1. Introduction

Power transformers are a very crucial apparatus in the electric power system of transmission and distribution. Utilities tend to measure transformer condition and prioritize them to develop maintenance schedules. Transformer oil plays a very significant role in transformer operation as it is used in its core for cooling and insulation [

1]. During transformer operation, the oil is exposed to thermal and electrical stresses, and if these stresses are not dealt with, it may affect the transformer’s life and efficiency. Therefore, it is important to monitor the health of a transformer to prevent further degradation of the transformer insulation and breakdown, which may eventually lead to disturbance of the power system as a whole [

2]. The majority of transformer diagnostic procedures are costly and difficult to utilize because they require strict testing protocols. One of the most effective methods in terms of affordability and ease of use is Dissolved Gas Analysis (DGA), which was developed over many years by R&D communities and engineers who specialize in defect diagnosis in original equipment manufacturing businesses. Power engineers can benefit from this technique as it provides a complete breakdown of the components that make up insulating oil. As more sophisticated and advanced diagnostic tools are being created, it is necessary to create a prototype algorithm that can consider the percentages of the various parts and provide us with a human-readable response that expresses the insulating oil’s condition.

DGA is used for identifying the health of the transformer depending on the concentration of various gases dissolved in transformer oil [

3]. The presence of certain gases is an indication of specific faults. Gases found in the transformer oil due to decomposition are hydrogen (H

2), methane (CH

4), ethane (C

2H

6), ethylene (C

2H

4), and acetylene (C

2H

2), while carbon monoxide (CO) and carbon dioxide (CO

2) are due to paper decomposition [

3]. Faults like partial discharge occur within the gaps of insulation, such as an air bubble or small sections of the fluid, but do not allow continuous discharge between metal contacts. Hydrogen is the key gas in this fault. Arcing or high-energy discharge, this fault suggests electricity is jumping between metal contacts, causing a continuous arc. It is characterized by the presence of hydrogen and acetylene; they are a sign of electrical stress in a transformer. High temperature overheating is a common defect that can compromise a transformer’s performance. When temperatures rise steeply, often due to overloading or inadequate cooling, fault gases are produced [

4]. Their concentration is normally determined by the temperature of the oil. For instance, hydrogen and methane are produced in large quantities if the temperature of the transformer rises to between 150 °C and 300 °C due to abnormal thermal stresses. If the temperatures rise above 300 °C, ethylene is produced in large quantities, and at 700 °C and above, a large amount of hydrogen and ethylene is produced. Therefore, ethylene is an indication of a very high temperature hot spot inside an electrical transformer [

5]. Paper insulation degradation is extremely important for the electrical and mechanical integrity of a transformer. It insulates the windings, provides a facility for cooling oil, and even acts as mechanical support. Paper degradation results in carbon monoxide discharge and, later on, carbon dioxide [

3,

5]. Lastly, it is important to mention that DGA can help identify the faults, namely partial discharge, arcing, hot spots in the core, overheating of oil or paper insulation, insulation aging, sparking between contacts, and internal short circuits well in time, accurately for predictive maintenance [

4,

6,

7].

2. Problem Statement

Power transformers are vital components in electrical power systems, utilized to ensure stable transmission and distribution of electricity. One of the most significant processes is constant transformer maintenance because, if it breaks down, there will be large interruptions, loss of funds, and even accidents. To avoid such unwanted failures and increase the service life of such critical components, fault detection as soon as possible and ongoing monitoring of the transformer’s condition are required.

As one of the fault detection methods, DGA is used, and it involves analyzing the types and concentration of gases dissolved in the transformer’s insulation oil. In the case of an internal transformer fault, some gases are released due to oil degradation or insulation materials. DGA can perhaps provide critical information about the condition of the transformer by analyzing and detecting these gases, enabling early intervention and maintenance.

Despite its proven effectiveness, the traditional use of DGA is attended by a unique set of difficulties. Despite their accuracy, modern methods of diagnosis tend to be based on more sophisticated or technical interpretation techniques and specialist expertise; therefore, they are less accessible to non-specialists. Decision-makers also want to have information that is readily understandable and actionable, and such techniques will tend to produce a technical report, which can be hard for them to analyze. Also, with transformer design increasingly improving and operating demands growing, there is a greater need for even more sophisticated diagnostic tools that can keep pace with current standards.

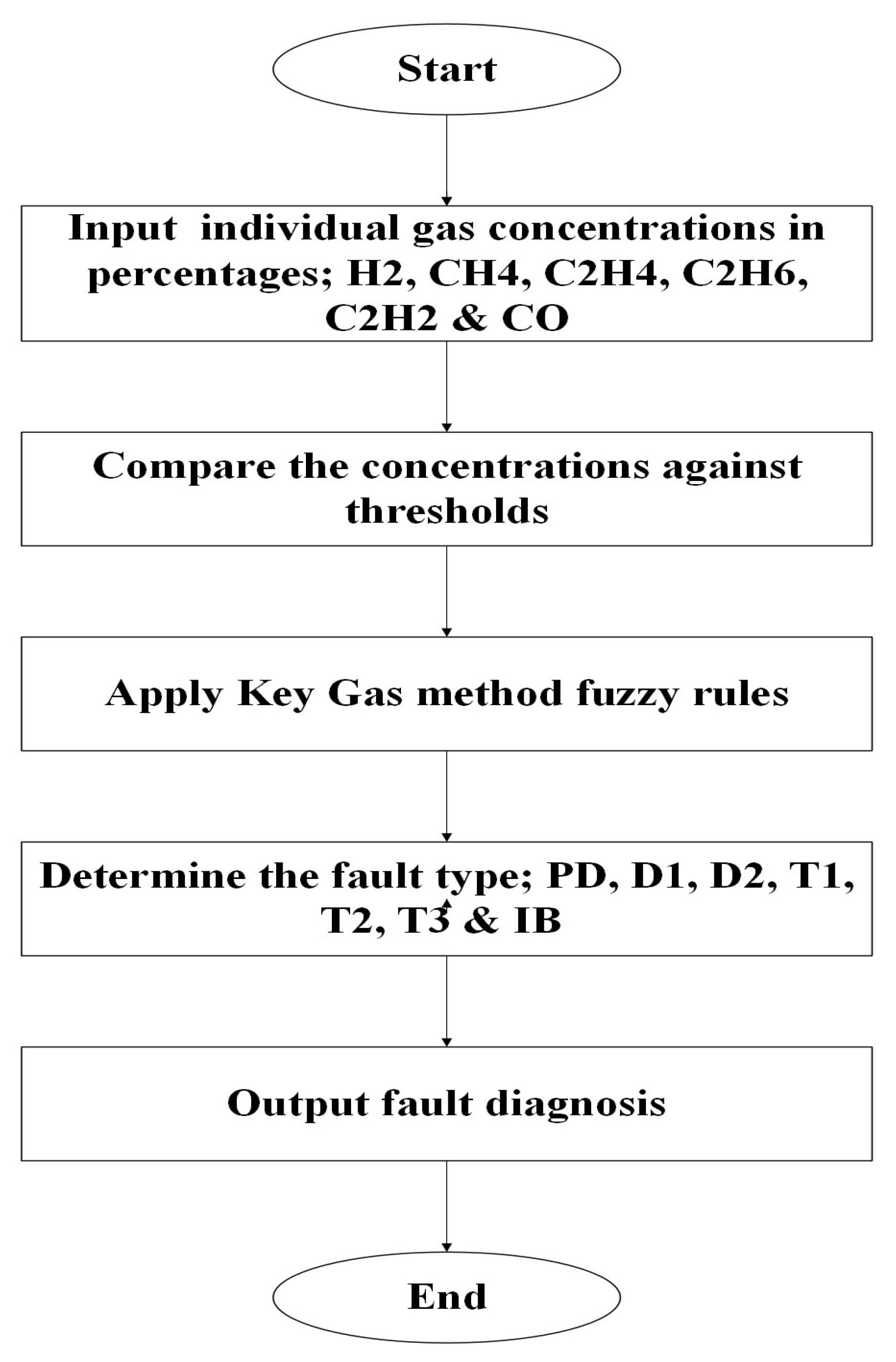

The main challenge that this paper seeks to overcome is the need for a more efficient diagnostic approach that maintains the accuracy and reliability of DGA but allows for simpler interpretation of the results. More specifically, there is a need for a prototype algorithm that would read DGA data and convert it to an easily understandable, human-readable diagnosis. The dissolved gas concentrations, potential faults, and general condition of the transformer must be calculated based on such an algorithm. This would enable numerous users, such as non-specialists, to make intelligent decisions regarding the operation and maintenance of transformers.

4. Literature Review

DGA has been utilized over the years, and due to some imperfections, various research have been carried out with the aim of improving its overall efficiency. This section goes through previous studies to try and identify gaps and justify the need for this proposal.

DGA has developed into a fundamental method for condition monitoring and fault detection of power transformers. Transformers form an important element of electrical power networks; therefore, it is necessary to check whether they work properly or not. By checking dissolved gases present in the insulation oil, DGA provides an efficient, inexpensive, and universally accepted technique of transformer fault identification and diagnosis [

8]. Over the years, several studies have been conducted to improve the effectiveness of DGA techniques such as Key Gas Method, Roger’s Ratio, Dornenburg’s ratio, and Duval Triangle method [

9], to make it an indispensable tool for engineers and maintenance personnel. But the difference in the outcomes of several DGA techniques has grown to be problematic. Studies by [

10,

11] targeted a consistent DGA interpretation using a fuzzy logic method. This study compared and then merged a number of techniques, including the Duval Triangle, Key Gas Method, Dornenburg’s ratio, IEC (International Electrotechnical Commission) ratio, and Roger’s Ratio. However, a study by [

12] assessed the precision of different DGA methods for diagnosing transformer faults. The authors wanted to know the accuracy of various ways of fault type prediction in comparison to the Key Gas Method, Dornenburg’s, Roger’s, IEC, and Duval Triangle methods. Although there are merits in every method, they have observed that the Duval Triangle gave the maximum total accuracy. But with the inclusion of AI, the DGA methods can be developed further for transformer oil quality testing. In references [

13,

14], DGA methods are mainly utilized for the monitoring of transformer faults like PD, electrical discharges, thermal faults, and paper Insulation Breakdowns. With the goal of increasing accuracy, [

15] brought forward a new graphical triangle approach founded on innovative three gas concentration ratios. Five combustible gases, like C

2H

6 and H

2, which are originally not considered under the Duval Triangle, are taken into consideration by it. These gases are defined in terms of three gas ratios, which are translated into three percentage ratios represented in triangular coordinates. Despite the notable limitation of its inability to detect multiple faults simultaneously, the proposed triangle technique was highly effective in the comprehensive detection of fault types, surpassing traditional approaches in its transparency, directness, reliability, and accuracy.

In their study, [

16] presented a numerical method based on MATLAB 2024b that expanded the Duval Triangle diagnostic graph for transformer failure diagnosis. This method makes it easier to discover electrical and thermal faults in transformers on a more user-friendly platform. However, the approach is very MATLAB-reliant and has a greater focus on thermal faults, which restricts its applicability. Traditional DGA methods often need manual operation, specialized equipment, and professional interpretation, are slow and time-consuming, and may overlook low-energy faults or early-stage issues. Without considering the percentage of components that may aid in determining the condition of the transformer and insulating oil, the studies primarily concentrated on the consistency of the DGA interpretations. Additionally, these studies do not consider how to make the DGA process simple to use and eliminate the need for personal expertise, which would make the engineering and maintenance staff’s jobs easier. Recently, research has investigated using Artificial Intelligence (AI) tools and combining them with DGA to increase overall effectiveness in an attempt to address the limitations noted above.

AI refers to the simulation of human intelligence in machines that are programmed to think, learn, and solve problems like a human [

17]. AI methods often do not need human expertise to analyze the data since they can make decisions based on input from gas concentrations. Numerous writers have conducted studies to determine how to enhance the DGA processes by utilizing AI approaches such as fuzzy logic. The IEC 60599-2007 [

