf. Eng. 2018, 35, 742–750. [Google Scholar] [CrossRef]

- Xu, Z.; Li, Q.; Zhang, G.; Yang, Y.; Sun, C. Study on the feature of overlying rock failure and the height of water-conductingfracture zone after muli-seam coal mining in Shendong Mlining Areal. J. Min. Strat. Control Eng. 2023, 5, 063042. [Google Scholar]

- Lei, P.; Yang, H.; Yin, Z.; Shan, F. Ghost particle suppression multiplicative algebraic reconstruction technique for tomographic PIV. Exp. Fluids 2025, 66, 29. [Google Scholar] [CrossRef]

- Fan, J.; Guo, C.; Gong, S.; Zhao, G.; Luo, C. Investigation of the correlation between nozzle structure and particle motion during shot peening using the PIV method. Int. J. Adv. Manuf. Technol. 2024, 134, 4839–4850. [Google Scholar] [CrossRef]

- Timoshenko, S.; Goodier, J.N. Theory of Elasticity; McGraw-Hill Book Company, Inc.: New York, NY, USA, 1951. [Google Scholar]

- Zhang, G.; Zhang, Y. Immediate roof first fracture characteristics of soberest and extremely thick coal. J. China Coal Soc. 2018, 43, 1220–1229. [Google Scholar] [CrossRef]

| No. | Rock Stratum | Thickness /m | Density kg/m3 | RQD | Tensile strength/MPa | Compressive Strength/MPa | Modulus of Elasticity/GPa | Poisson’s Ratio | Cohesion/MPa | Friction Angle/° |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Aeolian sand | 36.0 | 1720 | 0.00 | 0.00 | 0.72 | 0.01 | 0.30 | 0.02 | 20.0 |

| 2 | Fine-grained sandstone | 2.9 | 2219 | 70.19 | 1.81 | 22.62 | 3.08 | 0.26 | 10.72 | 24.9 |

| 3 | Sandy mudstone | 3.5 | 2308 | 63.71 | 2.70 | 34.01 | 2.89 | 0.26 | 21.06 | 21.8 |

| 4 | Fine-grained sandstone | 3.6 | 2219 | 70.19 | 1.81 | 22.62 | 3.08 | 0.26 | 10.72 | 24.9 |

| 5 | Medium-grained sandstone | 10.5 | 2108 | 34.61 | 1.06 | 4.57 | 0.35 | 0.24 | 5.81 | 27.6 |

| 6 | Siltstone | 4.9 | 2313 | 88.92 | 2.77 | 30.95 | 2.66 | 0.29 | 11.67 | 33.1 |

| 7 | Fine-grained sandstone | 3.0 | 2219 | 70.19 | 1.81 | 22.62 | 3.08 | 0.26 | 10.72 | 24.9 |

| 8 | Sandy-mudstone | 3.4 | 2368 | 61.93 | 4.21 | 72.56 | 14.01 | 0.24 | 19.99 | 25.9 |

| 9 | Siltstone | 2.6 | 2353 | 50.11 | 3.62 | 64.73 | 6.51 | 0.24 | 23.80 | 22.3 |

| 10 | 2-2 coal loading | 0.8 | 1274 | 63.08 | 1.17 | 24.75 | 1.99 | 0.28 | 19.25 | 24.5 |

| 11 | Siltstone | 3.5 | 2353 | 50.11 | 3.62 | 64.73 | 6.51 | 0.24 | 23.80 | 22.3 |

| 12 | Fine-grained sandstone | 2.8 | 2370 | 53.43 | 2.52 | 66.41 | 11.65 | 0.25 | 15.48 | 30.9 |

| 13 | Medium-grained sandstone | 4.0 | 2294 | 94.37 | 2.38 | 34.47 | 7.42 | 0.24 | 15.68 | 28.7 |

| 14 | Sandy mudstone | 3.9 | 2421 | 61.53 | 5.24 | 52.49 | 7.27 | 0.20 | 18.96 | 26.1 |

