1. Introduction

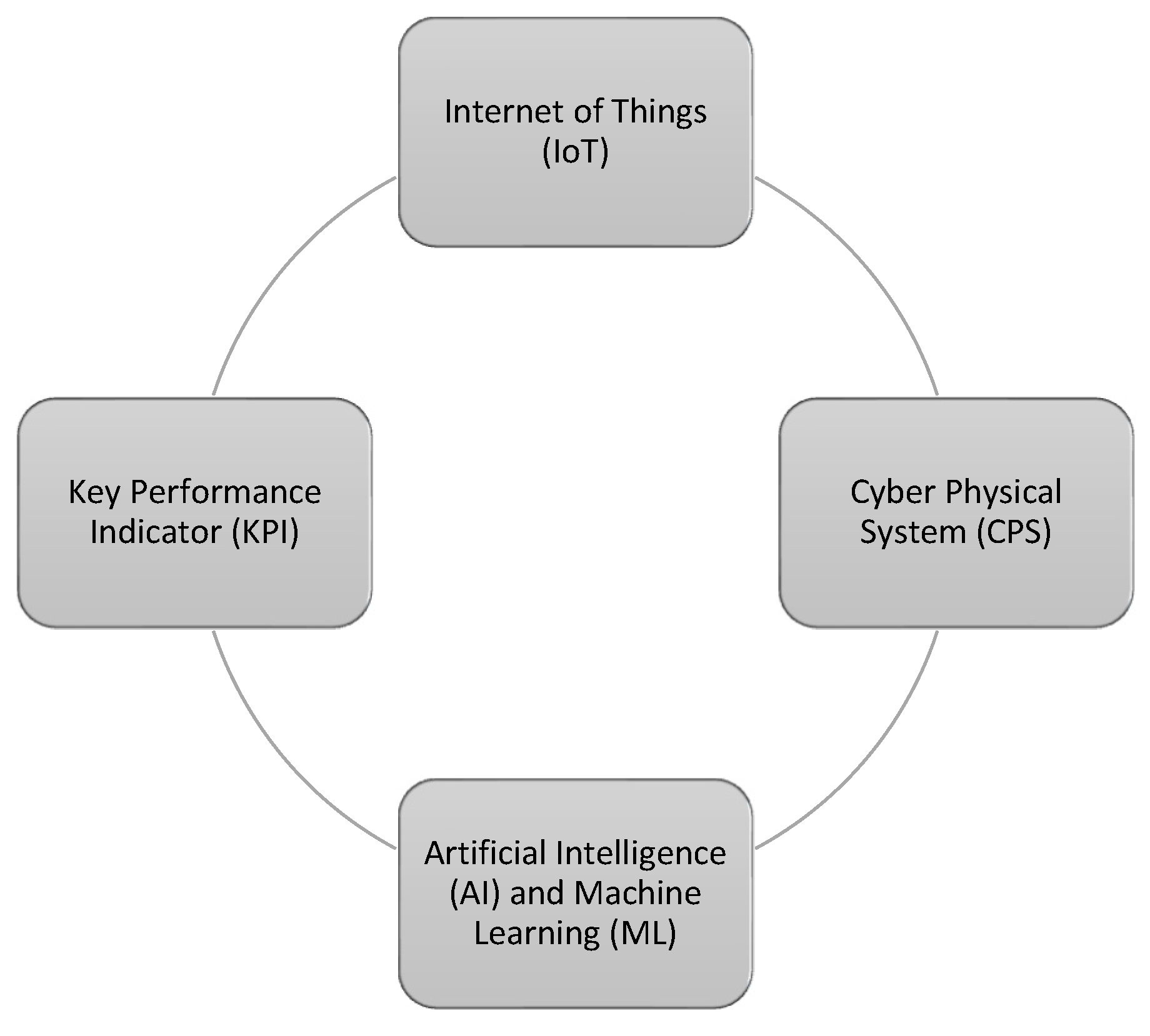

Modern industry is undergoing a digital transformation epitomised by Industry 4.0, wherein intelligent, data-driven systems optimise processes in real time (

Figure 1). In this paradigm, factories and infrastructure employ Cyber-Physical Systems (CPS) and the Internet of Things (IoT) to collect and analyse data continuously, enabling “smart” operation with minimal human intervention [

1]. Elevators, critical components of smart buildings and urban mobility infrastructure, are increasingly instrumented with sensors and connected to building management networks. This elevates elevators from mere transport devices to intelligent CPS devices that can be monitored and optimised continuously. Ensuring the efficiency and reliability of elevator systems is paramount for safety, energy conservation, and user satisfaction in high-rise smart buildings.

This evolution positions the OEEE within the broader context of smart asset management, where performance indicators must capture the complexities of cyber-physical systems [

2]. The design of such KPIs is intrinsically linked to the data streams enabled by the Internet of Things (IoT), which allow for the fusion of operational and energy data into a single, cohesive framework. Our proposed indicator can thus be seen as a key metric for digital twin models, quantifying the real-time effectiveness of the physical elevator and enabling a more accurate and dynamic virtual representation [

3].

Overall Equipment Effectiveness (OEE) is a well-established metric in manufacturing for evaluating how effectively equipment is utilised. Introduced as part of Total Productive Maintenance by Nakajima in 1988 [

4], OEE combines Availability, Performance, and Quality to identify productivity losses (

Figure 2). It essentially measures the percentage of planned operational time that is truly productive, by accounting for downtime losses, speed losses, and quality losses. Because of its intuitive formulation and ability to pinpoint inefficiencies, OEE has been widely adopted in industry as a Key Performance Indicator (KPI) for operations. Traditional OEE, however, was conceived for manufacturing settings (e.g., production lines) and does not explicitly include energy utilisation or sustainability aspects. In the era of Industry 4.0 with growing emphasis on energy efficiency and environmental impact, there is a need to extend such metrics.

Elevator systems present a unique case for performance measurement. Like machines on a factory floor, elevators have uptime/downtime, speed of operation, and quality of service (e.g., fault occurrences) that determine their effectiveness. Classical OEE metrics can be analogously applied: for example, Availability of an elevator can be defined as the proportion of scheduled operating time that the elevator is actually in service, that is, not out of order or under unscheduled maintenance [

5], Performance could relate to whether the elevator operates at its designed speed and efficiency, and Quality could relate to the fraction of trips completed without incidents or faults. Indeed, we can draw an analogy between a production machine producing defect-free parts and an elevator completing trips without faults, both reflect quality of output. However, one major consideration in elevators, largely absent in the original OEE formulation, is energy efficiency. Elevators can consume significant electrical energy both during motion and even when idle, that is, in standby. Studies have shown that an elevator’s standby mode consumption can constitute a very large portion of its total energy usage (on the order of 80% in some cases). Thus, an elevator could be highly available, fast, and reliable, yet still be energy inefficient. The classical OEE metric would overlook this aspect, potentially giving a misleadingly high effectiveness score to an energy-wasteful elevator. It is important to note that the scope of this work is intentionally focused on the operational phase of the elevator’s life cycle, as the OEEE is designed as a real-time asset management tool for in-service equipment.

It is critical to establish that operational safety is the absolute prerequisite for any performance measurement. The OEEE framework is applicable only to an elevator that is functioning within its certified safety limits and in full compliance with all regulatory standards. Safety systems are not a component of the OEEE calculation; rather, they act as a foundational, non-negotiable condition for its application. A safety-critical failure results in an immediate cessation of operation, rendering the Availability, and consequently the OEEE, equal to zero.

The rationale for creating an Overall Equipment Effectiveness for Elevators (OEEE) is to adapt OEE methodology to the context of elevators, explicitly incorporating energy performance as a first-class dimension alongside availability, performance, and quality. This extension aligns with broader trends in operations management to include sustainability and energy metrics in performance evaluation. Recent research in manufacturing has begun moving from OEE to OSEE (Overall Sustainable Equipment Effectiveness) by adding environmental and energy factors to the traditional productivity metrics. Similarly, other extensions of OEE have been proposed: for example, an Overall Process Effectiveness (OPE) was developed to measure effectiveness of logistic operations, adding aspects like punctuality to the standard OEE factors [

6]. Another new metric, Overall Equipment Effectiveness for Mobility (OEEM), was introduced for urban freight transport, integrating additional components reflecting delivery quality, vehicle utilisation, and other factors beyond classical OEE [

7]. These efforts underscore a recognition that one-size OEE does not fit all domains, and that KPIs must be tailored to specific systems and their unique loss factors.

In the specific domain of elevators, incorporating energy efficiency is particularly crucial. Buildings are striving to become smarter and greener; elevators in high-rise buildings can account for 2–10% of a building’s energy demand, being even up to 40% at peak usage [

8]. Improving elevator energy efficiency can thus yield substantial energy savings, for instance, using regenerative drives to recapture energy has been shown to cut elevator energy consumption by about one-third. Monitoring such improvements requires metrics that explicitly capture energy performance. Moreover, elevator manufacturers and building operators are increasingly equipping elevators with IoT-based monitoring: modern elevator systems now use sensors and virtual sensing approaches to track ride quality and energy usage in real time [

9]. This data rich context provides the opportunity to compute a composite indicator like OEEE continuously, enabling proactive maintenance and optimisation. Indeed, Esteban et al. [

9] demonstrate a system where virtual sensors estimate elevator conditions and compute four KPIs, two of which are ride quality and energy efficiency, to trigger maintenance actions. Such approaches illustrate the practical demand for integrated performance-energy metrics.

