1. Introduction

Addressing climate change remains one of the most pressing challenges for humanity in the 21st century. Photovoltaic (PV) power generation provides clean renewable energy, and its large-scale application can effectively reduce greenhouse gas emissions, thereby facilitating the global decarbonization process. Therefore, expanding the installed solar power capacity has become a core initiative to achieve economic decarbonization [

1]. Projections indicate that the global installed PV power capacity will reach 6000–8000 GW by 2050, with China accounting for 60% of the new additions [

2]. However, the large-scale development of the PV industry has intensified land use conflicts [

3]. Satellite monitoring data reveals that most non-residential PV systems worldwide are constructed on cultivated land [

4]. By 2020, PV power stations had occupied 911 km

2 of arable land [

5]. Agrivoltaic technology provides a comprehensive land use solution to balance food security and energy supply through the organic integration of PV power generation and agricultural production on the same land [

6].

At present, agrivoltaic systems can be divided into three types according to the categories of agricultural land: agrivoltaic systems combined with cultivated land, livestock farms, and solar greenhouses [

7]. When PV systems are integrated with cultivated land, the installation height and layout of PV panels may restrict the passage of large agricultural machinery (such as harvesters and seeders), thereby hindering mechanized agricultural operations [

8]. In PV systems combined with farms, livestock manure, hair, and dust can easily adhere to the surfaces of PV panels, reducing power generation efficiency [

9]. Moreover, the maintenance of PV panels requires access to farm areas, which may interfere with animal activities. In contrast, solar greenhouse PV systems are less constrained by compatibility with the natural environment and conflicts in production management, making them the preferred model for current agrivoltaic technology.

Research on solar greenhouse PV systems has involved crops such as tomatoes, lettuce [

7], sweet peppers [

10], grapes, onions [

11], berries [

12], and potatoes [

13]. Yano et al. [

14] found that the use of semitransparent PV panels has minimal impact on the growth of horticultural crops, only slightly reducing plant biomass yield while accelerating the apical growth mechanism of light-loving plants. Chatterjee et al. [

15] explored a cost-effective combination of poly (3-hexylthiophene) (P3HT) donors and a non-fullerene acceptor based on fluorinatednaphthobisthiadiazole (FNTz-FA) for applications in green light wavelength-selective organic solar cells. These cells convert solar energy in the green light spectrum into electrical energy while utilizing the transmitted blue and red light to grow crops. Torrente et al. [

16] proposed a new model to simulate the distribution and uniformity of radiation within agricultural greenhouses with PV panels installed on the roof, which are critical factors in PV greenhouse design. The model enables scientists and engineers to design agricultural power-generating greenhouses. Boccalatte et al. [

17] designed a high-efficiency micro-PV greenhouse with near-zero energy consumption, establishing a dynamic simulation model of a real greenhouse to predict its performance and explore beneficial energy-saving control strategies. Petrakis et al. [

18] investigated the impact of semitransparent PV units on global horizontal irradiance and photosynthetically active radiation. Jamil et al. [

19] studied the impact of varying PV transparency on strawberry yield and growth with Cd-Te PV modules, and evaluated the potential of agrivoltaics as a sustainable solution for strawberry production in northern climates. Hermelink et al. [

20] provided the yield response curves of individual berry crops to increasing shade, also distinguishing between different radiation intensity environments, which can help in selecting optimal crop and panel density combinations for different locations. Zhang et al. [

21] presented spectral-splitting concentrator agrivoltaics (SCAPV), which can effectively photosynthetically harvest excess light energy for photovoltaic power without compromising crop productivity. This system transmits a selected light spectrum for plant growth while reflecting the remaining spectrum for electricity generation. Jamil et al. [

22] compared strawberry agrivoltaics using two different types of solar PV modules—uniform illumination provided from semi-transparent thin-film cadmium telluride (Cd-Te) and non-uniform illumination from semitransparent crystalline silicon (C-Si) including rows of solar cells and transparent solar-grade glass. Results showed that non-uniform illumination from C-Si PV modules significantly increased fresh weight by 18% compared to controls while lowering soil temperature and increasing humidity.

Existing research on PV greenhouses has primarily focused on improving crop yield and PV conversion efficiency, with less attention given to the integrated design of PV and electrical systems. This study presents the comprehensive design of a 50 MW agrivoltaic power station in Shaanxi Province, China. PV modules are installed on the greenhouse roof. The design encompasses both the PV power generation system (including simulation) and the primary electrical system for step-up and grid connection. Crucially, the PV system design carefully considers the impact of the shading rate on crop production. A variety of optimized PV module layout schemes are employed to minimize shading while ensuring power generation efficiency. The grid connection design encompasses the main circuit design (including N − 1 contingency analysis), short-circuit current calculation, and key electrical equipment selection. The design of this project addresses a gap in the integrated design of PV and electrical systems, which can serve as a valuable reference for similar engineering projects.

2. Project Overview

This study proposes the construction of a 50 MW centralized agrivoltaic power plant in Hengshan County, Yulin City, Shaanxi Province. The PV panels will be installed on the roofs of solar greenhouses, covering a total construction area of 30,000 square meters. The station is designed to operate in grid-connected mode. The power plant is planned to connect to the grid via a 110 kV outlet with a double feeder.

Hengshan District is located at approximately 37.95° N and 109.26° E, deep in the inland areas of Northwest China. The terrain is dominated by plains and hills, with relatively gentle undulations. Influenced by a temperate continental climate, it enjoys plenty of sunny days throughout the year, with few cloudy ones and minimal cloud cover blocking sunlight. Such climatic conditions are conducive to enhancing the power generation efficiency of photovoltaic modules.

