Mechanical Behavior of Sustainable Concrete with Alkali-Activated Pumice as Cement Replacement for Walkway Slabs in Humid Tropical Climates

Abstract

1. Introduction

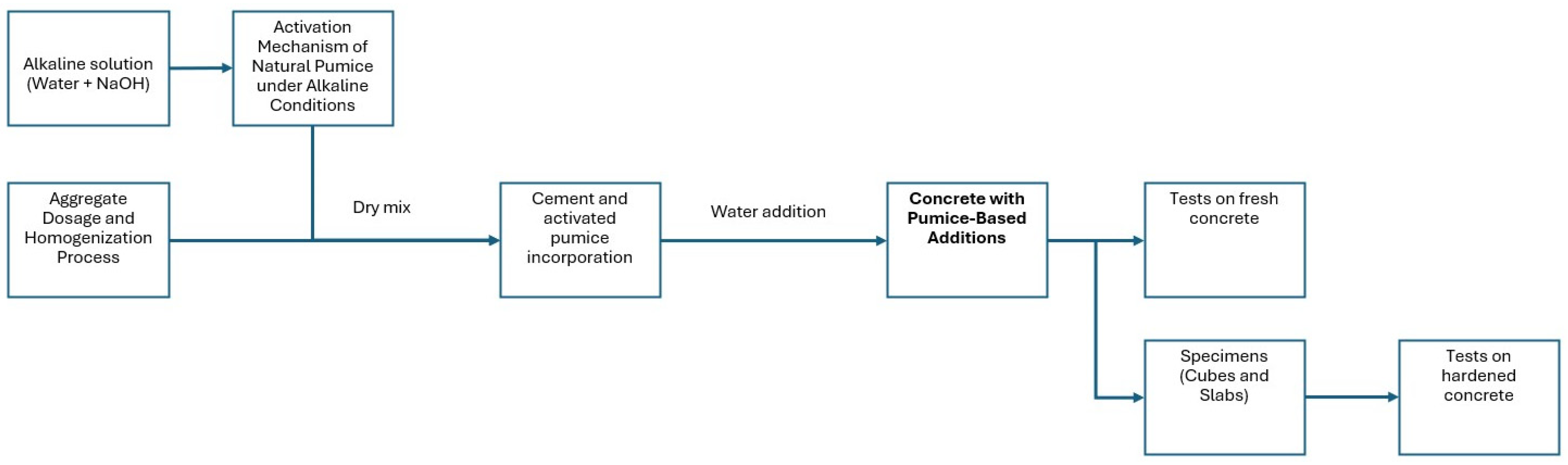

2. Materials and Methods

2.1. Materials

2.2. Experimental Methods

2.3. Sample Preparation

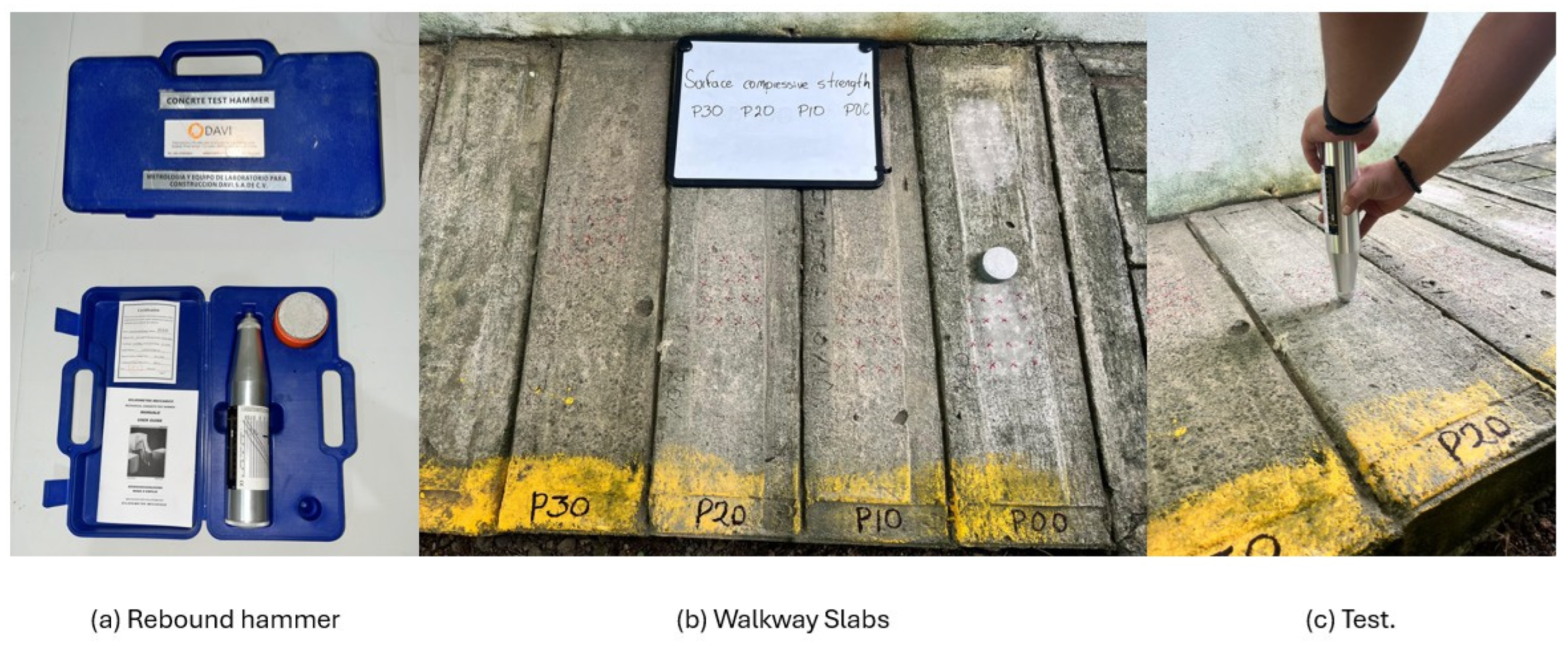

2.4. Tests Conducted

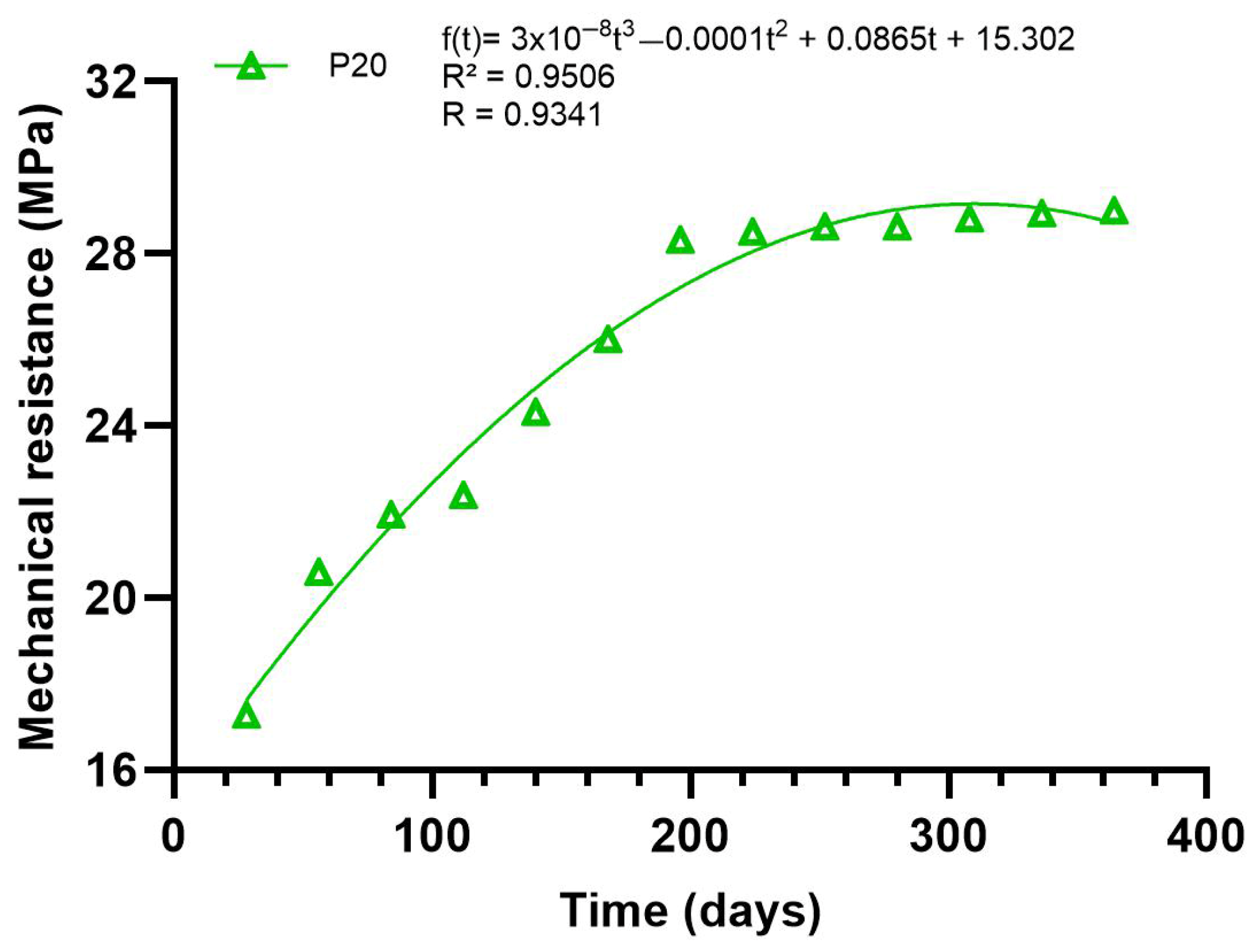

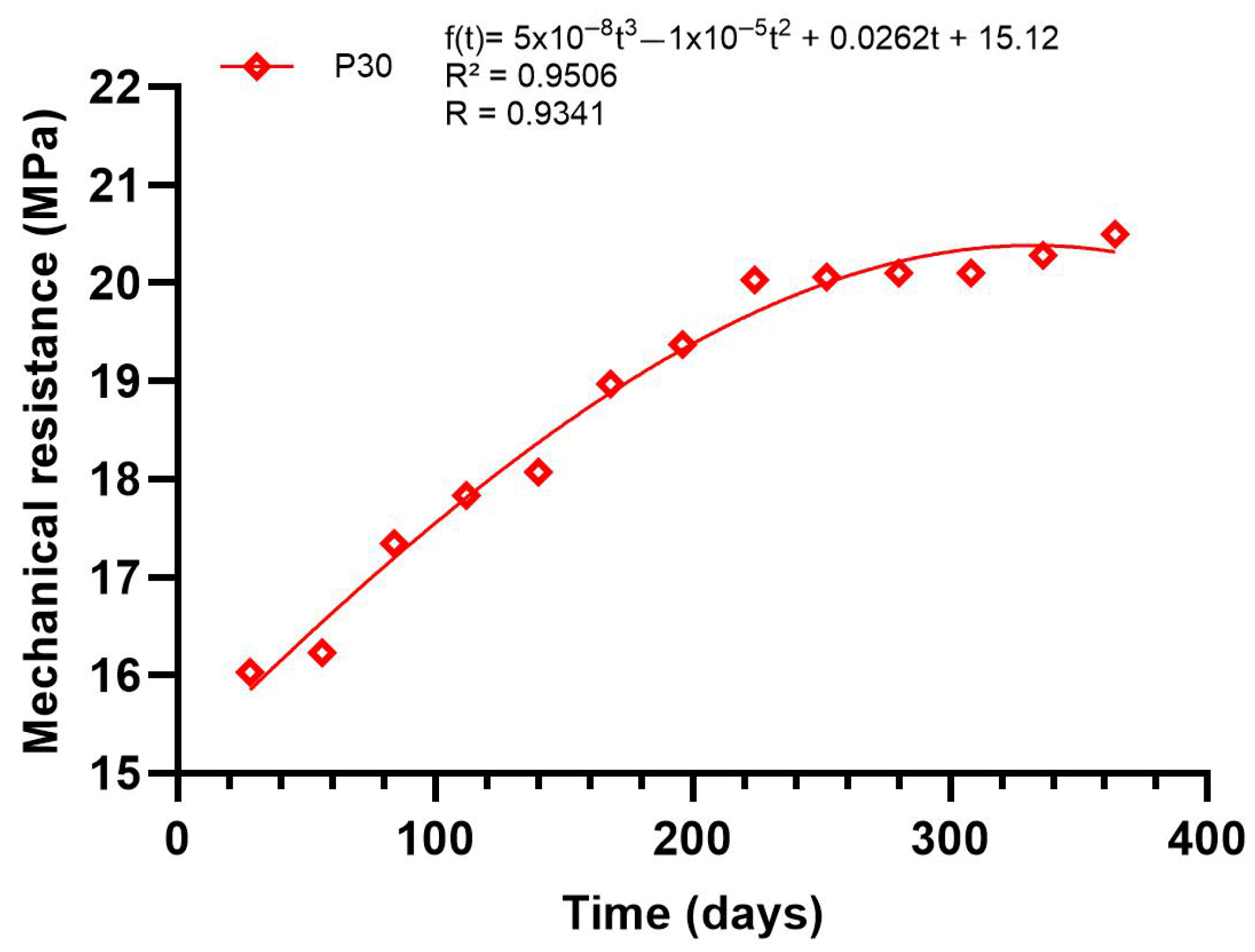

2.4.1. Compressive Strength

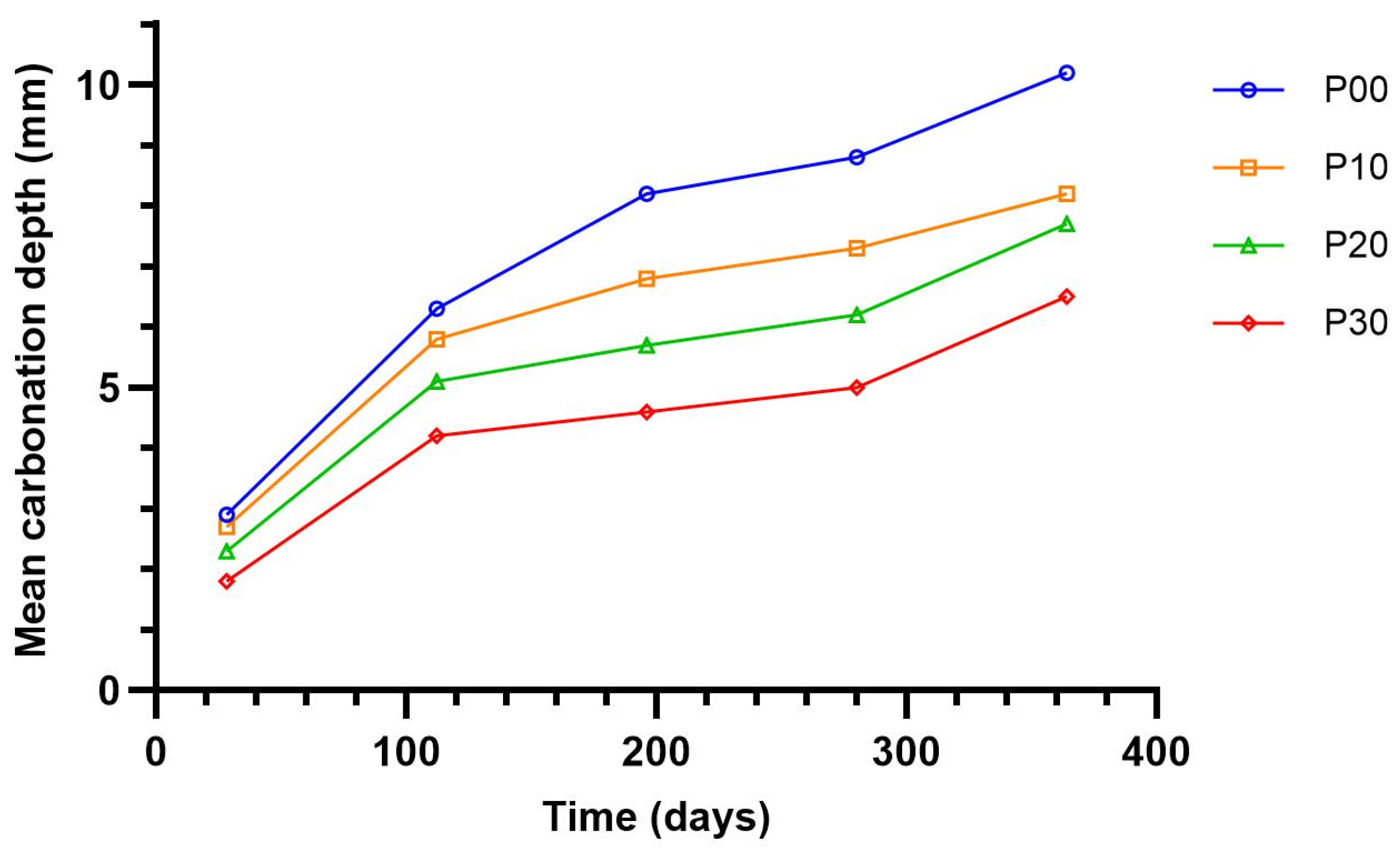

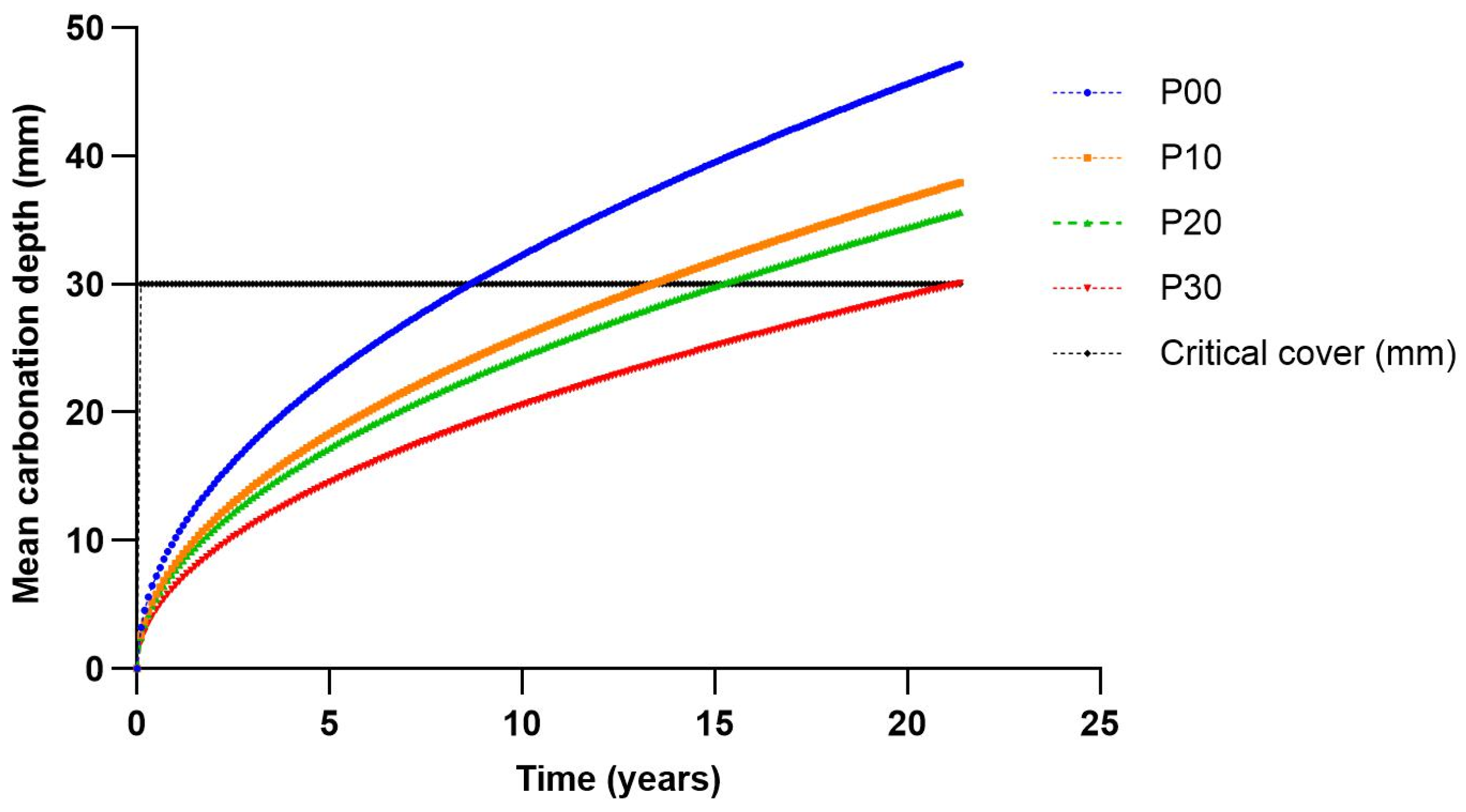

2.4.2. Carbonation Depth

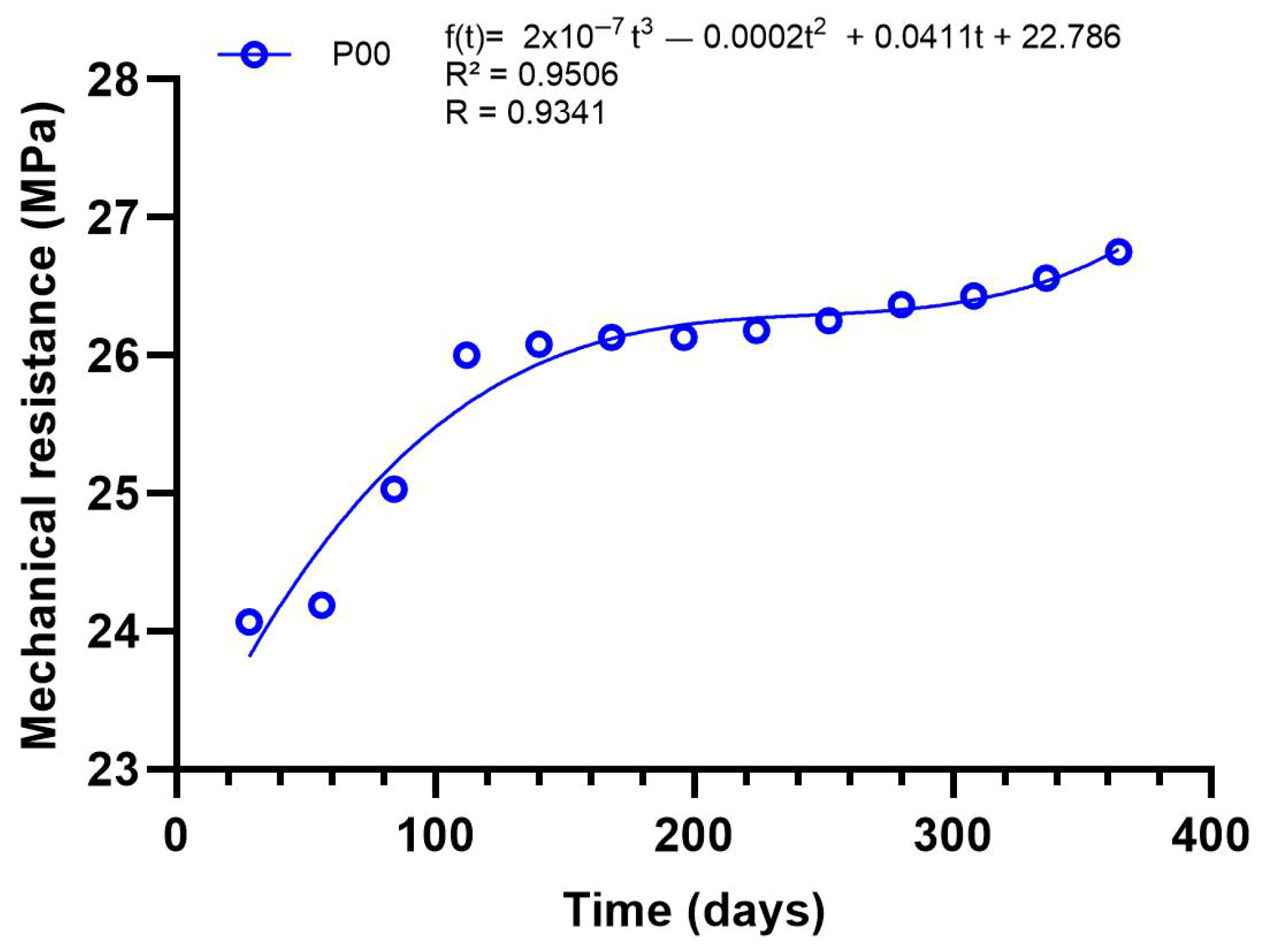