This paper aims to establish the theoretical and conceptual foundation of Overall Equipment Effectiveness for Elevators (OEEE). The definition of OEEE from the classical OEE model is developed, explaining each of its constituent dimensions and indicators. We situate the concept within the context of Industry 4.0 and CPS, where real-time data from elevator operation (speeds, energy consumption, faults, etc.) can be leveraged to calculate OEEE dynamically. The Literature Review Section will first summarise the OEE concept and its evolution in recent research, including extensions to new domains and inclusion of energy metrics. Next, the Methodological Framework for OEEE is presented: defining its four dimensions (Availability, Performance, Quality, Energy Efficiency), and the six indicators proposed (two under Performance and two under Energy Efficiency, in addition to single indicators for Availability and Quality). The theoretical basis for each indicator and how they are formulated is proposed. In the Discussion, implementation challenges and practical considerations are considered, as for example, data requirements for each indicator, integration with elevator control systems and Building Management Systems, and ensuring comparability of OEEE across different installations. Relevance of OEEE to industry practitioners is discussed, from elevator maintenance providers to building facility managers, especially in smart building and mobility infrastructure contexts. The Discussion further covers how OEEE can tie into real-time data analytics, predictive maintenance, and digital twin models of elevators, thus aligning with Industry 4.0’s predictive and adaptive ethos. Finally, Practical Implications of adopting OEEE (such as improved energy management and service reliability), acknowledge Research Limitations, and suggest Future Research Directions including pilot studies and enhancements of the metric are outlined.

By introducing OEEE as a theoretical construct, this paper contributes to both the academic literature on performance measurement and the practical toolkit for smart infrastructure management. In formalising OEEE, a comprehensive KPI that encapsulates an elevator’s operational effectiveness and energy efficiency in one value is provided, supporting more holistic decision-making for sustainable and efficient vertical transportation systems.

2. Materials and Methods

2.1. Foundations of OEE and Its Extensions

Overall Equipment Effectiveness (OEE) was originally developed as a metric within Total Productive Maintenance to evaluate how effectively a manufacturing operation is utilised. It is defined as the product of three components: Availability, Performance, and Quality, where each component captures a different type of loss.

Mathematically, OEE is defined as the product of the three indicator values, that is, OEE = A·P·Q, where A represents the Availability, P is Performance, and Q is the Quality component. Typically, all these values are represented as a percentage and, consequently, OEE result is a percentage.

While OEE serves as the foundation for our proposed framework, it is important to acknowledge other Key Performance Indicators (KPIs) used in asset and facility management. Metrics such as Mean Time Between Failures (MTBFs) and Mean Time To Repair (MTTR) are widely used to quantify reliability and maintainability [

10]. Similarly, in the context of building performance, indicators often focus on specific service aspects like passenger waiting times or energy consumption evaluated in isolation, such as kWh per year or per transport cycle [

11]. However, these indicators are typically siloed; maintenance metrics often lack an operational performance dimension, while energy metrics are seldom integrated directly with mechanical availability and service quality. This creates a fragmented view of an asset’s overall performance. The unique strength of the OEE methodology lies in its multiplicative and holistic structure, which provides a single, integrated score that reflects the interdependence of different performance aspects. It is this integrated, diagnostic capability that makes OEE a more suitable foundation for developing a comprehensive indicator like OEEE, which aims to bridge the gap between operational effectiveness and energy efficiency.

Availability accounts for downtime losses (machine breakdowns, setup, maintenance) and is calculated as the ratio of actual operating time to planned production time. Performance accounts for speed losses (reduced speed, small stops) and is typically the ratio of actual output to the theoretical maximum output (or actual operating speed to design speed). Quality accounts for output losses due to defects, computed as the fraction of good products out of total produced. These definitions are standardised in the literature and practice [

6]. By multiplying the three ratios, OEE yields a percentage of fully productive time; an OEE of 100% would mean an asset produces only good parts, as fast as possible, with no downtime.

Originally, OEE was directly tied to the concept of the “Six Big Losses” identified by Nakajima [

4], with two major loss categories that correspond to each of the three OEE factors. In other words, OEE provides a structured way to quantify how much productivity is lost to the six classic loss sources (unscheduled stops, setup/adjustments, small stops, reduced speed, start-up rejects, production rejects). Because of this comprehensive coverage, OEE has been embraced as an essential KPI in manufacturing. It allows organisations to pinpoint whether the primary improvement opportunity is to reduce downtime, increase speed, or improve quality yield. As Ullah et al. note [

12], OEE is widely accepted due to its ability to offer valuable and applicable information on operational performance. Many industries treat an OEE of 85% as a world-class target, though the benchmark varies by sector, underscoring its role as a benchmark for operational excellence.

However, the scope of OEE has limits. Traditional OEE assumes a manufacturing context and focuses on production efficiency; it deliberately omits factors like cost or energy to maintain simplicity and universality. With evolving priorities, such as energy efficiency, sustainability, and broader operational contexts, researchers have proposed extensions or analogues of OEE tailored to new purposes:

- •

Sustainability and Energy in OEE: Madreiter and Ansari [

13] argue that the classic OEE needs reinforcement to address sustainability, proposing an extension termed Overall Sustainable Equipment Effectiveness (OSEE). OSEE would integrate environmental indicators (like energy or resource efficiency) into the effectiveness measurement. This reflects a general trend of augmenting productivity metrics with green performance metrics in the era of carbon footprint tracking and energy management.

- •

Overall Process/Performance Effectiveness: Ng Corrales et al. [

6] developed Overall Process Effectiveness (OPE) as a lean performance indicator for logistic operations. Their OPE metric, derived from OEE, is intended to quantify the effectiveness of an operation process (such as a truck unloading process) rather than a single machine. In their framework, additional loss factors like scheduling delays or punctuality of the process were introduced [

14]. This highlights that OEE’s principles (availability, performance, quality) can be generalised to other processes by identifying the analogous “loss” in each category for that process.

- •

Mobility and Transport: Les et al. [

7] introduced an indicator called Overall Equipment Effectiveness for Mobility (OEEM) for urban freight transportation efficiency. This is particularly relevant as a parallel to our work on elevators. OEEM adapts OEE logic to measure the efficiency of delivery vehicle fleets in urban environments. Notably, OEEM incorporates five components: the quality of deliveries (e.g., correct, damage-free and on-time deliveries), vehicle utilisation, availability of the vehicle–driver pair, and a composite efficiency factor reflecting traffic conditions and stop efficiencies. The motivation was to have a quick overview of the performance of urban delivery operations, considering not just technical uptime of vehicles but also logistical performance and environmental impact (as implied by the triple bottom line approach). The OEEM study also involved implementing the metric in real-time with telematics data and visualising it on a dashboard, demonstrating the Industry 4.0 approach to KPI monitoring.

- •

Human and Organisational Factors: Another contemporary angle is integrating human factors into OEE. Luozzo et al. [

15] investigated the relationship between human factors and OEE, using an Analytical Hierarchy Process (AHP) combined with ISO 22400 standard [

16] KPIs. ISO 22400 is an international standard defining KPIs for manufacturing operations management, providing a common structure and terminology for metrics. By aligning OEE analysis with ISO 22400 and AHP, Luozzo et al. sought to formally weight and evaluate how aspects like worker performance or skill, a human factor, can impact OEE values. This kind of work, while not creating a new variant of OEE, extends the understanding of OEE by considering contributory factors outside the purely technical realm. Other examples, as the application of Artificial Intelligence, are shown in other studies [

17,

18].

- •

Other industries, like mill industries [

19] and mining [

20].

The above extensions illustrate a rich trend in the recent literature over the last five years to broaden the applicability of OEE. In summary, researchers have added new dimensions to OEE (energy, environment, human factors) or applied the OEE concept analogously in new domains (logistics processes, transportation, drilling, etc.). All share the underlying logic of measuring how well a system performs relative to its ideal capacity, minus various losses. This literature provides a foundation and justification for extending OEE to elevator systems, which have their own unique profile of losses and performance factors.

2.2. Elevator Systems, Efficiency, and Industry 4.0 Context

Elevators are a prime example of cyber-physical systems in smart infrastructure. A modern elevator installation includes sensors, controllers, and connectivity enabling data collection on usage patterns, travel cycles, energy consumption, and equipment status. In the realm of smart buildings, elevator performance data can be integrated with building management systems to optimise traffic flow and energy use. Indeed, CPS and IoT technologies form the backbone that allows real-time monitoring of elevator KPIs. Marinagi et al. [

1] emphasise that IoT and CPS are pillars of Industry 4.0 enabling smart factories and by extension can support any smart system’s KPIs by providing timely, granular data. In building operations, this means an elevator’s operational parameters can be continuously measured and improved through feedback loops.