As a major agricultural area in Shaanxi, Hengshan is suitable for large-scale deployment of PV systems due to its abundant solar radiation and relatively flat terrain. Additionally, its solid agricultural foundation provides favorable external conditions for agricultural cultivation in photovoltaic greenhouses. According to the 2024 monthly meteorological data (

Table 1), the annual average temperature in this area is about 9.4 °C, and the annual total solar radiation on the horizontal surface reaches 1568.3 kWh/m

2 with a peak sunshine duration of 4.3 h, making Hengshan a region with rich solar energy resources. This not only facilitates the construction of agrivoltaic power stations and agricultural production but also lays a foundation for building a new green and low-carbon agricultural model in the region.

The design consists of two main parts: the PV power generation system and the grid-connected step-up primary electrical system. The PV system design involves the layout of PV arrays as well as the selection of DC combiner boxes and inverters among other components. The grid-connected step-up primary electrical system design includes the main electrical wiring configuration, main transformer selection, short-circuit current calculation, and selection of key equipment (e.g., busbars, current transformers, voltage transformers, circuit interrupters, disconnector switches).

3. PV System Design

3.1. PV Module Selection

The selection of PV modules shall be comprehensively evaluated based on technical indicators including conversion efficiency, production cost, weather resistance, and impact on crop growth. As demonstrated in [

11], double-glass modules (especially the semi-transparent, amorphous, silicon glass-based type) are better suited to meeting the lighting requirements of greenhouse crops due to their high light transmittance and low sensitivity to shadow obstruction. Compared with conventional polycrystalline silicon modules, they can significantly optimize the growth environment of crops in greenhouses, which was adopted for this project. The LR5-72 HBD 550 M bifacial double-glass module with a rated power of 550 Wp. The specific technical parameters are detailed in

Table 2, and a total of 90,909 pieces of this module type need to be configured for the project.

3.2. Inverter and DC Combiner Box Selection

It is proposed to adopt centralized converters for this project, in view of its large-scale system capacity of over 20 MW and the requirements for high-efficiency, economical, and stable operations of the system. Fourteen units (one unit on standby) of SG3125-HV-20 model centralized inverters from Sungrow, with a capacity ratio of 1.23, meet the power generation demand and were selected. The inverter’s parameters are shown in

Table 3.

Given the large number of connections between photovoltaic modules and inverters, DC combiner boxes were selected to reduce wiring complexity, enhance system reliability, and facilitate subsequent operation and maintenance. The KBT-PVX16 DC combiner box was selected, and detailed parameters are shown in

Table 4. A total of 232 units (with 5% as backup) of 16-in-1 combiner boxes are planned along the pre-reserved channels on the ground of each greenhouse to ensure stable operation of the PV system and efficient power collection.

3.3. PV String Design and Array Layout

Combining the above parameters of photovoltaic modules and inverters, the number of series-connected PV modules is calculated according to Formulas (1) and (2) in Standard GB 50797-2012 [

23].

where

Kv and

K′v are the PV module temperature coefficient of the open-circuit voltage and operating voltage, respectively.

N is the number of series-connected PV modules (

N is an integer), and t and t’ are the extreme low and high temperatures under the PV module’s operating conditions (°C), respectively.

Vdcmax is the maximum DC input voltage permitted by the inverter (V).

Vmpptmax and

Vmpptmin are the maximum and minimum MPPT voltage of the inverter (V), respectively.

Voc and

Vpm are the open-circuit voltage and operating voltage of the PV module (V), respectively.

The annual maximum and minimum temperatures at the project site are 24.1 °C and −8.4 °C, respectively. According to the above formulas, the calculated range for the number of series-connected PV modules N was 21 ≤ N ≤ 28. A total of 27 modules were selected for each string, and the rated power of each string was 14,850 W. Based on the total installed capacity of the PV power station and the rated power of each string, the number of PV strings required for the project was approximately 3367.

Shading is the most critical issue in greenhouse PV systems. PV panels block sunlight from reaching crops in the greenhouse, creating partial shadows that may affect crop growth [

24]. Therefore, the setting of shading rates should be adjusted according to different crop types. When the shading rate was 30% in a previous study, there was no significant impact on lettuce yield, and the specific leaf area was increased [

25]. However, at a 50% shading rate, lettuce yield decreased by 21–42%, with a significant reduction in leaf count [

26]. When the shading rate was 25.9%, strawberry yield increased by 16.73% (equivalent to 447.9 g per plant) [

27]. It is evident that light-loving crops such as vegetables and fruits require a shading rate below 30% [

28]. Unlike light-loving crops, shade-tolerant crops like mushrooms and yellow sweet potatoes generally require a shading rate above 50% [

28]. At a 17.97% shading rate, the growth and development of yellow sweet potatoes were inhibited, with dry weight reduced by 21.6% [

29]. When the shading rate reached 75%, mushroom yield increased by 102% [

30].

A reasonable panel layout can minimize shading effects and maintain a uniform light distribution [

31]. For instance, at a 10% shading rate, when PV panels were arranged in a linear pattern, tomato ripening was slightly delayed, with reduced fruit quality and diameter [

32]. However, when the panels were arranged in a checkerboard pattern, tomato plants grew taller, and yields increased significantly [

33]. Therefore, different from conventional long-row arrangements, a combination of checkerboard and long-row layouts was adopted for the PV array in this project to meet the shading requirements of various crops, given the large project scale and diverse crop types. The plans of this project include the installation of PV modules on the top of greenhouse sheds. Each greenhouse has an arched roof, with a north–south width of 8 m and an east–west length of 60 m. A fixed adjustable bracket system was adopted for the PV panels, with adjustment of the tilt angle twice a year: it is set at 20° from April to September, and adjusted to 40° from October to March of the following year. All modules are fixed facing due south. The arrangements are as follows:

In greenhouses requiring a shading rate below 30%, the PV modules are arranged in a quasi-checkerboard pattern (

Figure 1a): spaced along the east–west direction with 3 rows in the north–south direction and a 1.139 m gap between adjacent rows.

In greenhouses with a shading rate between 30% and 50%, the checkerboard layout (

Figure 1b) was adopted: east–west spacing with 4 rows in the north–south direction.