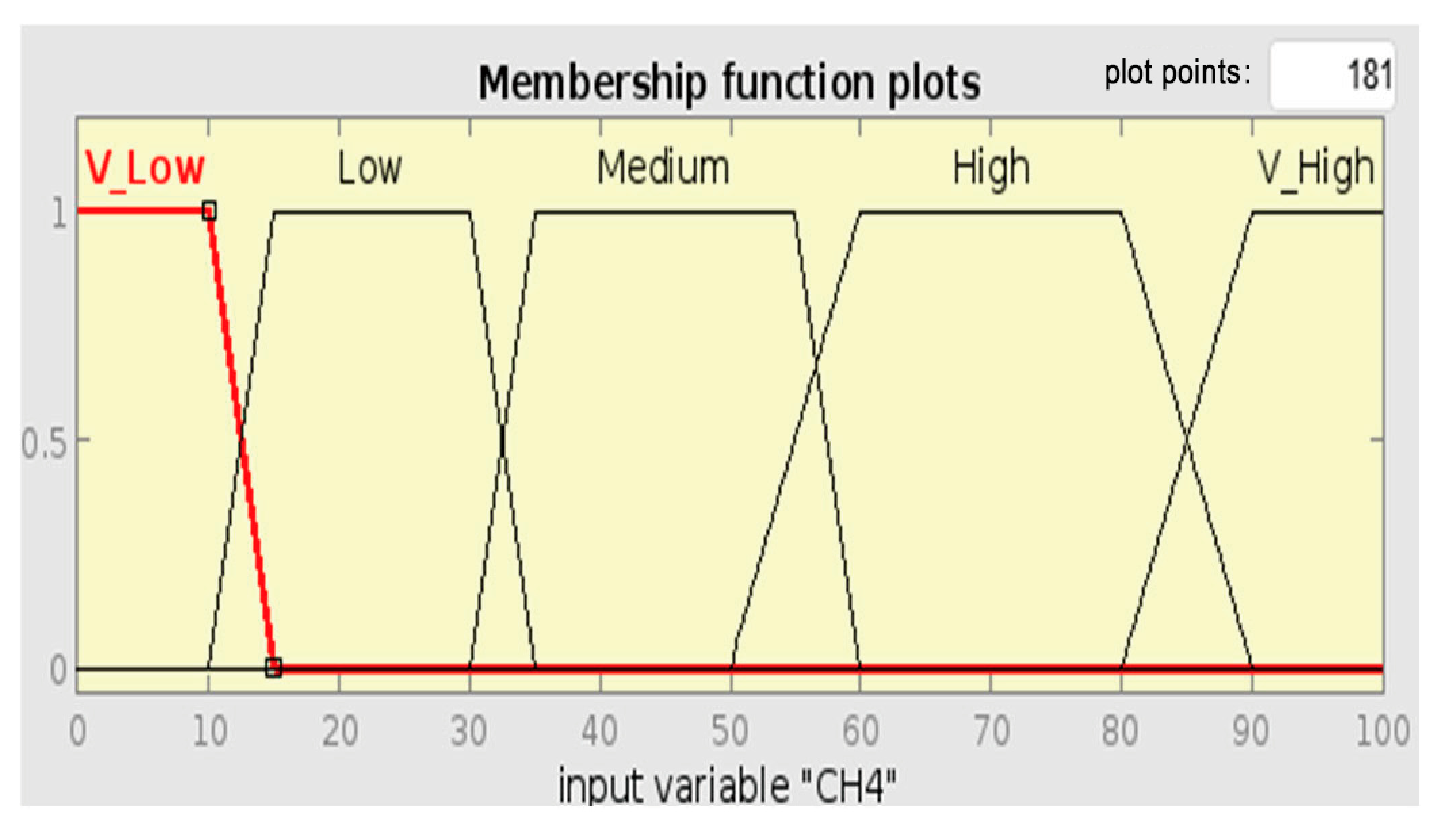

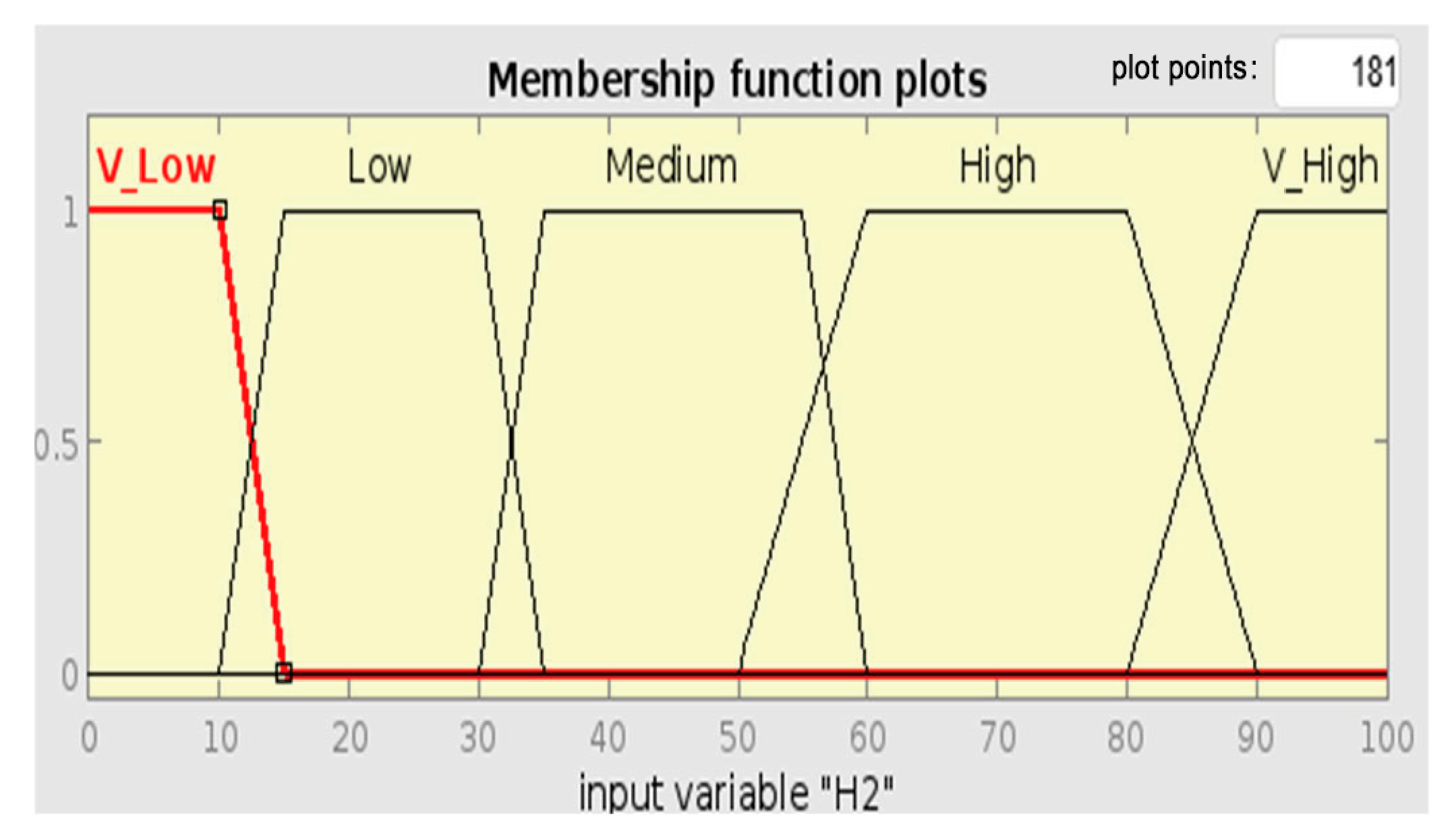

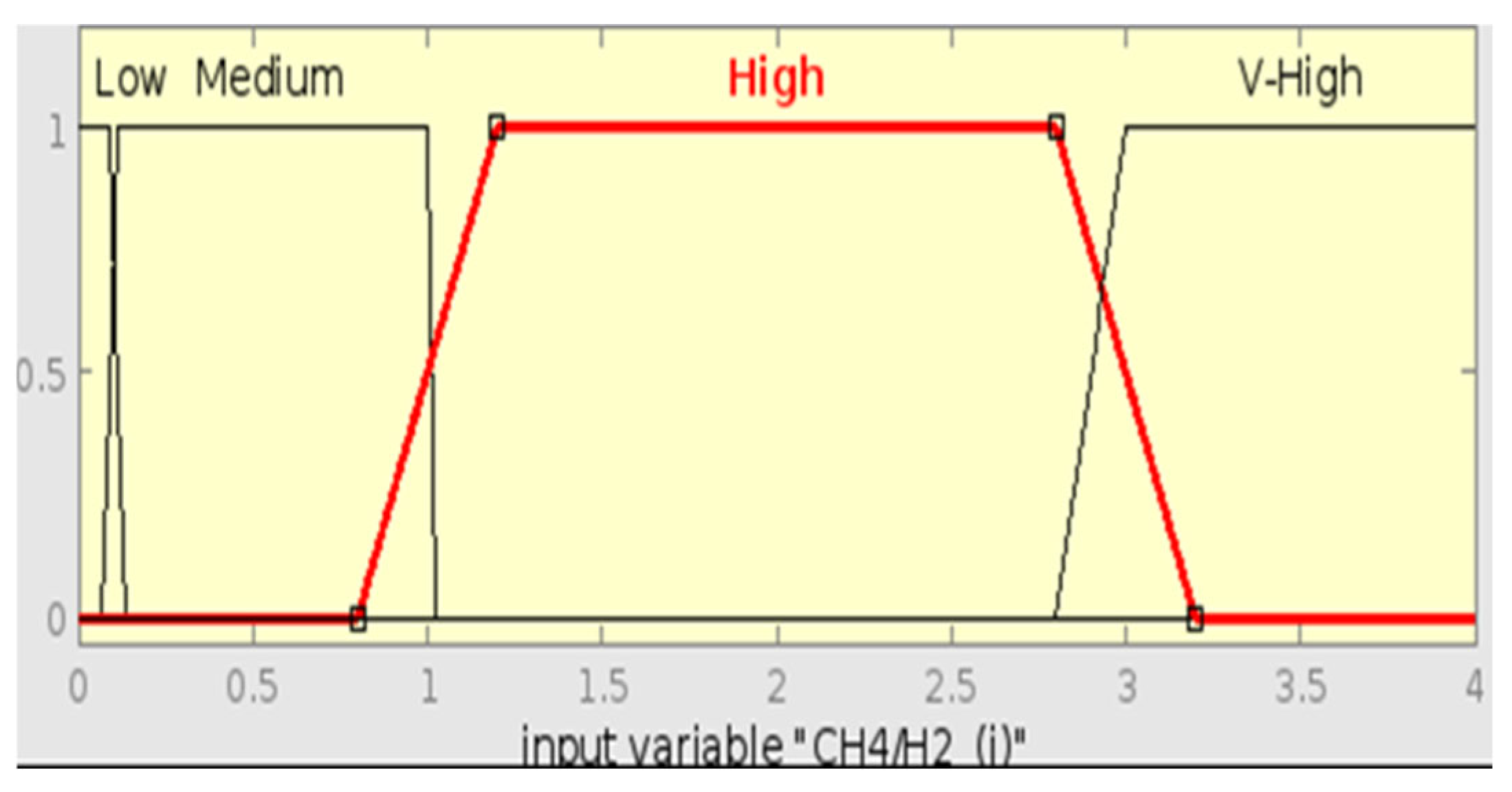

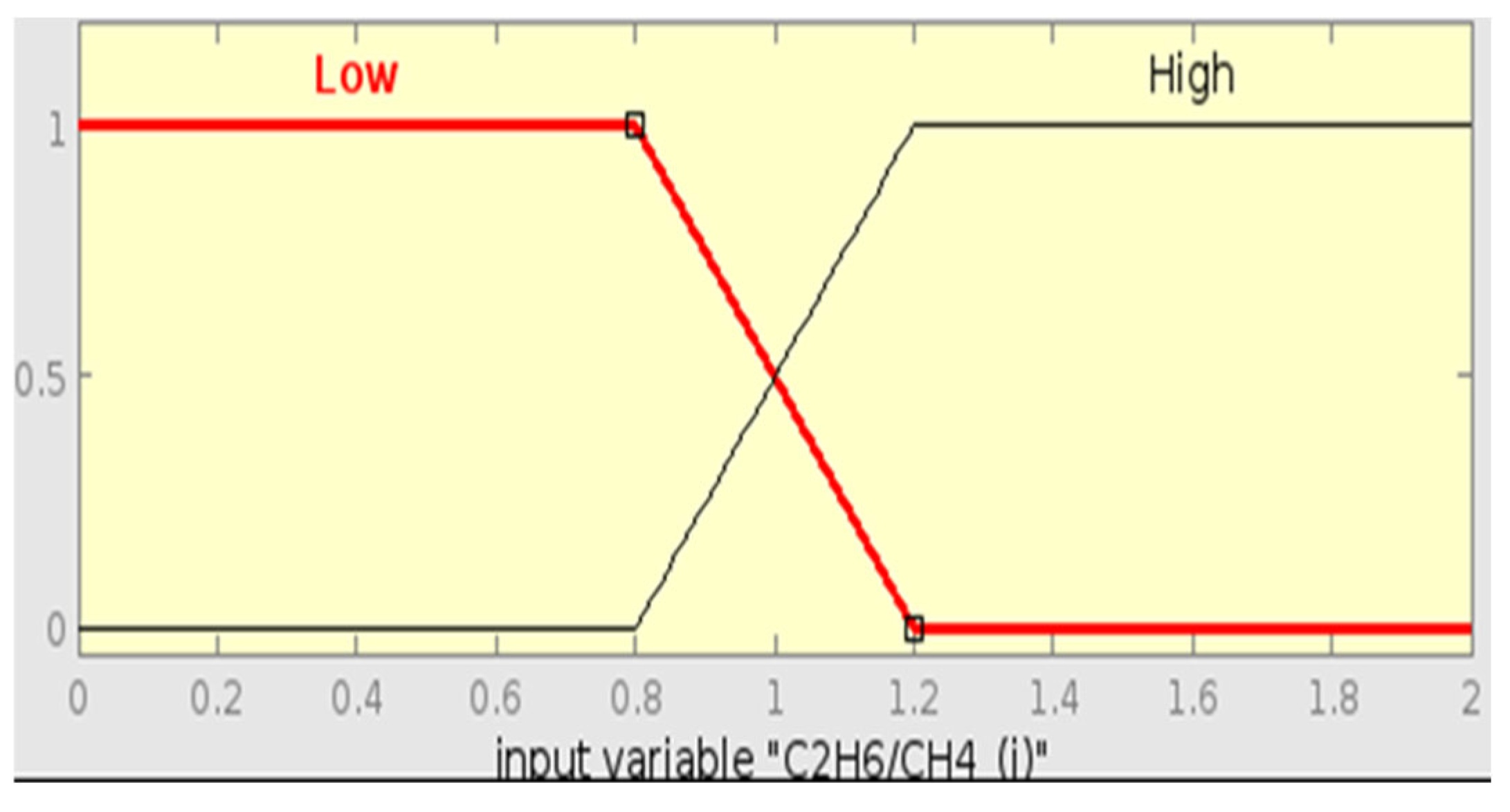

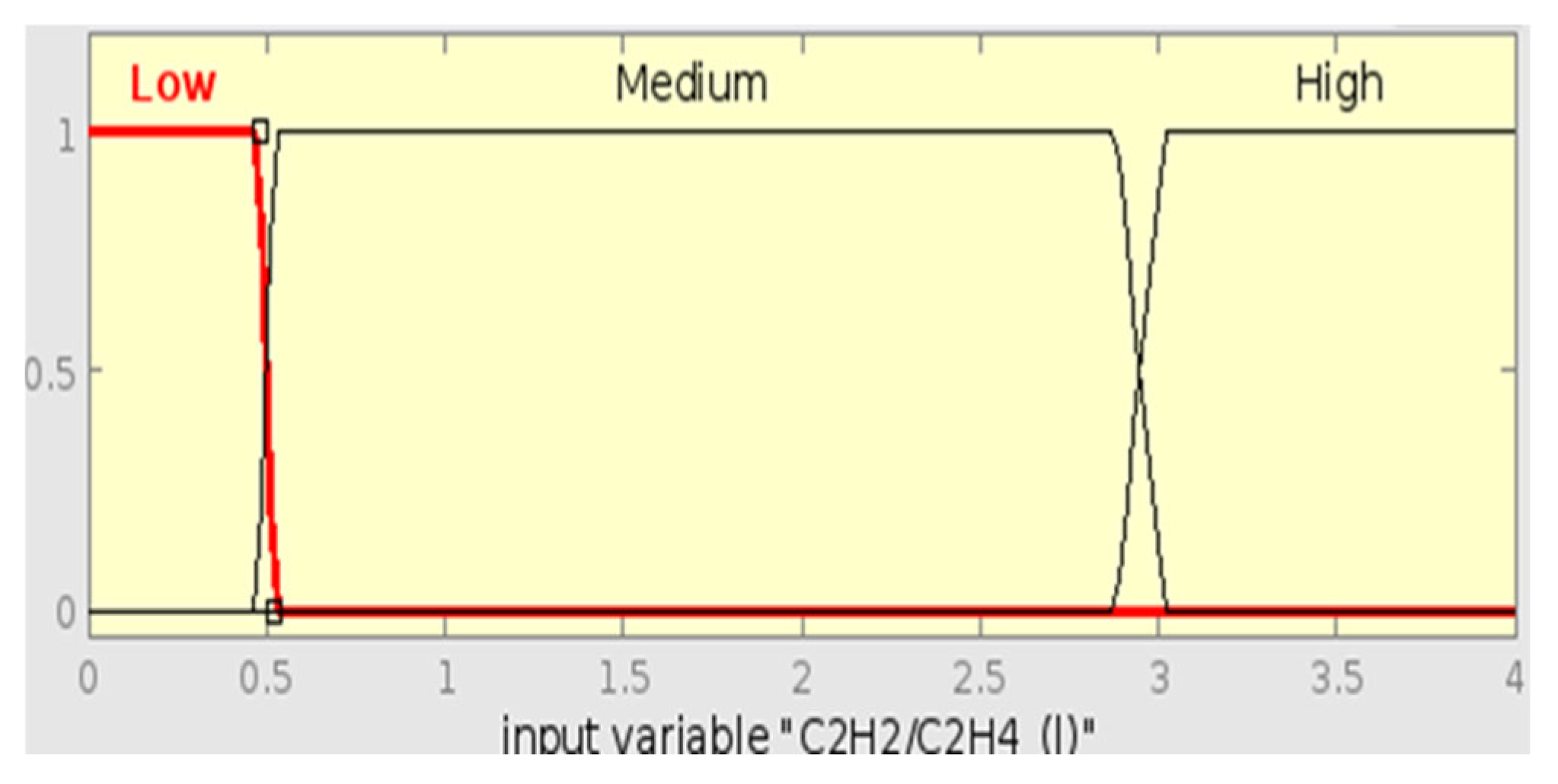

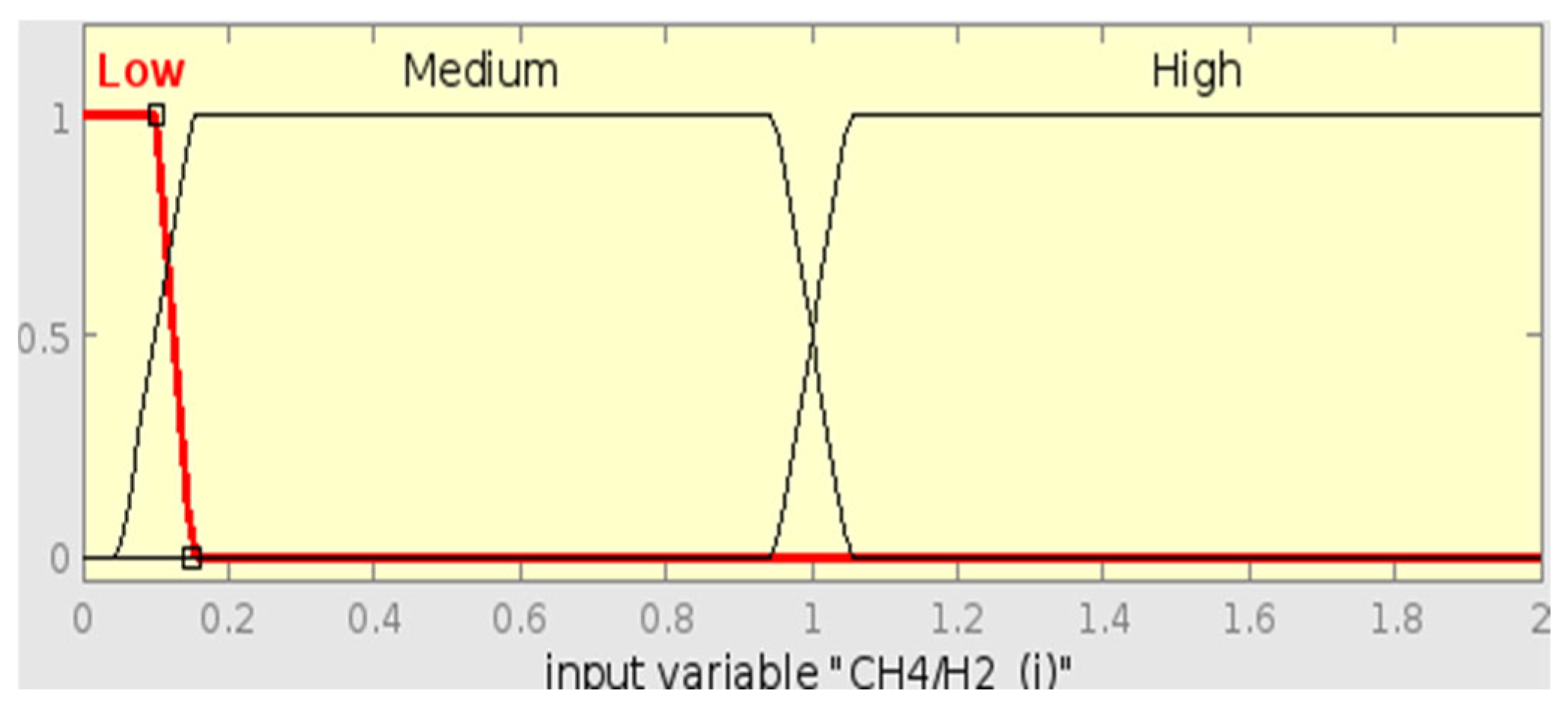

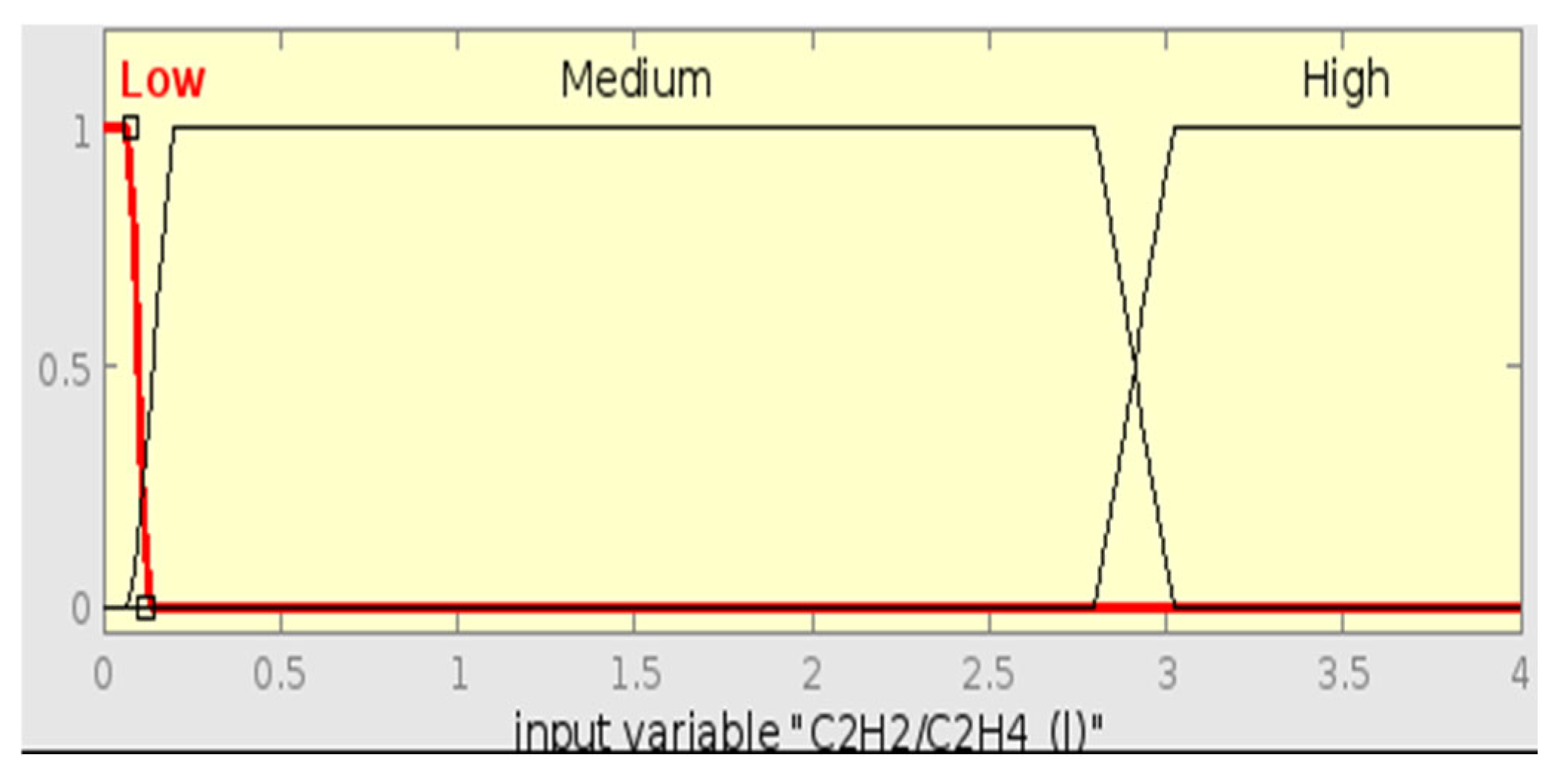

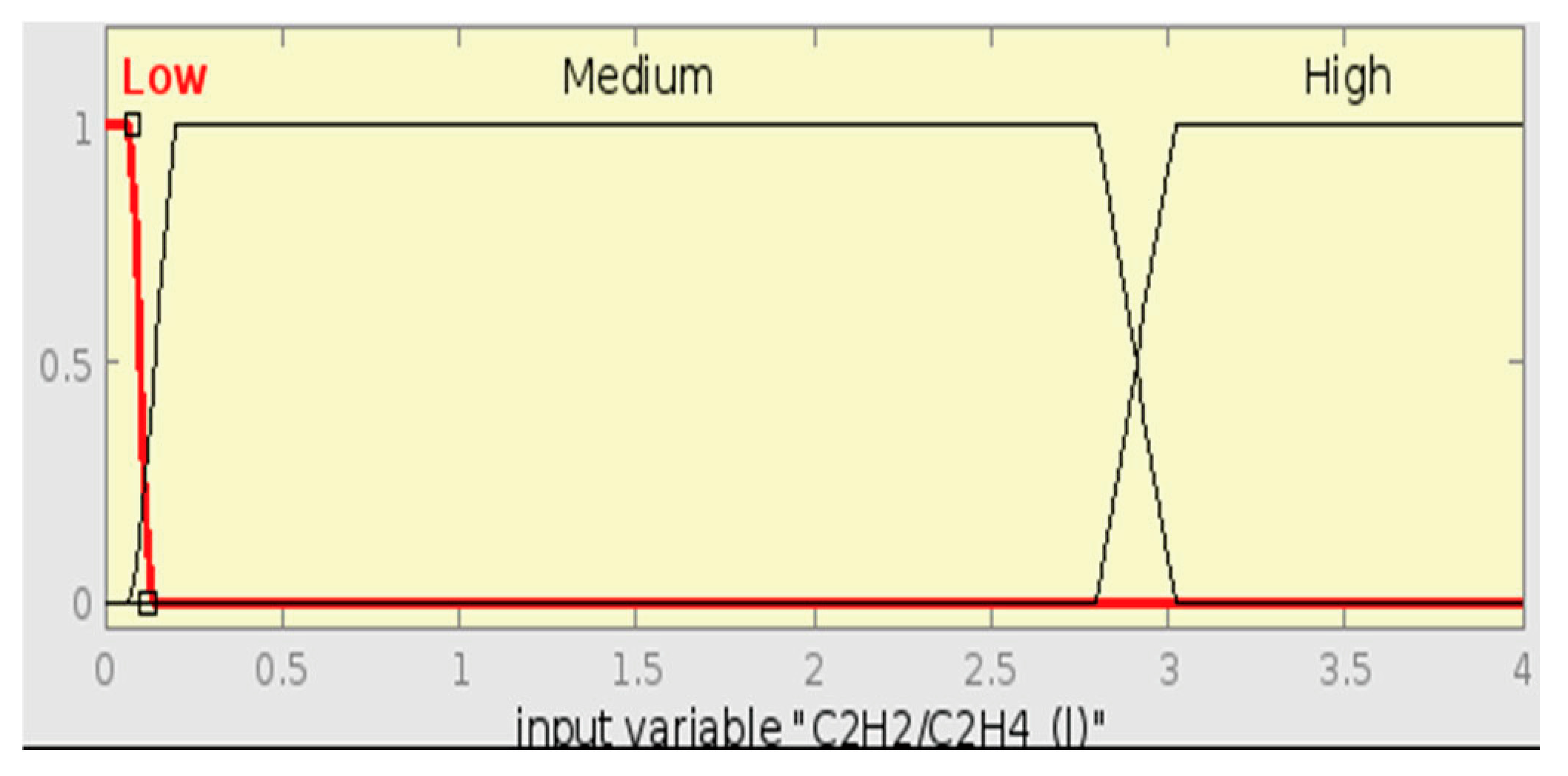

18] standard serves as a foundational guide for interpreting DGA in diagnosing faults within oil-filled electrical equipment. To differentiate among various types of faults, such as partial discharges, electrical discharges, and thermal faults, it lists important gas ratios like CH

4/H

2 and C

2H

2/C

2H

4 and concentration levels. Through the definition of fuzzy logic membership functions based on the threshold of gas concentration, the standard helps to automate fault detection and decrease expert interpretation requirements. Because of this, it is especially useful in assisting diagnostic accuracy and guaranteeing early fault detection of the transformer. Similarly, the IEEE Std C57.104-2019 [

6] is an essential tool to utilize when interpreting transformer oil DGA in order to identify such gas concentration limits that classify conditions of a transformer. It emphasizes the identification of key gases, such as H

2, CH

4, and C

2H

2, which indicate different fault conditions like overheating, arcing, or partial discharge. These concentration limits act as standards for fault severity, facilitating a systematic approach to diagnosing transformer issues. A study by [

19] proposed a method that took into consideration the fault’s severity, and it is made up of five fuzzy logic (FL) models, like gas level FL, gas rate FL, gas level and rate FL, Duval Pentagon Method (DPM) FL, and fault severity FL. But the study only used five gases: H

2, CH

4, C

2H

6, C

2H

4, and C

2H

2, hence not tackling the fault severity of paper Insulation Breakdown, which is also as significant as other faults. In a study by [

20], they enhanced transformer fault diagnosis by integrating Rogers’s ratio and IEC ratio DGA methods with fuzzy logic to address multiple and borderline faults. The fuzzy logic model, developed in MATLAB, interprets gas ratios using membership functions and rules for diagnosing faults like arcing, overheating, and partial discharge. While this approach improves diagnostic accuracy, the model’s effectiveness is constrained by the small sample size and imprecise membership functions. A study by [

21] compared the results of different conventional and intelligent DGA methods and inspections. The techniques are compared based on consistency, precision, and detectability. Duval Pentagon method and Fuzzy Inference System (FIS) based on IEC 60599 [

18] were found to be the best performance in the comparison, hence using a FIS based on Duval Pentagon could yield a new promising, useful, and effective method. In their study, Ref. [

22] developed a Fuzzy Sugeno Inference System (FIS) with 1920 rules for interpreting DGA data to assess power transformer insulating oil quality. Their method took six input gases, such as hydrogen (H

2) and methane (CH

4), into consideration in order to compute Total Dissolved Combustible Gas (TDCG) levels, which categorize transformer oil conditions into Normal, Repair, Danger, or Fault. Limitations of the method are the computational effort required by the large rule base and the absence of carbon dioxide (CO

2) and nitrogen (N

2), which can limit the scope of the diagnosis, although it is 100% accurate when compared to actual DGA testing. Additional work must be performed to optimize rule sets, include other gases, and implement the method across a wider range of transformer types.

For one to improve DGA of power transformer fault diagnosis, the study of [

