1. Introduction

Grain storage in silos is a crucial part of the agri-food supply chain, as it directly affects the preservation of the nutritional and sanitary quality of products intended for human and animal consumption. Among the most important cereals worldwide are corn and wheat, which are key pillars of food security due to their high nutritional content, wide adaptability to different climatic conditions, and their role as dietary staples in many parts of the world [

1,

2,

3,

4]. Furthermore, they serve as essential raw materials in the food, livestock, and biofuel industries. Safe and efficient storage of these grains is crucial to minimize postharvest losses, prevent deterioration caused by fungi and insects, and ensure a consistent supply of staple foods. In this context, metal silos have become the most widely used storage structures, both in large-scale agri-food industries and among small rural producers, due to their numerous advantages. These structures can store large quantities of grain in a relatively small space, facilitate handling and unloading, provide protection against adverse weather conditions, and minimize exposure to insects and fungi. Additionally, their design enables them to adapt to various geographic areas, making them a versatile and practical option for many grain-producing regions worldwide.

However, during the grain storage in silos, two key factors determine the quality of the stored grain: temperature and moisture [

5,

6,

7,

8]. These parameters directly influence the grain respiration rate, the development of fungi and insects, and the formation of hot spots prone to condensation or deterioration. The distribution of these two parameters within the silo primarily occurs through the phenomenon of natural convection, which arises from density differences in the intergranular air due to thermal and moisture gradients, both internal and environmentally induced [

9]. These convective currents can lead to the formation of high-temperature zones and the migration of moisture toward cooler regions, creating critical conditions for grain preservation.

Considering the importance of temperature and moisture in determining the quality of stored grain, it is essential to understand how these parameters are distributed within the silo over time [

10,

11]. However, obtaining this distribution experimentally poses a significant challenge, as the measuring devices—such as thermocouples and humidity sensors—are typically limited to discrete locations and cannot accurately capture the conditions throughout the entire silo volume. Moreover, installing dense sensor networks can be costly, invasive, and impractical in silo environments. For these reasons, several research groups have developed mathematical models to simulate temperature and moisture gradients within silos [

2,

9,

12,

13,

14,

15,

16,

17,

18,

19,

20,

21,

22]. These models are based on the conservation equations of momentum, mass, and energy, formulated for multiphase systems that represent the coupling between grain and intergranular air in porous media. This numerical approach has enabled more detailed predictions of critical zone evolution, the optimization of preservation strategies, and the development of more accessible and efficient monitoring and control tools.

One of the first contributions to three-dimensional thermal modeling of silos was presented by Alagusundaram et al. [

23], who developed a conduction-only heat transfer model applied to the storage of canola and barley. The model was formulated in Cartesian coordinates and incorporated realistic boundary conditions, including solar radiation on the south wall and natural convection with the surrounding environment. It was experimentally validated in two silos located in Winnipeg, Canada. The results showed temperature errors ranging from 1.5 °C to 4.9 °C and demonstrated that 3D models predict temperature gradients more accurately than 2D approaches, particularly when thermally asymmetric conditions are induced by climate change. Years later, Thorpe [

24] proposed a comprehensive two-dimensional model of the silo ecosystem, specifically designed for wheat storage, which simultaneously incorporated the interactions between grain, intergranular air, insect dynamics, and the effects of fumigants. This model incorporated natural convection of heat and mass for the different species, enabling the identification of critical zones within the silo where high temperatures, moisture, and insect populations coincide—factors that pose a significant risk for grain spoilage. Additionally, it provided a tool to simulate the impact of aeration and fumigation strategies, becoming one of the first models to treat the silo as a complete multiphase and biological system.

Subsequently, Jia et al. [

4] developed a two-dimensional model in cylindrical coordinates to simulate the temperature distribution in a wheat storage silo with an internal heat source. The study showed that the hottest zones are located at the center and upper part of the silo, while the walls follow external temperature fluctuations. Montross et al. [

6] developed a 3D model to study the thermal behavior of corn stored in silos, which was validated using experimental data obtained in Kansas. The model considered heat transfer by conduction through the grain and convection between the silo walls and the ambient air, incorporating variables such as external temperature, solar radiation, and wind speed. The results showed that the grain mass has high thermal inertia and that silo walls exhibit greater temperature variability than the core, which remains more stable.

That same year, Andrade et al. [

14] developed a 3D model to predict corn temperature in metallic silos, experimentally validated in Brazil. The corrugated steel silo was instrumented with thermocouples distributed across different quadrants and heights. The mathematical model incorporated environmental conditions, such as solar radiation and convection, with the exterior, and accurately reproduced the thermal behavior over a 160-day storage period. The results showed good agreement between simulated and experimental data, with errors below 5%, demonstrating that the center of the silo maintains a more stable temperature than the wall-adjacent zones exposed to radiation.

Jiménez-Islas et al. [

25] conducted a two-dimensional numerical study to analyze natural convection of heat and mass in cylindrical silos filled with air and sorghum, using an axisymmetric domain and considering heat and moisture generation due to grain respiration and temperature gradients on the silo walls. The model simultaneously solved the conservation equations for energy, mass, and momentum under the Boussinesq approximation for porous media. A hot core formed at the upper section of the central axis of the silo, along with a single convective flow cell. The warmest regions also showed relative humidity buildup, which poses a risk to the stored grain’s quality. Abalone et al. [

16] compared the thermal and hygroscopic behavior of wheat and soybean stored in real silos in Rosario, Argentina, using a two-dimensional axisymmetric model. The study accounted for the specific properties of each grain and the real environmental conditions during winter. It was observed that soybeans had higher moisture accumulation near the wall areas, while wheat exhibited less migration, keeping intergranular air humidity below the critical level for fungal growth. The model enabled the identification of thermal and moisture risk zones that differ between grains.

Jian et al. [

26] conducted an experimental study on wheat storage over 15 months under real conditions in Canada. Temperature, intergranular air relative humidity, grain moisture content, and insect population were monitored. It was found that the highest temperatures were concentrated in the upper and central regions of the silo. At the same time, moisture content remained within safe ranges for most of the storage period. The study demonstrated that temperature control is crucial in preventing insect proliferation hotspots. Wang et al. [

27] developed a three-dimensional model to simulate the temperature distribution of wheat stored in a metal silo exposed to ambient temperature conditions. The model solved the transient conservation equations of mass, energy, and momentum, taking into account solar radiation and convection between the silo walls and the surrounding air. The simulation results were validated against experimental data obtained in China. The results showed that the warmest area was located in the upper region and along the south-facing wall of the silo, which was exposed to solar radiation, highlighting the impact of solar orientation. Carrera-Rodríguez et al. [

19] developed a two-dimensional numerical model to study the effect of variable ambient temperature on natural convection within sorghum silos. The model solved the conservation equations of mass, energy, and momentum in porous media, considering metabolic heat from the grain, environmental thermal gradients, and double diffusion. A hot core was observed forming at the upper central axis, along with zones of elevated relative humidity, which are associated with an increased risk of fungal growth. The model demonstrated that environmental thermal control is critical for designing conservation strategies in the absence of aeration.

In more recent years, Quemada-Villagómez et al. [

17] developed a two-dimensional numerical model to simulate natural convection in a cylindrical silo filled with sorghum and exposed to variable environmental conditions. The study solved the conservation equations of mass, energy, and momentum under the Boussinesq approximation, considering the metabolic heat generation from the grain and solar radiation on the south-facing wall. The results showed the formation of an upward flow vortex on the heated side and a downward flow on the shaded side, accompanied by the accumulation of heat and moisture in the upper part of the silo, indicating a critical environment for microbial development. Wang et al. [

27] proposed a hybrid model that combines computational fluid dynamics (CFD) with a neural network–based prediction algorithm to forecast the internal temperature of stored rice. The model was trained using historical data and experimentally validated, showing a significant improvement in accuracy compared to traditional methods. This methodology enabled the simulation of long-term storage scenarios, reducing computational time and optimizing thermal management strategies in silos.

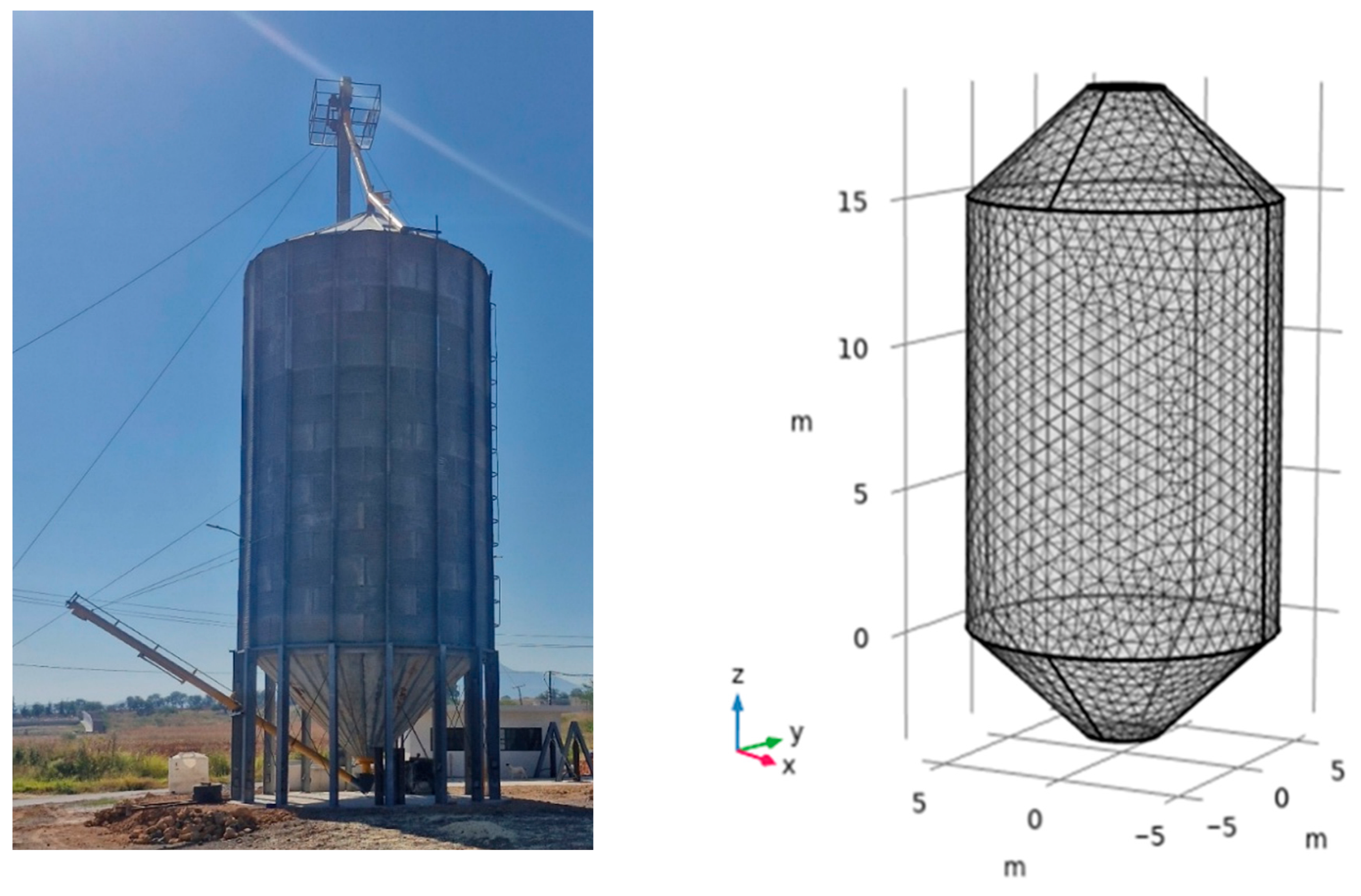

Despite the development and implementation of mathematical models for analyzing grain storage in silos, there are no prior studies that specifically examine the thermal and hygroscopic behavior of corn and wheat, two important agri-food cereals in the state of Guanajuato. This is especially true in the Bajío region, where their cultivation is a key economic activity. This study aims to analyze and compare the natural convection phenomena occurring in an industrial-scale metal silo during the storage of corn and wheat separately, under actual climatic conditions and incident solar radiation during December, which aligns with the local harvest and storage period. This analysis will help identify differences in temperature and moisture distribution patterns for each grain, which are crucial for designing more effective preservation strategies. This is particularly important for small-scale producers who rely on passive storage systems and have limited technological means to control internal silo conditions. Additionally, the results will enhance understanding of natural convection in porous media and support efforts to improve regional food security through better management of stored cereals.