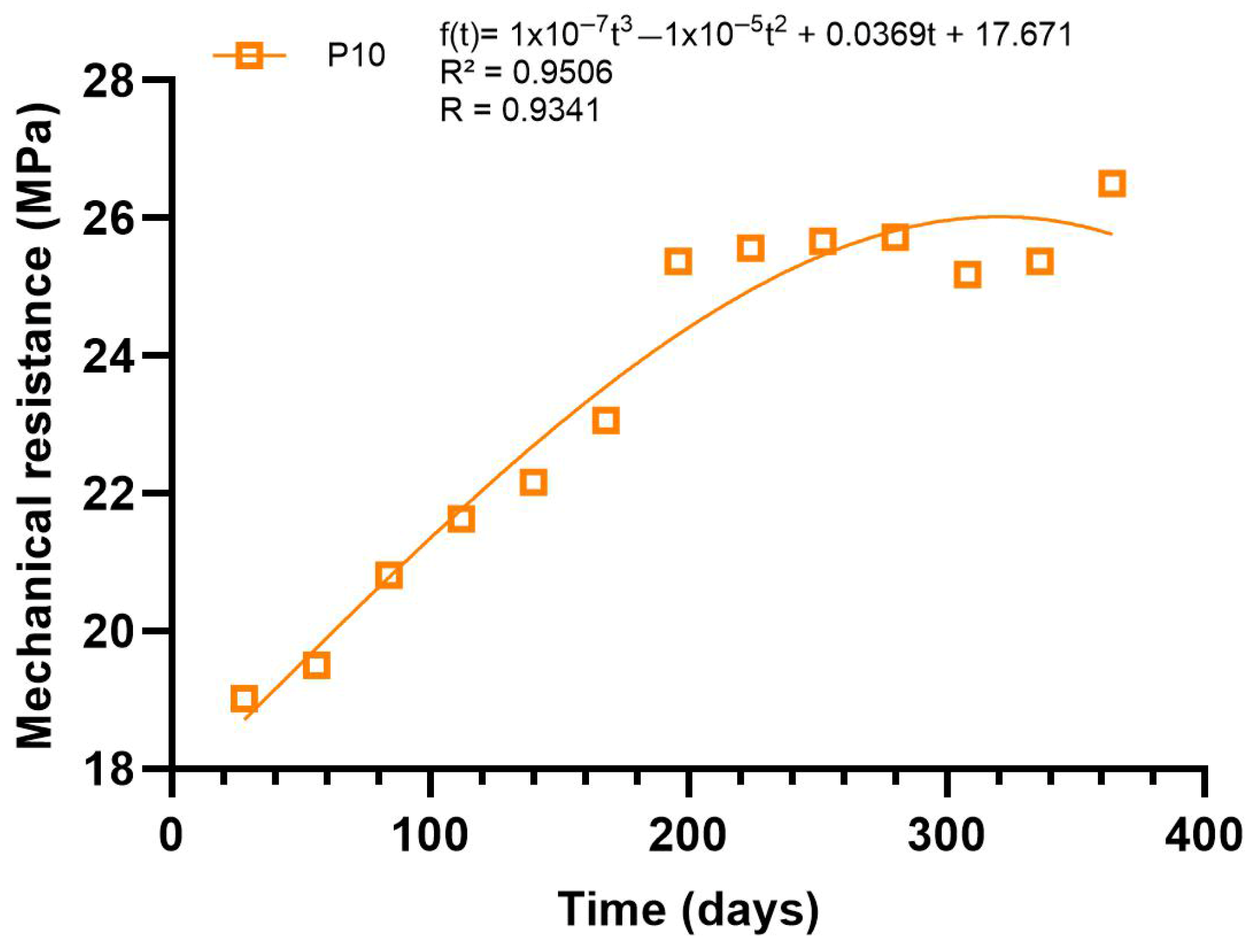

3. Results

4. Discussion

5. Conclusions

- -

- Core sampling for compressive and tensile strength testing;

- -

- Microstructural analysis of hardened materials using XRD, SEM, and thermal analysis (TG/DTG);

- -

- Assessment of other durability factors, such as resistance to chloride ingress, freeze–thaw cycles, and wet–dry cycling.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CO2 | Carbon dioxide |

| DTA-TG | Differential Thermal Analysis—Thermogravimetry |

| MPa | Megapascals |

| PC | Portland Cement |

| PM | Pumice |

| SCM | Supplementary Cementitious Materials |