Recent research has demonstrated growing interest in performance evaluation methods specific to elevator systems. Traditional studies have examined parameters such as waiting time, journey time, handling capacity, and ride comfort as core indicators of elevator effectiveness. For instance, Siikonen [

21] provides a foundational traffic analysis model that considers round-trip time and passenger flow optimisation in high-rise buildings. Complementary simulation-based approaches have been explored to analyse elevator behaviour under varying traffic patterns and design configurations [

22].

Beyond traffic metrics, recent studies have integrated energy consumption profiles and control strategies into performance assessments. Boonmee and Aung [

23] propose a framework for evaluating energy efficiency in smart elevators, highlighting the trade-offs between idle time, motor design, and system configuration. Moreover, some works have begun to link elevator performance to broader smart building management systems through the use of sensor networks and IoT infrastructure.

However, to our knowledge, no study has yet proposed a unified indicator that holistically combines operational uptime, quality of movement, and energy efficiency within a single, integrative KPI framework tailored for the Industry 4.0 paradigm. This gap is particularly relevant given the current trend toward cyber-physical systems and autonomous asset management. The proposed OEEE addresses this gap by synthesising key sub-indicators into a consolidated performance metric designed for deployment in connected vertical transportation environments.

Two performance aspects are especially significant for elevators in the context of efficiency: reliability/service continuity and energy consumption. On one hand, an elevator out of service causes inconvenience, potential safety issues, and operational bottlenecks in a building, what is analogous to downtime on a critical machine halting a production line. On the other hand, elevators, if inefficient, can be a silent energy drain in buildings. Research by de Almeida et al. [

24] and Tukia et al. [

25] showed that elevators consume energy even when idle, and that improving standby efficiency is crucial for overall savings. A Swiss study cited by Elevator World in 2025 [

26] found standby mode accounted for roughly 80% of total energy usage across a sample of elevators, highlighting how significant idle losses can be.

The elevator industry and research community have increasingly focused on “green elevator” technologies. These include regenerative drives which recover energy when the elevator goes up empty or down full, supercapacitor energy storage systems, LED lighting and sleep modes for cab ventilation, among others [

27]. The impact can be substantial: implementing regeneration and smart traffic management in a high-rise building’s elevators achieved energy reductions of almost 36%. A study by Makar et al. [

28] demonstrated that using supercapacitor-based recovery, regeneration rates up to 54% can be achieved under high demand conditions, meaning more than half of otherwise wasted energy can be reused. These advances not only reduce energy cost, but also align with sustainability goals for buildings. However, to validate such improvements and drive continuous optimisation, appropriate metrics are needed. Traditional OEE would not capture, for example, that one elevator uses 30% less energy than another for the same service level, whereas an energy-integrated OEEE can.

Significantly, elevator manufacturers have started to introduce their own KPI-based monitoring solutions. Esteban et al. [

9], for instance, present a virtual sensor approach to monitor elevator condition without adding extra physical sensors. They utilise a combination of physical models and existing measurements (like motor current, speed) to estimate additional quantities (virtual sensors), which are then used to compute four KPI values to assess the elevator’s health. Notably, two of these indicators correspond to ride quality and energy efficiency, which are metrics already employed by elevator manufacturers to evaluate performance. The other two relate to condition diagnosis of the mechanical guide system and the hoisting machine. This example underscores that energy efficiency metrics for elevators are not only academically desirable but have practical precedence as manufacturers see value in tracking how efficiently their elevators run, both for marketing (energy ratings) and for offering services like energy audits or guarantees.

From a maintenance perspective, integration of such KPIs allows for predictive maintenance and service optimisation. A high incidence of minor faults or a downward trend in a Quality KPI could signal component wear and trigger a pre-emptive service call. Likewise, a drop in an energy efficiency indicator might indicate an emerging mechanical friction issue (e.g., guide rails needing lubrication or misalignment in the counterweight) causing energy loss, thus prompting maintenance to restore optimal condition. This predictive approach is exactly what Industry 4.0 promotes: using data and AI (machine learning) to learn normal patterns and detect anomalies, thereby optimising reliability and performance with minimal human input. In the words of Jan et al. [

17], intelligent processes “learn” from data to continually optimise with very little human intervention. In elevator terms, an intelligent elevator management system could learn when to shift elevators into standby modes, how to schedule trips for minimal wait times and energy use, and when to self-report a need for maintenance based on KPI thresholds.

In summary, it can be said that while OEE and its variants have been studied in manufacturing and even applied to some service and transport sectors, there is a clear gap in the literature regarding a unified effectiveness metric for elevator systems. Elevators straddle the line between industrial equipment and infrastructure service. No standard KPI, beyond basic availability or uptime percentages, currently encapsulates their overall effectiveness, including energy. Existing elevator standards such as ISO 25745 [

29] provide methods for energy classification (e.g., assigning an energy efficiency class to an elevator) and guidelines for measurement, but these are not combined with operational effectiveness metrics (downtime, performance) into one model. Our work on OEEE thus extends the OEE philosophy explicitly into the vertical transportation domain, meeting the identified need to integrate energy considerations with operational KPIs. In doing so, it draws upon the lessons from the reviewed extensions like OEEM and OPE and leverages the enabling technologies of Industry 4.0, such as CPS/IoT for data collection and real-time analytics.

In the next section, the methodological framework for OEEE is detailed, defining how each dimension is conceived for elevators and how the composite index is formed. Each indicator is rooted in theoretical rationale and, where applicable, existing standards or prior research for formula formulation. This lays the groundwork for implementing OEEE in practice and for future empirical studies to validate and refine the concept.

2.3. Characterisation of the System

The elevator system considered in this study is a standard elevator, classified as Usage Category 5 under the international standard ISO 25745-2:2015 [

29], corresponding to high-intensity applications such as large office buildings or commercial environments. In this category, systems are designed for between 1000 and 2000 trips per day, operating 360 days per year, with a nominal speed specification of 2.5 m/s, reflecting both high operational demands and significant energy consumption potential.

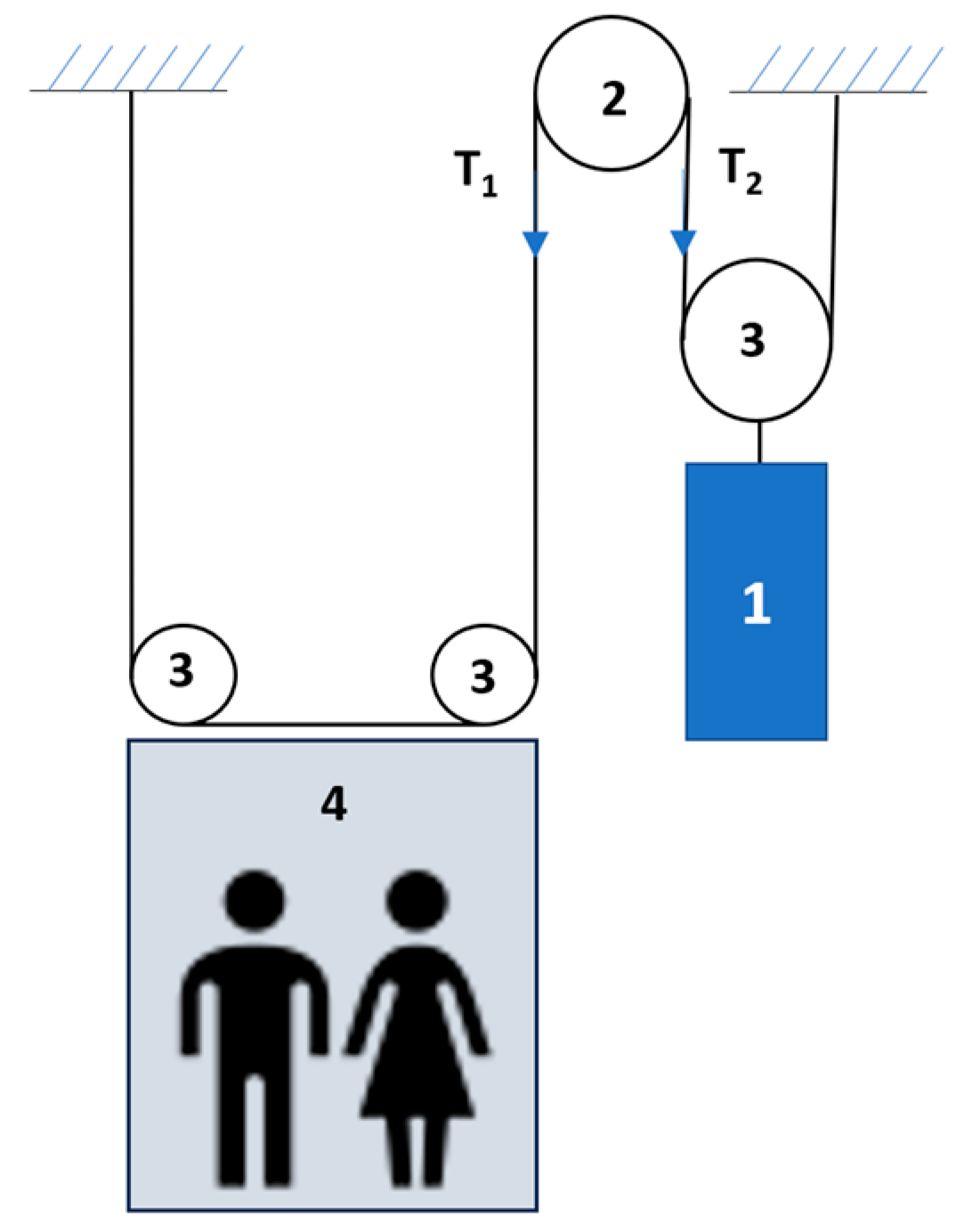

The elevator employs a traction system with an overhead machine room, a configuration prevalent in buildings with continuous and demanding transport needs. In this system, an electric traction motor drives a sheave, over which steel suspension cables transmit motion between the elevator car and the counterweight (

Figure 3). The counterweight is sized to balance approximately 50% of the car’s maximum rated load, thereby reducing the motor’s workload, particularly during regular transport cycles. This design prioritises energy efficiency by leveraging gravitational balance and optimised mass distribution.