In greenhouses requiring a shading rate above 50%, long-row parallel arrangements (

Figure 1c) are used, with a 1.139 m gap between adjacent rows.

3.4. PVsyst Simulation and Results Analysis

The PVsyst software Version 8.0.5 was used to simulate and predict the power generation of the PV system based on the meteorological data of the project site, PV module parameters, and system configuration. The corresponding meteorological data are derived from Meteonorm 8.0. Given that the greenhouse roof is transparent, part of the radiation will be reflected onto the back of the PV modules, so albedo was designed in the PVsyst simulation. Based on the literature [

34], the albedo was set to 40%. A three-dimensional shadow scenario was defined in the simulation, and the shadow coefficient was corrected according to the linear influence model.

Yulin City is located in the arid and water-scarce area of Western China. Strong wind and sand lead to dust accumulation on the surfaces of solar panels, which blocks light absorption and directly reduces the photoelectric conversion efficiency. The actual power generation efficiency of panels dropped from 23% to 25% to approximately 17% to 18% according to the measured data from a 20 MW PV power station in Yulin, Shaanxi Province, China. This was due to the failure to thoroughly solve the problem of panel cleaning. Therefore, the soiling loss was assumed to be 6% in this project. To simplify the design, local climate data were directly used for temperature parameters, and the effect of humidity was not considered in this simulation for the time being.

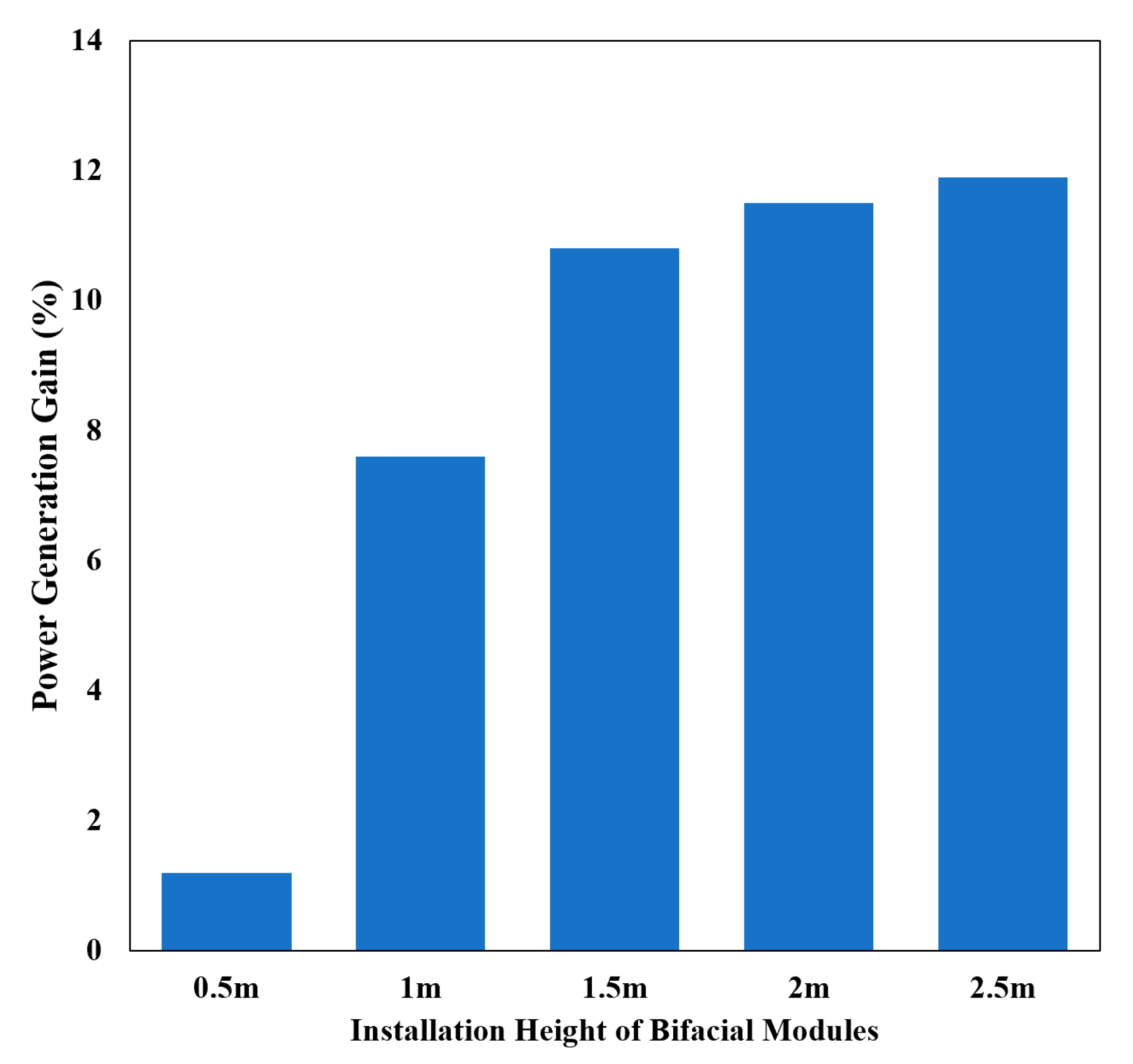

3.4.1. Analysis of Power Generation Gain of Bifacial Modules

Taking the arrangement of all PV modules in long rows in the PV power station as an example, the power generation gain of bifacial modules is analyzed. The power generation gain can be calculated with Formula (3).

where

is the power generation gain;

and

are the power generation of bifacial modules and conventional modules, respectively.