| SEM | Scanning Electron Microscopy |

| XRD | X-Ray Diffraction |

References

- Bungau, C.C.; Bungau, T.; Prada, I.F.; Prada, M.F. Green Buildings as a Necessity for Sustainable Environment Development: Dilemmas and Challenges. Sustainability 2022, 14, 13121. [Google Scholar] [CrossRef]

- Barbhuiya, S.; Kanavaris, F.; Das, B.B.; Idrees, M. Decarbonising cement and concrete production: Strategies, challenges and pathways for sustainable development. J. Build. Eng. 2024, 86, 108861. [Google Scholar] [CrossRef]

- Belaïd, F. How does concrete and cement industry transformation contribute to mitigating climate change challenges? Resour. Conserv. Recycl. Adv. 2022, 15, 200084. [Google Scholar] [CrossRef]

- Soomro, M.; Tam, V.W.; Evangelista, A.C.J. Production of cement and its environmental impact. In Recycled Concrete; Woodhead Publishing: Cambridge, UK, 2023; pp. 11–46. [Google Scholar] [CrossRef]

- Antunes, M.; Santos, R.L.; Pereira, J.; Rocha, P.; Horta, R.B.; Colaço, R. Alternative Clinker Technologies for Reducing Carbon Emissions in Cement Industry: A Critical Review. Materials 2022, 15, 209. [Google Scholar] [CrossRef]

- Snellings, R.; Suraneni, P.; Skibsted, J. Future and emerging supplementary cementitious materials. Cem. Concr. Res. 2023, 171, 107199. [Google Scholar] [CrossRef]