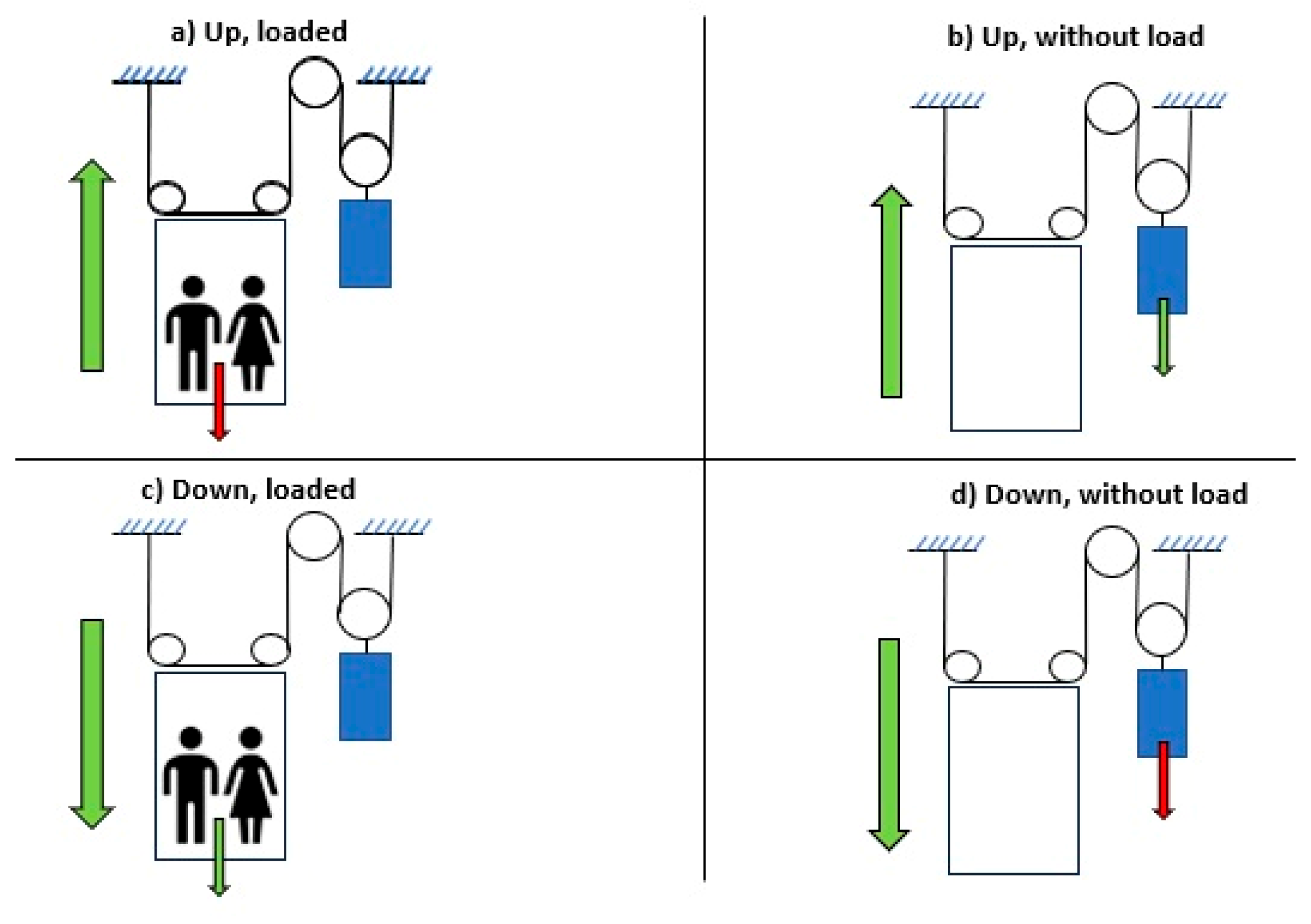

From an operational perspective, the elevator’s energy demand varies according to four fundamental movement scenarios (

Figure 4), determined by travel direction and load condition. Maximum energy consumption occurs when the motor actively lifts the heavier side of the system, when ascending with full load or descending with minimal load, whereas minimal energy is consumed when gravitational forces favour movement, requiring only controlled braking by the motor, in case of descending with full load or ascending with minimal load.

The essential components influencing system performance and energy behaviour include the traction motor, control system, suspension assembly, and auxiliary subsystems, such as cabin lighting, ventilation, and standby electronics. Additionally, position sensors, load detectors, and safety mechanisms ensure precise operation and user safety, while providing critical data for evaluating real-time effectiveness and give the system the CPS denomination. This characterisation provides the technical foundation for implementing the proposed Overall Equipment Effectiveness for Elevators (OEEE), integrating operational and energy performance into a unified, systematic indicator.

2.4. Methodology

Overall Equipment Effectiveness for Elevators (OEEE) is conceived as a multifactor indicator that evaluates an elevator’s holistic efficiency and effectiveness in operation. Mirroring the structure of OEE, OEEE is composed of several dimension-specific indicators, whose product gives the final index as a percentage. OEEE expands on the classical OEE framework [

4] by integrating energy consumption during both active operation and standby phases, aligning with evolving energy efficiency and sustainability objectives [

13].

This study applies a theoretical and technical approach to define the OEEE indicator structure based on established standards, system modelling, and literature review. The methodology combines an engineering characterisation of a high-usage elevator system with an analytical formulation of performance and energy efficiency indicators. Technical parameters, operational modes, and energy profiles are extracted from ISO 25745-2:2015 guidelines, manufacturer data, and prior research on elevator dynamics and energy consumption. The proposed indicator is designed to be implemented using real-time operational data from elevators equipped with IoT-enabled monitoring and control platforms, ensuring practical applicability within Industry 4.0 environments.

Thus, four principal dimensions for elevator effectiveness are defined: Availability, Performance, Quality, and Energy Efficiency. Each of these corresponds to a cluster of factors affecting elevator operation:

- •

Availability (A): This is the proportion of the planned operational time that the elevator is actually available for service, that is, not out of service due to faults or unscheduled maintenance.

- •

Performance: In the elevator context, this dimension is broken into two complementary indicators:

- ▪

Mechanical Energy Conversion efficiency (EC), which means how efficiently the elevator’s motor energy is converted into useful lifting work [

30,

31].

- ▪

Speed Performance (SP), that is, how closely the elevator adheres to its rated speed during operation.

- •

Quality (Q): the fraction of elevator trips completed without any incident or failure, a concept analogous to quality yield in production.

- •

Energy Efficiency: two indicators are defined to capture energy usage in different modes:

- ▪

Energy Efficiency during Movement (EEM): how optimal the elevator’s energy consumption is while moving (transporting passengers or cargo).

- ▪

Energy Efficiency in Standby (EES): how optimal the energy consumption is when the elevator is idle but ready (standby mode).