Figure 2 exhibits the power generation gain at different installation heights of bifacial modules (the height from the module edge to the vault of the greenhouse). When the installation height is 0.5 m, the power generation gain of bifacial modules is insignificant, due to severe light shading on the back of the modules. When the installation height is less than 1.5 m, the power generation gain increases rapidly with the rise in installation height. When the installation height exceeds 1.5 m, the growth rate of the power generation gain slows down. As the height increases, ground-reflected light attenuates and the proportion of scattered light decreases, leading to a significant reduction in the increase in backside irradiance. The modules in this project are installed on the greenhouse roof. The higher the installation height of the modules, the greater the wind load. Considering safety factors, the module installation height is set to 1 m, resulting in a power generation gain of 7.6%.

3.4.2. PV Panel Arrangement Pattern Analysis

Table 5 presents the performance indicators of different PV panel arrangement patterns. Among the three patterns, the checkerboard pattern features the highest system efficiency, the smallest irradiance loss, and a slight lead in power generation, with a moderate shading rate (39%), making it suitable for greenhouses requiring a shading rate between 30% and 50%. The quasi-checkerboard pattern has the lowest shading rate (29%), but its lower system efficiency and larger irradiance loss result in slightly lower power generation, making it suitable for scenarios with poor light conditions or low shading rate requirements. The long-row pattern has the highest shading rate (58%). However, it achieves a unit power generation comparable to that of the checkerboard arrangement through balanced system efficiency and irradiance loss. This arrangement saves more horizontal land space. Due to its higher shading rate, it is more suitable for shade-tolerant plants such as mushrooms that require a higher shading rate.

3.4.3. Final Simulation Results

Given the large scale of this project and the diversity of crop species, the design needs to meet the growth requirements of different crops. It is assumed that each of the three arrangement patterns accounts for one-third. The simulation results show that the annual energy conversion of the PV array is 79,796 MWh, and the final power generation after various losses is 84,004 MWh. The performance ratio (PR) is 84.65%. The irradiation, illumination, and temperature differences in the PV system are uncontrollable, and long-term operation may cause performance degradation of inverters and PV modules. The main energy losses of this system are pollution loss (6.0%), shield irradiance loss (2.7%), PV energy loss due to temperature (1.9%), module and string mismatch loss (2.1%), and PV loss caused by irradiation intensity (1.0%).

The Datang Huayin 100 MW Agrivoltaic Power Generation Project (Weinan City, Shaanxi Province, China) has an AC-side capacity of 100 MW, with an annual power generation of 150.3653 million kWh and an annual utilization hour of 1251.4 h, equivalent to an AC-side annual unit power generation of 1503.65 kWh/kWp/yr and a PR of 87.15%. The 100 MW Agrivoltaic Photovoltaic Power Generation Project in Baota District (Yan’an City, Shaanxi Province, China) has an AC-side installed capacity of 100 MW, with an average annual on-grid power of 158.5059 million kWh and an annual utilization hour of 1317.49 h, equivalent to an AC-side annual unit power generation of 1585.06 kWh/kWp/yr and a PR of 85.55%. The AC-side annual unit power generation of this project is 1596 kWh/kWp/yr, with a PR of 84.6%. Through comparison with the measured data of similar projects, this design is proven to be feasible.

Assuming the same equipment configuration (photovoltaic modules, inverters, etc.), a vertical bifacial agrivoltaic system was adopted with PV modules arranged in long rows. The simulation results show that the system generates 52,405 MWh/yr, with an annual unit power generation of 1048 kWh/kWp/yr and a daily unit power generation of 2.87 kWh/kWp/day, along with a system efficiency of 72.1%. All the above indicators are lower than the design indicators of this project.

In addition, to reduce shading of PV modules by the greenhouse in the vertical bifacial agrivoltaic system, the modules need to be installed above the greenhouse roof (4.5 m). When combined with the module height (9.112 m), the total height at the top of the modules reaches approximately 11 m. Excessively high modules will lead to excessive wind loads given the strong wind and sand in the project construction area, posing certain safety risks. Therefore, the system designed in this project is superior to the vertical bifacial agrivoltaic system.

4. Electrical Primary System Design

4.1. Main Wiring Design

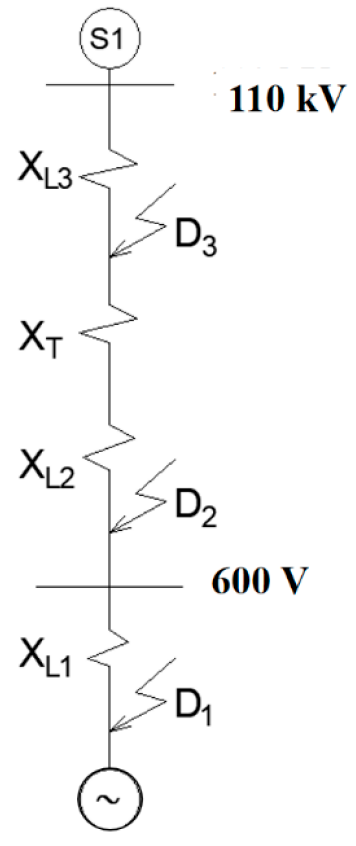

The total installed capacity of the designed agrivoltaic power generation system was 50 MW. According to calculations, the system consists of 90,909 bifacial double-glass PV modules with a rated power of 550 Wp each and 14 centralized inverters rated at 3125 kW. Considering the project’s requirements for a straightforward configuration with minimal equipment and reduced investment costs, a non-segmented single-bus topology was selected. This configuration is particularly suitable for applications with a limited number of outgoing circuits, due to its simplicity in operation and maintenance.

The non-segmented single-bus configuration minimizes the use of bus couplers (e.g., circuit interrupters and disconnectors), reducing both the initial investment and operational complexity. Although the single-bus structure poses a single-point-of-failure risk, reliability is enhanced through the following measures: redundant design of inverters and combiner boxes (N + 1 configuration), comprehensive protection systems for the main transformer (differential, overcurrent, and overvoltage protection), remote monitoring and rapid fault diagnosis capabilities for critical equipment.