- Mohammadi, A.; Ramezanianpour, A.M. Investigating the environmental and economic impacts of using supplementary cementitious materials (SCMs) using the life cycle approach. J. Build. Eng. 2023, 79, 107934. [Google Scholar] [CrossRef]

- Shukla, B.K.; Gupta, A.; Gowda, S.; Srivastav, Y. Constructing a greener future: A comprehensive review on the sustainable use of fly ash in the construction industry and beyond. Mater. Today Proc. 2023, 93, 257–264. [Google Scholar] [CrossRef]

- Zeng, Q.; Liu, X.; Zhang, Z.; Wei, C.; Xu, C.C. Synergistic utilization of blast furnace slag with other industrial solid wastes in cement and concrete industry: Synergistic mechanisms, applications, and challenges. Green Energy Resour. 2023, 1, 100012. [Google Scholar] [CrossRef]

- Amran, M.; Fediuk, R.; Murali, G.; Vatin, N.; Karelina, M.; Ozbakkaloglu, T.; Krishna, R.S.; Sahoo, A.K.; Das, S.K.; Mishra, J. Rice Husk Ash-Based Concrete Composites: A Critical Review of Their Properties and Applications. Crystals 2021, 11, 168. [Google Scholar] [CrossRef]

- Alqarni, A.S. A comprehensive review on properties of sustainable concrete using volcanic pumice powder ash as a supplementary cementitious material. Constr. Build. Mater. 2022, 323, 126533. [Google Scholar] [CrossRef]