3. Results

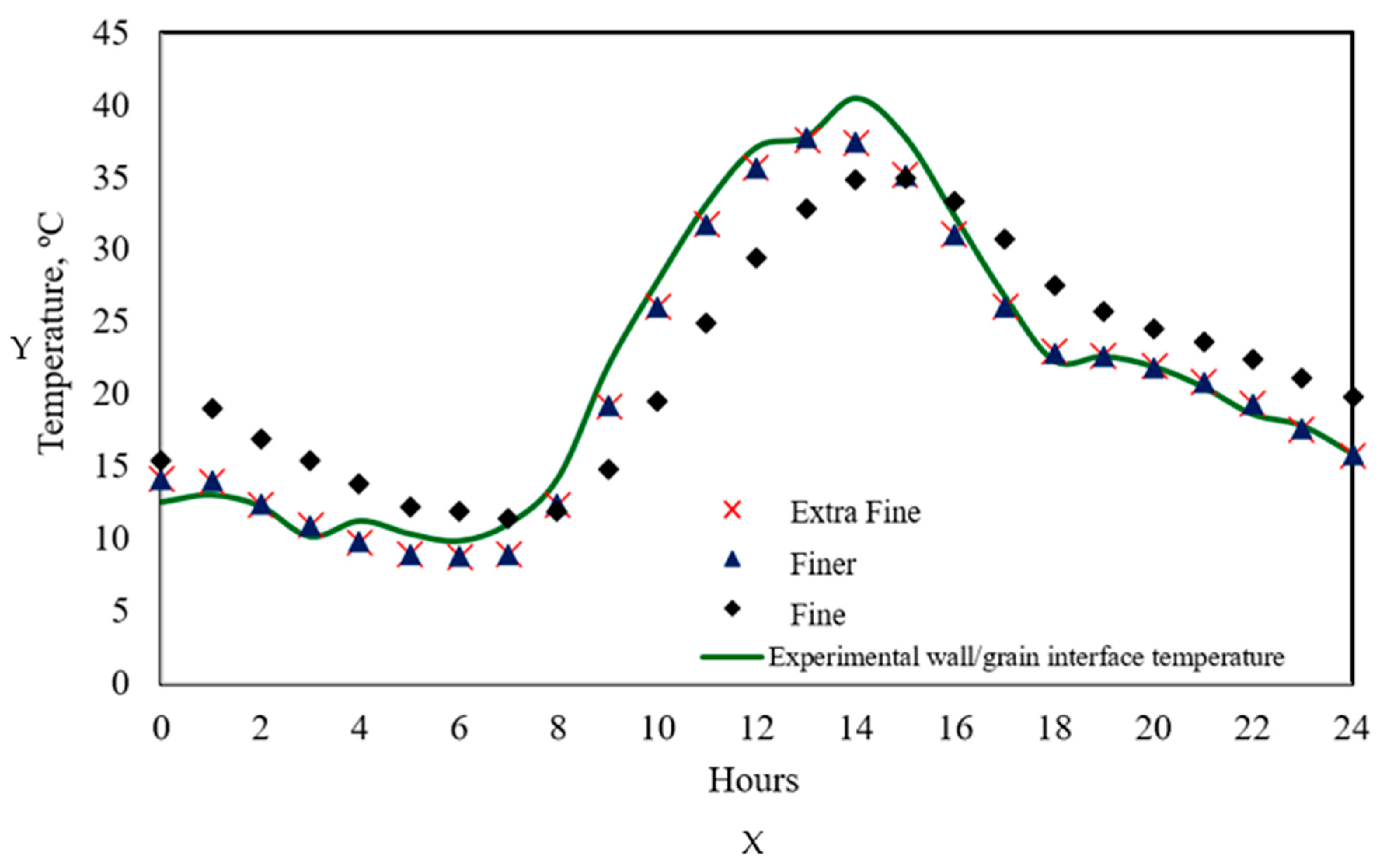

The mathematical model, represented by Equations (1)–(9), was used to compare the distribution of temperature and moisture profiles during the independent storage of corn and wheat throughout December. However, it is essential to note that due to the limited availability of experimental biochemical data in the literature for wheat, a constant respiration heat generation was assumed throughout the simulation period in this case. In contrast, for corn, a more comprehensive model was implemented, in which the respiration heat was considered as a function of grain temperature and moisture, thereby more realistically representing the metabolic heat generation of the grain during storage.

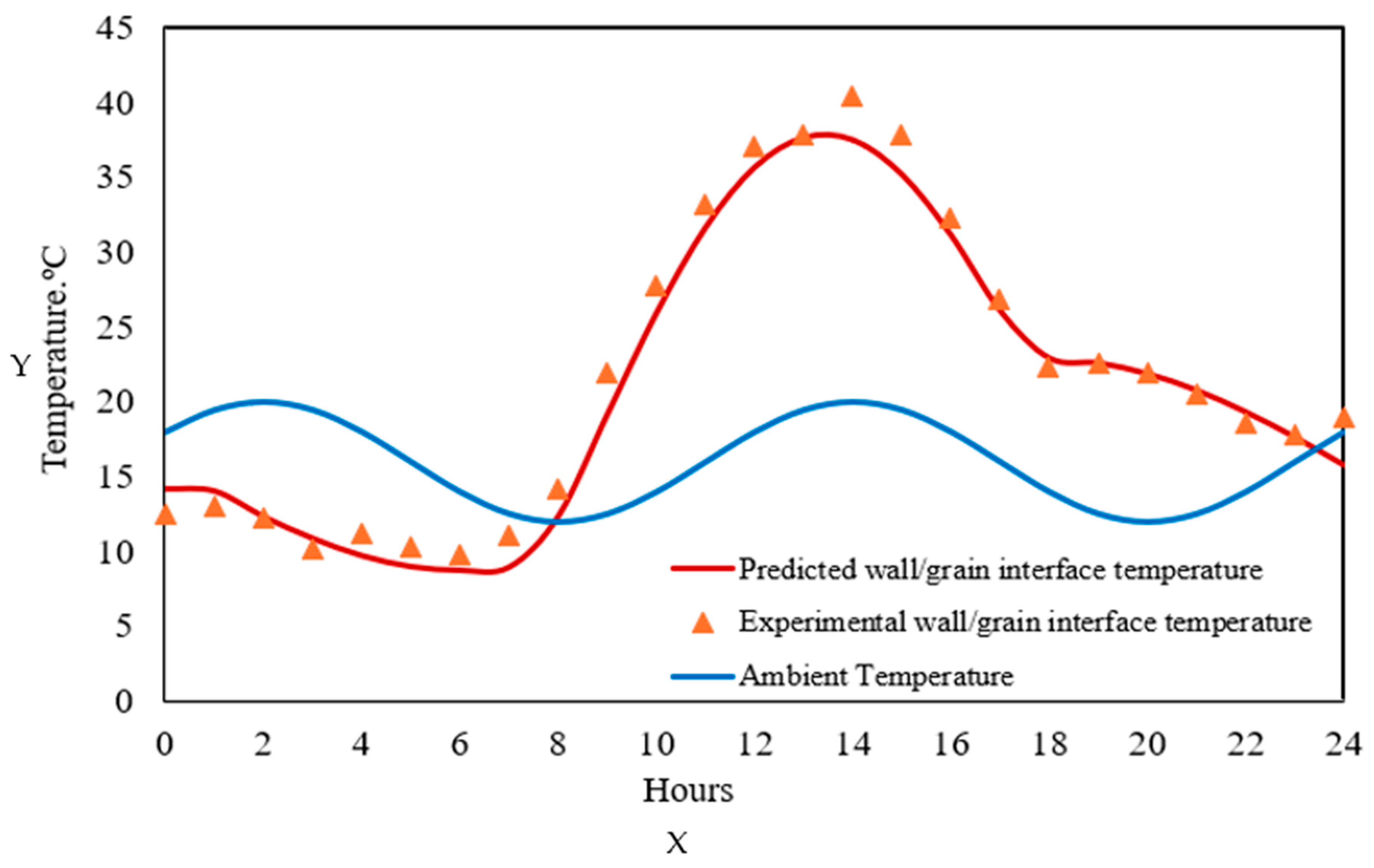

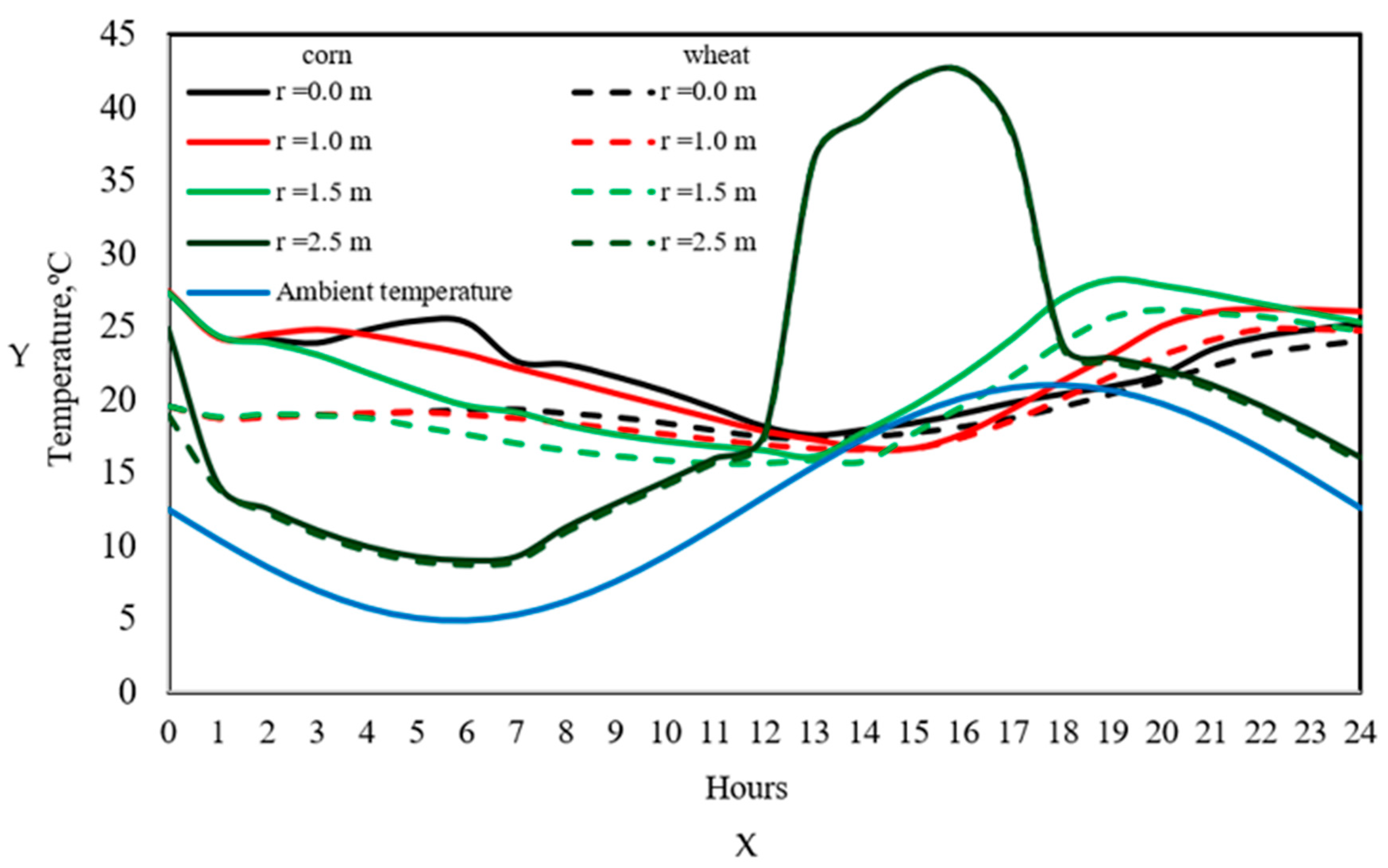

Figure 7 presents the radial temperature profiles during a storage day in December for both corn (solid lines) and wheat (dashed lines). The solid blue line represents the ambient temperature, while the other curves correspond to different distances from the center of the silo to the wall. The figure shows that, for corn, the temperature at the center of the silo remains higher than the ambient temperature during the early morning and lower during the warmest hours of the day, increasing again in the afternoon. This behavior highlights the thermal buffering effect of the grain, acting as an insulator, as also reported by Balzi et al. [