The power station is unable to transmit 100% of the power in the event of a short circuit, open circuit, or an external grid-side fault occurring on the 110 kV outgoing cable/overhead line. To ensure system safety, a double-circuit configuration (Line 1 and Line 2) is employed for the 110 kV outgoing line. During normal operation, Line 1 is in service, while Line 2 remains on cold standby, with the circuit interrupters (DL2) on Line 2 open and the disconnector switch (GS2) closed, allowing for immediate switching when needed. In case of a fault on Line 1, the power supply automatically switches to Line 2 (switching time < 200 ms).

The high-voltage side of the main transformer outgoing line via double-winding bushings taps into the two circuits, and an overcurrent intertrip device is included to prevent fault escalation. To enhance the system’s ride-through capability, an SVG (Static Var Generator) is configured on the high-voltage bus side, with a capacity of ±20 Mvar, a response time of ≤5 ms, and a reactance rate of 5%. A grounding resistor is installed at the neutral point of the main transformer.

In the aforementioned configuration (main transformer impedance of 12% + Line 1 current-limiting reactor with a reactance rate of 5% + Line 2 in cold standby), the periodic component of the short-circuit current on the 110 kV side bus is 6.51 kA, the impact short-circuit current value is 16.57 kA, and the maximum effective value of the total short-circuit current is 9.84 kA. All these current values are far below the limit values of conventional 110 kV equipment (25 kA for breaking/40 kA for closing), providing a sufficient safety margin. It can be seen that although the double-circuit line scheme increases the short-circuit current, the combination of the main transformer’s high impedance (12%), the 5% reactance rate of Line 1’s current-limiting reactor, and the cold standby operation of Line 2 can suppress the short-circuit current to a safe level while ensuring N − 1 reliability.

Therefore, the system architecture was structured as follows: 3367 strings of PV arrays were aggregated via 232 16-input-1-output combiner boxes into 14 inverters (1 unit on standby), which feed into a 600 V non-segmented single bus. The power was then stepped up to 110 kV through a main transformer and transmitted via two outgoing lines. The detailed configuration is illustrated in

Figure 3. The single-bus design allows for future expansion by adding transformers and bus section interrupters.

4.2. Main Transformer Selection and Short-Circuit Current Calculation

The main transformer is tasked with stably stepping up the low-voltage electrical energy output by the inverter to a voltage level suitable for grid connection. Meanwhile, it reduces voltage fluctuations and distortions, transmits power smoothly to the grid, and ensures the normal operation of equipment in the grid. The main transformer selected was of the SFSZ11-63000/110 model, the parameters of which are shown in

Table 6 below.

The design capacity of this project was 50 MW, the main transformer capacity was 63 MVA, the transformer impedance U

K% = 12, and the reference capacity was taken as S

b = 100 MVA. The short-circuit current was simplified into an equivalent circuit diagram, as shown in

Figure 4. The short-circuit current was calculated based on the equivalent circuit diagram, and the calculation results are shown in

Table 7.

4.3. Selection of Main Electrical Equipment

4.3.1. Busbars

Under normal operating conditions, the rated current of the equipment (

Ial) for the 0.6 kV side should meet the condition that

Ial ≥

Imax (the maximum continuous operating current); that is,

When determining the busbar cross-sectional area, the economic current density method is adopted for calculation. The economic density value j is set to 1.65 A/mm2, so the economic cross-section of the busbar is 2014.28 mm2.

The aluminum busbar of model LMY-125 × 10 was selected. The specification of the aluminum busbar was double strips placed vertically with 125 mm × 10 mm. At the reference ambient temperature of 25 °C, when the maximum allowable temperature of the busbar was set to 70 °C (

), the skin effect coefficient

Ks was calculated to be 1.45, and the long-term allowable current-carrying capacity I

N of the busbar reached 3426 A. In view of the actual ambient temperature of 24.1 °C (

), which deviated from the reference temperature, a temperature correction coefficient

K needed to be introduced for corresponding correction as Formula (5).

Therefore, the long-term allowable current-carrying capacity is as follows:

Thus, the requirements for long-term heating conditions were satisfied.

Similarly, the aluminum busbar of model LMY-63 × 6.3 was selected for the 110 kV side, with a single strip placed horizontally in the specification of 63 mm × 6.3 mm. The economic cross-section of the busbar is 221.50 mm2.

4.3.2. Circuit Interrupters

To meet the selection requirements for electrical equipment, the rated current of the circuit interrupter for the 0.6 kV side must be greater than the maximum continuous operating current

Imax:

After comprehensively considering that the rated voltage and rated current under normal operating conditions both meet the requirements, the DW45-4000 type circuit interrupter was selected. The detailed parameters are shown in

Table 8. After verification, the dynamic stability current of the DW45-4000 type circuit interrupter (100 kA) was greater than the impact short-circuit current value (2.32 kA), and the thermal stability current (4 s) (31.5 kA) was greater than the maximum effective value of the full current (1.37 kA), thus meeting the dynamic and thermal stability requirements.

Similarly, the LW36-126 type circuit interrupter for the 110 kV side was selected, and other detailed parameters are shown in

Table 8.

4.3.3. Disconnector Switches

The maximum continuous operating current

Imax for the 0.6 kV side was 3157.38 A. The model selected for this project was the MGR3-4000, the specific parameters of which are shown in

Table 9. After verification, the dynamic stability current of the MGR3-4000 type disconnector switches (50 kA) was greater than the impact short-circuit current value (2.32 kA), and the thermal stability current (4 s) (50 kA) was greater than the maximum effective value of the full current (1.37 kA), meeting the dynamic and thermal stability requirements.

Similarly, the model selected for the 110 kV side was the GW4-110D, and the specific parameters are shown in

Table 9.

In the selection of disconnectors, the verification of the dielectric margin is a core step to ensure that the insulation performance of the equipment remains reliable under various voltage stresses. The rated voltage of the disconnectors on the 110 kV side is 110 kV. In accordance with DL/T 620-1997 [

35], the standard value of the maximum operating voltage (

Umax) for the 110 kV system is 126 kV.