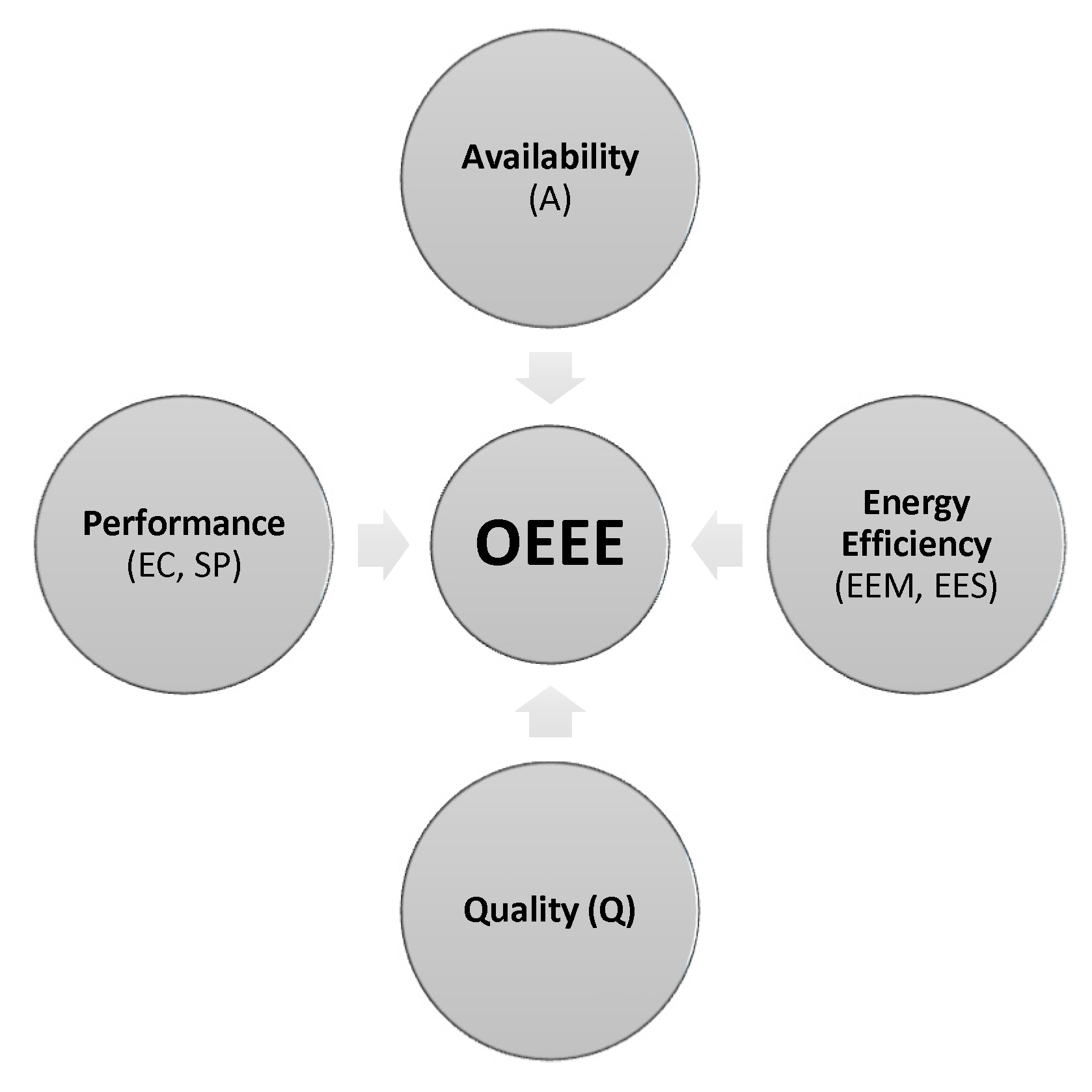

Thus, in total, six specific indicators are defined, grouped under the four-dimension headings above. This structure (summarised in

Figure 5) adds an entire energy dimension (with two indicators) to the classical three OEE dimensions. By doing so, OEEE ensures that an elevator which might excel in availability, performance, and quality but wastes energy will reflect that shortcoming in a lower overall score. Conversely, an energy-efficient elevator gains credit in the OEEE score, encouraging balanced improvement.

The terminology used in this framework is deliberately adapted from the classical OEE standard to maintain conceptual consistency. The Quality pillar, in this context, does not refer to the broader ISO 9000 [

32] definition but maintains the specific OEE meaning, representing the proportion of fault-free operational cycles, in this case, elevator trips completed without any recorded incidents. Furthermore, while energy efficiency is indeed a component of overall operational effectiveness, it is established here as a distinct, primary pillar. This strategic separation is a core contribution of the OEEE framework, designed to elevate the importance of energy consumption, prevent it from being obscured by other performance metrics, and facilitate targeted analysis and improvement strategies in line with modern sustainability goals.

The selection of these six specific sub-indicators is based on a systematic analysis of both industry standards and academic literature. The energy-related components (

EC,

EEM,

EES) are directly informed by the methodologies outlined in the ISO 25745-2 standard, which provides the benchmark for measuring and classifying elevator energy performance [

15]. The operational indicators (

A,

SP,

Q) represent an adaptation of the classical OEE pillars, tailored to the specific service functions of vertical transportation systems as identified in recent performance management literature [

33]. To clarify these design choices and highlight the novelty of our proposal,

Table 1 provides a comparative summary of OEEE against classical OEE.

Mathematically, the developed OEEE is defined as the product of the six indicator values, in a similar way to OEE. If each indicator is expressed as a percentage, with 100% representing ideal performance, then

Each component indicator (A, EC, SP, Q, EEM, EES) is itself defined between 0 and 100% in percentage terms. For clarity, we will describe each indicator’s theoretical definition and formula. The formulas are inspired by the standard OEE definitions and adapted using domain knowledge of elevator operation, as well as existing standards, as ISO 25745 for energy calculations, where relevant.

The OEEE adopts a multiplicative scalarization structure to aggregate sub-indicators. This approach maintains the interdependence logic of the original OEE metric and ensures that low performance in one dimension substantially penalises the overall score. Although more sensitive to small values, this characteristic reinforces the robustness of OEEE for safety-critical systems such as elevators. Future adaptations may consider additive or weighted schemes to tailor aggregation behaviour [

34].

3. Results

This section presents the results of the methodological proposal, offering a detailed and systematic exposition of the individual indicators that collectively constitute the Overall Equipment Effectiveness for Elevators (OEEE). The framework detailed herein is the outcome of adapting the foundational principles of classical OEE to the distinct operational context and energy consumption profile of modern vertical transportation systems. The core result is a multidimensional metric comprising six specific indicators, each formulated to be quantitatively robust and practically implementable using data readily available from contemporary elevators equipped with Cyber-Physical Systems (CPS) and IoT monitoring capabilities.

The indicators are structured within four principal dimensions: Availability, which assesses operational readiness; Performance, which is uniquely bifurcated to capture both electromechanical conversion efficiency and adherence to design speed; Quality, reflecting the rate of successful, incident-free service cycles; and the framework’s key innovation, Energy Efficiency, which is further subdivided to separately analyse energy consumption during active movement and idle standby periods. The following subsections will methodically dissect each of these six indicators and for each one, the theoretical basis, precise mathematical formula, and practical interpretation are provided, grounded in established engineering principles and aligned with international standards like ISO 25745-2:2015 where applicable. The objective is to provide a complete, transparent, and replicable methodology for calculating OEEE, thereby establishing a holistic and data-driven KPI for optimising elevator performance and sustainability in smart infrastructure.

3.1. Availability (A)

Availability (

A) in OEEE measures the percentage of the scheduled operating time that the elevator is actually available for use. It mirrors the availability factor in OEE. For a given reference period, (for instance, per day or per month), Availability (

A) is defined in

Table 2. In practical terms, this indicator simply represents the percentage of scheduled time that the elevator was available to users, excluding all planned and unplanned stops.

where

- •

TR is the reference time period or total scheduled time the elevator is supposed to be operational (e.g., 24 h for a day, minus planned building closure times).

- •

TM is the total planned maintenance time within that period (time reserved for routine maintenance or inspections that is scheduled in advance).

- •

TP is the total unplanned downtime within the period, is time lost due to unexpected stoppages such as breakdowns, faults, or emergency interventions.

This formulation is directly analogous to manufacturing OEE’s availability, as it essentially computes Operating Time/Scheduled Time as a percentage. By subtracting planned maintenance, TM, from the denominator, it does not penalise the indicator for regular service downtime (since planned maintenance is a necessary, expected loss). It only counts unscheduled outages, TP, against availability. In effect, A captures how often the elevator is unexpectedly out of service.

High availability means the elevator reliably serves users during the intended hours. Low availability (due to frequent breakdowns or long repairs) directly translates to poor service for building occupants and is a critical issue for safety and operational continuity. By monitoring Availability, facility managers can quantify if an elevator’s downtime exceeds acceptable norms. For example, if an elevator is meant to run 24/7 but suffers 2 h of random downtime in a day (with no scheduled maintenance that day), then A = [1 − (120 min/1440 min)] × 100 = 91.7% If another elevator of similar usage achieves 99% availability in the same building, it underlines a disparity possibly due to maintenance quality or equipment age. Leading elevator companies target annual availability above 99%, considering anything below about 98% as subpar service. This indicator provides a straightforward, interpretable measure to ensure reliability: a downward trend in Availability would prompt investigation into recurring failure causes or maintenance adequacy.

3.2. Performance

In manufacturing OEE, the Performance rate captures if the equipment is running slower than its theoretical speed or experiencing micro-stops. For elevators, we interpret Performance in two ways: how efficiently the system converts energy into motion, and whether it maintains its rated speed.

- (a)

Converted Energy Efficiency (

EC). This indicator measures the percentage of the elevator’s consumed motor energy that is actually converted into useful work (lifting the car with its load). It addresses energy losses in mechanical conversion such as friction, heat, and other inefficiencies in the drive system. We define this indicator as (

Table 3):

where

- •

EU is the useful energy expended in moving the elevator car (the theoretical minimum energy required to lift the passengers/cargo over the distance travelled).