5], Montross et al. [

6], Barreto et al. [

9], and Gastón et al. [

15], who observed a thermal lag in the silo core relative to the ambient temperature due to the low thermal conductivity of grain. At 1 m from the center, the temperature profiles exhibit similar behavior to those at the center, although with a slightly greater thermal amplitude. At 1.5 m from the center, the temperatures exhibit a progressive transition toward ambient temperature variations, remaining lower than at the center until noon. After 16:00 h, the temperatures in this region become higher than the ambient temperature due to the combined effect of respiration heat and the onset of ambient temperature decline. In the zones closest to the wall, 2.5 m from the center, the temperature profiles more closely follow the fluctuations of the ambient temperature, but with higher values reaching peaks of approximately 40 °C [

15,

18,

30]. This phenomenon is explained by the absorption of solar radiation by the metal sheet, whose high thermal conductivity allows for rapid heat transfer to the adjacent grain. This effect was also observed by Wang et al. [

27] and Lawrence et al. [

33], who noted that zones near the wall are thermally unstable and susceptible to grain deterioration due to the accumulation of heat and moisture. In the case of wheat, the temperature profiles (dashed lines) exhibit a qualitatively similar trend to that of corn, although with slightly lower values, particularly at the center and at 1.5 m. This difference is attributed to two main factors: on the one hand, the model applied to wheat assumes a constant rate of heat generation due to respiration; on the other hand, wheat has a lower thermal conductivity compared to corn [

38]. However, in the zone adjacent to the wall, the predicted temperatures for both grains are practically identical, both qualitatively and quantitatively. This highlights the dominant influence of environmental conditions and solar radiation in this region, regardless of the type of grain being stored. As reported by Markowski et al. [

18] and Thorpe [

24], these zones represent critical points during storage due to their susceptibility to moisture condensation and fungal proliferation.

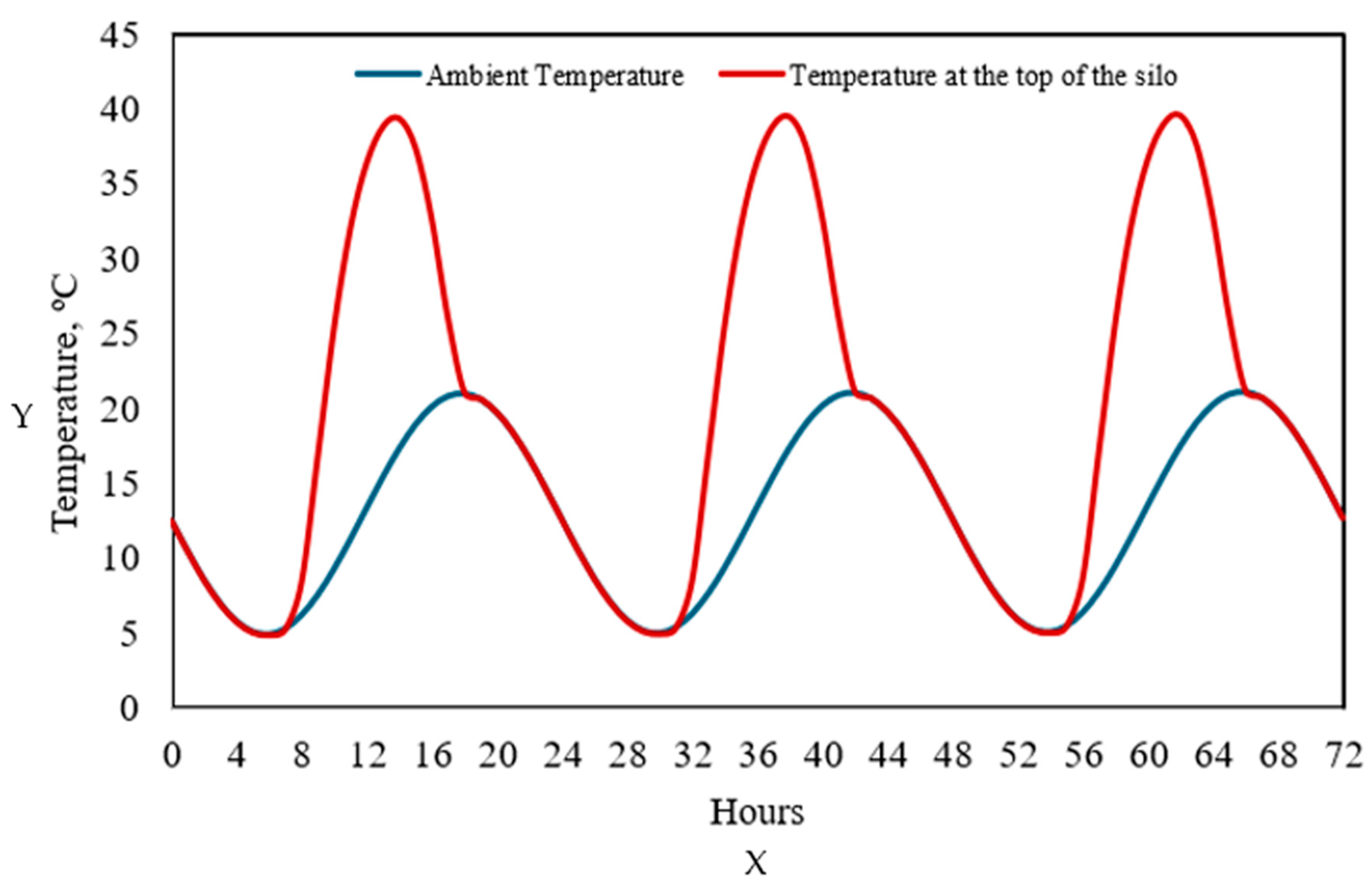

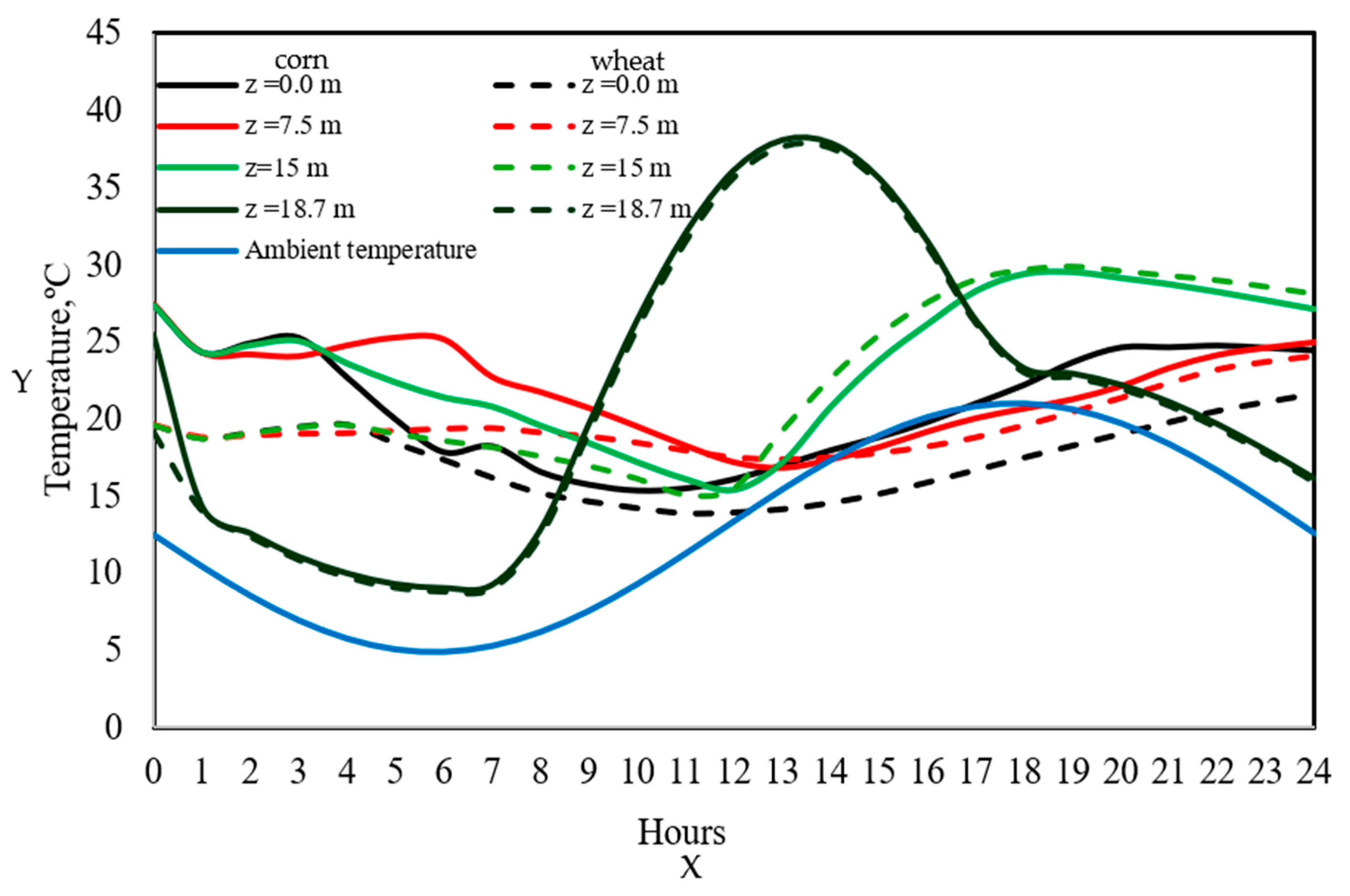

Figure 8 shows the temperature profiles at different heights within the silo, corresponding to the previous case, for a one-day storage period. As shown in the last figure, the solid lines represent the temperature gradients for corn, while the dashed lines represent those for wheat; the blue line indicates the variation in ambient temperature over the 24 h period. The figure reveals that the temperature gradients at the bottom of the cylinder are higher than the ambient temperatures, with differences of up to 10 °C compared to the ambient temperature, particularly between 00:00 and 10:00 h. This difference decreases during the hours of maximum solar radiation. However, it widens again after 18:00, when the external temperature begins to fall, while the grain still retains part of the absorbed heat. This thermal lag has been reported by Barreto et al. [

9], Markowski et al. [

18], Wang et al. [

27], Ledao et al. [

39], and Zheng et al. [

40], who showed that grain exhibits a delayed response to environmental variations, particularly in regions with low air exchange. In the case of the grain adjacent to the top of the silo, the temperature gradients coincide with ambient temperature during hours without solar radiation (before 08:00). However, after this time, the direct incidence of sunlight on the upper part of the silo causes a rapid temperature increase, reaching up to 40 °C around 13:00 h, when the Sun is nearly perpendicular to the silo roof [

31]. This behavior confirms the findings of Thorpe [

24] and Lawrence et al. [

33], who identify the top section of the silo as a critical zone for thermal accumulation due to direct solar radiation. For wheat (dashed lines), the temperature profiles exhibit a qualitatively similar trend to those of corn at the same heights, but with lower thermal gradients. These differences arise from the constant respiration heat model applied to wheat, as well as from the low thermal diffusivity, which limits the rapid transfer of heat through the grain. While corn exhibits a thermal diffusivity of 1.33 × 10

−7 m

2/s, the diffusivity of wheat is only 6.48 × 10

−11 m

2/s—approximately four orders of magnitude lower. This disparity means that wheat responds much more slowly to temperature changes, acting as a more effective insulator but also posing a greater risk of heat accumulation in poorly ventilated areas [

6,

19,

38].

It is also important to note that, in both cases, the areas near the roof and walls of the silo exhibit the highest grain temperatures, primarily due to direct solar radiation. This underscores the need to implement monitoring and control measures in these zones, as they are particularly susceptible to moisture condensation, which can promote fungal growth and grain spoilage, as also reported by Abalone et al. [

16] and Balzi et al. [

5].