| 15 | 2-2 coal | 1.8 | 1274 | 63.08 | 1.17 | 24.75 | 1.99 | 0.28 | 19.25 | 24.5 |

| 16 | Sandy mudstone | 2.2 | 2421 | 61.53 | 5.24 | 52.49 | 7.27 | 0.20 | 18.96 | 26.1 |

| 17 | Fine-grained sandstone | 11.3 | 2370 | 53.43 | 2.52 | 66.41 | 11.65 | 0.25 | 15.48 | 30.9 |

| 18 | Siltstone | 12.1 | 2390 | 69.00 | 6.61 | 72.41 | 10.85 | 0.24 | 21.78 | 28.9 |

| 19 | Sandy mudstone | 2.5 | 2326 | 61.17 | 5.03 | 54.29 | 7.59 | 0.21 | 24.36 | 28.3 |

| 20 | Fine-grained sandstone | 8.6 | 2355 | 74.98 | 5.67 | 72.23 | 13.08 | 0.34 | 22.39 | 31.8 |

| 21 | Sandy mudstone | 3.4 | 2326 | 61.17 | 5.03 | 54.29 | 7.59 | 0.21 | 24.36 | 28.3 |

| 22 | 3-1 coal | 3.5 | 1274 | 63.08 | 1.17 | 24.75 | 1.99 | 0.28 | 19.25 | 24.5 |

| 23 | Sandy mudstone | 3.1 | 2326 | 61.17 | 5.03 | 54.29 | 7.59 | 0.21 | 24.36 | 28.3 |

| 24 | Siltstone | 1.5 | 2413 | 74.17 | 9.26 | 101.73 | 12.87 | 0.25 | 35.60 | 24.7 |

| 25 | Fine-grained sandstone | 1.1 | 2359 | 51.76 | 5.61 | 42.83 | 7.39 | 0.28 | 30.91 | 20.0 |

| 26 | Sandy mudstone | 7.0 | 2391 | 94.90 | 6.66 | 81.65 | 10.56 | 0.25 | 27.79 | 26.6 |

| 27 | Siltstone | 7.0 | 2480 | 68.36 | 6.91 | 89.07 | 13.96 | 0.27 | 28.96 | 30.9 |

| No. | Rock Stratum | Compressive Strength /MPa | Density kg/m3 | Density Similarity Ratio | Strength Similarity Ratio | Similar Material Strength/kPa | Sand /kg | Lime /kg | Gypsum /kg | Water /kg |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Rock stratum | 0.72 | 1720 | 1.000 | 100 | 7.200 | 357.59 | 0.00 | 32.51 | 29.26 |

| 2 | Aeolian sand | 22.62 | 2219 | 1.290 | 129 | 175.333 | 27.93 | 2.44 | 1.05 | 2.36 |

| 3 | Fine grained sandstone | 34.01 | 2308 | 1.342 | 134 | 253.454 | 34.13 | 1.90 | 1.90 | 2.84 |

| 4 | sandy mudstone | 22.62 | 2219 | 1.290 | 129 | 175.333 | 34.68 | 3.03 | 1.30 | 2.93 |

| 5 | Fine grained sandstone | 4.57 | 2108 | 1.226 | 123 | 37.288 | 101.14 | 10.11 | 2.53 | 8.53 |

| 6 | Medium grained sandstone | 30.95 | 2313 | 1.345 | 134 | 230.151 | 47.79 | 2.65 | 2.65 | 3.98 |

| 7 | Siltstone | 22.62 | 2219 | 1.290 | 129 | 175.333 | 28.90 | 2.53 | 1.08 | 2.44 |

| 8 | Fine grained sandstone | 72.56 | 2368 | 1.377 | 138 | 527.041 | 32.75 | 2.05 | 2.05 | 2.76 |

| 9 | sandy mudstone | 64.73 | 2353 | 1.368 | 137 | 473.164 | 25.04 | 1.57 | 1.57 | 2.11 |