- •

CM is the actual energy consumption of the motor for that motion.

Both are measured over the same set of trips in the period.

To calculate EU, it can use the physics of potential energy

EU = m·g·heff, where

- •

m is the mass moved (taking into account passenger load and counterweight effect);

- •

g is gravitational acceleration, and;

- •

heff is the net height raised (accounting for both up and down trips).

Essentially, EU is how much energy ideally would be needed in a frictionless, lossless system to do the elevator’s work. The actual consumption CM can be obtained either by direct metering of the elevator drive or by standardised calculation. Notably, ISO 25745-2:2015 provides a method to estimate an elevator’s energy consumption based on its usage category (trips per day), rated load, travel height, etc., which can serve as a reference. However, direct measurement via an energy metre on the motor drive yields more precise data.

EC represents the drive system’s energy conversion efficiency during movement. If, for instance, EC = 80%, it means 20% of the electrical energy is lost to friction, heat in the motor and gear, aerodynamics, etc., while 80% goes into raising/lowering the elevator (including recapturing potential energy on descents if regeneration is present). Losses that commonly affect EC include guide rail friction (which depends on lubrication and guide shoe condition), rope traction losses (slippage or bending losses), and the efficiency of the motor and gearbox. A high EC (close to 100%) indicates a very efficient mechanical system; a low EC points to significant mechanical losses. In practice, modern traction elevators might have conversion efficiencies in the range of 65 to 85%. If EC drifts downward over time, it could indicate mechanical degradation, as for example, increasing friction due to wear or misalignment. This measure helps diagnose when an elevator is underperforming mechanically, despite perhaps still running on schedule.

- (b)

Effective Speed Index (

SP): This indicator compares the elevator’s actual operating speed to its rated design speed. In other words, this indicator measures how closely the elevator’s actual travel speed adheres to its ideal design speed, penalising any slowdowns caused by technical or operational issues. Many elevators have a nominal rated speed (e.g., 2.5 m/s for a high-speed lift) at which they are supposed to travel when conditions permit. The Effective Speed Index (

SP) is defined in a way that penalises any deviation (either slower or faster, though faster is usually prevented by safety systems) from this nominal speed (

Table 4).

where

- •

Ve is the effective average speed of the elevator car during travel, and;

- •

Vn is the nominal speed specified by the manufacturer.

In simpler terms, if an elevator consistently runs at its rated speed, Ve = Vn, thus SP = 100%. If it runs slower, Ve < Vn, SP will be below 100%. In normal operation, elevators should not exceed Vn; any such occurrence would trigger safety governors, so the main concern is running below speed.

The Speed Index captures performance losses due to velocity deviations, akin to how the manufacturing performance rate captures speed losses. An elevator might run below its rated speed for various reasons: overloading (excess weight causes the controller to limit speed), power supply issues, or control system settings (for instance, an older elevator might gradually slow down due to wear or be intentionally slowed for comfort). Mechanical issues like slipping traction ropes/cables or a faulty motor drive could also prevent reaching full speed. Even environmental factors such as voltage drops in the building power could momentarily affect speed. Since elevator service quality and handling capacity are tied to speed (a slower elevator means longer wait and travel times), it is important to track if the elevator is meeting its performance spec. Safety standards, such as EN 81-20 [

35], typically allow only a limited overspeed or under speed tolerance (often ±5% to ±10%) before protective measures engage. This

SP formula is designed so that even minor deviations, positive or negative, reduce the percentage. This ensures the indicator is sensitive to any drift from optimal performance. If we measure over a period that the average effective speed is 2.3 m/s versus a nominal 2.5 m/s, then

A consistently low SP would prompt investigation: perhaps the elevator is frequently overloaded or there is an unaddressed control issue.

Together, EC and SP represent the Performance dimension for OEEE, splitting it into energy performance and speed performance. Here, the option of two indicators was preferred because an elevator’s performance has both an energy aspect (efficiency of performing work) and a service aspect (speed of service). An elevator could be mechanically efficient (high EC) but slow (low SP) if, for example, a deliberate speed reduction mode is in effect; or vice versa, it could run at correct speed (SP around 100%) but be wasting energy through friction (low EC). Only by considering both is it possible to obtain a full picture of performance effectiveness.

3.3. Quality (Q)

Quality in the OEE sense refers to the rate of defect-free output. For an elevator, it is interpreted a “defect” as any trip or service cycle that is affected by a failure or incident. In other words, if during a trip something goes wrong, the elevator stops due to a fault, doors jam, an emergency alarm triggers, etc., that trip is not a fully successful service. Quality (

Q) indicator is defined as (

Table 5).

where

- •

TI is the number of trips or elevator runs during the period that had any incidents or faults, and;

- •

TT is the total number of trips in the period.

A “trip” can be defined as one complete journey from start to destination with or without stops in between, and typically we consider a trip from the time the doors close at one floor until they open at the requested floor. An “incident” means any unscheduled interruption or error: examples include safety gear activation, the car getting stuck, doors failing to open, or even significant service quality issues like excessive vibration triggering a safety sensor. Essentially, if a trip does not complete normally, it is counted in TI.

This is analogous to counting defective parts in manufacturing. If an elevator made 1000 trips in a week and 5 of those trips were aborted or problematic due to faults, then

High Q means nearly all trips are smooth and issue-free, which reflects good maintenance and system health. Low Q would indicate frequent failures or stops, directly impacting passenger satisfaction and safety.

While major breakdowns are captured under Availability (downtime), Quality here captures those in-trip failures or minor faults that might not take the elevator completely out of service for the day but still represent a failure to deliver perfect service on that trip. For instance, an elevator might have a door sensor issue causing occasional entrapments, and each entrapment would count against Quality. As another example, if the elevator skipped a floor due to a control error, that trip could be counted as faulty service. These incidents can be rare, especially in well-maintained elevators. In fact, elevators are highly reliable: manufacturers report that a properly maintained elevator might average on the order of only a few breakdowns per year out of tens or hundreds of thousands of trips. For example, one source indicates a typical range of about 2 to 18 faults per year for a well-maintained lift making approximately 0.5 million trips annually. That corresponds to a “defect rate” well below 0.01%. Given such low expected incidence, the Quality indicator often will be very high, near 100%. If it is not, or in other words, if Q is 95% in a month, that is a red flag of severe problems (perhaps a batch of sensor failures or a control system glitch causing frequent errors).

It is worth noting that a few incident trips in thousands will not drastically change the overall OEEE product, since Q is near 100%. But OEEE includes it to ensure a complete view of service effectiveness. Even if it contributes small numerical impact, its diagnostic value is high: it directs attention to the state of components and maintenance. A dip in Q suggests deteriorating component reliability (maybe a door motor failing intermittently, etc.). Therefore, Q serves as an internal quality control metric for elevator upkeep and user experience.

3.4. Energy Efficiency

The introduction of energy metrics is what fundamentally differentiates OEEE from the classical OEE. In this study, two indicators are proposed under the energy dimension, targeting the two distinct operating modes of an elevator: moving (active trips) and standby (idle, parked between calls).

- (a)

Energy Efficiency in Movement (

EEM): This indicator evaluates how close the elevator’s energy consumption during travel is to an ideal minimum, given the work performed and the system’s inherent efficiency limits. Even a well-designed elevator uses more energy than the theoretical minimum due to losses, but there is often room for optimising how much above the minimum it is.

EEM is defined as shown in

Table 6.

where

- •

CM is again the actual motor energy consumption for all trips, and;

- •

CI is the ideal feasible consumption for those trips, given realistic system efficiency constraints. Here, “ideal feasible” means the lowest energy one could expect the elevator to use, not in a perfect lossless scenario, but taking into account the inherent efficiency of the machinery.

For example, if the hoisting motor has an efficiency of about 90% and cannot do better, then even an optimally run trip will use at least EU/0.90 energy (because 10% is lost in the motor). Additionally, if regeneration technology is present, the ideal case would fully utilise regeneration up to its capacity. Essentially, CI attempts to model the consumption if the elevator were operated in the most energy-optimal way possible for the given duty, within physical limits.

To compute CI, several factors are considered as follows:

- •

The useful energy E

U needed for the work (from

Section 3.2).

- •

The best achievable overall efficiency of the system (motor + drive + mechanical), that can be nominated as ηmax. For many modern traction elevators, ηmax might be around 80–92% (90% being a representative value including motor and traction efficiency).

- •

If the elevator has regenerative braking, in ideal conditions a portion of the potential energy on descent can be recovered. Suppose the maximum regeneration efficiency (feedback to grid or to a battery) is r %, then the net ideal consumption should subtract what could be recovered on balance.

In a simplified form, it could be said,

for a non-regenerative system.

For a regenerative system,

, where EREGEN is the potential energy returned bounded by regen capacity. In practice, data from manufacturers or standards can give a baseline. For example, if the elevator’s spec sheet or standards like ISO 25745 say this elevator should consume X kWh for a certain usage profile in a best-case scenario, that X can serve as CI for that profile.