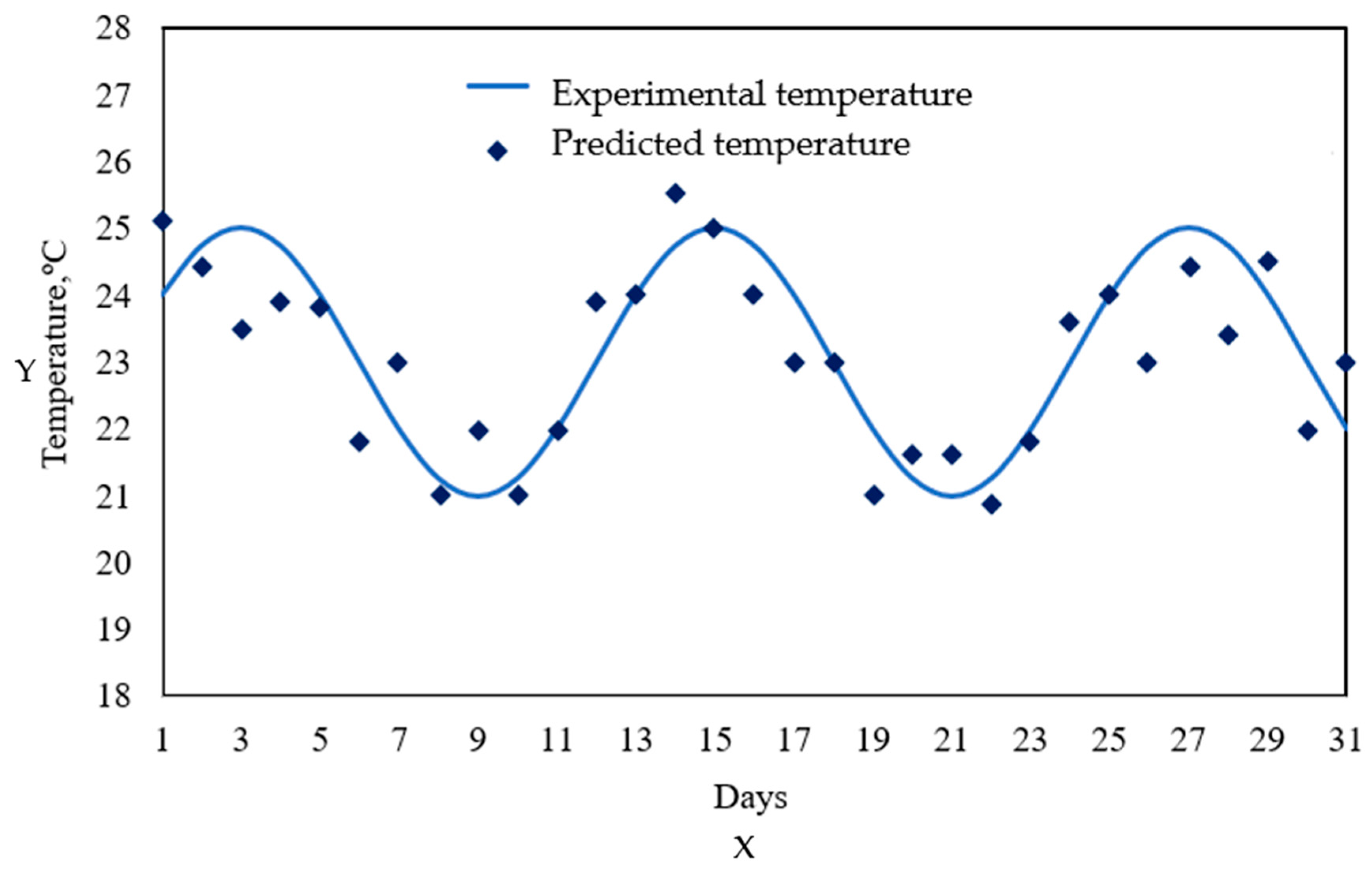

To evaluate the thermal behavior during the postharvest period characteristic of the region, numerical simulations were conducted for both corn and wheat over a continuous 31-day storage period corresponding to December. The simulations began on 1 December at 00:00 h. They ended on 31 December at 00:00 h, allowing for the analysis of temperature profile evolution inside the silo in response to daily variations in ambient temperature, incident solar radiation, and the grain’s respiration heat. This analysis helps identify cumulative temperature trends, critical zones within the silo, and thermal differences between the grains, considering both external conditions and the specific physical properties of each grain [

6,

9,

14,

22,

23].

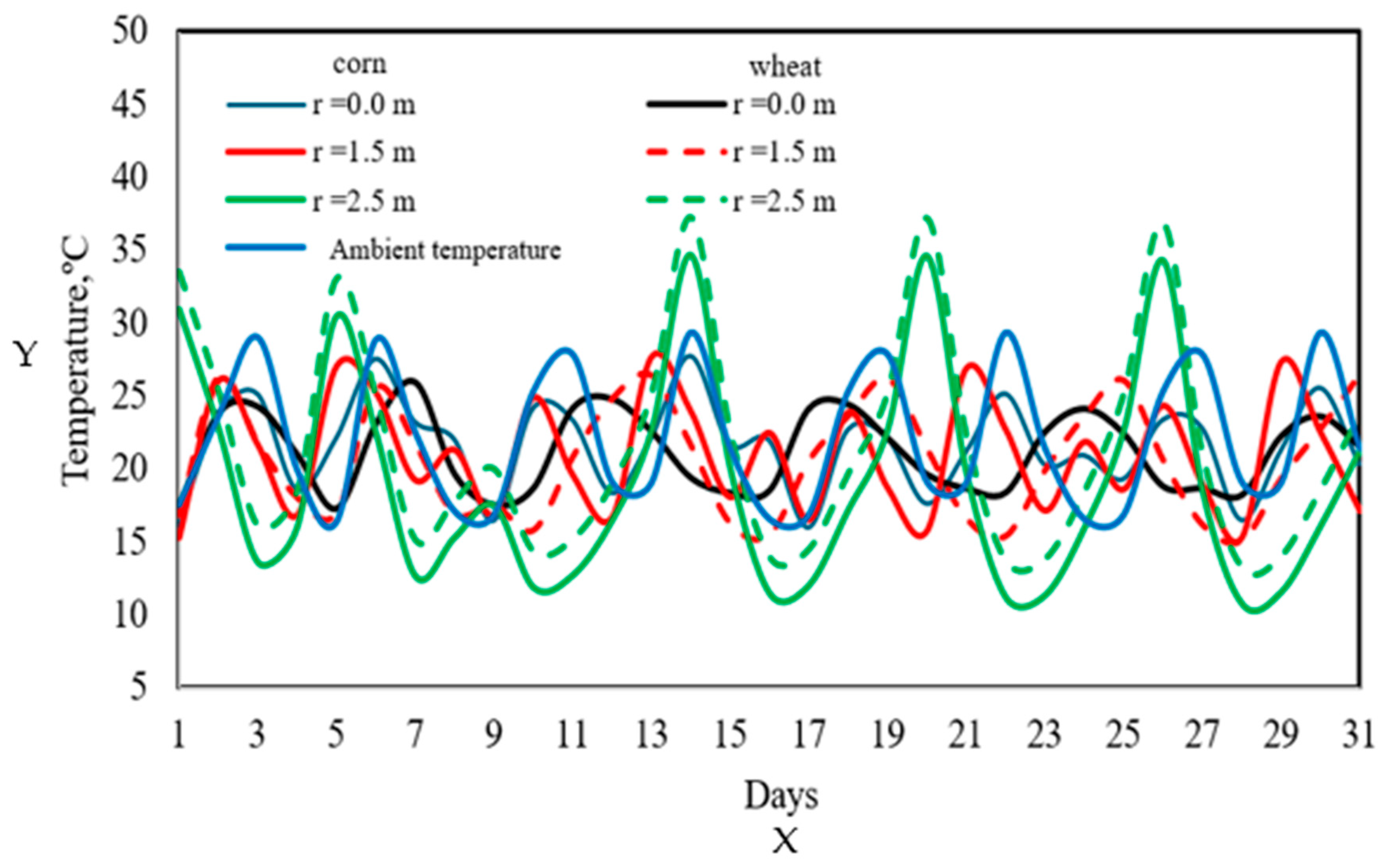

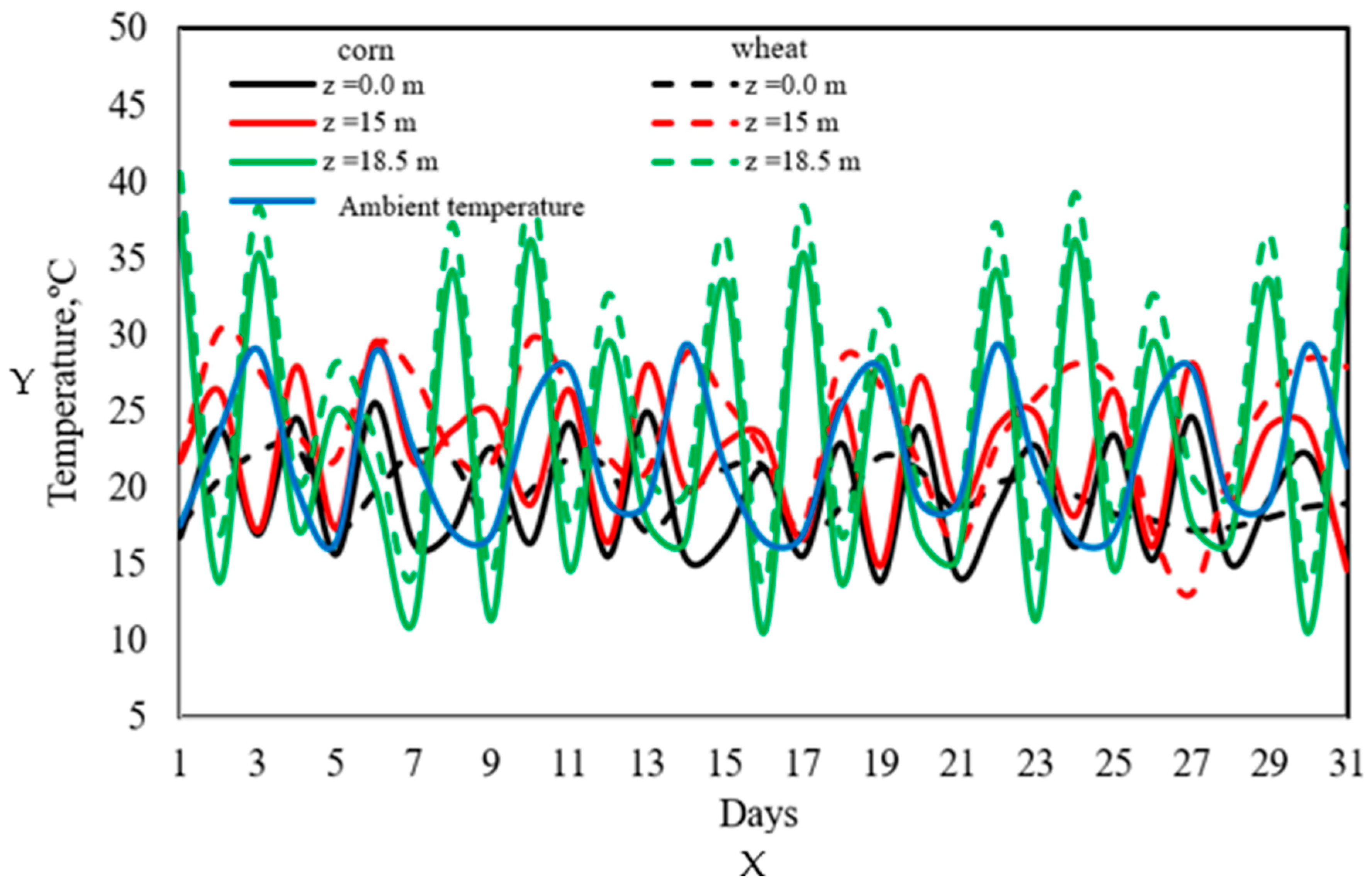

Figure 9 shows the evolution of temperature profiles as a function of the silo radius during December for corn (solid lines) and wheat (dashed lines), compared with the ambient temperature (blue line). It is important to note that the ambient temperature during this period does not exceed 30 °C, which establishes an upper limit for interpreting the radial temperature profiles of both grains. In the case of corn, the temperature at the center of the silo (solid black line) follows a trend similar to the ambient temperature, but with values up to 5 °C lower. This difference is attributed to two factors: first, the insulation effect of the grain, whose low thermal conductivity slows down heat diffusion toward the lower regions, and second, the limited direct influence of solar radiation in this zone. Additionally, the metabolic heat generated by respiration is distributed gradually and does not fully compensate for nighttime heat losses. At 1.5 m from the center, corn temperature profiles exhibit values comparable to the ambient temperature, but with a time lag in the thermal peaks. This phenomenon is typical during grain storage, where heat diffusion is not instantaneous and temperature gradients propagate with a delay from the surface to the interior, as described by Khankari et al. [