23] suggests a multi-faceted solution using machine learning. The article suggests improving diagnosis accuracy and reliability through the fusion of traditional methods with Random Forest algorithms. Nevertheless, there is still room for overfitting, and its effectiveness largely depends on large datasets. Different research papers have proceeded to investigate fuzzy logic techniques with a view to increasing the reliability and accuracy of transformer insulation system diagnostics.

Table 1 below compares fuzzy logic-based studies.

Several pieces of work in the literature have proven the potential of AI techniques, particularly fuzzy logic, in complementing DGA to identify transformer faults; yet, there exist gigantic areas for enhancement. The techniques proposed, such as fuzzy logic models and neuro-fuzzy hybrid systems, have proven capable of providing proper diagnoses and reducing reliance on human expertise. However, some of the drawbacks are that it is impossible to integrate critical fault parameters like paper insulation failure and the complexity of other models, making it difficult to implement them, and too time-consuming. The challenges suggest continued research to enhance AI-based DGA methods with features like process simplification, fault detection accuracy, and complete identification of all categories of faults. The need to perform further research in this area as a way of designing even more functional, effective solutions for detecting faults in transformers is also indicated by this.

Other various methods of Artificial Intelligence-based DGA techniques have been proposed over the years, as shown in

Table 2 below. Similarly to fuzzy logic methods, their aim is to improve the effectiveness of DGA and prolong the transformer life.

Even though ANN, RNN, and CVA from the above studies have improved the accuracy and performance of DGA as compared to the traditional methods, fuzzy logic is still a better approach because of its interpretability, handling of uncertainty, simplicity, and adaptability. Fuzzy logic is a better option for real-time DGA-based transformer fault diagnosis because it can represent expert knowledge in an understandable and operationally efficient manner. This is also stated by [

39] as they used both fuzzy logic and ANN together. This is very important because the goal is to make sure that human operators trust and understand the decision-making process. Fuzzy logic, being a better approach, can also be justified by

Table 3 below, which describes the strengths and limitations of various AI-based techniques that are covered in this literature review.

4.1. DGA Traditional Methods

- (a)

Key Gas Method

It is attributed to the quantity of fault gases produced by the insulating oil as the chemical structure breaks down at various temperatures within the transformer [

40]. Every type of fault will give a characteristic set of gases; hence, this method is a sound way of identifying the type of fault.

- (b)

Dornenburg’s Ratio Method

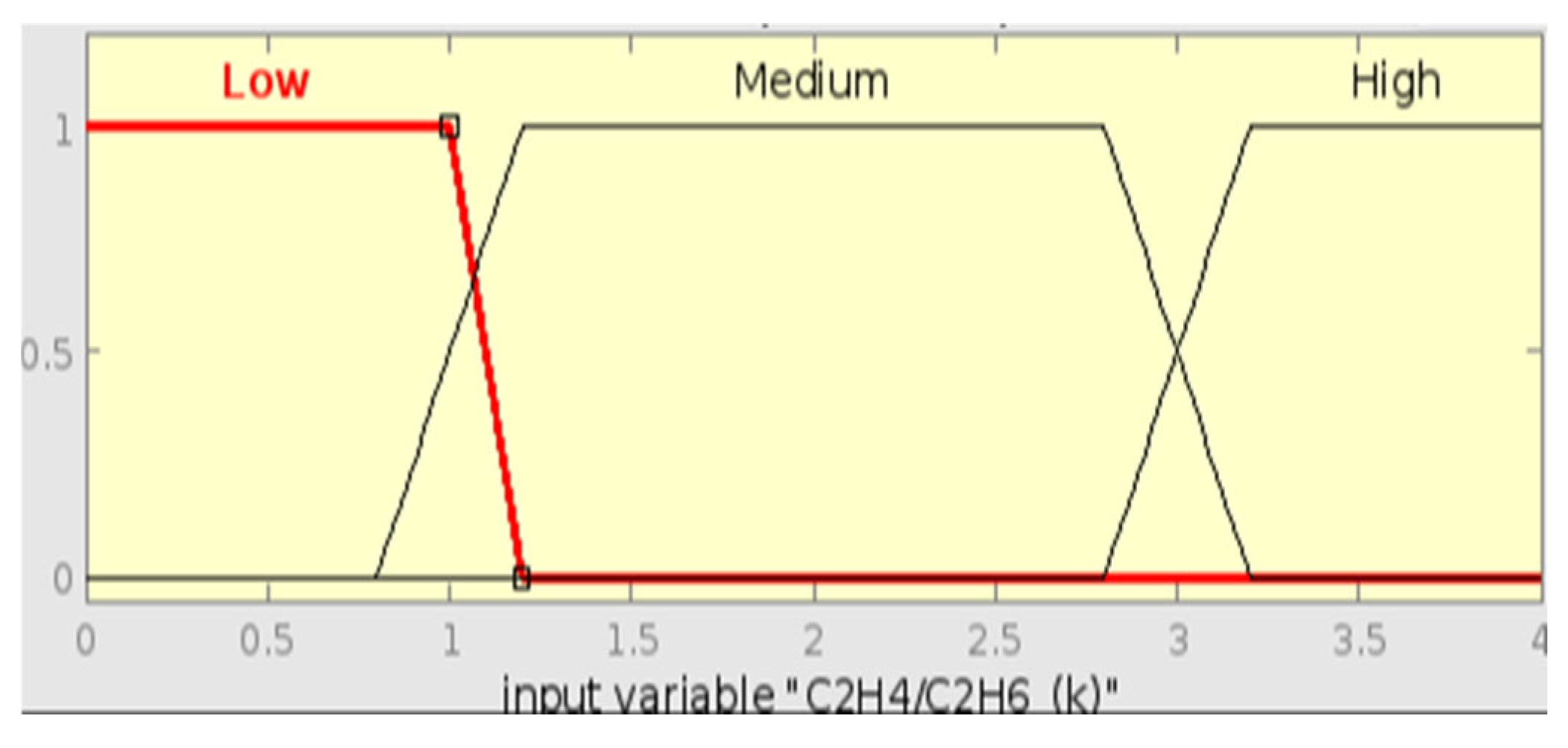

This technique used four different gas ratios, such as CH

4/H

2, C

2H

2/C

2H

4, C

2H

6/C

2H

2, and C

2H

2/CH

4. It detects various fault types, including partial discharge, arcing, and thermal faults, using these gas ratio ranges [

41].

Table 4 below gives the Dornenburg’s ratio ranges and their related faults.

- (c)

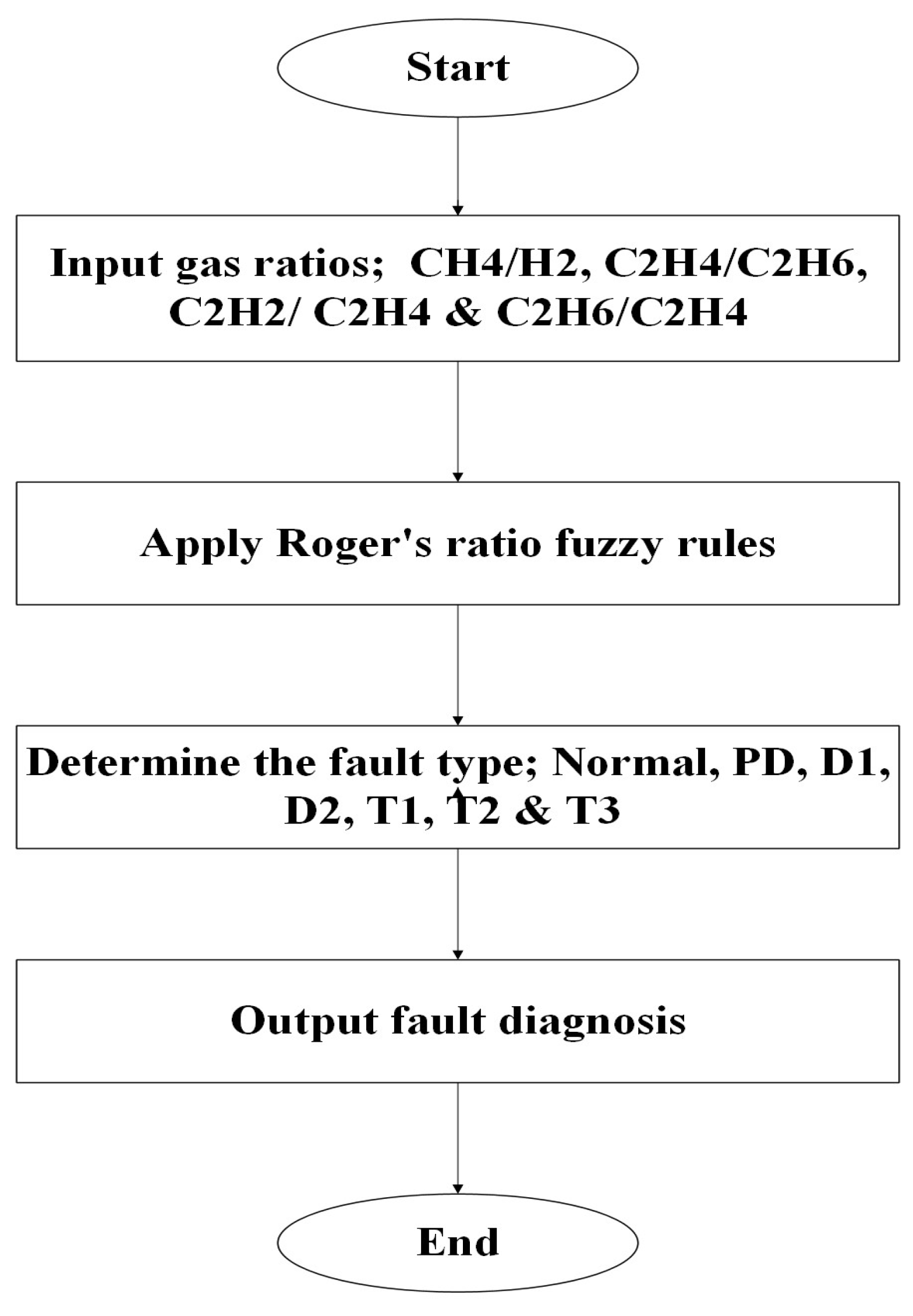

Roger’s Ratio Method

Similarly to Dornenburg’s ratio, this method also identifies the faults by using the ranges of gas ratios in the insulation oil, but it utilizes only the following gas ratios: CH

4/H

2, C

2H

2/C

2H

4, C

2H

4/C

2H

6, and C

2H

6/CH

4 [

42].