The dielectric margin shall meet the requirement of , (as specified in DL/T 620-1997).

Verification of lightning overvoltage: The lightning overvoltage in the 110 kV system is limited by the arrester. The lightning impulse residual voltage of the 110 kV zinc oxide arrester (under 10 kA) is approximately 260 kV (peak value). The lightning impulse withstand voltage of the GW4-110D is 450 kV. Thus the insulation margin K = 450/260 ≈ 1.73 ≥ 1.25, which meets the requirement.

Verification of switching overvoltage: The switching overvoltage multiple of the 110 kV system (relative to the maximum operating voltage) is generally ≤ 2.0, that is, the peak value of switching overvoltage Uop = 2.0 × 126 × √2 ≈ 356 kV. The lightning impulse withstand voltage of 450 kV for the GW4-110D already covers the switching overvoltage (there is no need to separately specify the switching impulse withstand voltage), so the margin is sufficient.

Verification of power frequency overvoltage: The system power frequency overvoltage (relative to the maximum operating voltage) is generally ≤ 1.3, that is, Upf = 1.3 × 126 = 163.8 kV (effective value). The power frequency dry withstand voltage of the GW4-110D is 185 kV, and the insulation margin K = 185/163.8 ≈ 1.13. Although slightly lower, it meets the “short-time withstand” requirement. The duration of power frequency overvoltage is short, and 185 kV is much higher than the maximum operating voltage of 126 kV.

The core of the external insulation margin lies in the creepage distance meeting the requirement of a creepage ratio distance corresponding to the pollution level. The creepage ratio distance (unit: cm/kV).

The Yulin area is dominated by coal and chemical industries, with relatively serious industrial pollution. Based on operational experience and GB/T 26218.2-2010 [

36], it is tentatively classified as pollution class II. According to GB/T 16434, the required creepage ratio distance for 110 kV outdoor equipment is λ ≥ 1.6 cm/kV. Therefore, the minimum required creepage distance is

Lmin = 1.6 × 126 = 201.6 cm. The typical creepage distance of the GW4-110D is 240 cm, which is greater than 201.6 cm, meeting the requirements for pollution level II.

According to GB/T 11022-2020 [

37], when the altitude is higher than 1000 m, the external insulation strength decreases by 1% for every 100 m increase in altitude. The average altitude of Hengshan County is approximately 1000–1200 m, and the average value of 1100 m was selected. Therefore, altitude correction is required.

The withstand voltage correction factor Kh = 1/(1 − 1 × 1%) = 1.01.

The corrected required lightning impulse withstand voltage is 450/1.01 ≈ 445.5 kV, which is higher than the system lightning overvoltage of 260 kV, indicating a sufficient margin.

Therefore, under the conditions that the Yulin area is assumed to be of pollution level II and the altitude is ≤1500 m, the lightning impulse and power frequency withstand voltage margins of the GW4-110D disconnector meet the requirements, the external insulation creepage distance is suitable for pollution level II, and the model passes the insulation margin verification.

4.3.4. Current Transformers

The maximum continuous operating current

Imax for the 0.6 kV side was 3157.38 A. The current transformer model selected was LDZJ-10-4000/5, and the specific parameters are shown in

Table 10. After verification, the dynamic stability current of the LDZJ-10-4000/5 type current transformer (100 kA) was greater than the impact short-circuit current value (2.32 kA), and the thermal stability current (4 s) (31.5 kA) was greater than the maximum effective value of the full current (1.37 kA), meeting the dynamic and thermal stability checks.

Similarly, the current transformer model selected for the 110 kV side was LB7-110-500/5, and the specific parameters are shown in

Table 10.

4.3.5. Voltage Transformers

When selecting a voltage transformer, the rated voltage must first be satisfied; that is,

. The model TYD110/√3-0.02H was selected, and the specific parameters are shown in

Table 11.

5. Conclusions

This study focused on the design of a 50 MW agrivoltaic power station in Shaanxi Province, China, which integrates PV power generation with agricultural production. An integrated model of PV modules and agricultural greenhouses was adopted, with PV modules installed on the sunny slope roof of the greenhouse at an inclination angle of 40°. Bifacial modules with high light transmittance were selected to facilitate the growth of greenhouse crops. To address the shading problem caused by PV modules, the modules were arranged in quasi-chessboard (coverage < 30%), chessboard (30% < coverage < 50%), and long-row (50% < coverage < 80%) patterns, according to the growth characteristics of different crops. Among these patterns, the checkerboard pattern features the highest system efficiency, the smallest irradiance loss, and a slight lead in power generation, with a moderate shading rate. The expected energy gain from the bifacial modules’ rear side in this specific setup is 7.6%. Centralized inverters and DC combiner boxes were configured. The PVsyst simulation results showed that the system power generation is 79,796 MWh/year, the annual specific power generation is 1585.06 kWh/kWp/yr, and the PR is 84.65%, which is in agreement with actual measurement data from similar projects, proving the feasibility of the design’s implementation.

The primary electrical design includes the completion of the main wiring design, main transformer selection, short-circuit current calculation, and selection of major electrical equipment. The single-busbar non-segmented mode was adopted, and the SFSZ11-63000/110 main transformer steps up the power output by the inverter to 110 kV for double-circuit connection to the power grid, meeting the power transmission requirements. This design rationally utilizes the roof space of greenhouses, meets grid-connected requirements, provides technical reference for the construction of agrivoltaic power systems, and has the potential to be widely adopted.

However, this study still has some shortcomings in terms of agricultural adaptability and systematic technical integration. Although various layout schemes take into account the differences in light requirements of different crops, they lack quantitative analysis of key parameters such as the light compensation and saturation points. Research on the spatial heterogeneity of the temperature, humidity and wind speed fields formed in different layout modes remains insufficient, making it impossible to accurately predict the microenvironmental characteristics of different crop growing areas. The design lacks a dynamic tracking system with a crop alignment algorithm, which limits the potential of synergistic efficiency improvement between agriculture and photovoltaics.