| 10 | Siltstone | 24.75 | 1274 | 0.741 | 74 | 334.144 | 7.71 | 0.67 | 0.29 | 0.65 |

| 11 | 2-2 coal loading | 64.73 | 2353 | 1.368 | 137 | 473.164 | 33.71 | 2.11 | 2.11 | 2.84 |

| 12 | Siltstone | 66.41 | 2370 | 1.378 | 138 | 481.963 | 26.97 | 1.69 | 1.69 | 2.28 |

| 13 | Fine grained sandstone | 34.47 | 2294 | 1.334 | 133 | 258.450 | 39.01 | 2.17 | 2.17 | 3.25 |

| 14 | Medium grained sandstone | 52.49 | 2421 | 1.408 | 141 | 372.915 | 37.56 | 2.82 | 1.88 | 3.17 |

| 15 | sandy mudstone | 24.75 | 1274 | 0.741 | 74 | 334.144 | 17.34 | 1.52 | 0.65 | 1.46 |

| 16 | 2-2 coal | 52.49 | 2421 | 1.408 | 141 | 372.915 | 21.19 | 1.59 | 1.06 | 1.79 |

| 17 | sandy mudstone | 66.41 | 2370 | 1.378 | 138 | 481.963 | 108.84 | 6.80 | 6.80 | 9.18 |

| 18 | Fine grained sandstone | 72.41 | 2390 | 1.390 | 139 | 521.110 | 116.55 | 7.28 | 7.28 | 9.83 |

| 19 | Siltstone | 54.29 | 2326 | 1.352 | 135 | 401.457 | 24.08 | 1.81 | 1.20 | 2.03 |

| 20 | sandy mudstone | 72.23 | 2355 | 1.369 | 137 | 527.540 | 82.84 | 5.18 | 5.18 | 6.99 |

| 21 | Fine grained sandstone | 54.29 | 2326 | 1.352 | 135 | 401.457 | 32.75 | 2.46 | 1.64 | 2.76 |

| 22 | sandy mudstone | 24.75 | 1274 | 0.741 | 74 | 334.144 | 34.68 | 3.03 | 1.30 | 2.93 |

| 23 | 3-1 coal | 54.29 | 2326 | 1.352 | 135 | 401.457 | 29.86 | 2.24 | 1.49 | 2.52 |

| 24 | sandy mudstone | 101.73 | 2413 | 1.403 | 140 | 725.137 | 14.22 | 1.02 | 1.02 | 1.22 |

| 25 | Siltstone | 42.83 | 2359 | 1.372 | 137 | 312.283 | 10.60 | 0.79 | 0.53 | 0.89 |

| 26 | Fine grained sandstone | 81.65 | 2391 | 1.390 | 139 | 587.361 | 67.42 | 1.69 | 6.74 | 5.69 |

| 27 | sandy mudstone | 89.07 | 2480 | 1.442 | 144 | 617.744 | 66.37 | 4.74 | 4.74 | 5.69 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, G.; Fu, S.; Li, Y.; Chi, M.; Zhao, X. Mechanisms of Overburden and Surface Damage Conduction in Shallow Multi-Seam Mining. Eng 2025, 6, 235. https://doi.org/10.3390/eng6090235

Zhang G, Fu S, Li Y, Chi M, Zhao X. Mechanisms of Overburden and Surface Damage Conduction in Shallow Multi-Seam Mining. Eng. 2025; 6(9):235. https://doi.org/10.3390/eng6090235

Chicago/Turabian StyleZhang, Guojun, Shigen Fu, Yunwang Li, Mingbo Chi, and Xizhong Zhao. 2025. "Mechanisms of Overburden and Surface Damage Conduction in Shallow Multi-Seam Mining" Eng 6, no. 9: 235. https://doi.org/10.3390/eng6090235

APA StyleZhang, G., Fu, S., Li, Y., Chi, M., & Zhao, X. (2025). Mechanisms of Overburden and Surface Damage Conduction in Shallow Multi-Seam Mining. Eng, 6(9), 235. https://doi.org/10.3390/eng6090235