3], Barreto et al. [

9], Lawrence et al. [

21], and Thorpe [

24]. Near the wall of the silo (2.5 m from the center), grain temperatures exceed ambient temperatures, particularly from the tenth day of storage onward, reaching peaks of approximately 40 °C. This progressive increase is explained by the accumulation of heat caused by the incident solar radiation on the metal sheet, which has high thermal conductivity and transfers energy to the adjacent grain. The cumulative effect persists until approximately day 27 of storage, after which a thermal decrease begins, coinciding with a drop in ambient temperature during the final days of the month. This pattern indicates that although silo buffers rapid thermal changes, external conditions remain a key factor in areas near the walls and roof [

1,

21,

30]. In the case of wheat, temperature gradients exhibit a qualitatively similar behavior to that of corn, with center and intermediate zone temperatures being lower throughout the storage period compared to corn gradients. As a result, wheat transfers heat more slowly, remaining more thermally insulated and exhibiting lower gradients along the radial axis. However, in the zone near the wall, wheat and corn temperatures are both quantitatively and qualitatively similar, highlighting the dominant influence of external conditions—particularly solar radiation—on the thermal behavior in that region. In this case, grain properties play a secondary role, as direct exposure to the external heat source homogenizes temperatures regardless of the type of grain stored. This phenomenon is consistent with observations by Thorpe [

24], who identifies these zones as critical for condensation and fungal infestation due to elevated temperatures and potential moisture differences [

2,

19,

28].

Regarding the axial temperature profiles,

Figure 10 illustrates the temperature distribution along the height of the silo for corn (solid lines) and wheat (dashed lines), compared to the ambient temperature throughout December. For corn, it is observed that at the bottom of the silo (black solid line), temperatures remain below the ambient temperature for most of the month. This occurs because this region does not receive direct solar radiation and is less exposed to environmental heat exchange, acting as a thermal buffer zone, as previously reported by Montross et al. [

6], Lawrence and Maier [

7], and Barreto et al. [

8]. At a height of 15 m, temperatures increase significantly compared to the bottom and begin to partially follow the ambient temperatures, reflecting greater sensitivity to environmental thermal variations, particularly during the warmest hours of the day. In the upper part, near the walls adjacent to the roof, grain temperatures exceed ambient values, reaching peaks of up to 40 °C and lows of 10 °C, indicating the cumulative effect of direct solar radiation on the metal roof. This zone exhibits the most significant temperature fluctuations, making it a critical area for grain preservation, as demonstrated in studies by Thorpe [

24]. In the case of wheat (dashed lines), the temperature gradients display a qualitatively similar pattern to that of corn, but with slightly higher values, particularly in the upper region. This is due to the low thermal diffusivity of wheat, which allows for more heat retention in the grain mass, thereby preventing the rapid dissipation of energy. Despite this, the overall shape of the curves and the sensitivity to radiation are comparable for both grains.

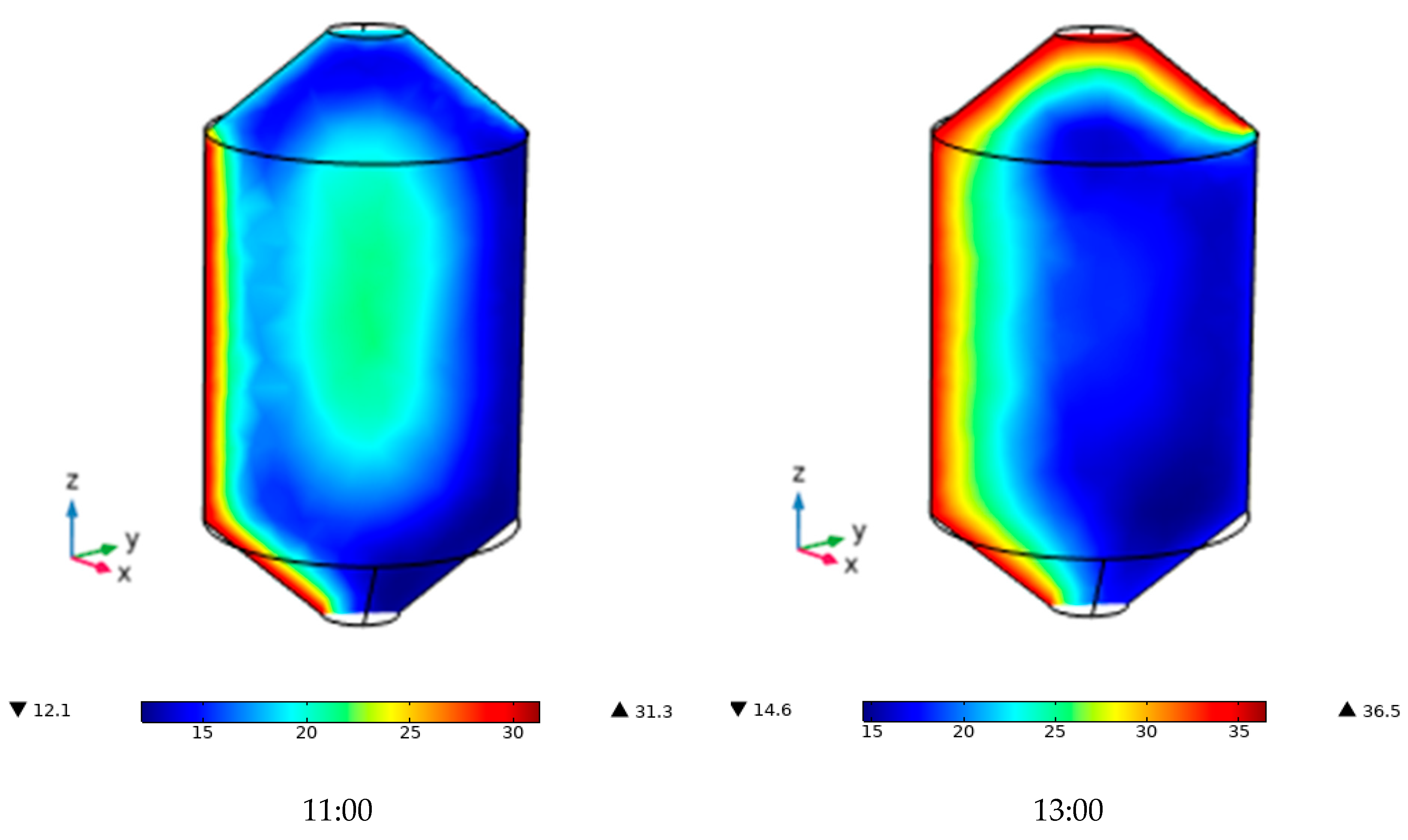

The following section analyzes the temperature contours, which serve as a fundamental tool for understanding the dynamics of grain storage in silos. Unlike point temperature profiles, contours enable the spatial and continuous visualization of how heat is distributed within the stored volume. This is crucial for identifying critical zones of heat accumulation, temperature gradients, and potential areas of deterioration due to condensation or microbial growth. The analysis of temperature contours obtained through computational fluid dynamics (CFD) clearly illustrates the thermal evolution of the grain inside the silo under realistic conditions of solar radiation and ambient variation. The orientation of the silo (with east on the left and west on the right), combined with the solar incidence model, captures the thermal asymmetrical energy generated throughout the day.

Figure 11 shows the temperature contours for a day in December in the case of stored corn. During the early hours of the day, the left wall of the silo receives a greater amount of solar radiation. The temperature of the grain adjacent to the metal sheet reaches approximately 30 °C due to direct solar incidence. Meanwhile, the west wall, in shadow, remains near 15 °C, and the center of the silo reaches about 20 °C, indicating that the grain acts as a thermal insulator. This behavior is consistent with that described by Zheng et al. [

40], who identified horizontal thermal gradients in partially irradiated silos. As the Sun approaches its zenith (noon h), the angle of solar incidence becomes more perpendicular, intensifying heat absorption on the roof and east wall. The maximum temperature of the grain near the sheet rises to 36 °C, and the heat begins to propagate toward the silo core, increasing internal temperatures. The west wall remains cooler, further accentuating the horizontal thermal gradients. These gradients not only affect grain uniformity but can also induce internal natural convection flows, as reported by Balzi et al. [

5] and Abalone et al. [

16]. During the afternoon, around 15:00 h, the Sun is nearly perpendicular to the silo roof, causing significant overheating in the upper section of the silo. The heat is rapidly transferred to the grains adjacent to the roof and descends along the west wall, which now begins to warm up. In contrast, the left wall begins to cool, creating a thermal inversion. This dynamic asymmetry favors nighttime condensation processes, particularly at the grain–metal sheet interface. In the absence of solar radiation during the nighttime hours (22:00), the silo cools down due to ambient temperature, and both the walls and roof lose heat rapidly. However, a hot core forms near the west wall, with temperatures of around 30 °C, which represents an optimal condition for insect development. This residual heat originates from the energy accumulated during peak hours and is reinforced by heat generated through grain respiration, which increases in magnitude due to previous thermal gradients. Moreover, the cyclic heating and cooling of the silo walls can induce condensation in the outer layers of grain, promoting fungal development [

21,

30,

39].

Figure 12 shows the temperature contours for wheat during a single day of storage in December. The thermal behavior is mainly characterized by low thermal diffusivity, which influences how the grain absorbs, transfers, and retains heat throughout the day. At 11:00 h, the temperature distribution shows a predominantly cool interior, with a slight increase in temperature on the east-facing wall due to early solar radiation. A thin thermal gradient appears on the outer surface. At the same time, the inner mass remains cool, indicating that wheat, due to limited thermal conductivity, initially retains heat on the metal sheet surface without transferring it inward. Around 13:00 h, the temperature contours indicate the start of heating in the upper grain layers, especially near the roof of the silo, where solar radiation strikes more directly as the Sun approaches zenith.

The angle of incidence becomes nearly perpendicular, increasing heat absorption on the metal surface [

22,

30]. As a result, the thermal core shifts upward, replacing the previous central position and marking the beginning of a thermal gradient from the top to the interior. By 15:00 h, a critical point in thermal behavior is reached. The figures for this time show widespread overheating in the upper section and along both lateral walls of the silo, with maximum temperatures occurring in the grain next to the metal sheet. These elevated temperatures, symmetrically distributed on both sides, result from the accumulated solar radiation. In contrast, the central core stays relatively cool, confirming the insulation properties of wheat and its high thermal inertia [

29,

31]. This uneven temperature distribution creates steep gradients between the outer and inner layers, which may cause condensation and localized deterioration in the outermost grain layers. At 22:00 h, without direct or diffuse solar radiation, a general cooling of the silo walls and bottom occurs due to the drop in ambient temperature [

40,

41,

42,

43,

44]. However, a well-defined warm core remains in the upper central region of the silo, where temperatures stay close to 30 °C. This residual heat, retained because of wheat’s low thermal dissipation, represents a critical zone for preservation. The presence of warm internal layers and cold external surfaces causes interstitial air condensation, especially near the top of the silo, which may promote fungal and insect development, as reported by several authors [

45,

46,

47,

48,

49].

Overall, the thermal behavior of wheat shows a resistance profile, with significant surface heat retention and a tendency to form persistent hot spots. This sets it apart from other grains and calls for specific ventilation and thermal monitoring strategies. Compared to corn, wheat exhibits a slower and more symmetrical thermal response, with limited heat penetration toward the center but a higher risk of localized accumulation in the upper region of the silo, especially during nighttime cooling.