Future research should focus on synergistic efficiency improvement between agriculture and PV power generation. Key efforts should be made to break through the crop–light environment feedback mechanism, establish long-term microenvironment observation, develop bifacial module layout algorithms based on crop spectral response, expand long-term economic benefit evaluation based on life-cycle cost, and promote the qualitative leap of agrivoltaic systems from a “mechanical superposition” to “organic integration”.

Author Contributions

Investigation, Z.L. and C.X.; data curation, Y.Y. and L.Z.; writing—original draft preparation, R.L.; writing—review and editing, S.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the “Nanxun Scholars Program for Young Scholars of ZJWEU”, grant number RC2022021036, the “Science and Technology Project of Water Resources Department of Zhejiang Provincial”, grant number RB2208 and 2025 Innovative Training Program for College Students, grant number S202511481062.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Acknowledgments

The financial support from the “Nanxun Scholars Program for Young Scholars of ZJWEU” and Nanxun Innovation Institute is kindly acknowledged.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Creutzig, F.; Agoston, P.; Goldschmidt, J.C.; Luderer, G.; Nemet, G.; Pietzcker, R.C. The underestimated potential of solar energy to mitigate climate change. Nat. Energy 2017, 2, 17140. [Google Scholar] [CrossRef]

- International Energy Agency. World Energy Outlook. 2024. Available online: https://www.bp.com/en/global/corporate/energy-economics/energy-outlook.html (accessed on 10 July 2024).

- Nieto-Morone, M.-B.; Munoz-Garcia, M.-A.; Lopez, D.P.; Bernal-Basurco, C.; Rosillo, F.G.; Alonso-Garcia, M.d.C. Agrivoltaics: Integration of Reused PV Modules. Agron.-Basel 2025, 15, 730. [Google Scholar] [CrossRef]

- Kruitwagen, L.; Story, K.T.; Friedrich, J.; Byers, L.; Skillman, S.; Hepburn, C. A global inventory of photovoltaic solar energy generating units. Nature 2021, 598, 604–610. [Google Scholar] [CrossRef]

- Xia, Z.; Li, Y.; Guo, S.; Jia, N.; Pan, X.; Mu, H.; Chen, R.; Guo, M.; Du, P. Balancing photovoltaic development and cropland protection: Assessing agrivoltaic potential in China. Sustain. Prod. Consump. 2024, 50, 205–215. [Google Scholar] [CrossRef]

- Zainali, S.; Lu, S.M.; Fernandez-Solas, A.; Cruz-Escabias, A.; Fernandez, E.F.; Zidane, T.E.K.; Honningdalsnes, E.H.; Nygård, M.M.; Leloux, J.; Berwind, M.; et al. Modelling, simulation, and optimisation of agrivoltaic systems: A comprehensive review. Appl. Energy 2025, 386, 125558. [Google Scholar] [CrossRef]

- Zahrawi, A.A.; Aly, A.M. A Review of Agrivoltaic Systems: Addressing Challenges and Enhancing Sustainability. Sustain.-Basel 2024, 16, 8271. [Google Scholar] [CrossRef]

- Weselek, A.; Ehmann, A.; Zikeli, S.; Lewandowski, I.; Schindele, S.; Hoegy, P. Agrophotovoltaic systems: Applications, challenges, and opportunities. A review. Agron. Sustain. Dev. 2019, 39, 35. [Google Scholar] [CrossRef]

- Kegang, W. An Automatic Cleaning Device for New Energy Photovoltaic Panels. Chinese Patent CN 118232824 A, 21 June 2024. [Google Scholar]

- Trommsdorff, M.; Hopf, M.; Hoernle, O.; Berwind, M.; Schindele, S.; Wydra, K. Can synergies in agriculture through an integration of solar energy reduce the cost of agrivoltaics? An economic analysis in apple farming. Appl. Energy 2023, 350, 121619. [Google Scholar] [CrossRef]

- Feng, R.; Li, S.; Xiao, Y.; Xu, M. Photovoltaic power generation technology for smart agriculture systems: A review. In Proceedings of the 41st Chinese Control Conference (CCC), Hefei, China, 25–27 July 2022; pp. 5333–5338. [Google Scholar]

- Laub, M.; Pataczek, L.; Feuerbacher, A.; Zikeli, S.; Hoegy, P. Contrasting yield responses at varying levels of shade suggest different suitability of crops for dual land-use systems: A meta-analysis. Agron. Sustain. Dev. 2022, 42, 51. [Google Scholar] [CrossRef]

- Trommsdorff, M.; Kang, J.; Reise, C.; Schindele, S.; Bopp, G.; Ehmann, A.; Weselek, A.; Hogy, P.; Obergfell, T. Combining food and energy production: Design of an agrivoltaic system applied in arable and vegetable farming in Germany. Renew Sustain. Energy Rev. 2021, 140, 110694. [Google Scholar] [CrossRef]

- Yano, A.; Onoe, M.; Nakata, J. Prototype semi-transparent photovoltaic modules for greenhouse roof applications. Biosyst. Eng. 2014, 122, 62–73. [Google Scholar] [CrossRef]

- Chatterjee, S.; Shimohara, N.; Seo, T.; Jinnai, S.; Moriyama, T.; Saida, M.; Omote, K.; Hama, K.; Iimuro, Y.; Watanabe, Y.; et al. Green-light wavelength-selective organic solar cells: Module fabrication and crop evaluation towards agrivoltaics. Mater. Today Energy 2024, 45, 101673. [Google Scholar] [CrossRef]

- Torrente, C.J.; Reca, J.; Lopez-Luque, R.; Martinez, J.; Casares, F.J. Simulation model to analyze the spatial distribution of solar radiation in agrivoltaic Mediterranean greenhouses and its effect on crop water needs. Appl. Energy 2024, 353, 122050. [Google Scholar] [CrossRef]