EEM tells us how much more energy the elevator is using compared to a best-case scenario. If

EEM = 100%, the elevator is consuming as little as theoretically possible, given its technology, and can be said that it is essentially fully optimised. If

EEM is lower, say 80%, it means it is using 20% more energy than the best case. Causes for a low

EEM could include suboptimal drive settings, lack of regenerative braking where it could be beneficial, or poor energy management (e.g., running the motor under inefficient loads). For instance, an oversized motor lightly loaded can be inefficient; scheduling or group control that causes unnecessary trips or long runs could waste energy.

EEM is somewhat similar to

EC but focuses on operational optimisation rather than mechanical losses.

EC is about inherent conversion efficiency in each trip;

EEM is about how much of the avoidable excess energy is eliminated. One can think of

EC as addressing how much energy is lost to physics, vs. EEM addressing how much we could reduce consumption by smarter operation. To illustrate it, an elevator might have

EC of 75% (so 25% lost), but perhaps by optimising start/stop patterns or using regenerative drives [

36], we could cut down the net consumption by 10%.

EEM measures that kind of improvement potential, comparing actual consumption to an ideal reference that already accounts for the fundamental losses.

Monitoring

EEM over time can signal if the system is drifting from optimal energy usage [

37,

38]. A decline in

EEM might indicate a need to retune the drive, check power settings, or see if additional energy-saving measures, like updated software for group control, could be applied. It essentially asks: Is the elevator using more energy than it theoretically needs to, and by how much?

- (b)

Energy Efficiency in Standby (

EES): Elevators spend a considerable portion of time not moving, especially in buildings with off-peak hours or lower traffic. During standby, various systems (cab lighting, ventilation fan, control systems, door motor readiness, etc.) consume power.

EES evaluates how efficient the elevator’s idle mode is by comparing actual standby consumption to an ideal minimum standby consumption. This indicator is defined in

Table 7.

where

- •

CStandby_minimum is the ideal minimum energy that the elevator could consume in standby, given technical limitations, and;

- •

CStandby is the actual energy consumed while the elevator is in standby mode over the period (essentially the “idle energy”, that is, there is consumption in lights, ventilators, etc., and control system).

Modern elevators often have energy-saving standby features, for example, turning off cab lights or displays when not in use, or using low-power sleep modes for drive electronics after a timeout. The ideal standby consumption

CStandby_minimum would be the energy use if all possible savings features are in effect and only the absolutely necessary systems remain powered, like minimal control circuitry. Manufacturers typically specify a standby power consumption in different modes. For instance, one might have a base “sleep mode” consumption of X watts. If further technology, like powering down the ventilation fan when idle, can reduce it to Y watts, that Y is closer to the ideal. In some cases, standards or manufacturers can provide a theoretical minimum. For example, if the elevator’s controller supports a deep sleep that only draws 50 W and the lights are off, that might be

CStandby_minimum baseline, whereas if currently it is drawing 200 W when idle, there is room to improve. It must be emphasised that any energy-saving strategy, such as deactivating auxiliary components during idle periods, must be implemented in strict accordance with all relevant safety standards and regulations (e.g., EN 81-20/50 [

39]) to ensure that passenger safety and comfort are never compromised, particularly under fault or emergency conditions.

EES is crucial because, as noted, standby power can dominate total energy usage in elevators that are infrequently moving [

40]. A study by the Swiss Federal Office of Energy [

41] across 33 elevators found that around 80% of energy consumption was standby. Thus, improving standby efficiency yields large gains. An

EES of 100% means the elevator’s idle consumption is as low as it possibly can be (maybe it is effectively shutting almost everything off). An

EES of 50% means it is using double the power it could in idle, and this is a sign that perhaps energy-saving modes are not enabled or functioning. Factors that reduce

EES include outdated control systems (older elevators that do not have standby power save), cabin lights left on continuously, or cab fans running constantly. Even things like the parking algorithm, whether the elevator parks at a certain floor with doors open or closed, etc., can influence if the motor occasionally kicks in and therefore might have an effect.

This indicator also captures gradual drifts. For instance, if friction in the system causes the motor to kick in periodically even when idle (some older designs might do brake slips), or if someone overrides the energy-save settings (maybe for security lights), the EES would decline.

Both EEM and EES deal with energy but in different modes. There could be trade-offs; for example, turning off equipment in standby might cause slightly longer response time or more wear when starting up, but yields higher EES. Our framework isolates the two so that improvements or regressions in each can be tracked independently. In a typical use scenario, one might find that standby energy constitutes a large fraction of total energy use, so EES is a very important indicator for overall energy performance. On the other hand, if an elevator is extremely busy (e.g., in a skyscraper’s peak hours), the movement energy dominates and EEM becomes more critical. The OEEE structure allows weighting implicitly by the operation profile: a busy elevator will naturally have more weight on EEM and an idle one on EES through how the multiplication works when the values depart from 100%.

4. Preliminary Assessment and Robustness of the OEEE

In order to give a more rigorous justification of the proposed Overall Equipment Effectiveness for Elevators (OEEE), this section provides an initial computational assessment to demonstrate its internal consistency, practical sensitivity, and potential advantages compared to traditional approaches. While the current stage of research is conceptual, this evaluation offers evidence that the OEEE is a robust, interpretable, and implementation-ready performance metric for smart vertical transportation systems.

The OEEE metric was designed to address a well-recognised gap in performance assessment: the absence of an integrative indicator that combines classical equipment effectiveness with energy performance under Industry 4.0 conditions. Traditional metrics, such as standard OEE or energy intensity per ride, fail to capture the trade-offs between operational availability, movement precision, and energy efficiency, particularly in the presence of IoT-based dynamic monitoring.

To illustrate the reliability and computational performance of the proposed measure, a dataset was obtained covering 10 days of operation of a lift undergoing testing in a commercial building (Zaragoza, Spain), with performance values for each of the six sub-indicators that make up the OEEE. All indicators are normalised in percentage terms, and the OEEE is calculated as their multiplicative combination.

Table 8 summarises the results obtained.

The OEEE is calculated as the product of six sub-indicators, which ensures that poor performance in one area cannot be obscured by high performance in another. The resulting OEEE values in the simulation range from 40.81% to 60.49%, demonstrating the indicator’s ability to reflect different daily operational profiles.

To evaluate results, an analysis of Individual Indicators is presented as follows:

- •

Availability (A): This indicator measures the percentage of scheduled time that the elevator is operational, excluding unplanned stops. In the simulation, availability values are consistently high, ranging from 92.41% (Day 7) to 98.66% (Day 2). A high value, such as that on Day 2, indicates near-perfect operational reliability with minimal unplanned downtime. Conversely, the lower value on Day 7, while still high, suggests an increase in unexpected stops, contributing to a lower overall OEEE for that day.

- •

Energy Conversion Efficiency (EC): This indicator quantifies the efficiency with which the motor’s electrical energy is converted into useful mechanical work to lift the car and its load. The EC values in the table vary from 85.21% (Day 1) to 94.70% (Day 2). This variation may reflect differences in load conditions or increased frictional losses. The high value on Day 2 suggests near-optimal energy conversion, whereas the lower value on Day 1 indicates greater energy loss in the drive system.

- •

Effective Speed Index (SP): This measures the elevator’s adherence to its nominal operating speed. Fluctuations in this indicator, ranging from 88.46% (Day 10) to 95.85% (Day 6), reflect the elevator’s ability to maintain its designed speed. A low value, such as on Day 10, could be due to power supply issues, overloading, or mechanical wear, resulting in longer travel times and reduced handling capacity.

- •

Quality (Q): This represents the proportion of trips completed without incidents, such as door failures, unexpected stops, or safety system activations. With values ranging from 90.59% (Day 3) to 98.69% (Day 5), this indicator reflects service reliability. The highest value on Day 5 indicates nearly flawless operation, translating to high passenger satisfaction and safety. The lowest value on Day 3 suggests a higher frequency of minor incidents that, while not causing a complete shutdown (as measured by Availability), degrade the quality of service.

- •

In-Motion Energy Efficiency (EEM): This indicator compares the actual energy consumption during motion against a feasible ideal consumption, taking into account the system’s inherent efficiency. The values range from 80.41% (Day 3) to 90.91% (Day 4). The peak value on Day 4 indicates that the elevator operated very close to its energy optimum during trips. In contrast, the value on Day 3 suggests higher-than-ideal energy consumption, possibly due to inefficient usage patterns or increased friction;

- •

Standby Energy Efficiency (EES): This measures the efficiency of energy consumption while the elevator is idle (in standby mode), comparing actual consumption to an ideal technical minimum. This indicator is crucial, as standby consumption can account for a significant portion of total energy use. The table shows considerable variation, from 70.90% (Day 9) to 89.39% (Day 1). The sharp drop on Days 7, 8, and 9 points to significant inefficiency in standby mode, which drastically reduces the overall OEEE on those days. This could indicate that energy-saving modes were not activated or were malfunctioning.