- Becerra-Duitama, J.A.; Rojas-Avellaneda, D. Pozzolans: A review. Eng. Appl. Sci. Res. 2022, 49, 495–504. [Google Scholar]

- Moolchandani, K. Advancements in pumice-based concrete: A comprehensive review. Next Mater. 2025, 8, 100646. [Google Scholar] [CrossRef]

- Tuncer, M.; Bideci, A.; Çomak, B.; Durmuş, G.; Sallı Bideci, Ö. Experimental Investigation of Durability Properties of Polymer Coated Pumice Aggregate Lightweight Concretes. Polymers 2025, 17, 253. [Google Scholar] [CrossRef]

- Wang, H.; Chen, Y.; Wang, H. Under Sulfate Dry–Wet Cycling: Exploring the Symmetry of the Mechanical Performance Trend and Grey Prediction of Lightweight Aggregate Concrete with Silica Powder Content. Symmetry 2024, 16, 275. [Google Scholar] [CrossRef]

- Zeyad, A.M.; Magbool, H.M.; Tayeh, B.A.; de Azevedo, A.R.G.; Abutaleb, A.; Hussain, Q. Production of geopolymer concrete by utilizing volcanic pumice dust. Case Stud. Constr. Mater. 2022, 16, e00802. [Google Scholar] [CrossRef]

- Wang, H.; Shu, L.; Ma, K.; He, X. Durability Improvement of Pumice Lightweight Aggregate Concrete by Incorporating Modified Rubber Powder with Sodium Silicate. Materials 2024, 17, 786. [Google Scholar] [CrossRef]

- Ngo, V.D.; Nguyen, N.T.; Duprat, F.; Vu, N.T.; Nguyen, V.P. Climatic Issue in an Advanced Numerical Modeling of Concrete Carbonation. Sustainability 2021, 13, 5994. [Google Scholar] [CrossRef]

- Fuhaid, A.F.A.; Niaz, A. Carbonation and Corrosion Problems in Reinforced Concrete Structures. Buildings 2022, 12, 586. [Google Scholar] [CrossRef]

- Lamaa, G.; Duarte, A.P.C.; Silva, R.V.; de Brito, J. Carbonation of Alkali-Activated Materials: A Review. Materials 2023, 16, 3086. [Google Scholar] [CrossRef] [PubMed]

- Krentowski, J.R. Assessment of Destructive Impact of Different Factors on Concrete Structures Durability. Materials 2022, 15, 225. [Google Scholar] [CrossRef] [PubMed]

- Tran, C.N.N.; Illankoon, I.M.C.S.; Tam, V.W.Y. Decoding Concrete’s Environmental Impact: A Path Toward Sustainable Construction. Buildings 2025, 15, 442. [Google Scholar] [CrossRef]

- Zeyad, A.M.; Magbool, H.M.; Amran, M.; Mijarsh, M.J.A.; Almalki, A. Performance of high-strength green concrete under the influence of curing methods, volcanic pumice dust, and hot weather. Arch. Civ. Mech. Eng. 2022, 22, 134. [Google Scholar] [CrossRef]

- Chen, X.; Li, X.; Song, X. Structural Design and Performance Optimization of Green Concrete Based on Recycled Pumice and Modified Rubber Powder. Appl. Sci. 2024, 14, 3372. [Google Scholar] [CrossRef]

- Amirnuddin, S.S.; Manda, M.S.; Hassan, S.A.; Wahit, M.U.; Rejab, M.R.M.; Binoj, J.S.; Ilyas, R.A. Compressive behaviour of tin slag polymer concrete confined with fibre reinforced polymer composites exposed to tropical weathering and aggressive conditions. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Stratoura, M.C.; Lazari, G.-E.D.; Badogiannis, E.G.; Papadakis, V.G. Perlite and Rice Husk Ash Re-Use As Fine Aggregates in Lightweight Aggregate Structural Concrete—Durability Assessment. Sustainability 2023, 15, 4217. [Google Scholar] [CrossRef]

- Zeyad, A.M.; Tayeh, B.A.; Yusuf, M.O. Strength and transport characteristics of volcanic pumice powder based high strength concrete. Constr. Build. Mater. 2019, 216, 314–324. [Google Scholar] [CrossRef]

- Madani, H.; Norouzifar, M.N.; Rostami, J. The synergistic effect of pumice and silica fume on the durability and mechanical characteristics of eco-friendly concrete. Constr. Build. Mater. 2018, 174, 356–368. [Google Scholar] [CrossRef]

- NMX-C-414-ONNCCE-2017; Mexican Standard. Construction Industry—Hydraulic Cements—Specifications and Testing Methods. ONNCCE: Mexico City, Mexico, 2017.

- NMX-C-111-ONNCCE-2013; Mexican Standard. Construction Industry—Aggregates for Hydraulic Concrete—Specifications and Testing Methods. ONNCCE: Mexico City, Mexico, 2013.

- NMX-C-122-ONNCCE-2016; Mexican Standard. Construction Industry—Water for Concrete—Specifications and Testing Methods. ONNCCE: Mexico City, Mexico, 2016.