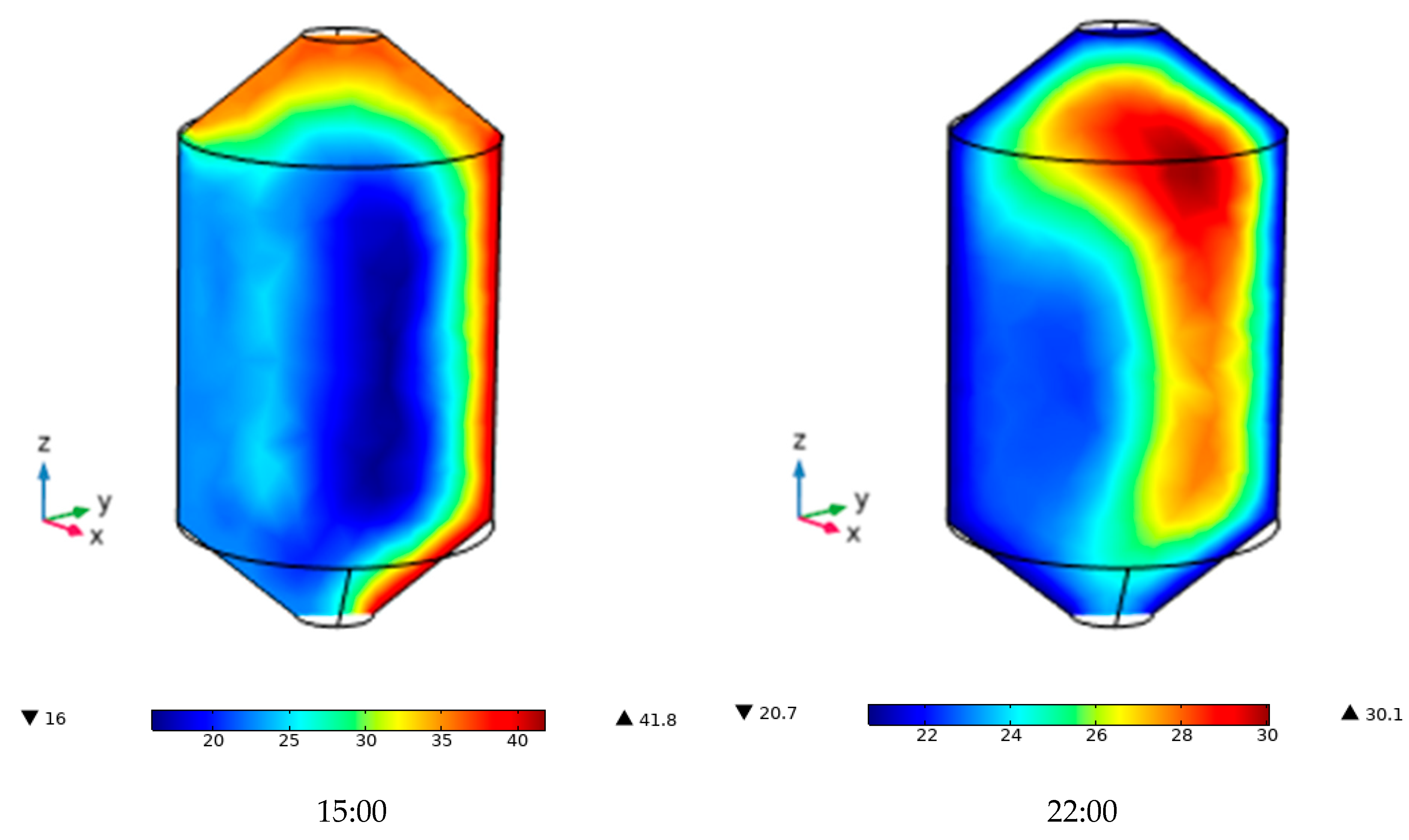

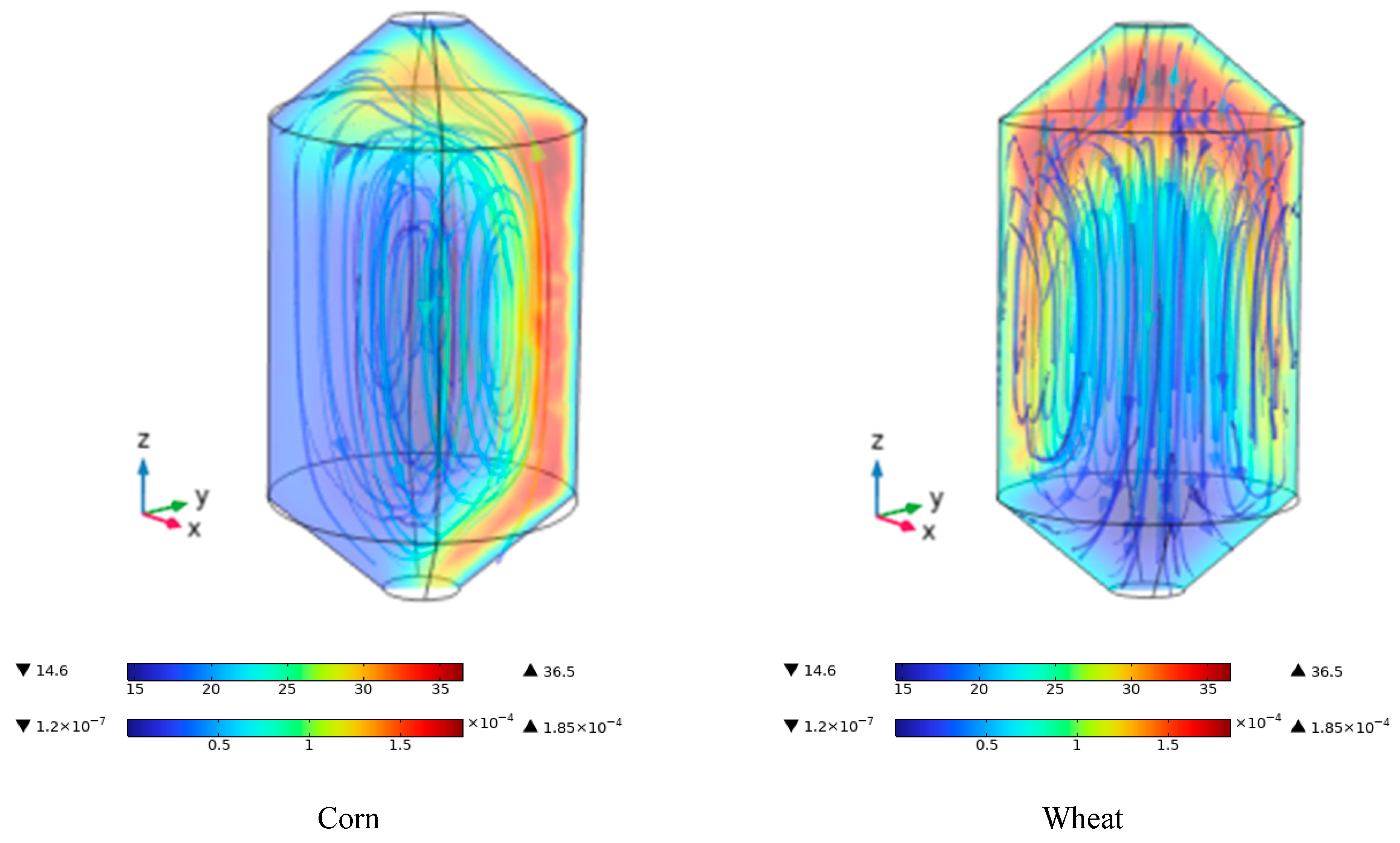

Figure 13 illustrates the effect of external temperature conditions at 14:00 h—when solar radiation is at its peak—on natural convection during the storage of corn and wheat. The figure corresponding to the corn case illustrates how heat accumulation on the left wall of the silo, which corresponds to the east-facing side, generates a strong temperature gradient that drives natural convection within the stored grain mass. This differential heating creates intense streamlines in the sun-exposed zone, which induce interstitial air movement from cooler to warmer regions. As a result, the warm air rises along the left side, and this convective flow tends to displace cooler air toward the center and the opposite side of the silo, promoting a thermal recirculation cycle. This flow pattern is characteristic of natural convection driven by temperature gradients in porous media, as described by Thorpe [

24], Barreto et al. [

8], and Gastón et al. [

15]. These authors demonstrated that irradiated areas generate upward flows that intensify interstitial air circulation. In this situation, the air movement not only transfers heat but also generates localized cooling zones near the hot wall, due to the contact of cooler air with the grain. However, this circulation also poses significant risks, as the resulting thermal gradients create conditions for moisture condensation—especially when warm, humid air encounters cooler regions of the silo, such as the center or the shaded side. These condensation-prone zones are critical points for fungal development and grain spoilage, underscoring the importance of understanding and controlling natural convection patterns during long-term storage. The extreme values of temperature (14.6 °C to 36.5 °C) and air velocities (1.2 × 10

−7 to 1.85 × 10

−4 m

3/day) reflect the magnitude of the phenomenon, with well-defined flow patterns highlighting the influence of solar radiation on the thermal behavior within the silo [

1,

29].

In the case of wheat, the temperature contours and streamlines reveal a distinct natural convection dynamic, unlike that observed in corn. Due to the low thermal diffusivity of wheat, heat does not rapidly penetrate the grain mass, allowing the center of the silo to remain thermally more stable and cooler throughout the day. This thermal stability is further reinforced by the higher specific heat capacity of wheat (1900 J/kg·K) compared to corn (1780 J/kg·K), meaning that more energy is required to raise the temperature of wheat grain, which therefore heats up more slowly. As a result, the metabolic heat generated by the grain dissipates more evenly toward the exterior, producing symmetrical and vertical interstitial airflows throughout the silo. Although this behavior indicates a more uniform thermal distribution, it also presents a potential risk: the homogeneous natural convection flow may facilitate condensation of interstitial air moisture not only on the walls and roof—as typically observed in corn—but throughout the entire grain mass [

50]. This phenomenon has been reported by authors such as Barreto et al. [

8,

9] and Thorpe [

24], who warn that in the absence of controlled ventilation, natural convection driven by mild temperature and humidity gradients can create ideal conditions for fungal development in various regions of the silo. Thus, while wheat’s slower and more symmetrical thermal response may initially appear advantageous, it requires close attention to prevent adverse effects associated with localized moisture accumulation [

18].