- (d)

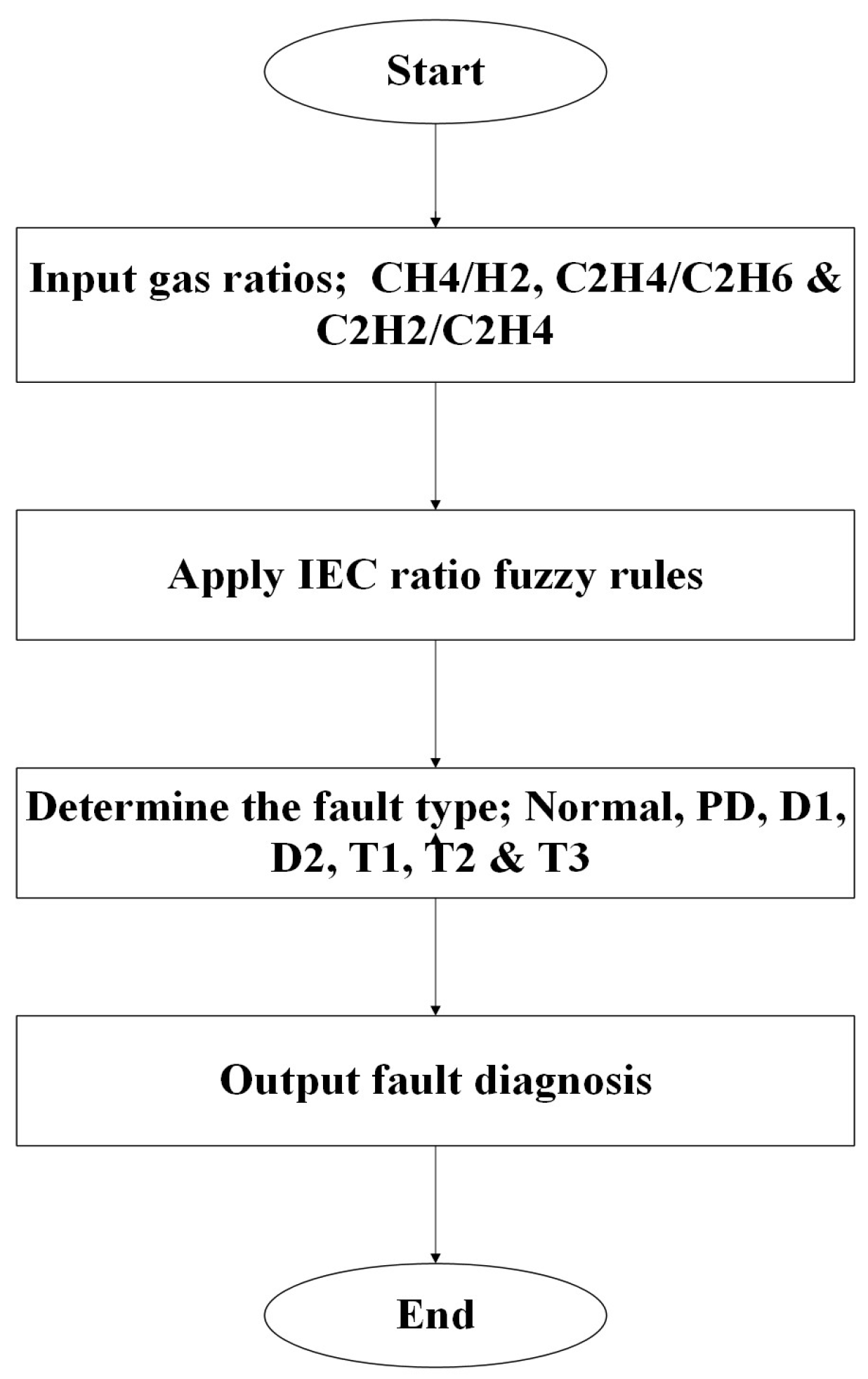

IEC Ration Method

This method also uses three ratios, CH

4/H

2, C

2H

2/C

2H

4, and C

2H

4/C

2H

6, which can be used to diagnose faults like thermal faults ranging from 300 °C to 700 °C [

43].

Table 5 below shows the different fault types and their related ratio ranges.

- (e)

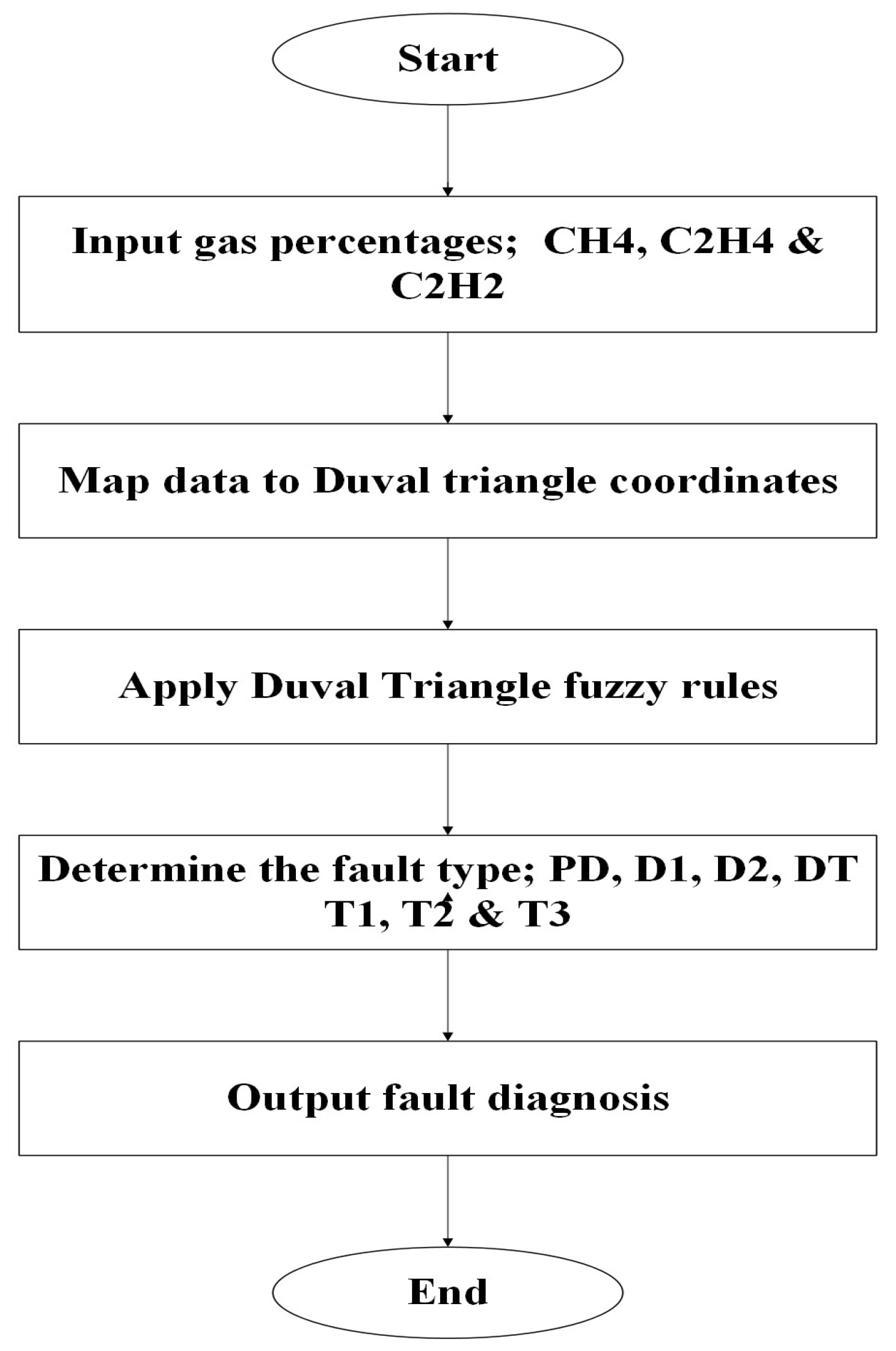

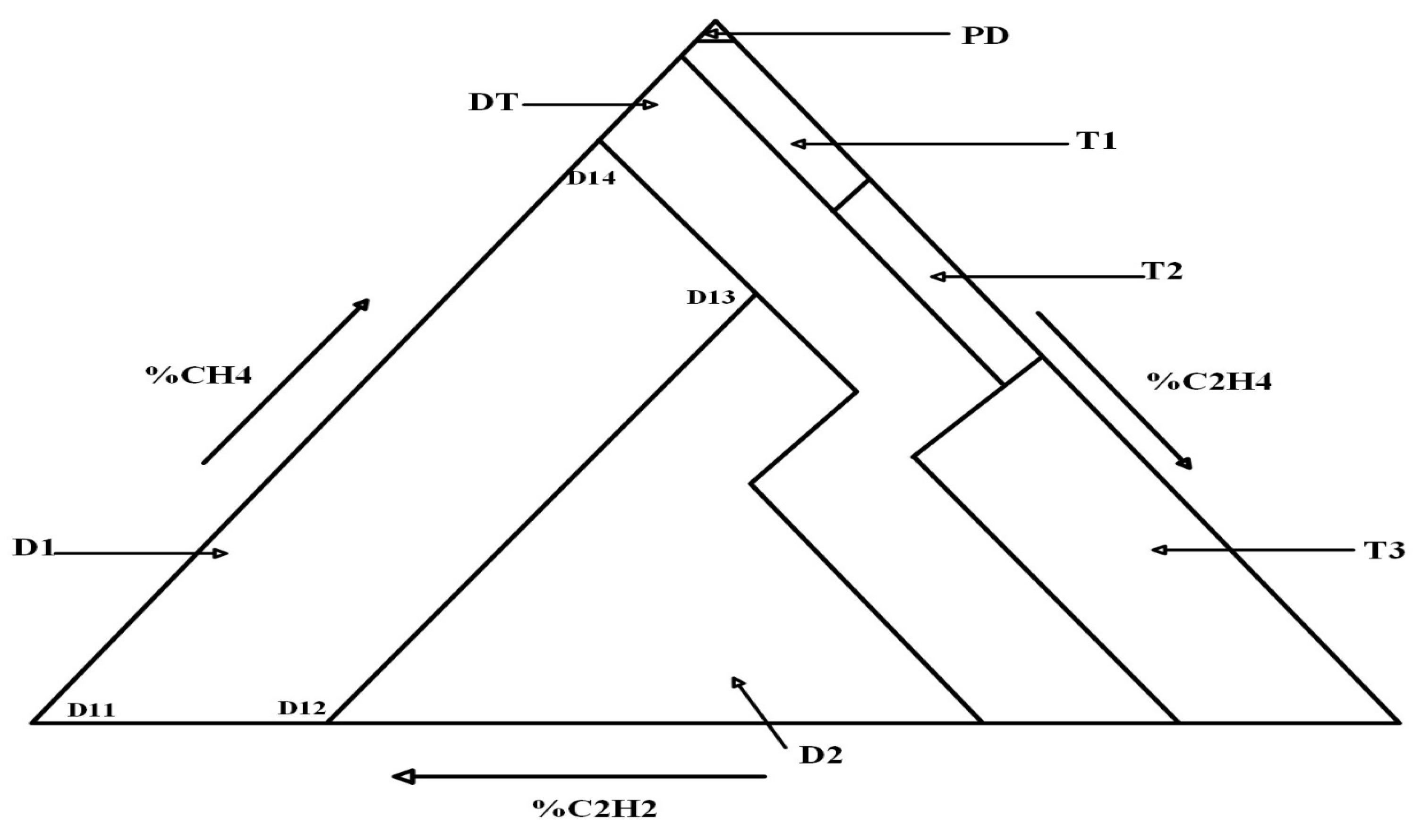

Duval Triangle

The concentrations of CH

4, C

2H

4, and C

2H

2 varied between ppms as a percentage of the sum (CH

4 + C

2H

4 + C

2H

2) of a point (%CH

4, %C

2H

4, %C

2H

2) on a triangular graph that has been divided into fault zones [

44]. The location of the plotted point within the Duval Triangle determines the most probable fault type associated with that specific gas concentration combination. The Duval Triangle categorizes faults into three main types: thermal faults with various temperature ranges, electrical discharges, both low- and high-energy, and partial discharges. These three kinds of faults are subdivided into seven zones, as illustrated by

Figure 1 below [

45].

- (f)

Duval Pentagon

In this method, all five fault gases are listed [

45]. The levels of the five gases are then displayed in the pentagon plot. The arrangement of these gases at the five meetings of Pentagon 1 corresponds to the increasing energy or temperature of the fault producing these gases [

45].

Compared to each other, the traditional DGA methods may have some abilities and weaknesses in terms of fault determination output.

Table 6 below provides a comparative analysis of traditional DGA methods based on IEC/IEEE standards [

18], highlighting their strengths and weaknesses in diagnosing transformer faults. While these methods have been widely adopted for a long time due to their simplicity and ease of implementation, they often face challenges in accurately detecting complex fault conditions, such as low-energy discharges or partial discharge faults. So, due to various weaknesses when using traditional DGA methods, there is a need to use multiple methods simultaneously for them to make up for one another’s disadvantages, then analyze and decide based on the cumulative results. This process is going to be time-consuming and needs experienced personnel for the decision-making, hence not making the interpretation any easier.

The comparison showcases the basic trade-offs between accuracy, detection capability, and consistency across various fault types, underscoring the need for improvements or integration with more advanced AI techniques like fuzzy logic systems.