In summary,

Table 8 demonstrates that the OEEE is a holistic indicator. For instance, Day 7 records the lowest OEEE (40.81%) due to a combination of the lowest availability and particularly poor standby efficiency. On the other hand, the highest OEEE (60.49%) on Day 4 is achieved through strong, balanced performance across all indicators, especially in-motion energy efficiency. The multiplicative structure of OEEE ensures that a balanced view of the elevator’s performance is captured, aligning with the objectives of asset management in Industry 4.0.

Additionally, several observations support the robustness of the formulation:

- •

Consistency with Expert Expectation: High availability, speed regularity, and energy savings lead to higher OEEE values. This behaviour aligns with engineering intuition and real-world performance targets;

- •

No Dominance of a Single Factor: No single sub-indicator dominates the final result due to the multiplicative structure. This ensures that poor energy performance cannot be masked by high availability, nor can safety be ignored in favour of efficiency;

- •

Granularity and Diagnostic Use: Day-to-day changes in OEEE correlate with drops in individual sub-indicators, making the measure suitable for identifying root causes of performance degradation;

- •

Mathematical Validity: The model remains bounded within 0–100%, with smooth behaviour under typical input ranges, and is computationally lightweight, enabling real-time use in embedded systems.

4.1. Alternative Forms and Extensions

Although the unweighted multiplicative model is sufficient for general applications, we acknowledge that alternative forms may offer advantages in certain contexts:

- •

Weighted OEEE: Incorporating weights (e.g., via exponents or coefficients) allows tuning the relative importance of safety, speed, or energy, especially where local regulations or priorities differ;

- •

Hybrid Aggregation: A partially additive formulation could be explored to reduce sensitivity to near-zero values, although this would compromise the current model’s strict interdependence principle.

These options confirm that OEEE is not only robust but also adaptable to operational priorities, safety constraints, or data availability.

4.2. Comparative Perspective and Future Validation

While the existing literature lacks an integrated KPI that captures the multidimensional nature of OEEE, the simulation presented in this research demonstrates that the proposed measure surpasses conventional, one-dimensional indicators, such as energy per trip or uptime alone. It achieves this by providing a more holistic, balanced, and interpretable score.

The subsequent phase of this research will be an empirical validation of the OEEE. Data from IoT-enabled elevator systems will be leverage to benchmark its trends against conventional metrics in a variety of performance scenarios. This analysis is expected to not only enhance the measure’s accuracy, but also to lay the groundwork for developing industry-specific calibration methods.

5. Discussion and Future Research

This study represents an initial step in the theoretical development of the Overall Equipment Effectiveness for Elevators (OEEE) metric. At this stage, the proposed formulation is conceptual and has not yet undergone full-scale empirical validation. Nevertheless, a preliminary assessment has been conducted using operating data from a test lift to illustrate the mathematical behaviour of the indicator under typical conditions. This preliminary test aims to verify internal consistency, sensitivity to sub-indicator variation, and computational feasibility. Future work will expand this effort through empirical validation involving more elevator systems and long-term operational datasets.

This OEEE provides a theoretical framework for evaluating elevator system performance by integrating operational reliability, mechanical efficiency, and energy consumption within a unified metric. Unlike conventional indicators, OEEE explicitly incorporates energy efficiency during both movement and standby conditions, responding to the growing emphasis on sustainability and resource optimisation in vertical transportation systems [

26,

42].

The characterisation of a representative traction elevator system, aligned with international standards such as ISO 25745-2:2015, establishes the technical foundation necessary for applying OEEE in practice. By considering core subsystems, including the traction motor, counterweight, control architecture, and auxiliary components, alongside diverse operating modes, this work demonstrates that energy demand is highly dependent on load conditions and system design, echoing findings from recent studies on elevator energy profiles [

24,

28].

The proposed OEEE framework contributes to existing literature by bridging gaps between traditional OEE metrics [

7,

13] and the specific performance challenges of elevator systems in Industry 4.0 environments. Through the inclusion of six distinct indicators covering availability, performance, quality, and energy behaviour, OEEE provides a comprehensive, scalable KPI suitable for real-time monitoring and integration with cyber-physical infrastructures [

9].

The Overall Equipment Effectiveness for Elevators (OEEE) constitutes a novel Key Performance Indicator (KPI) that extends the classical OEE formulation by incorporating dimensions specifically tailored to elevator systems operating within Industry 4.0 environments. While traditional OEE focuses on availability, performance, and quality, OEEE integrates energy efficiency as a critical additional component, thereby offering a comprehensive assessment of both operational and environmental performance.

The proposed OEEE framework is structured around four core dimensions, Availability, Performance, Quality, and Energy Efficiency, which collectively encapsulate the principal factors influencing elevator effectiveness in smart building and cyber-physical system (CPS) contexts. These dimensions are operationalised through six specific indicators, each quantitatively capturing distinct aspects of elevator operation:

- •

Availability (

A): Expressed as the percentage of scheduled operating time during which the elevator is actually available for service. It reflects system reliability, considering only unplanned downtime, and aligns with established reliability metrics in intelligent mobility systems [

43].

- •

Converted Energy Efficiency (

EC): Measures the proportion of electrical energy consumed by the traction motor that is effectively converted into useful mechanical work, i.e., the elevation of the cabin and its load. This indicator reflects the efficiency of the electromechanical drive system, including the impact of friction, alignment, and component degradation [

44].

- •

Effective Speed Index (

SP): Assesses whether the elevator operates at its nominal design speed. Deviations from rated speed, often symptomatic of mechanical wear, suboptimal control settings, or system overload, are penalised within this indicator, ensuring that service quality is maintained [

45].

- •

Quality (

Q): Captures the proportion of trips completed without incidents, malfunctions, or user-facing faults [

46]. Analogous to the “good product” metric in manufacturing, a high Q value signifies operational excellence and consistent user experience.

- •

Energy Efficiency in Movement (

EEM): Evaluates the actual energy consumption during active trips relative to an ideal achievable minimum, considering realistic physical constraints. This indicator supports the identification of hidden inefficiencies arising from mechanical or operational factors that increase energy demand during motion [

11].

- •

Energy Efficiency in Standby (

EES): Quantifies the energy consumption during idle periods compared to an optimised target. Given that standby consumption can represent up to 80% of total elevator energy use in some installations, this indicator is critical for assessing the system’s baseline energy performance [

47].

The adoption of OEEE enables real-time, data-driven evaluation of elevator systems, facilitated by CPS and IoT-enabled monitoring platforms common in smart buildings. By providing a unified, quantitative measure of operational and energy performance, OEEE supports predictive maintenance strategies, enhances resource optimisation, and aligns vertical transportation with broader sustainability and smart infrastructure objectives.

In addition, OEEE supports key functionalities of Industry 4.0, not only by requiring IoT-enabled monitoring systems for data collection and processing, but also by enabling intelligent elevator operation. The six sub-indicators can feed predictive maintenance systems (e.g., a drop in speed or energy conversion efficiency may indicate mechanical wear), be integrated into digital twin platforms for real-time performance tracking, and inform decentralised control algorithms that dynamically optimise dispatching and standby modes. These features position OEEE not only as a performance metric but also as a strategic input for smart, adaptive building management [

48].

From a practical standpoint, OEEE has significant potential to assist building operators, facility managers, and elevator service providers in identifying inefficiencies, guiding maintenance interventions, and supporting energy optimisation strategies. Furthermore, the metric aligns with broader sustainability objectives, enabling performance benchmarking that reflects both operational excellence and environmental responsibility.

Furthermore, OEEE addresses the limitations of classical OEE by explicitly incorporating energy consumption, thus responding to the growing demand for performance metrics that reflect environmental considerations. Its formulation draws upon recent academic advancements in KPI extensions for sustainability (e.g., OSEE, OEEM) and leverages established standards, such as ISO 25745, for consistent energy performance assessment [

49,

50].

In conclusion, OEEE represents a significant theoretical and practical contribution to performance measurement in the domain of vertical transportation. Its comprehensive scope, grounded in both operational and energy metrics, offers facility managers, engineers, and smart building stakeholders a robust tool for optimising elevator performance, reducing energy consumption and advancing the sustainability of urban mobility infrastructures [

51]. Future research directions include empirical validation of OEEE through field data acquisition, exploration of predictive maintenance applications using real-time indicator trends, and refinement of the framework to account for varying elevator configurations and usage profiles. Additionally, the integration of OEEE with ISO 22400 KPI structures may facilitate standardisation, enhancing comparability and widespread adoption across the vertical mobility sector.

In addition, while the proposed OEEE framework provides a holistic and integrated metric, it is important to acknowledge its current limitations and avenues for future enhancement. The present model assigns equal importance to each of the six sub-indicators through its unweighted multiplicative structure. However, we recognise that the relative importance of these indicators may vary depending on the specific operational context. For instance, a hospital may prioritise Availability above all else, while a certified green building might place a greater emphasis on energy efficiency metrics.

A significant area for future research is, therefore, the development of a weighted OEEE model (OEEEw). This would involve introducing customizable weighting factors that allow asset managers to adapt the indicator to their specific strategic priorities. The definition and validation of these weighting schemes for different building types and operational scenarios represents a promising direction for advancing this work.