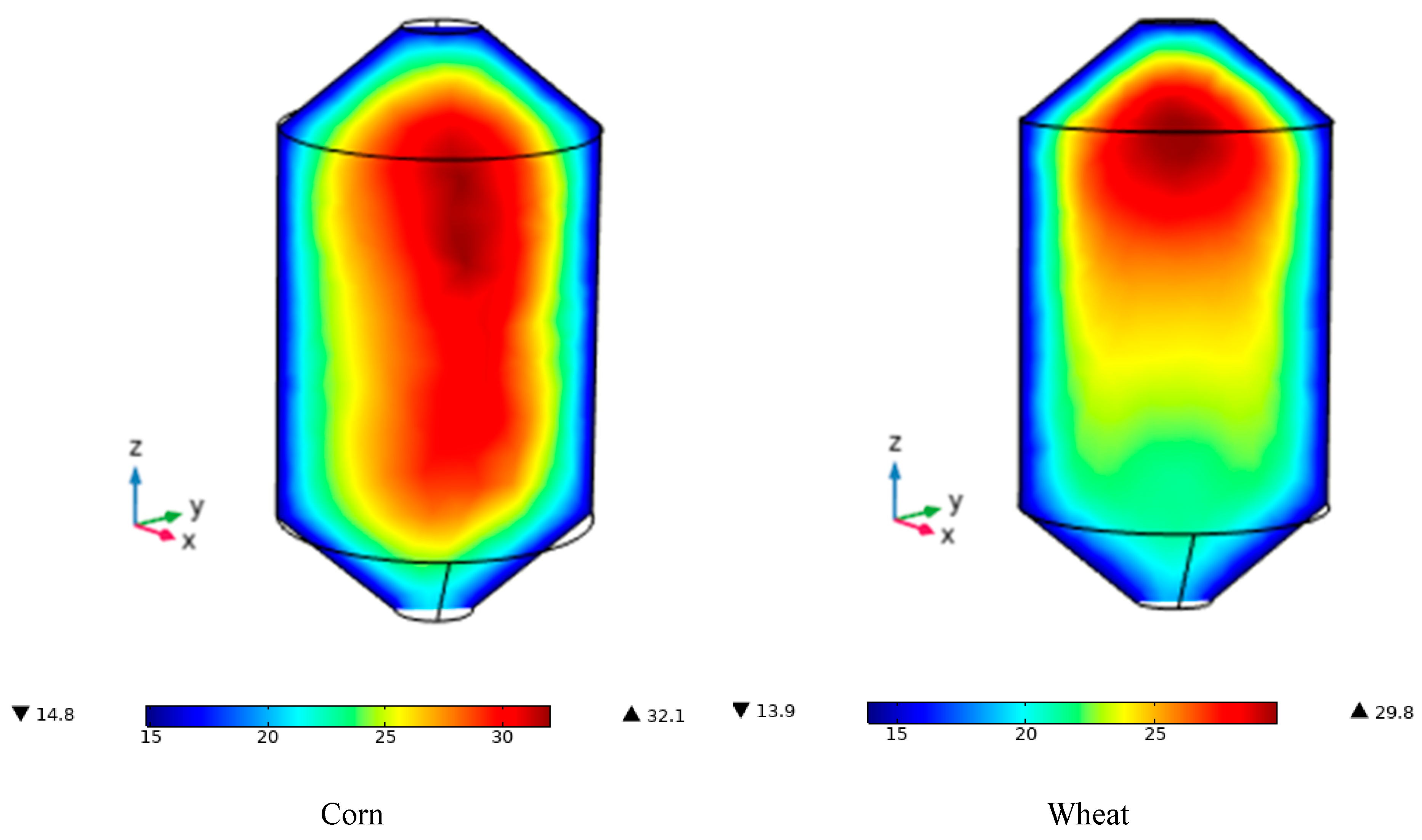

Figure 14 shows the temperature contours at the end of the storage period on December 31 at 00:00 h, corresponding to the corn case. The figure reveals the formation of a hot core in the central region of the silo, a phenomenon widely known in practice among operators as the appearance of a thermal heart. This area becomes a critical point for grain preservation, as it is far from the walls and therefore lacks direct contact with the cooler silo surfaces. Moreover, during storage without active ventilation systems or with poor airflow distribution, this area receives little or no aeration, favoring the accumulation of heat and moisture. This situation is further exacerbated by the heat generated by grain respiration and, in some cases, by the metabolic activity of insects and microorganisms, which can lead to a significant temperature rise, as noted by Khankari et al. [

3], Balzi et al. [

5], and Thorpe [

24]. The thermal data support this observation, with maximum temperatures of 32.1 °C recorded at the center of the silo and minimum temperatures of 14.8 °C at the walls, indicating a significant temperature gradient even in the absence of direct solar radiation [

29].

This nighttime thermal contrast highlights the cumulative effect of the grain’s metabolic heat during prolonged storage, underscoring the need for effective monitoring and ventilation strategies to prevent spoilage in these critical zones. In the case of wheat, by the end of the storage period, a different thermal behavior is observed compared to corn. Instead of forming a centered hot core, the thermal hotspot shifts toward the top of the silo, where the highest temperatures—around 29 °C—are concentrated, while the lower regions remain at approximately 25 °C. This vertical redistribution of heat is directly related to the thermal properties of wheat, which has a higher specific heat capacity than corn, allowing it to absorb more energy without experiencing rapid temperature increases. However, this also makes it more prone to retaining heat in its surface regions. Likewise, its lower thermal diffusivity limits the rate at which heat propagates inward, allowing respiration heat generated during storage to accumulate in the upper region, which is also indirectly affected by the residual effect of solar radiation [

29,

38]. Although the silo walls display the same cooling pattern observed in corn (minimum temperatures around 14.8 °C), this confirms that ambient variation continues to significantly influence the silo’s surface temperature, even in the absence of direct solar radiation. It is essential to note that, despite differences in the location of the thermal core, both corn and wheat cases present optimal conditions for insect development, as internal areas exceed 25 °C during the early morning hours when external temperatures are lower. Additionally, the silo’s cold walls create thermal gradients that promote interstitial air condensation, thereby establishing ideal conditions for fungal growth and microbiological spoilage [

22,

40]. These observations underscore the importance of thermal monitoring across various zones and the implementation of targeted ventilation strategies to maintain grain quality, tailored to each grain’s thermal properties [

51].

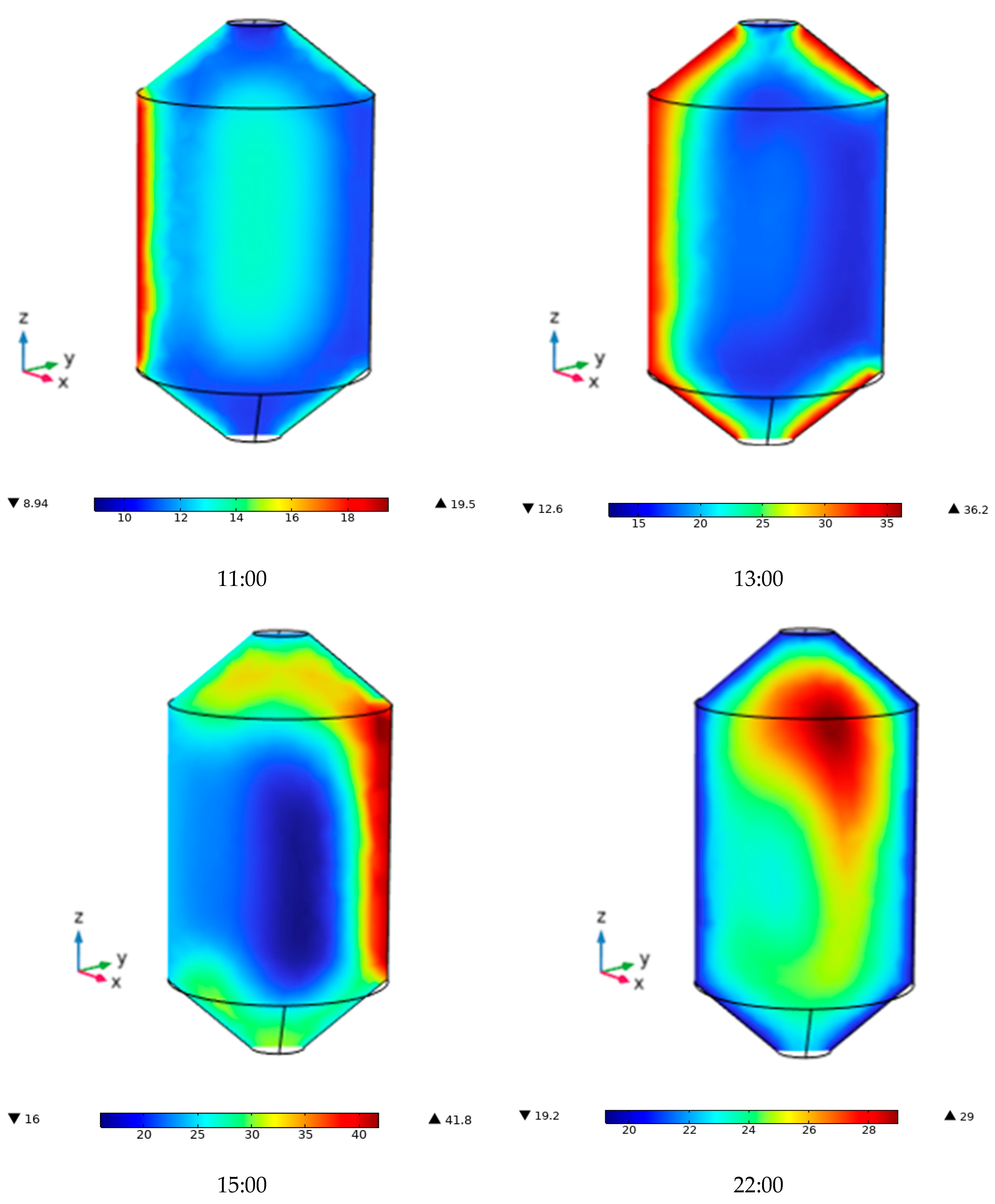

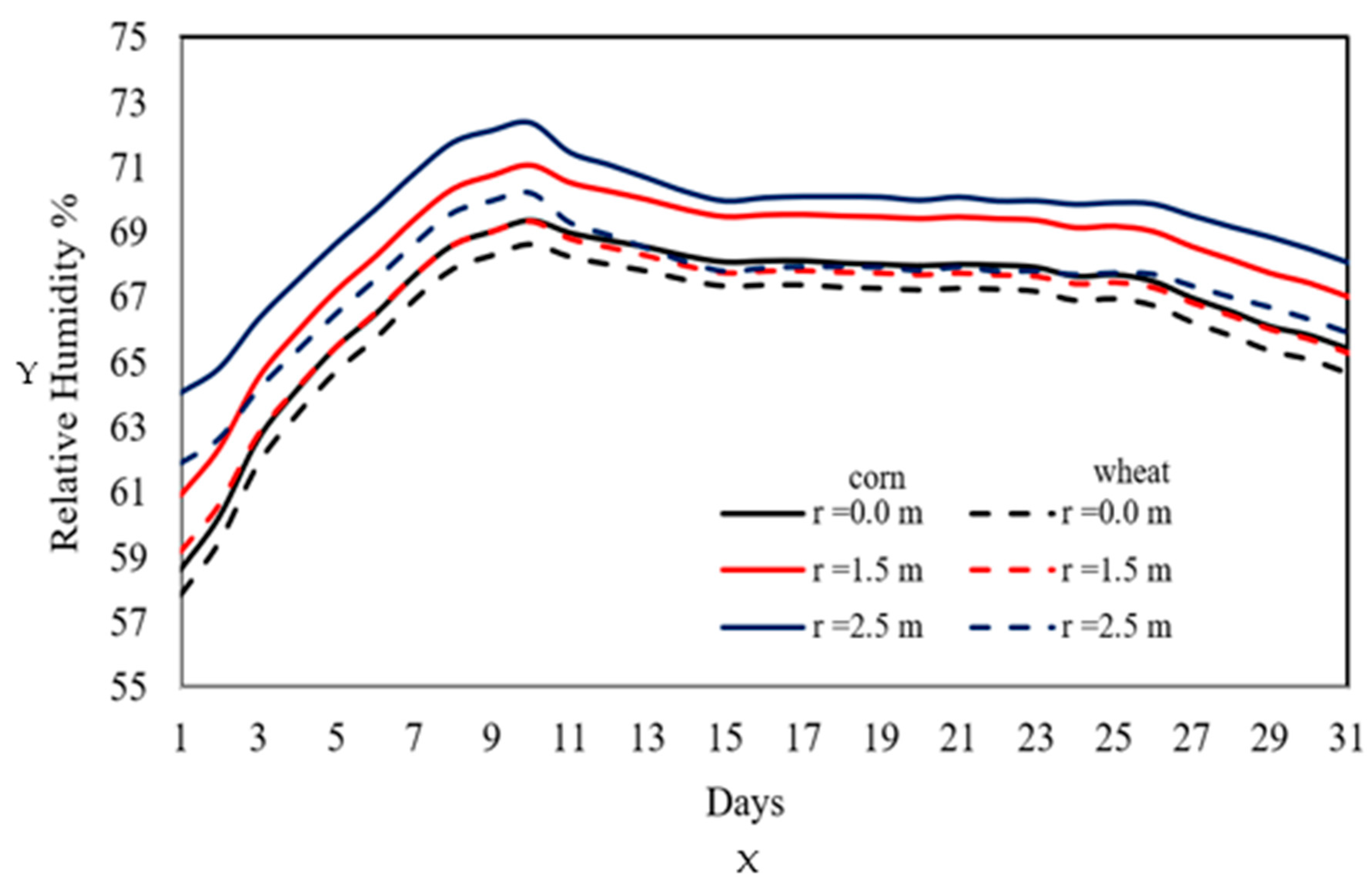

Figure 15 shows the distribution of interstitial air relative humidity (RH) at different radial positions inside the silo during the storage period of corn (solid lines) and wheat (dashed lines) in December. In the case of corn, it can be observed that RH in the center of the silo increases during the first 10 days, reaching a maximum value of 69%, followed by a gradual decrease that stabilizes around 66%. This distribution is associated with the high temperatures recorded in the silo core, as well as with the insulating effect of the grain, which helps maintain the moisture content within the optimal range for safe corn storage—typically between 65% and 68%. At 1.5 m from the center, RH values are slightly higher, reaching 70% in the first days and stabilizing at around 69%, which already represents a potential risk for the development of fungi and insects, especially when combined with temperatures above 25 °C. Finally, in the area closest to the silo walls (2.5 m), a significant increase in RH is observed, reflecting the effects of diurnal and nocturnal environmental variations that induce heating and cooling cycles. These cycles promote the condensation of interstitial moisture in this region, creating favorable conditions for biological deterioration [

6,

40,

41,

51].