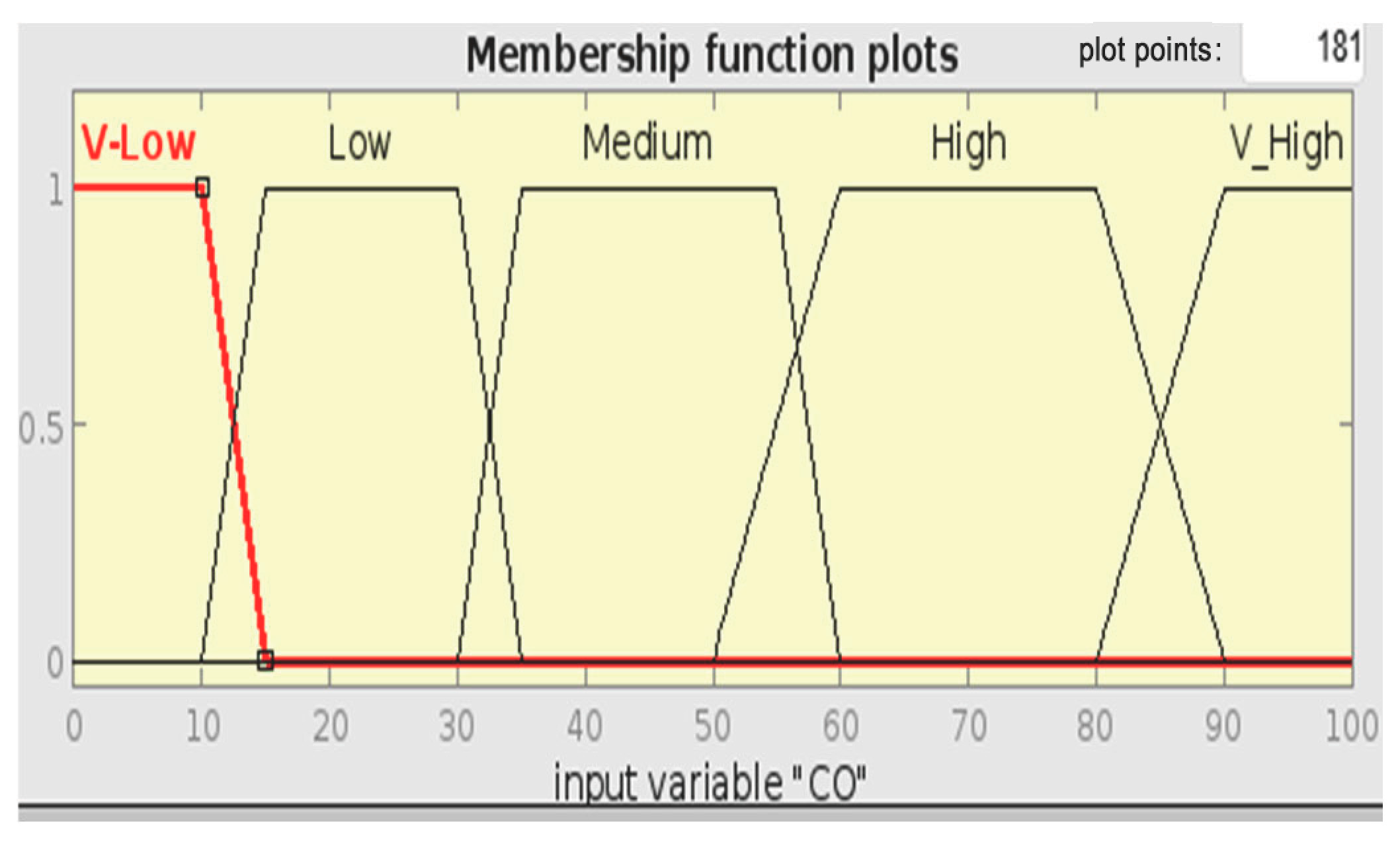

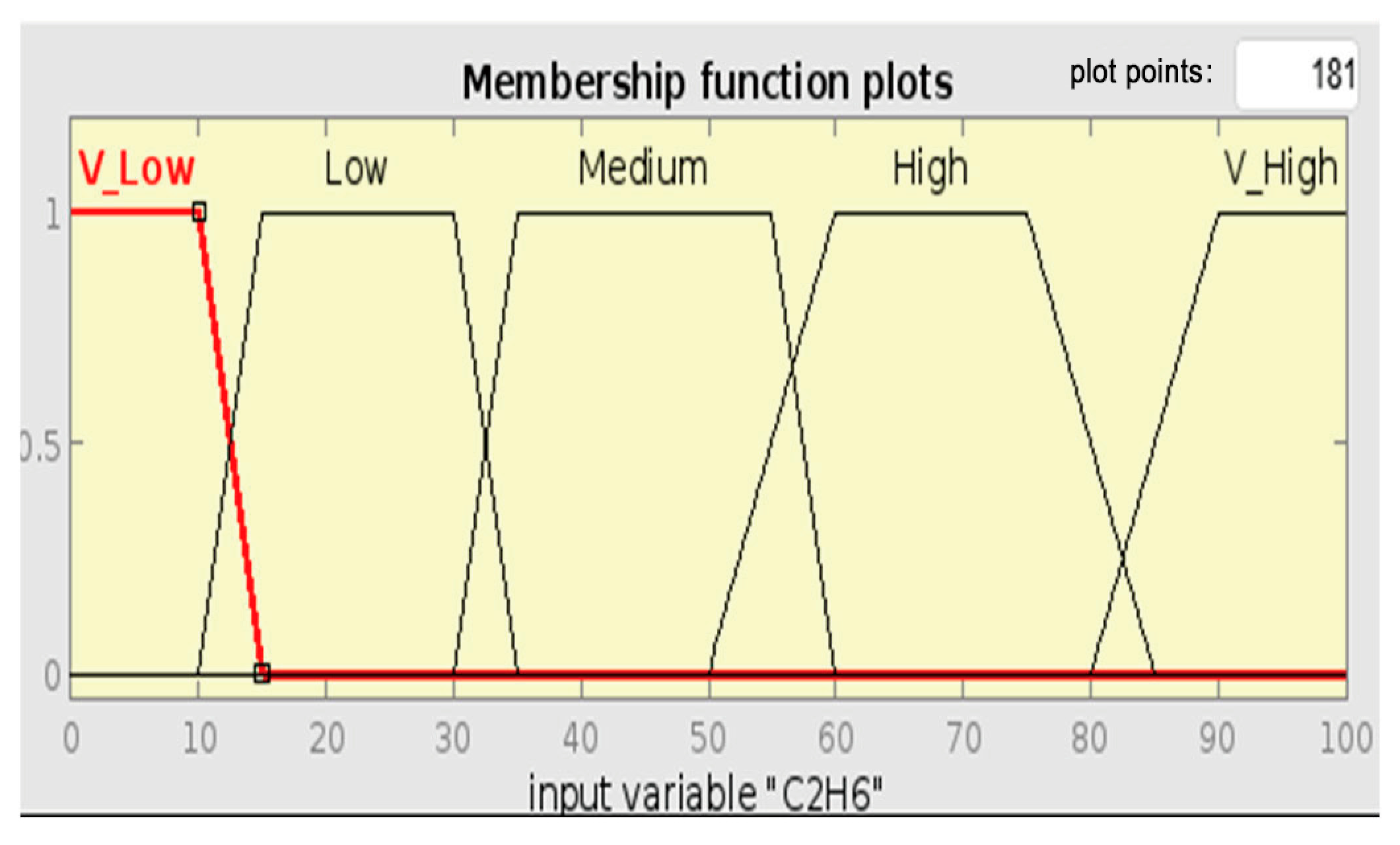

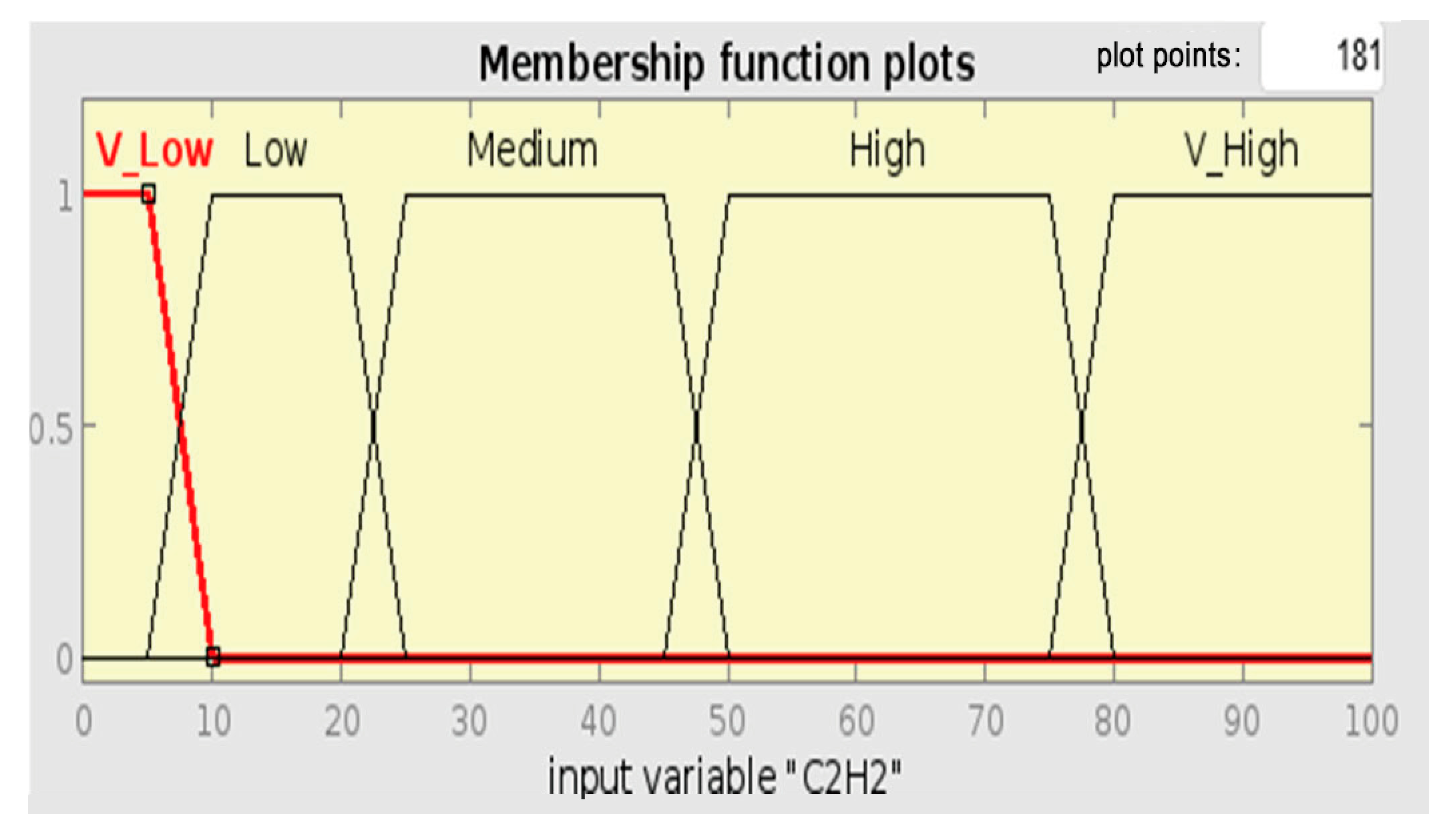

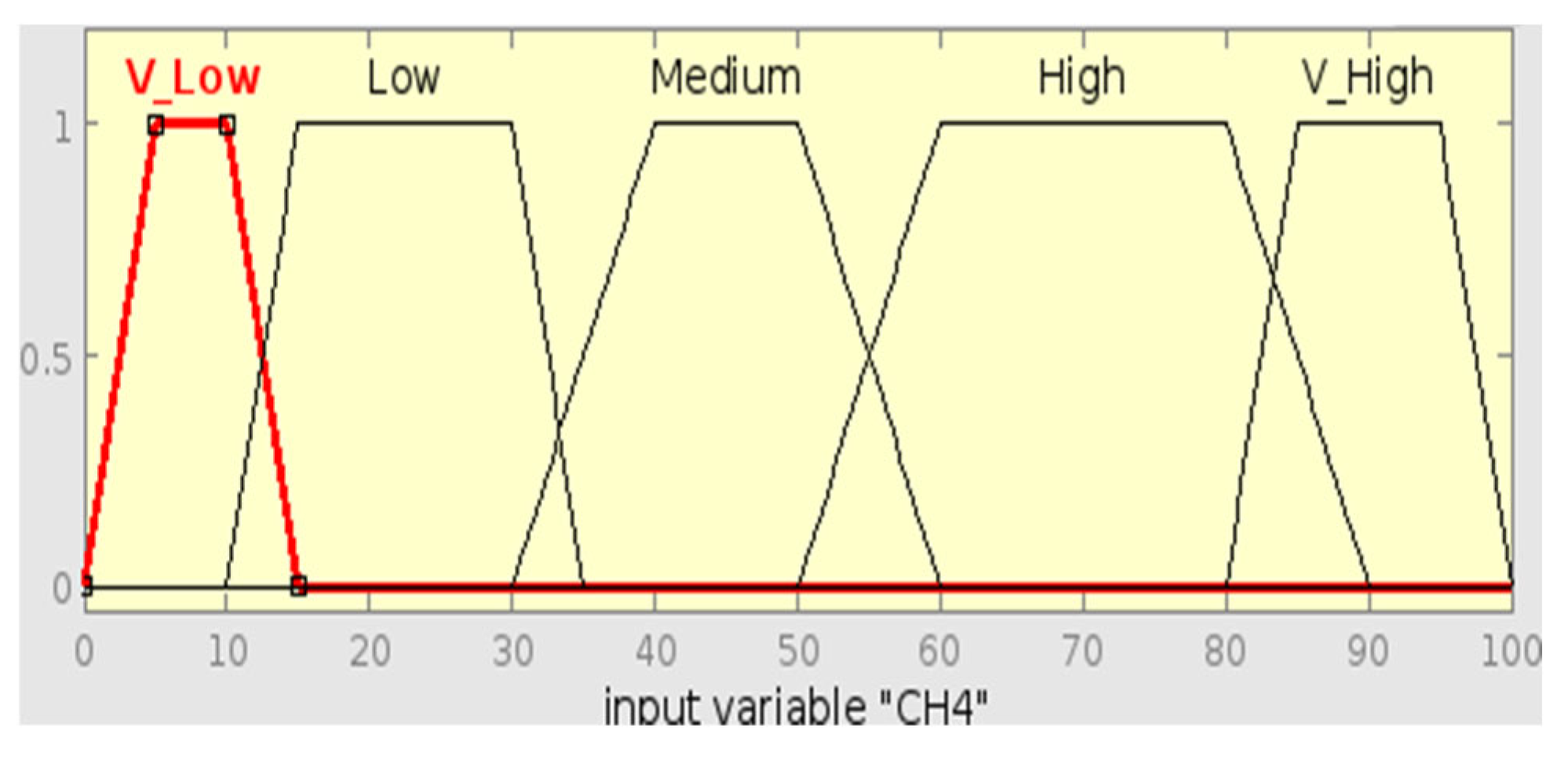

4.2. Fuzzy Logic Implementation

Fuzzy logic is a way of relating naturally analog processes to a continuous range of values, to a computer that would prefer things to be crisply defined, discrete numeric values. The output of a fuzzy logic system is derived from the fuzzifications of the inputs and outputs using the appropriate membership functions [

46].

The core processes involved in a fuzzy logic control system:

- (a)

Fuzzification: It is the process of converting classical or crisp data into fuzzy data that can be processed by a fuzzy logic system [

46]. This is performed using membership functions (MFs), which are mathematical functions that map each crisp input value to a degree of membership in a fuzzy set.

- (b)

Fuzzy inference process (FIS): This is where the actual decision-making occurs in a fuzzy logic system. This process combines fuzzified inputs with a set of fuzzy rules to derive fuzzy outputs. Fuzzy rules are represented by a sequence of the form IF-THEN, leading to algorithms describing what action or output should be taken in terms of the currently observed inputs and outputs [

46].

- (c)

Defuzzification: This is where the fuzzy output from the inference step is converted into a crisp value, which can be utilized to operate real-world devices or make decisions [

46]. Three of the defuzzification methods most commonly utilized are the mean of maximum method, the center of gravity method, and the height method.