- Boccalatte, A.; Fossa, M.; Sacile, R. Modeling, Design and Construction of a Zero-Energy PV Greenhouse for Applications in Mediterranean Climates. Therm. Sci. Eng. Prog. 2021, 25, 101046. [Google Scholar] [CrossRef]

- Petrakis, T.; Thomopoulos, V.; Kavga, A. Algorithmic advancements in agrivoltaics: Modeling shading effects of semi-transparent photovoltaics. Smart Agric. Technol. 2024, 9, 100541. [Google Scholar] [CrossRef]

- Jamil, U.; Pearce, J.M. Experimental impacts of transparency on strawberry agrivoltaics using thin film photovoltaic modules under low light conditions. Sol. Energy 2025, 290, 113375. [Google Scholar] [CrossRef]

- Hermelink, M.I.; Maestrini, B.; Ruijter, F.J. Berry shade tolerance for agrivoltaics systems: A meta-analysis. Sci. Hortic. 2024, 330, 113062. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, F.; Zhang, W.; Li, M.; Liu, W.; Omer, A.A.A.; Zheng, J.; Zhang, X.; Liu, W. Spectral-splitting concentrator agrivoltaics for higher hybrid solar energy conversion efficiency. Energy Convers. Manag. 2023, 276, 116567. [Google Scholar] [CrossRef]

- Jamil, U.; Givans, J.; Pearce, J.M. Impacts of type of partial transparency on strawberry agrivoltaics: Uniform illumination thin film cadmium-telluride and non-uniform crystalline silicon solar photovoltaic modules. Renew. Energy 2025, 247, 122913. [Google Scholar] [CrossRef]

- GB50797-2012; Code for Design of Photovoltaic Power Station. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2012.

- Amaducci, S.; Yin, X.; Colauzzi, M. Agrivoltaic systems to optimise land use for electric energy production. Appl. Energy 2018, 220, 545–561. [Google Scholar] [CrossRef]

- Valle, B.; Simonneau, T.; Sourd, F.; Pechier, P.; Hamard, P.; Frisson, T.; Ryckewaert, M.; Christophe, A. Increasing the total productivity of a land by combining mobile photovoltaic panels and food crops. Appl. Energy 2017, 206, 1495–1507. [Google Scholar] [CrossRef]

- Marrou, H.; Wery, J.; Dufour, L.; Dupraz, C. Productivity and radiation use efficiency of lettuces grown in the partial shade of photovoltaic panels. Eur. J. Agron. 2013, 44, 54–66. [Google Scholar] [CrossRef]

- Tang, Y.; Ma, X.; Li, M.; Wang, Y. The effect of temperature and light on strawberry production in a solar greenhouse. Sol. Energy 2020, 195, 318–328. [Google Scholar] [CrossRef]

- Gomez-Casanovas, N.; Mwebaze, P.; Khanna, M.; Branham, B.; Time, A.; DeLucia, E.H.; Bernacchi, C.J.; Knapp, A.K.; Hoque, M.J.; Du, X.; et al. Knowns, uncertainties, and challenges in agrivoltaics to sustainably intensify energy and food production. Cell Rep. Phys. Sci. 2023, 4, 101518. [Google Scholar] [CrossRef]

- Wei, L.; Yu, M.; Qin, N.; Huang, C.; Xie, Y.; Sun, W.; Wu, L.; Wang, W.; Wang, G. Effects of agro-photovoltaic integrating system on field illumination and sweet potato growth. J. Zhejiang Univ. Agric. Life Sci. 2019, 45, 288–295, (Abstract In Chinese). [Google Scholar]

- Kong, W.; Zhang, Y.; Yuan, R.; Kong, W.; Han, Y.; Liu, G.; Kang, Y. Analysis on economic benefits of solar PV and Lentinus edodes costruction model. Edible Fungi China 2016, 35, 71–73, (Abstract In Chinese). [Google Scholar]

- Tan, Y.; Liu, J.; Li, W.; Yin, J.; Chen, H.; Peng, Y.; Tan, J. Agrivoltaics development progresses: From the perspective of photovoltaic impact on crops, soil ecology and climate. Environ. Res. 2025, 266, 120540. [Google Scholar] [CrossRef] [PubMed]

- Urena-Sanchez, R.; Callejon-Ferre, A.J.; Perez-Alonso, J.; Carreno-Ortega, A. Greenhouse tomato production with electricity generation by roof-mounted flexible solar panels. Sci. Agric. 2012, 69, 233–239. [Google Scholar] [CrossRef]

- Ezzaeri, K.; Fatnassi, H.; Bouharroud, R.; Gourdo, L.; Bazgaou, A.; Wifaya, A.; Demrati, H.; Bekkaoui, A.; Aharoune, A.; Poncet, C. The effect of photovoltaic panels on the microclimate and on the tomato production under photovoltaic canarian greenhouses. Sol. Energy 2018, 173, 1126–1134. [Google Scholar] [CrossRef]

- Zhu, J.; Chu, C. Variation law of solar shortwave radiation parameters on the surface of plastic greenhouses. J. Nanjing Inst. Meteorol. 1991, 14, 551–558, (Abstract In Chinese). [Google Scholar]

- DL/T 620-1997; Overvoltage Protection and Insulation Coordination for AC Electrical Installations. Ministry of electric power industry of the People’s Republic of China: Beijing, China, 1997.

- GB/T 26218.2-2010; Selection and Dimensioning of High-Voltage Insulators Intended for Use in Polluted Conditions—Part 2: Ceramic and Glass Insulators for a.c. Systems. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2011.

- GB/T 11022-2020; Common Specifications for High-voltage Alternating-current Switchgear and Controlgear Standards. State Administration for Market Regulation of the People’s Republic of China: Beijing, China, 2020.

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).