- López-Gonzalez, P.J.; Vivar-Ocampo, R.; González-Moreno, H.R.; Moreno-Vazquez, O.; Meza-Ruíz, E.; Zamora-Castro, S.A.; Reyes-González, D.; Sangabriel-Lomeli, J. Impact of Pumice Substitution on Mortar Properties: A Case Study on Mechanical Performance and XRD Analysis. Infrastructures 2025, 10, 95. [Google Scholar] [CrossRef]

- American Concrete Institute (ACI). ACI PRC-211.1-22: Selecting Proportions for Normal-Density and High-Density Concrete—Guide; ACI: Farmington Hills, MI, USA, 2022. [Google Scholar]

- Ghazy, M.F.; Abd Elaty, M.A.; Mostafa, S.M. Properties of One-Part versus Two-Part Geopolymer Composites—A Review. Am. J. Eng. Res. 2022, 11, 1–14. [Google Scholar]

- NMX-C-435-ONNCCE-2004; Mexican Standard. Construction Industry—Hydraulic Concrete—Determination of the Temperature of Fresh Concrete. ONNCCE: Mexico City, Mexico, 2004.

- NMX-C-156-ONNCCE-2010; Mexican Standard. Construction Industry—Hydraulic Concrete—Determination of Slump in Fresh Concrete. ONNCCE: Mexico City, Mexico, 2010.

- NMX-C-159-ONNCCE-2016; Mexican Standard. Construction Industry—Concrete—Preparation and Curing of Test Specimens. ONNCCE: Mexico City, Mexico, 2016.

- NMX-C-131-ONNCCE-2014; Mexican Standard. Construction Industry—Concrete—Determination of Compressive Strength in Structural Elements Using the Rebound Hammer. ONNCCE: Mexico City, Mexico, 2014.

- NMX-C-178-ONNCCE-2010; Mexican Standard. Construction Industry—Concrete—Determination of the Carbonation Depth in Hardened Concrete Exposed to the Environment. ONNCCE: Mexico City, Mexico, 2010.

- Martirena Hernández, J.F.; Antoni, M.; Oquendo-Machado, Y.; Borrajo-Perez, R.; Alujas-Diaz, A.; Almenares-Reyes, R. Impact of calcination technology on properties of calcined clays. RILEM Tech. Lett. 2024, 8, 190–197. [Google Scholar] [CrossRef]

- Avet, F.; Snellings, R.; Diaz, A.A.; Haha, M.B.; Scrivener, K. Development of a new rapid, relevant and reliable (R3) test method to evaluate the pozzolanic reactivity of calcined kaolinitic clays. Cem. Concr. Res. 2016, 85, 1–11. [Google Scholar] [CrossRef]

- Robayo-Salazar, R.A.; Mejía de Gutiérrez, R.; Puertas, F. Effect of metakaolin on natural volcanic pozzolan-based geopolymer cement. Appl. Clay Sci. 2016, 132–133, 491–497. [Google Scholar] [CrossRef]

- Mohsen, M.O.; Aburumman, M.O.; Al Diseet, M.M.; Taha, R.; Abdel-Jaber, M.; Senouci, A.; Abu Taqa, A. Fly ash and natural pozzolana impacts on sustainable concrete permeability and mechanical properties. Buildings 2023, 13, 1927. [Google Scholar] [CrossRef]

- Raju, M.R.R.; Rahman, M.R.; Islam, M.M.; Hasan, N.M.S.; Hasan, M.; Sharmily, T.; Hosen, M.S. A comparative analysis of machine learning approaches for evaluating the compressive strength of pozzolanic concrete. IUBAT Rev. 2024, 7, 90–122. [Google Scholar] [CrossRef]

| Run | Nomenclature | % of PM | % of Alkaline Solution Concentration |

|---|---|---|---|

| 1 | P00 | 00 | 0.00 N |

| 2 | P10 | 10 | 0.25 N |

| 3 | P20 | 20 | 0.25 N |

| 4 | P30 | 30 | 0.25 N |

| Material | Mix Concrete | |||

|---|---|---|---|---|

| P00 | P10 | P20 | P30 | |

| Water | 205 | 205 | 205 | 205 |

| Gravel | 923 | 923 | 923 | 923 |

| Sand | 648 | 648 | 648 | 648 |

| Cement | 331 | 298 | 265 | 232 |

| Pumice | 0 | 33 | 66 | 99 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moreno-Vázquez, O.; López-González, P.J.; Zamora-Castro, S.A.; Trujillo-García, B.S.; Sangabriel-Lomelí, J. Mechanical Behavior of Sustainable Concrete with Alkali-Activated Pumice as Cement Replacement for Walkway Slabs in Humid Tropical Climates. Eng 2025, 6, 191. https://doi.org/10.3390/eng6080191

Moreno-Vázquez O, López-González PJ, Zamora-Castro SA, Trujillo-García BS, Sangabriel-Lomelí J. Mechanical Behavior of Sustainable Concrete with Alkali-Activated Pumice as Cement Replacement for Walkway Slabs in Humid Tropical Climates. Eng. 2025; 6(8):191. https://doi.org/10.3390/eng6080191

Chicago/Turabian StyleMoreno-Vázquez, Oscar, Pablo Julián López-González, Sergio Aurelio Zamora-Castro, Brenda Suemy Trujillo-García, and Joaquín Sangabriel-Lomelí. 2025. "Mechanical Behavior of Sustainable Concrete with Alkali-Activated Pumice as Cement Replacement for Walkway Slabs in Humid Tropical Climates" Eng 6, no. 8: 191. https://doi.org/10.3390/eng6080191

APA StyleMoreno-Vázquez, O., López-González, P. J., Zamora-Castro, S. A., Trujillo-García, B. S., & Sangabriel-Lomelí, J. (2025). Mechanical Behavior of Sustainable Concrete with Alkali-Activated Pumice as Cement Replacement for Walkway Slabs in Humid Tropical Climates. Eng, 6(8), 191. https://doi.org/10.3390/eng6080191