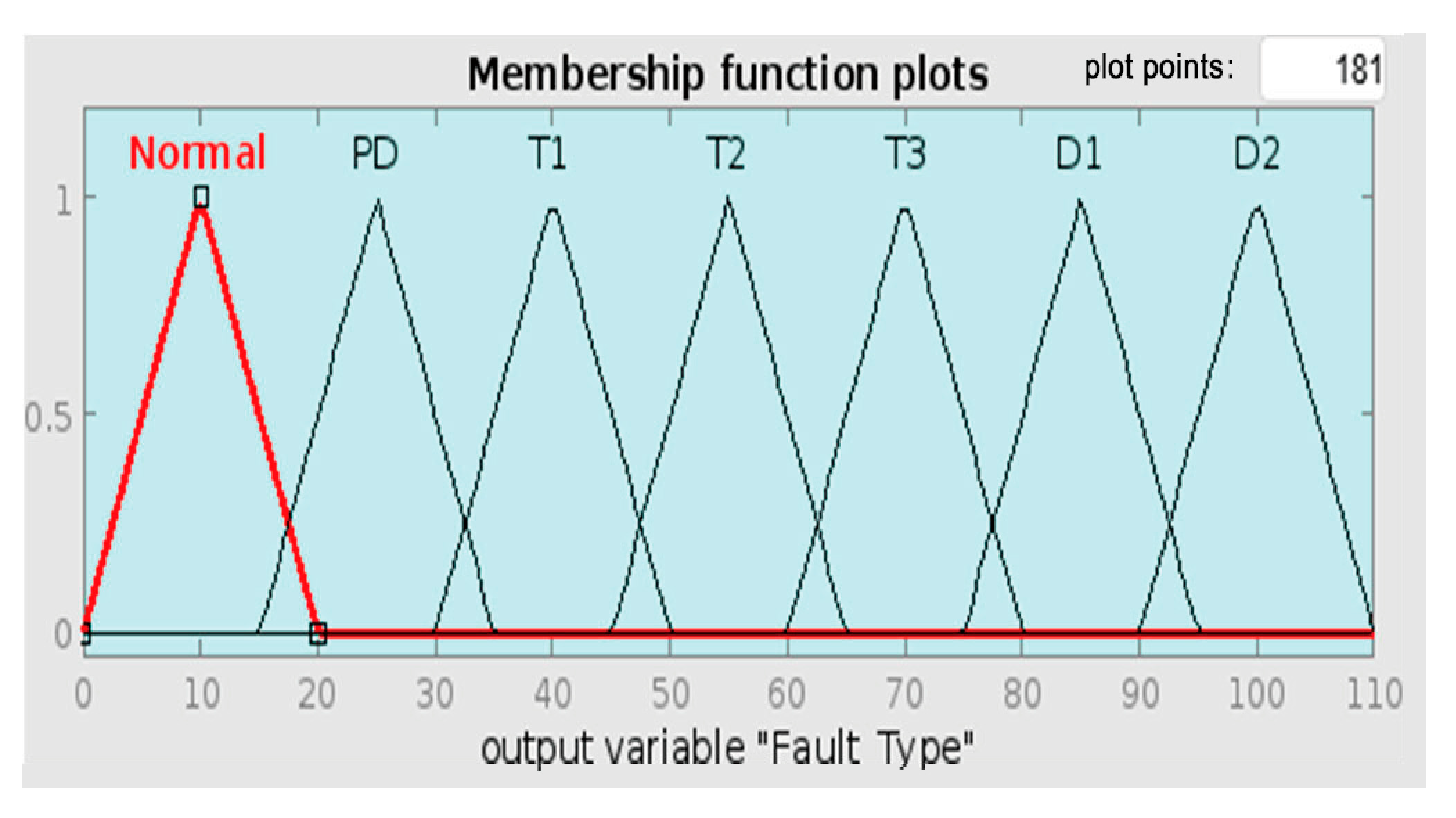

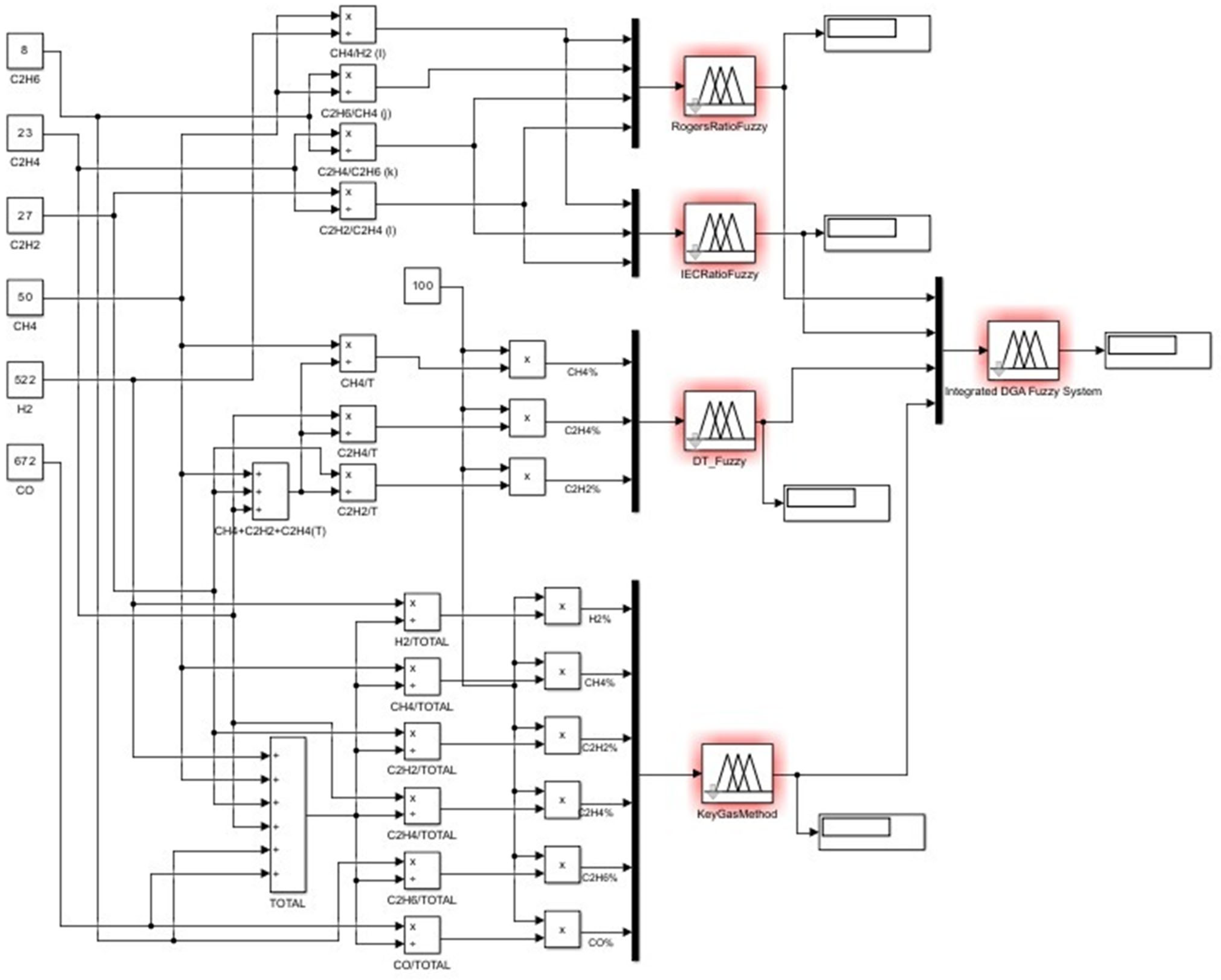

6. Results and Discussion

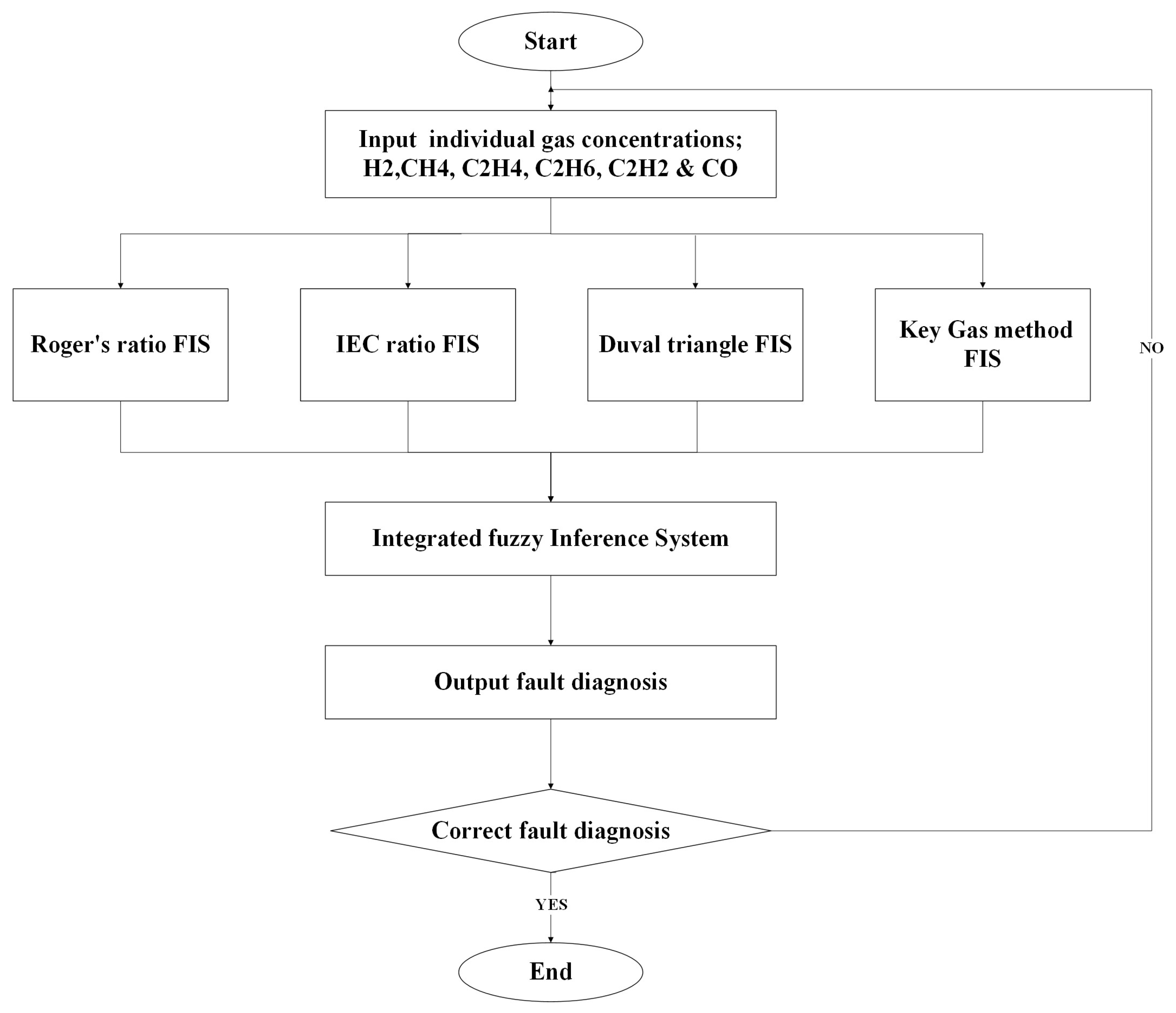

Taking some samples of gas concentrations of the seven key gases. The oil samples used are of known fault types collected from high voltage transformers. The concentrations were analyzed using the four developed individual fuzzy logic models, whose outputs are collectively analyzed by the integrated DGA fuzzy logic system for the final decision on the fault diagnosis. For instance, the following concentrations in ppm were used for the system, and

Table 15 below displays the results.

Table 16 below is a comparison table of diagnostic results from each individual fuzzy logic system with the output result of the integrated fuzzy logic system proposed. For each oil sample, the known fault is noted and compared with each individual method’s prediction. This table shows the performance of each stand-alone system in identifying individual transformer faults, and more importantly, shows the effectiveness of the integrated system in compiling these results into a more robust and consistent final diagnosis. The integrated method exploits the strengths of all four approaches to synthesize discordant results and maximize the overall accuracy of fault identification, as shown by its agreement with known fault types on a wide range of samples.