In the case of wheat, a general trend like that of corn is observed, although with slightly lower values at all radial positions. This difference is attributed to two specific factors: first, the physical properties of wheat—particularly its higher specific heat capacity and lower thermal diffusivity—and second, the assumption of a constant respiration heat in this case, which makes water vapor production by metabolism less sensitive to temperature variations. Despite these differences, RH values in the zone near the silo walls also exceed 70%, especially during the initial days of storage. This indicates that external environmental conditions and solar radiation continue to play a key role in moisture distribution. These conditions equally promote condensation and fungal growth, reinforcing the need to carefully monitor these silo regions, even when the thermal properties of the grain appear to offer greater stability [

2,

22,

42,

47,

48,

50].

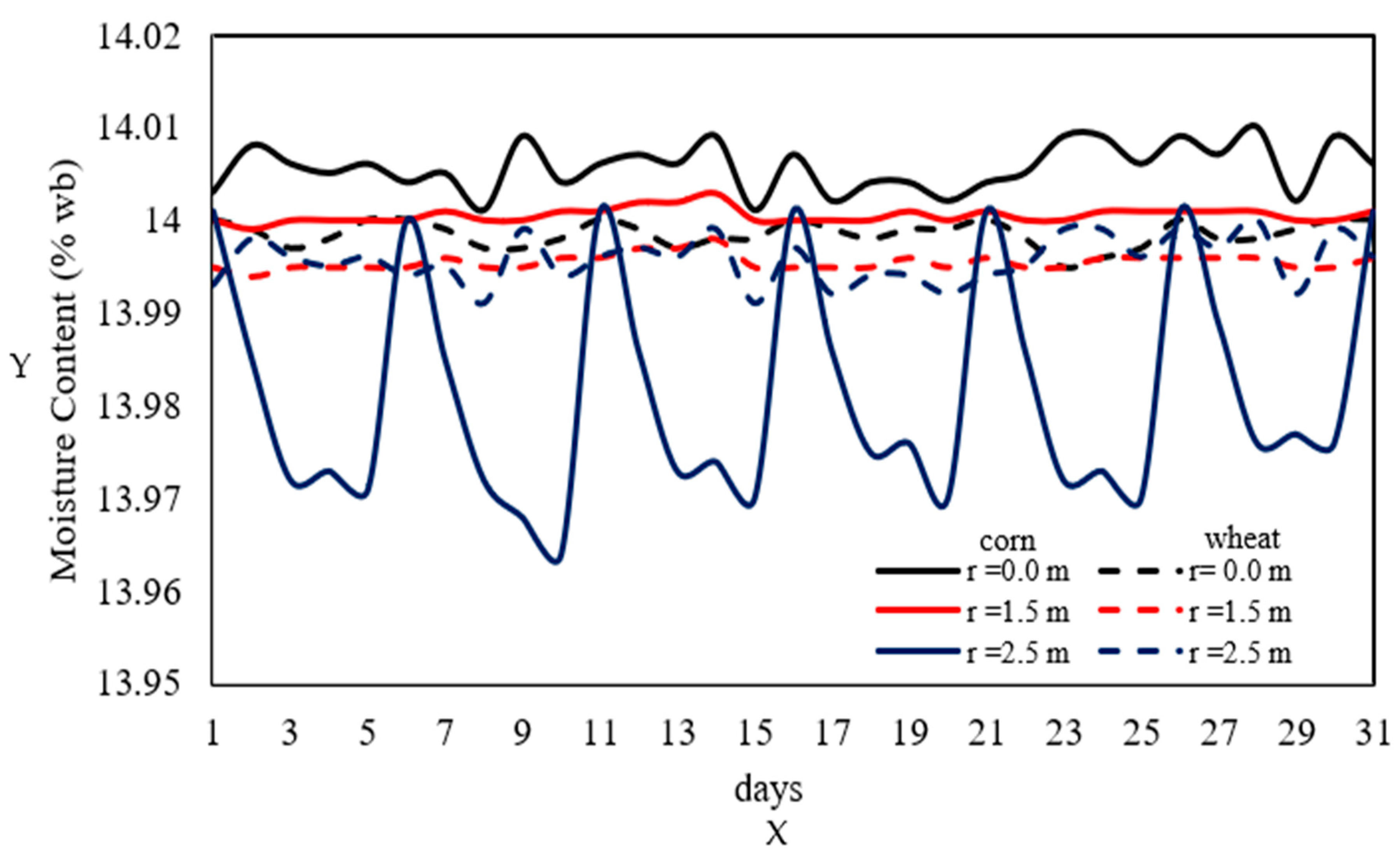

Figure 16 shows the variation in grain moisture content as a function of time and radial position inside the silo for corn (solid lines) and wheat (dashed lines) during December. For corn, the moisture content at the center of the silo exhibits slight variations throughout the storage period, not exceeding 14.01%. This behavior is consistent with the previously analyzed thermal and relative humidity patterns, confirming that the center remains relatively stable due to the insulating effect of the grain. At 1.5 m from the center, the moisture content shows a slight decrease, indicating a minor migration of moisture toward cooler regions. At 2.5 m from the center, near the silo walls, larger fluctuations are observed, attributed to the combined effects of solar radiation during the day and nighttime cooling, which generate condensation and evaporation cycles in the outer grain layers [

6,

22,

44,

45]. These variations intensify the interstitial relative humidity near the walls, as previously shown. In contrast, the behavior is much more stable, particularly at the center of the silo, where the moisture content remains virtually constant throughout the storage period. At 1.5 m from the center, a slight and insignificant decrease is observed, attributed to the low thermal diffusivity of wheat, which slows down heat and moisture transfer [

6,

42,

43,

44]. Finally, at approximately 2.5 m from the center, near the silo walls, the moisture content also exhibits fluctuations, albeit with a lesser amplitude than in corn, never dropping below 13.99%. This indicates low variability in wheat’s interstitial relative humidity in these regions. Overall, these results confirm that wheat exhibits more stable hygrothermal behavior than corn. However, both grains present specific risks depending on the silo region, with areas near the walls being the most vulnerable to condensation and microbiological spoilage [

39,

41,

42,

43,

44,

45].

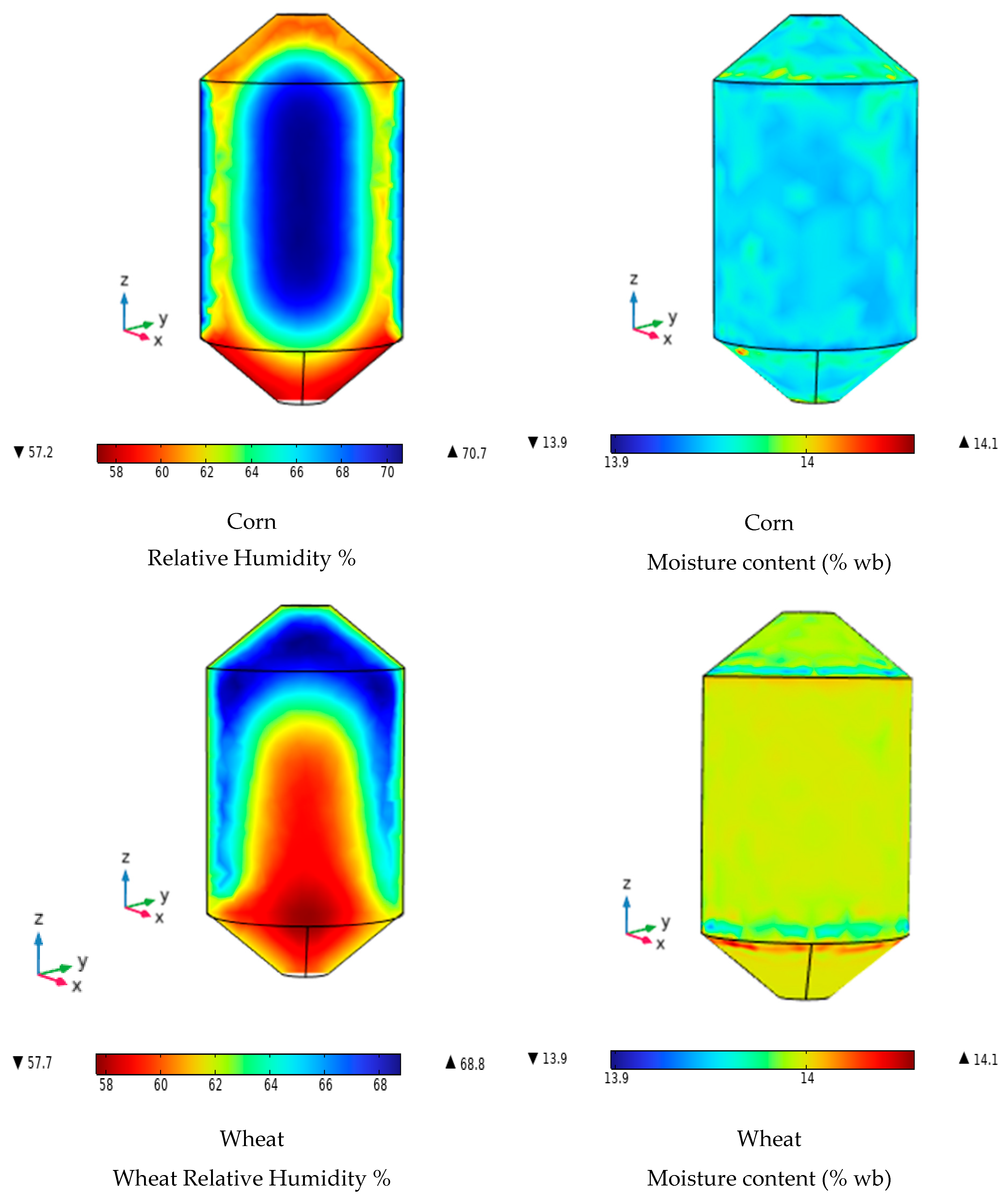

Finally,

Figure 17 shows the contours of interstitial relative humidity and grain moisture content of corn and wheat at the end of the storage period. In the case of corn, a core forms in the interior of the silo where the relative humidity reaches approximately 70.5%, increasing the risk of insect and fungal growth. In contrast, the regions near the silo walls, especially the bottom, maintain values around 60%, which are considered safe for storage. Regarding the grain moisture content of corn, it remains nearly uniform, close to the initial value of approximately 14.1%; however, respiration heat—dependent on temperature—promotes water transfer to the interstitial air, contributing to an increase in relative humidity [

15,

16,

40,

42]. For wheat, the interstitial relative humidity reaches its highest values (around 68%) near the silo walls and at the top, posing a risk of biological deterioration. In contrast, in the lower zone, values close to 58% are observed, which are considered safe. Meanwhile, the grain moisture content of wheat stays constant and nearly unchanged at about 14%, due to its physical properties—specifically its higher specific heat capacity and lower thermal diffusivity—and the assumption of constant respiration heat, which limits moisture transfer from the grain to the interstitial air. Overall, these results show that corn is more vulnerable in the central core of the silo, while in wheat, risks are mainly in the walls and upper part, emphasizing the need for targeted control and monitoring strategies to ensure safe storage [

14,

32,

36].