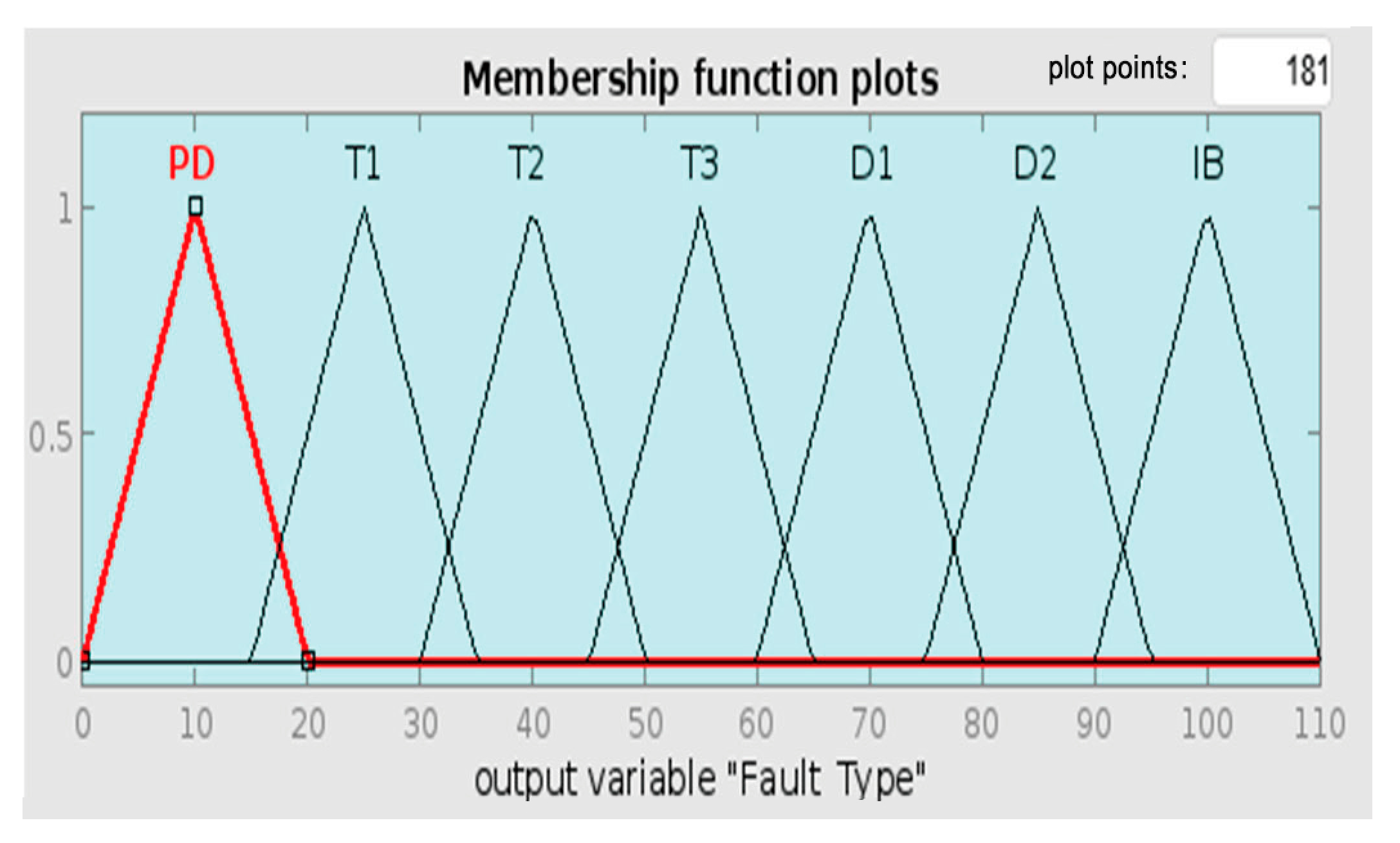

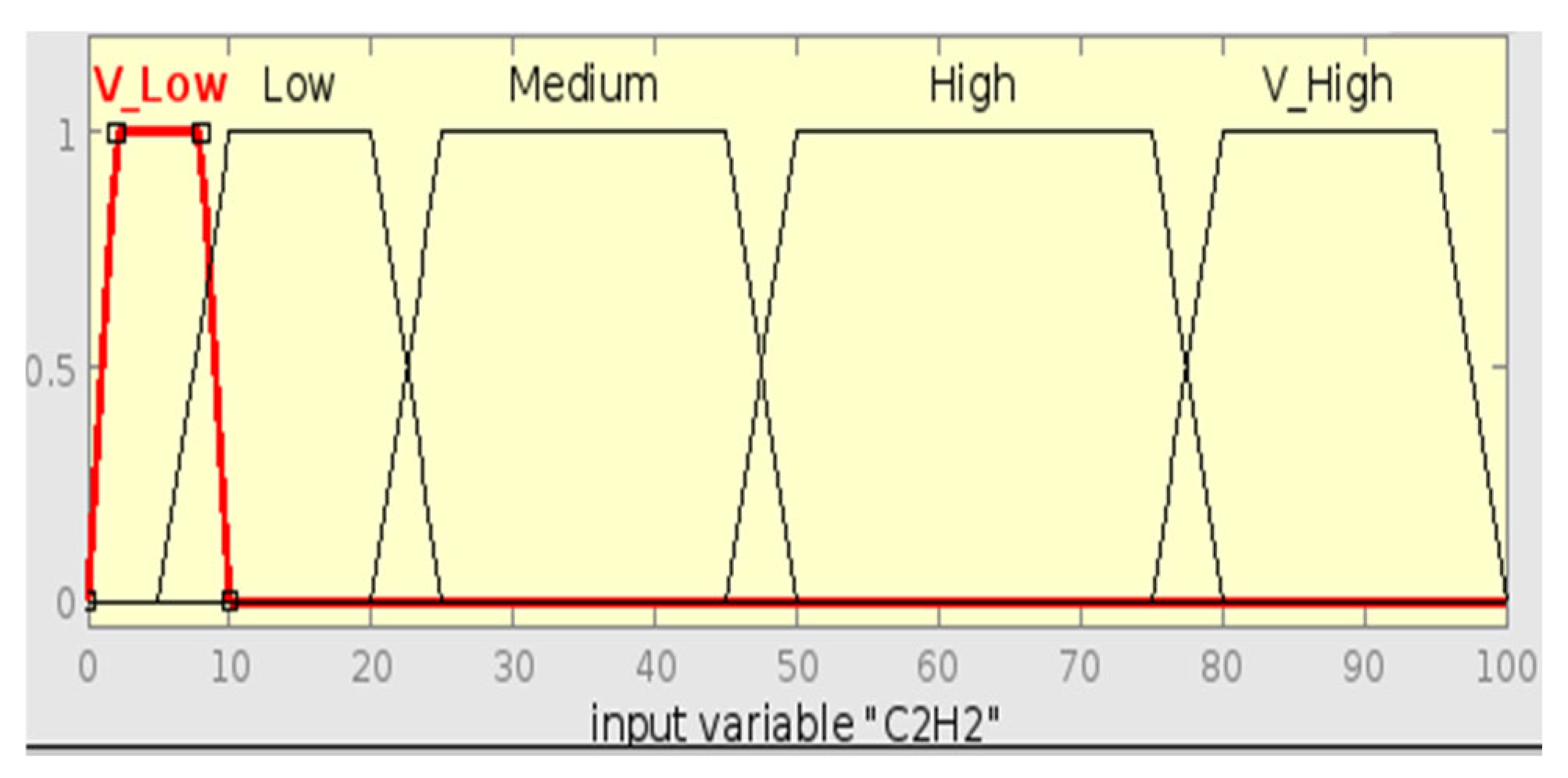

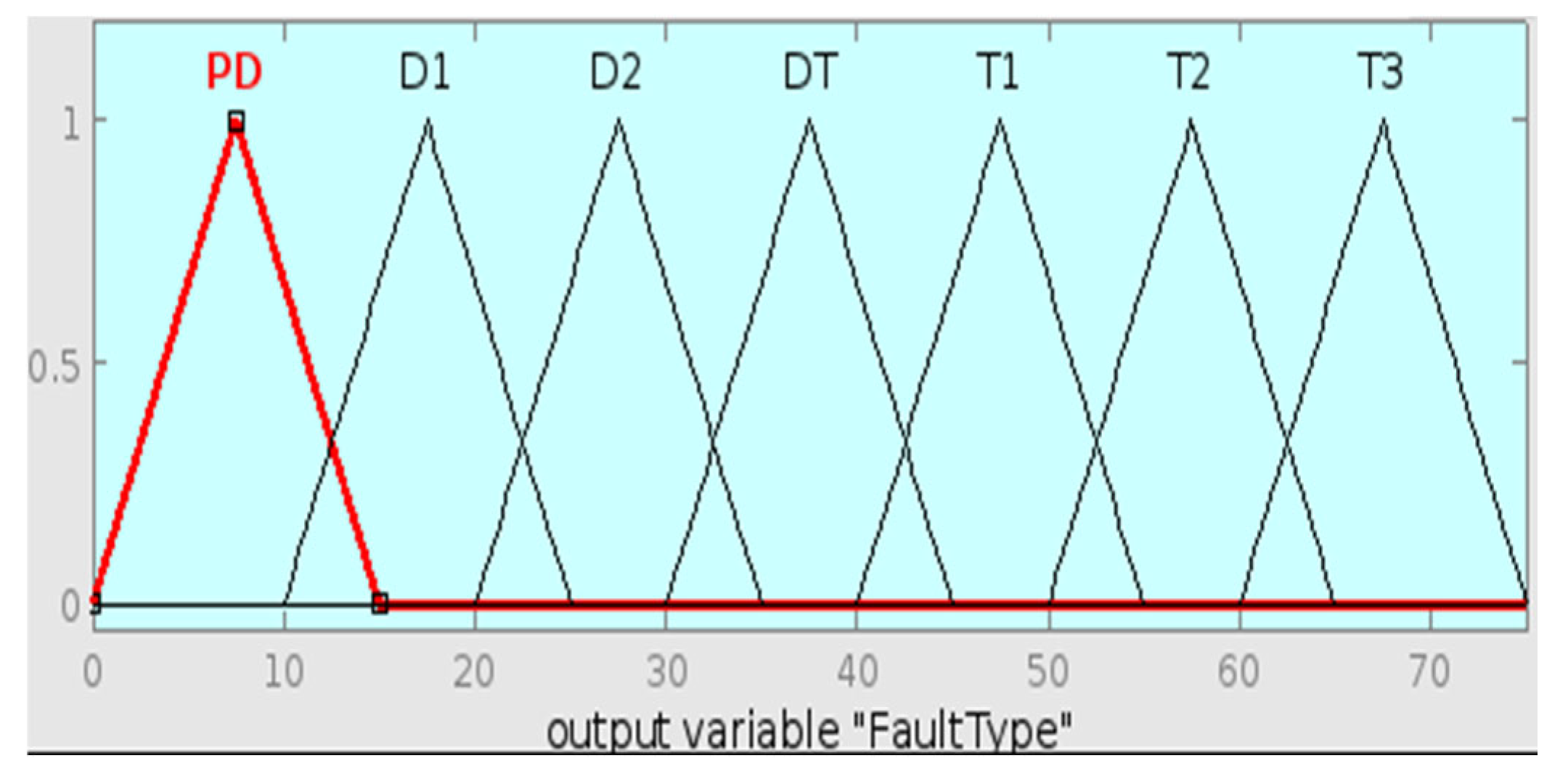

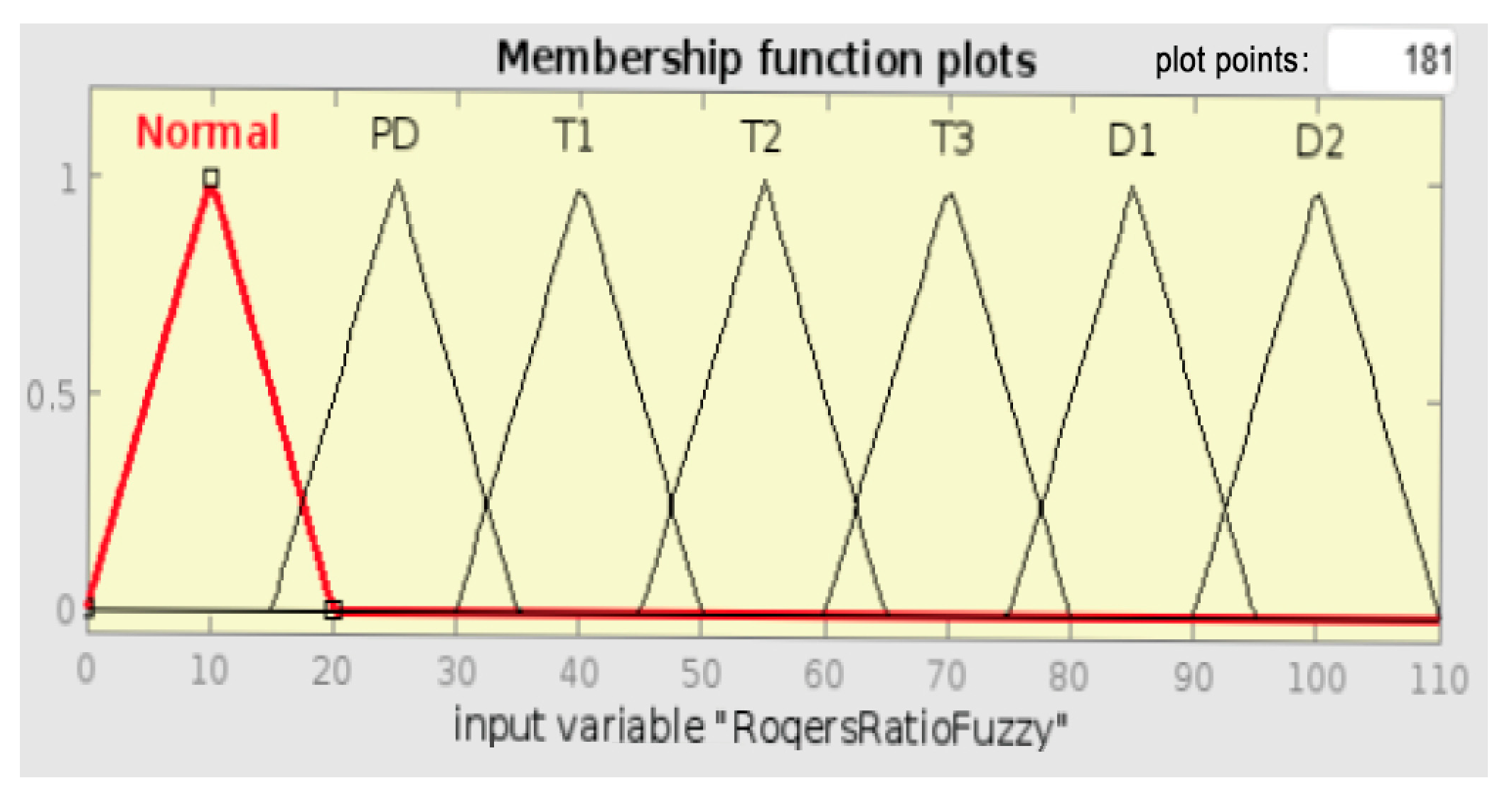

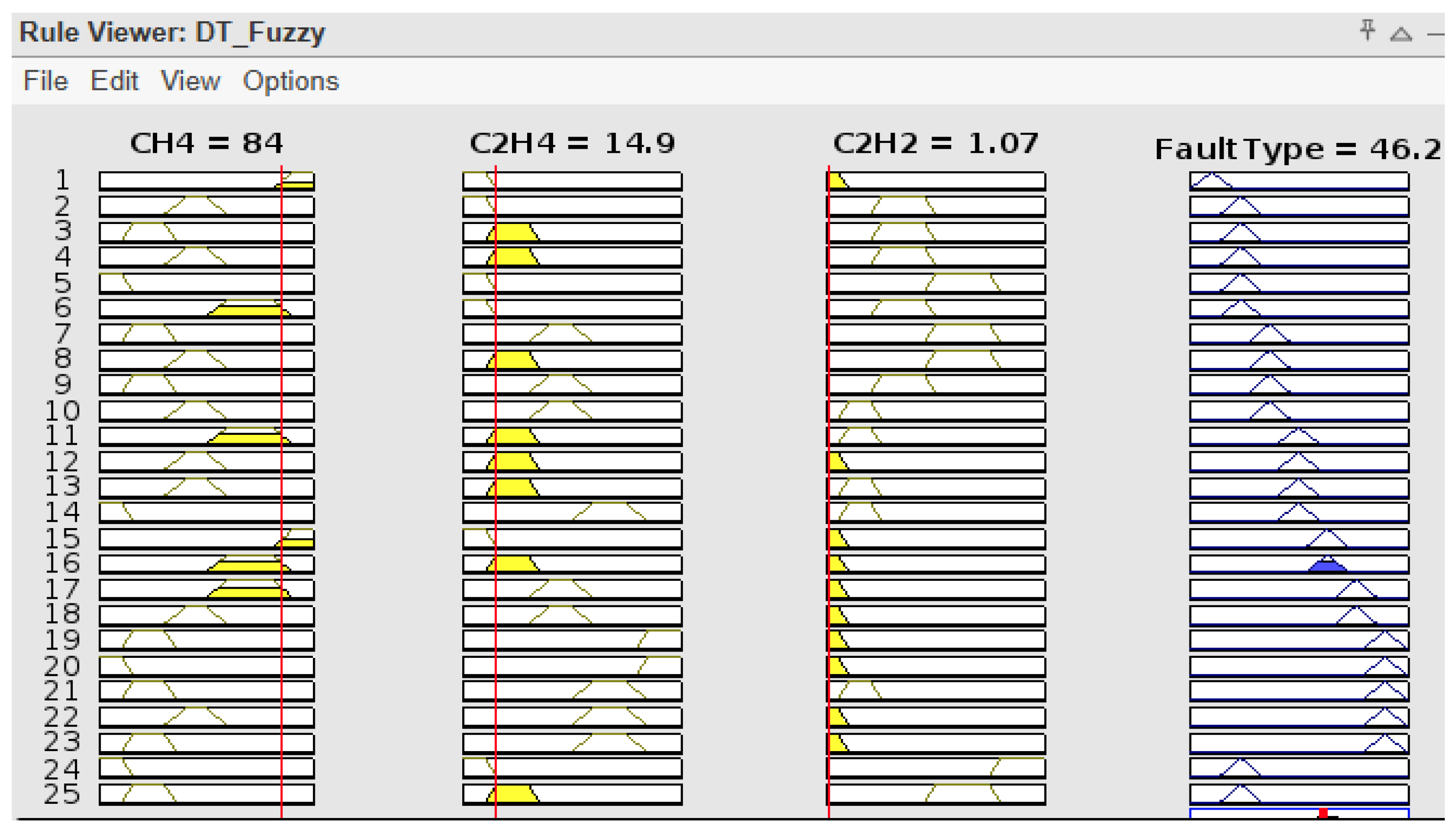

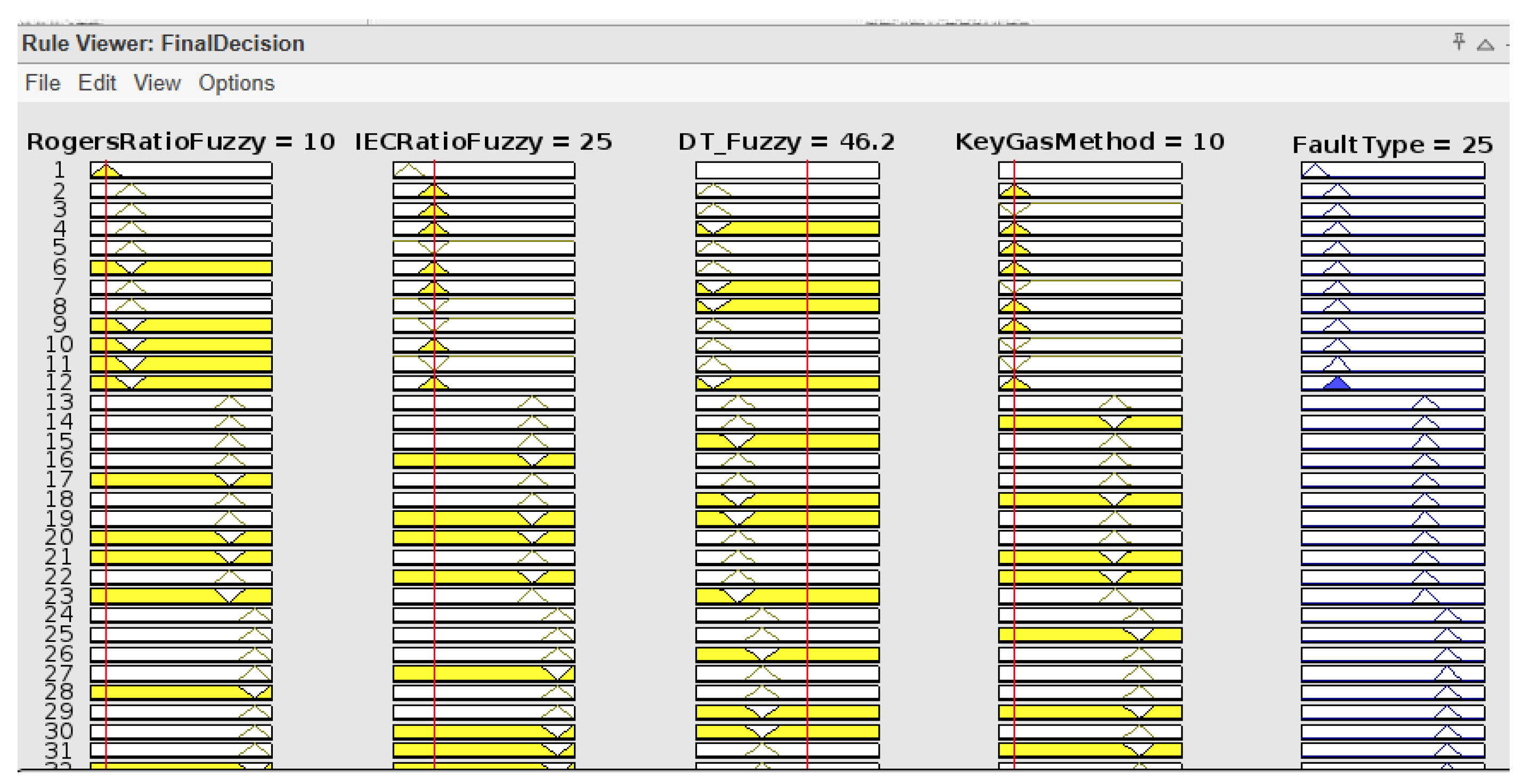

The following figures provide a detailed example of how each individual fuzzy logic system interprets the same oil sample (Sample 15) shown in Rule Viewer and how their outputs compare to the known fault. In this case, the actual fault is PD.

The actual discharge fault was not detected by the Rogers Ratio system, which mistakenly reported it as normal. The Duval Triangle system reported T1 (thermal fault), i.e., a thermal fault, because it is highly sensitive to ethylene concentration, whereas the IEC ratio method reported it as PD correctly. The high hydrogen concentration agreed with the correct report of PD by the Key Gas Method. Finally, the integrated fuzzy logic system demonstrated its higher ability to settle on conflicting diagnoses and agreed with the actual type of fault by appropriately establishing PD through fusing the individual outputs. This indicates that the integrated method is stronger and more dependable than any single technique in determining a diagnosis that is more accurate and reliable.

Figure 34 below shows Sample 15’s fuzzy rule assessment using Roger’s Ratio method. The Rule Viewer does not closely match any specific fault condition through the input gas ratios, hence the “Normal” diagnosis. This is an undesirable result, as Sample 15’s known fault is Partial Discharge (PD), which is represented membership function with a range of [15, 25, 35]. The Roger’s Ratio method cannot detect the actual fault due to sensitivity issues. The method might not be sensitive enough to detect PD conditions when gas ratios are near the boundary of defined ranges. It may also be due to rule limitations; the membership functions for PD-related gas ratios might overlap with normal conditions, resulting in a misclassification.

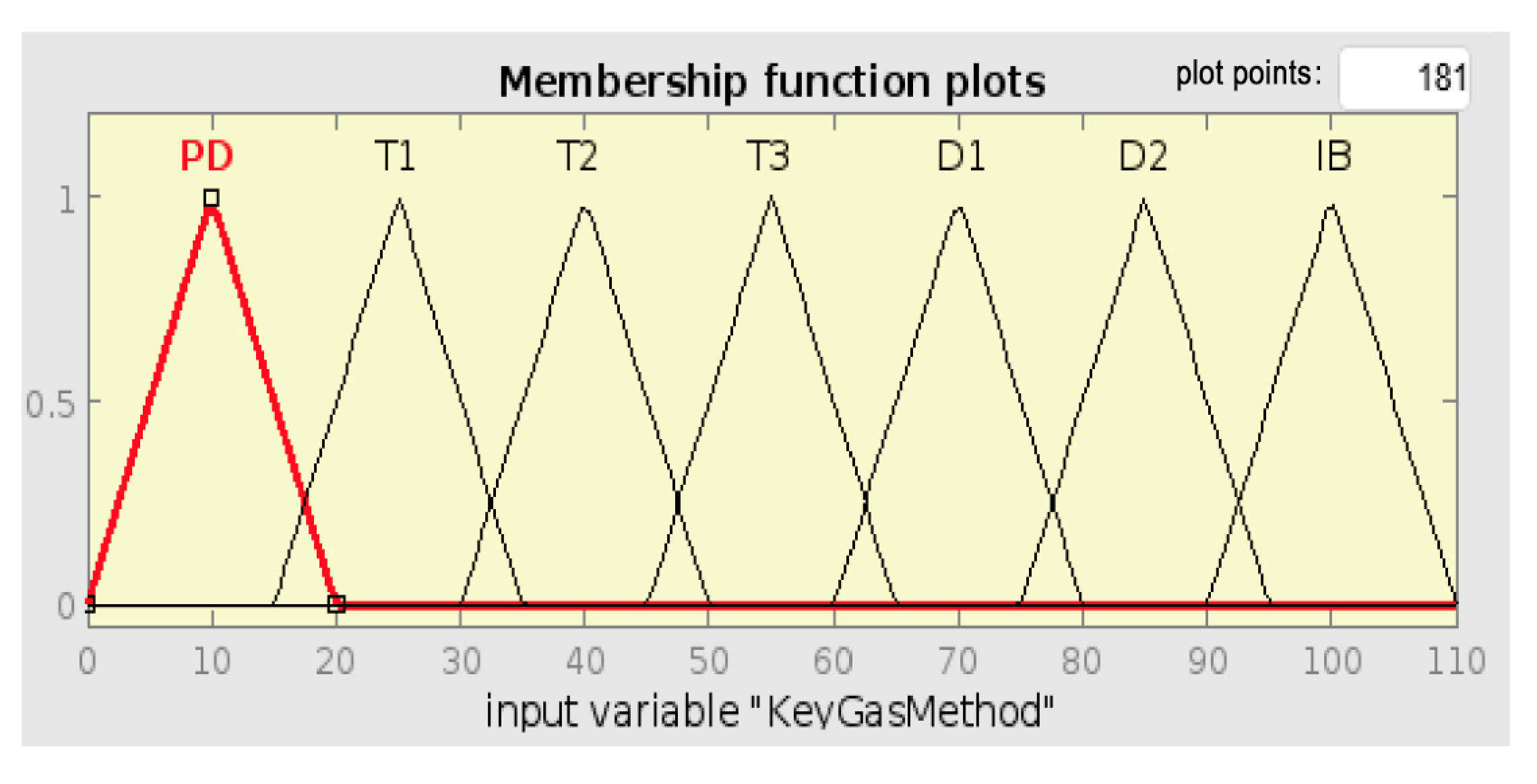

Figure 35 below shows the same sample diagnosed by the Key Gas Method. The FIS correctly diagnoses the fault to be PD. This result is justified by

Figure 10, which shows the membership function PD’s range of [0, 10, 20]. The Key Gas Method is better at detecting PD as it specifically looks at high H

2 concentrations, which are typical of PD faults. This method alone may not be reliable for other fault conditions, as observed from previous test examples.

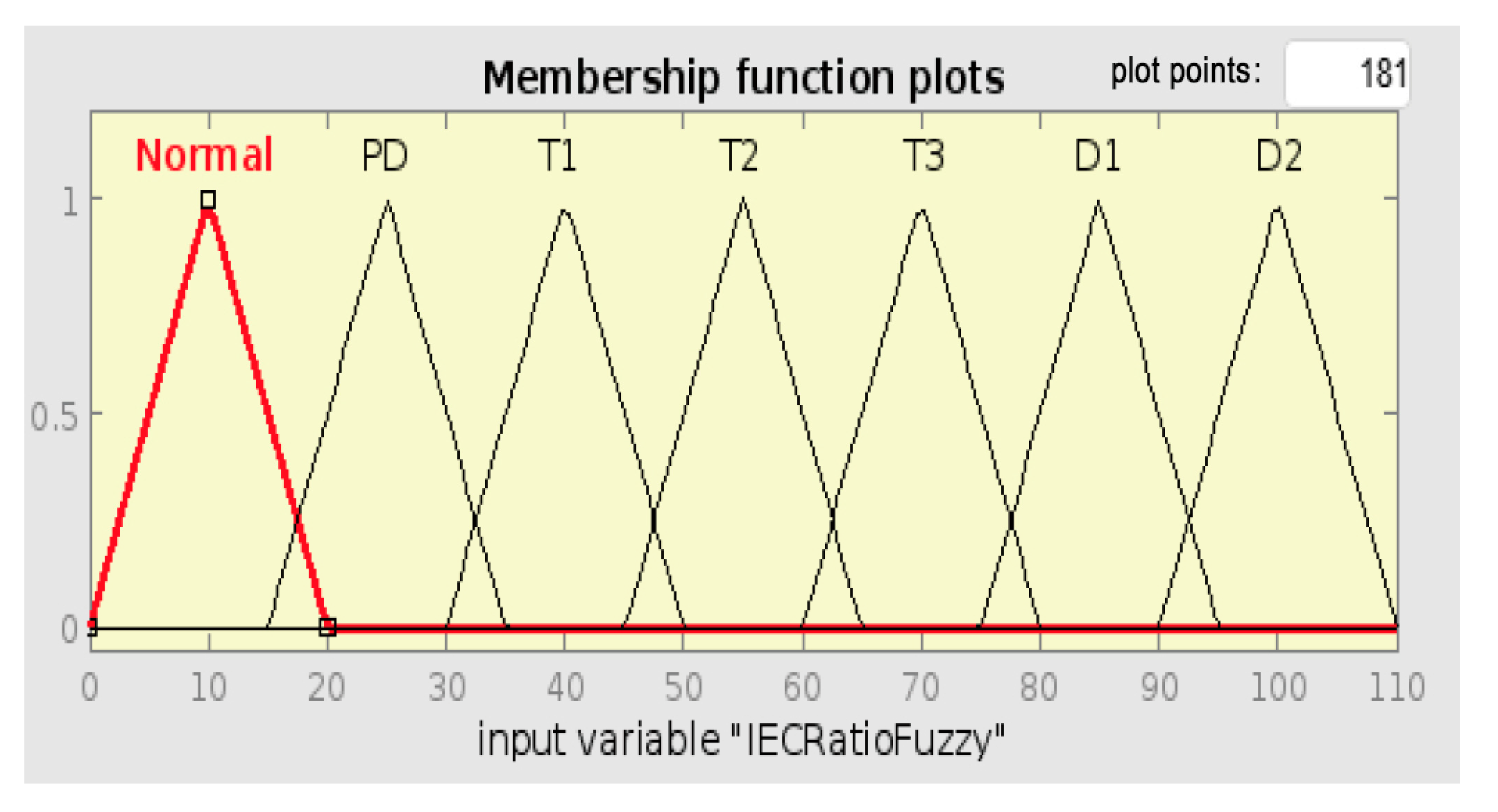

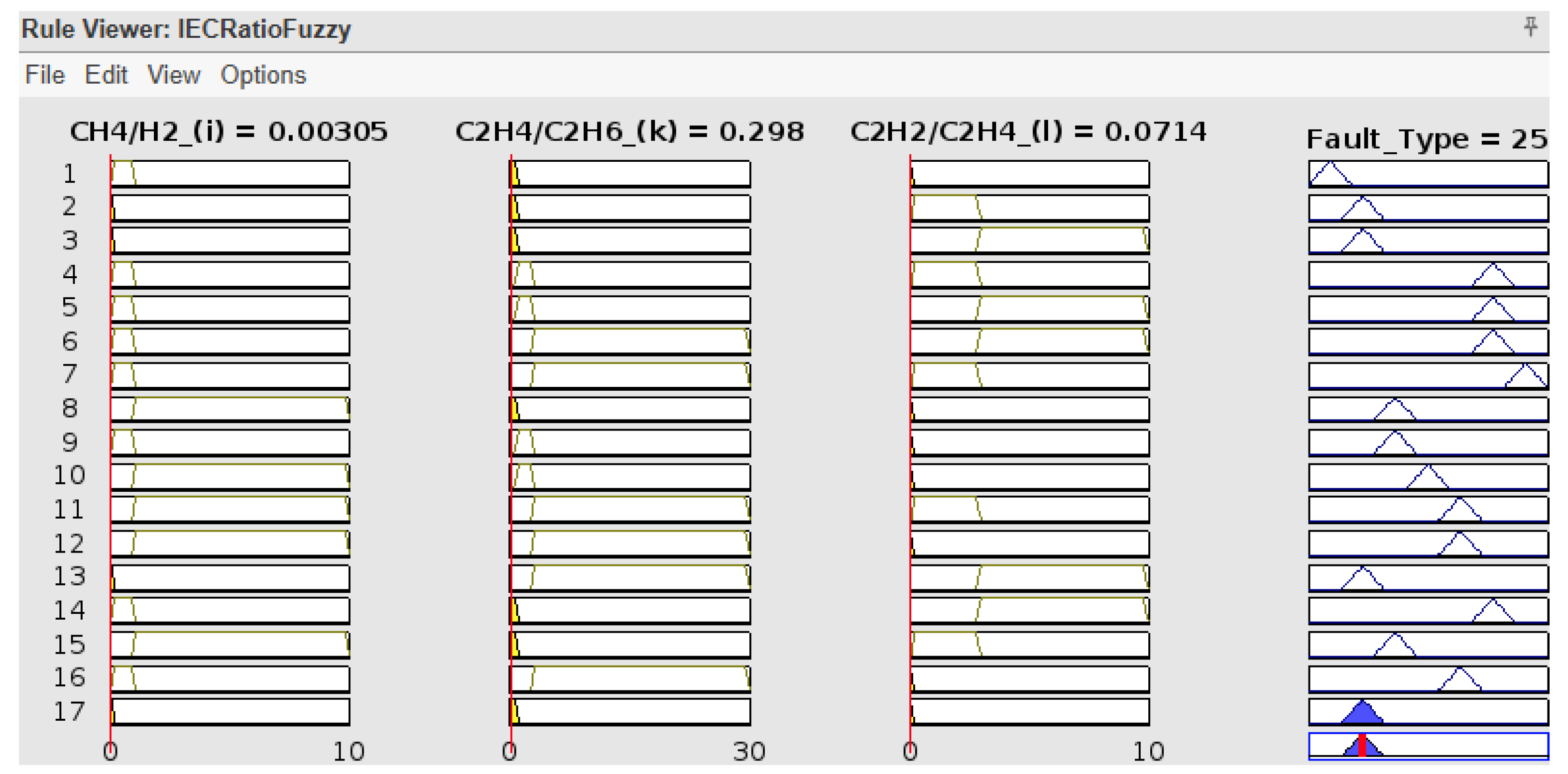

As shown by

Figure 36 below, Sample 15 diagnosis using the IEC ratio FIS also diagnosed the fault as PD, defined by the membership function with a central value of 25. This correct detection of the IEC method can be attributed to its robust processing of CH

4/H

2 and C

2H

2/C

2H

4 ratios that well represent the characteristics of PD. This shows that the IEC method is more reliable at identifying discharge faults than Roger’s Ratio.

Duval Triangle FIS incorrectly identifies the fault as T1, as indicated below by

Figure 37. This is due to the fact that the concentration of C

2H

4 in Sample 15 is quite high, and the Duval Triangle method is prone to identifying such a high concentration with thermal faults. This indicates that the method is not discriminative regarding PD when the C

2H

4 concentration is high.

Figure 38 below shows the final decision with the integrated DGA fuzzy logic system. The integrated system correctly diagnoses the fault as PD. This correct result shows the strength of the integrated method. With the integration of outputs from various methods, the system balances each method’s weakness. The combination of results ensures that even if one method incorrectly diagnoses, the combined output still points to the correct diagnosis.

6.1. Accuracy Comparison of Individual Fuzzy Inference Systems

For comparison of the diagnostic effectiveness of the individual DGA fuzzy logic systems and the proposed integrated method, accuracy is used as the primary measure of evaluation. Accuracy is the percentage of correct diagnoses interpreted by a method of the total number of transformer oil samples examined. By comparing and calculating the accuracy of each fuzzy logic system, we can clearly measure which approach yields the most reliable and consistent fault detection. This research provides important insight into the effectiveness of the integrated model to improve transformer fault diagnosis in comparison to traditional single models. Accuracy is calculated by the following formula:

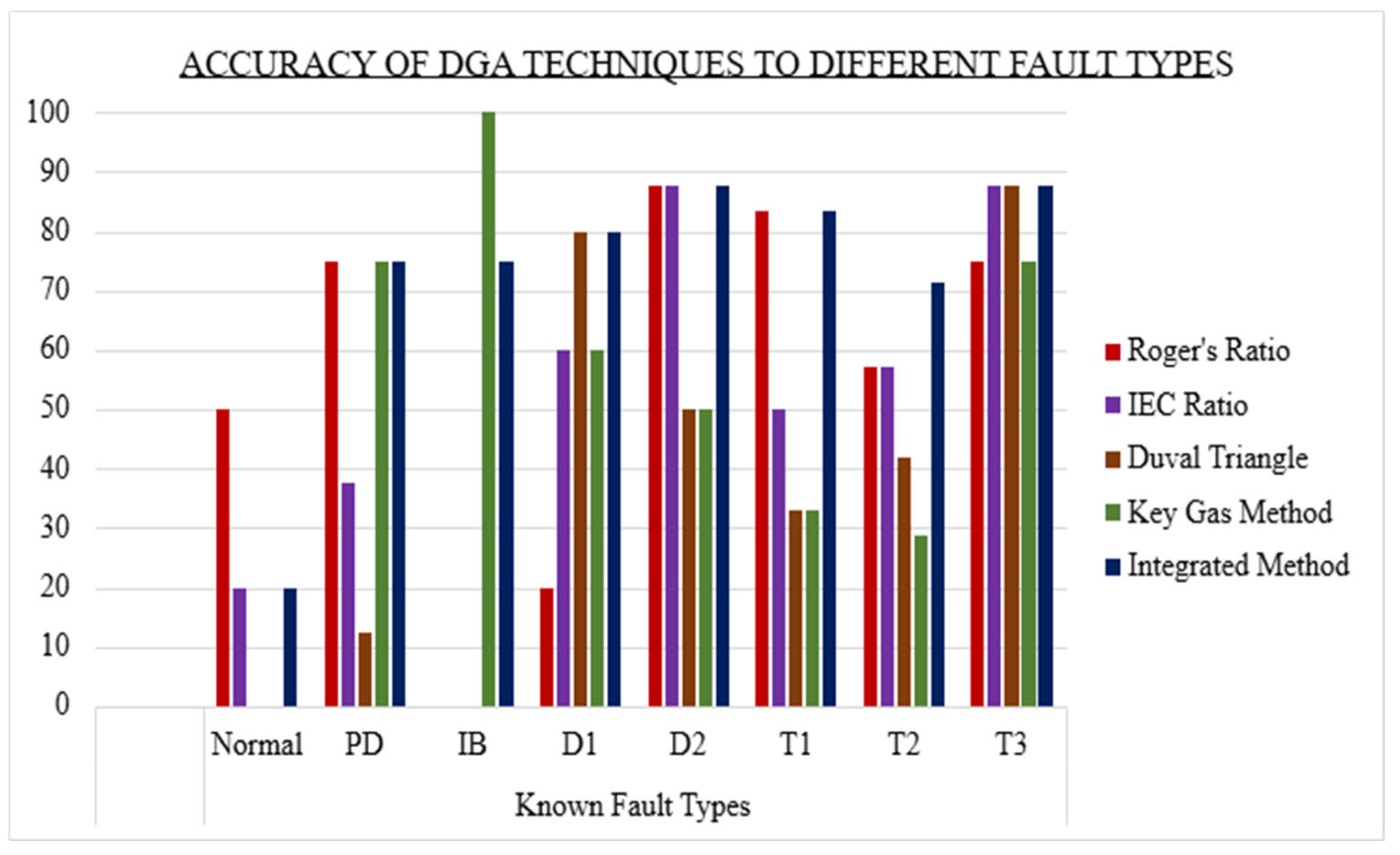

6.1.1. Accuracy of DGA Techniques to Different Fault Types

Understanding the accuracy of each DGA technique in detecting specific transformer fault types is essential to evaluating their diagnostic effectiveness and reliability. Each traditional method demonstrates different levels of sensitivity and accuracy, depending on the specific characteristics of the fault being diagnosed. This section provides a comparative analysis of these individual fuzzy logic-based DGA models, focusing on their performance across different conditions such as Normal, PD, T1–T3, D1–D2, and IB. By analyzing the detection patterns and error cases across fault types, this section highlights the diagnostic strengths and limitations of each method, providing a foundation for assessing the value added by the proposed integrated fuzzy logic system.

The bar chart in

Figure 39 below illustrates how individual traditional techniques show inconsistent performance across different fault types. A technique that performs well for one fault type might perform poorly for another. This is illustrated by Roger’s Ratio FIS, which had a high accuracy of 87.5% in diagnosing D2 and displayed a low accuracy of 20% when it came to diagnosing D1 faults. Another example can be the Duval Triangle method, as it showed a low accuracy percentage of 12.5% when diagnosing PD fault types and had a high accuracy of 87.5% for T3 faults. No single individual DGA technique demonstrates consistently superior accuracy across all fault types. For example, the Key Gas Method’s strength in PD detection comes from its direct focus on Hydrogen, while a ratio-based method might be disadvantaged if that hydrogen is accompanied by other gases that shift the ratios out of the PD diagnostic zone. Their strengths and weaknesses are distributed. It is also important to note certain traditional FISs are not able to diagnose some conditions at all; normal conditions can only be diagnosed by the Roger’s and IEC ratios, as it can be observed in

Figure 39, the Duval Triangle, and the Key Gas Method display 0% accuracy for the condition, as they are not designed to detect it at all. Another condition is the Insulation Breakdown (IB), as illustrated by

Figure 39. It can only be diagnosed by the Key Gas Method. This shows the importance of the integrated FIS as it helps make up for each technique’s setbacks.

However, with regard to the integrated method, for almost every single fault type displayed the bar representing the integrated method is consistently the tallest or among the tallest, indicating its highest accuracy compared to all other individual DGA techniques. This visually and quantitatively demonstrates that the integrated system effectively combines the diagnostic strengths of the individual. By taking the output of each fuzzified traditional method as input to a higher-level fuzzy inference system, the overall system can mitigate the respective weaknesses and take advantage of the aggregate diagnostic strength of the individual techniques. For example, whereas the Duval Triangle may miss a PD fault when there is ethylene present, the overall system can place more weight on the Key Gas and IEC ratio methods if they strongly indicate PD, leading to a correct overall diagnosis.

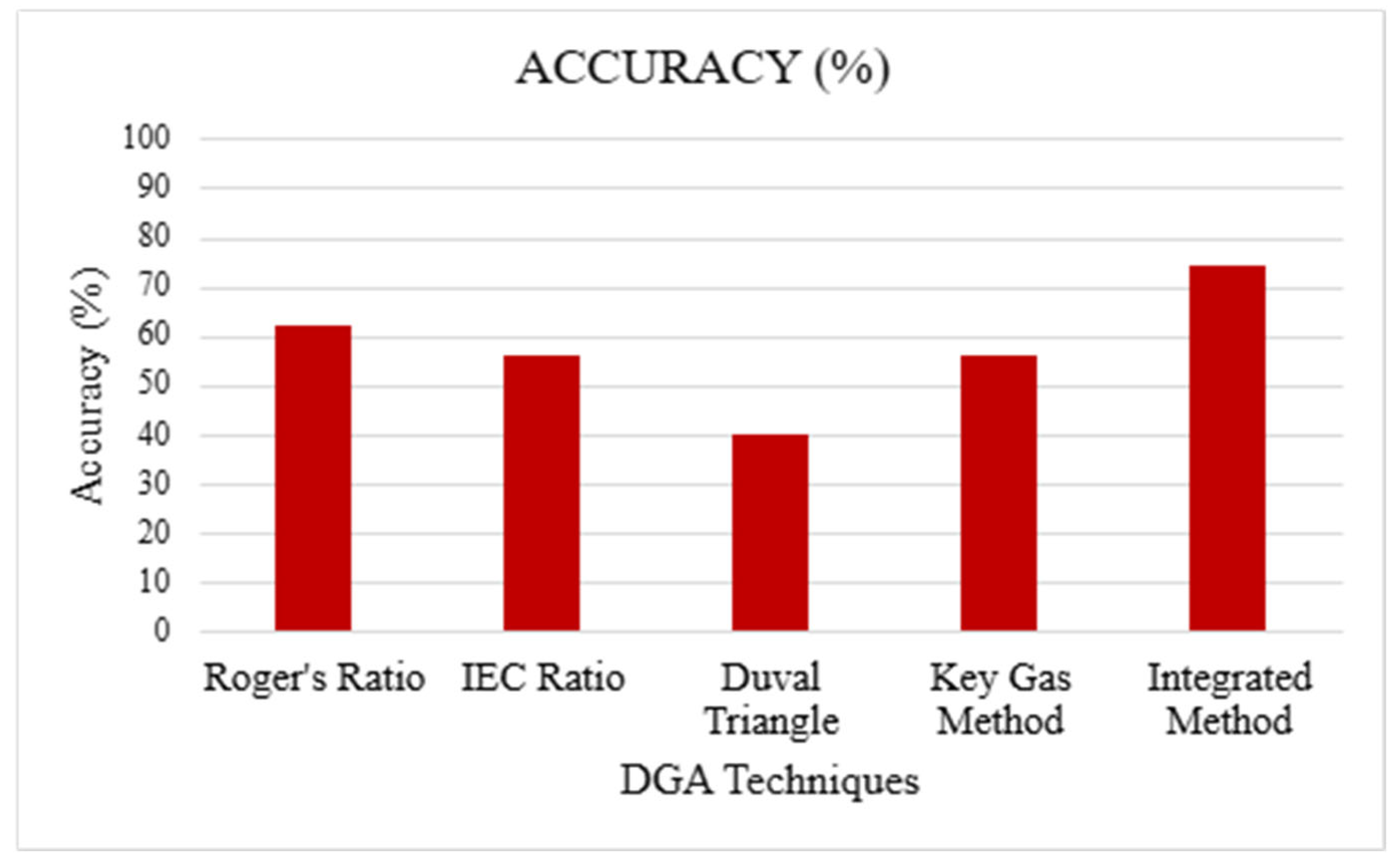

6.1.2. Overall Accuracy of DGA Techniques and Integrated Method

While the above section and

Figure 39 gave a close-up view of how each separately DGA-based FIS works in diagnosing fault types of interest, this section now takes a different approach to a more general assessment by examining the overall diagnostic performance of each individual method in comparison to the integrated approach proposed. This overall accuracy, presented visually in

Figure 40 below, offers a summative measure of their reliability and is crucial for supporting the enhanced diagnostic capabilities achieved through the integration of these diverse methodologies.

Figure 40 below presents a comprehensive graphical depiction of the diagnostic accuracies attained by the individual traditional DGA-based FISs compared to the success rate of the proposed integrated fuzzy logic system. This figure combines the particular performance metrics observed across specific fault types (as shown in

Figure 39 and explained in

Section 6.1.1) into a unique, comprehensive assessment of overall diagnostic accuracy for each approach studied.

The primary and most significant observation anticipated from

Figure 40 is the demonstrably superior overall accuracy of the proposed integrated diagnostic method, with an accuracy of 76% compared to 62%, 56%, 42% and 56% of Roger’s Ratio, IEC ratio, Duval Triangle, and Key Gas Method, respectively. This great performance is a direct result of the integrated system design, which is aimed at developing the diagnostic capabilities of each individual method while at the same time removing its weaknesses and inconsistencies. The integration facilitates a comprehensive analysis of the DGA data, utilizing the results of fuzzified traditional methods as inputs for an advanced decision-making system. As demonstrated by Sample 15’s accurate diagnosis of PD in spite of variable outputs from several individual techniques, this multilayered approach allows the system to reconcile contradictory diagnoses from individual methods and arrive at a more robust and reliable final diagnosis.

Conversely,

Figure 40 reflects the inherent limitations of sole reliance on individual classical DGA techniques. While they will show acceptable accuracy in specific fault categories, their overall diagnostic ability, evaluated over the total range of possible conditions for a transformer, will be relatively lower and more doubtful. This discrepancy emphasizes the fact that there is no one traditional method with the capability to provide high accuracy in all fault situations consistently. As an illustration, a method highly effective with thermal faults will not be equally effective with discharge faults, thus lowering the total rating for accuracy.

The benefits of such improved general accuracy are significant from a practical perspective. Unexpected transformer failure and the resulting financial losses are less in occurrence when a diagnostic system is more accurate in fault detection, since this implies that more accurate and timely maintenance intervention will be necessitated. Moreover, the capacity of the integrated system to provide a more certain and accurate diagnostic output relieves the interpretation load from maintenance staff and asset managers, especially those who may not have in-depth specialized knowledge of every element of every single DGA technique.

7. Conclusions

This thesis addressed the critical limitations of traditional DGA techniques, namely inconsistent results, reliance on specialized expertise, and interpretational complexity, which hinder effective MV/HV transformer condition assessment. Motivated by the need for a more reliable, accurate, and accessible diagnostic tool, this research developed and validated an integrated fuzzy logic system.

The experimental observations gathered strongly confirm the enhanced diagnostic capability of the proposed combined system. A comparative analysis of individual DGA-based FIS tested under various fault scenarios (as indicated in

Figure 39) revealed their inherent inconsistencies; a model having expertise for one case generally performed poorly in another. This range was improved by the integrated approach, which consistently showed improved or equal accuracy across the entire fault type spectrum. Condensing this, the overall success rate for diagnostic testing of 76% for the integrated system (

Figure 40) far surpassed any single one of the separate traditional approaches, such as Roger’s Ratio (62%), IEC ratio (56%), Duval Triangle (42%), and the Key Gas Method (56%). The system’s capacity for diagnosing inconsistencies, which has been illustrated through the Sample 15 analysis, supports the robustness of the system. While the validation has been conducted on 50 samples of the dataset, implying that further testing with a larger dataset would be useful for broader generalization, the results available are strongly positive.

The proposed integrated system directly solves the established problem statement through the provision of greatly improved diagnostic accuracy and reliability over single traditional methods alone. Its presentation of a clear, human-readable output reduces the need for expert interpretation, thereby fulfilling the motivation of enabling DGA diagnostics to be more user-friendly and accessible. This enables maintenance decisions to be made earlier and more informed.